Universidade Nova de Lisboa

Faculdade de Ciências e Tecnologia

Departamento de Conservação e Restauro

Archaeological Roman Glasses

Comparative characterisation by non-destructive

analytical techniques

Paula Alexandra Pinto Rodrigues

Dissertation presented in fulfilment of the requirements for the

Master’s degree in Conservation and Restoration

Supervisor

Professor Doctor Rui C. da Silva

Instituto Tecnológico e Nuclear

Co-Supervisors

Doctor Luís C. Alves

Instituto Tecnológico e Nuclear

Professor Doctor Márcia Vilarigues

Universidade Nova de Lisboa

Examiner

Doctor M. Fátima Araújo

Instituto Tecnológico e Nuclear

President of the Jury

Professor Doctor Ana Maria Ramos

Universidade Nova de Lisboa

ii

Archaeological Roman Glasses

Comparative characterisation by non-destructive analytical techniques

Copyright © 2011

Paula Alexandra Pinto Rodrigues

Faculdade de Ciências e Tecnologia – Universidade Nova de Lisboa

Universidade Nova de Lisboa

Direitos de cópia

A Faculdade de Ciências e Tecnologia e a Universidade Nova de Lisboa têm o direito, perpétuo e sem limites geográficos, de arquivar e publicar esta dissertação através de exemplares impressos reproduzidos em papel ou de forma digital, ou por qualquer outro meio conhecido ou que venha a ser inventado, e de a divulgar através de repositórios científicos e de admitir a sua cópia e distribuição com objectivos educacionais ou de investigação, não comerciais, desde que seja dado crédito ao autor e editor.

Copyright

iii

Acknowledgements

v

Sumário

As campanhas arqueológicas no sítio da villa Romana da Quinta da Bolacha na Amadora,

Portugal, resultaram na recolha de vários tipos de materiais e objectos diferentes. Estes

apontam para duas ocupações diferentes do espaço, entre os séculos III e IV d.C. De modo a

definir-se materialmente esses momentos, fragmentos de vidro recolhidos em contextos

associados a ambas as ocupações foram analisados não destrutivamente por técnicas de feixes

de iões, nomeadamente a emissão de raios X induzida por partículas (PIXE –Particle Induced X

ray Emission) em combinação com a emissão de raios γ induzida por partículas (PIGE –Particle Induced Gamma Emission) e fluorescência de raios-X (XRF –X ray Fluorescence). Devido ao seu deficiente estado de preservação, nomeadamente a delaminação das superfícies do vidro, os

objectos museológicos não puderam sofrer amostragem ou ser analisados em vácuo, fazendo

da análise em ambiente normal uma melhor opção para o seu estudo. Foram utilizados a nova

linha de feixe externo, MicroFEx, acoplada ao acelerador de partículas do ITN, e o espectrómetro

de micro-fluorescência de raios X, ArtTAX, pertencente ao DCR-FCT-UNL, para a produção de

conjuntos satisfatórios de resultados.

A combinação das técnicas provou ser adequada no estudo deste tipo de materiais, apesar

da necessidade de se efectuar alguns ajustes. Adicionalmente, a combinação das técnicas

espectrométricas PIXE/PIGE versus XRF permitiutambém estabelecer as bases para a utilização

das mesmas como sendo verdadeiramente complementares, tomando partido e assentando

no carácter específico de cada técnica.

O estudo permitiu determinar a ausência de correlação entre a composição dos fragmentos

e os seus contextos arqueológicos de origem. Tal, por sua vez, indica que os vidros

correspondentes têm uma composição comum, transversal aos diferentes períodos de

ocupação. Esta conclusão encontra-se em conformidade com o que é conhecido sobre vidro

Romano, cujas composições se revelaram muito uniformes entre países e ao longo dos séculos

(desde o primeiro milénio até ao séc. IX d.C.). Como consequência e à luz destas descobertas,

seria expectável que poucas ou nenhumas diferenças significativas fossem encontradas entre

vidros de dois períodos de ocupação tão próximos na História (cerca de um século de

diferença).

vii

Summary

The archaeological campaigns in the site of the Roman villa of Quinta da Bolacha at

Amadora, Portugal, provided a recollection of many different types of materials and objects.

These indicate two different occupations of the space, between III and IV centuries AD. In order

to materially define those moments, fragments of glass from contexts belonging to both

occupations were analysed non-destructively by ion beam techniques namely Particle Induced

X ray Emission (PIXE) in combination with Particle Induced Gamma Emission (PIGE) and X ray

Fluorescence (XRF). Because of their poor state of conservation, namely the delamination of

the glass surfaces, the museological objects could not be sampled nor analysed in vacuum,

making in air analysis a better option for their study. The new external microbeam line,

MicroFEx, at ITN particle accelerator, and micro-XRF spectrometer ArtTAX, at DCR-FCT-UNL,

were used in order to produce satisfactory data sets.

The combination of the techniques proved to be adequate to study this kind of materials,

although some adjustments need to be made. Additionally, combining the related

spectrometry techniques PIXE/PIGE versus XRF allowed establishing the starting grounds for

usage of these as truly complimentary, taking advantage of and building on the specific

character of each technique.

The study allowed establishing that no correlation exists between the composition of the

fragments and their contexts of origin. This in turn implies that the corresponding glasses have

a common composition, crossing the different occupation periods. This is in agreement with

what is known of Roman glasses which compositions were found to be fairly uniform across

countries and across centuries (during the first millennium, to the ninth century AD). As a

consequence and on the light of these findings, it is not unexpected that little or no significant

differences were found between glasses from two occupation periods so close in historical

time (roughly one century apart).

ix

Contents

Acknowledgements

………

iii

Sumário ………

.. v

Summary .

………

..

………...

vii

1.

Introduction ………..……….

1

2. Archaeological background

………

.

………

3

2.1.

Roman glass ………

3

2.2. The villa

……….

4

2.3. The glass fragments

………....

4

3. Experimental details ..

………..

7

3.1. Ion Beam Analyses

…….……….

7

3.2.

Energy Dispersive X Ray Fluorescence Spectrometry ………

...

8

4. Results and Discussion

………..………....

9

5. Conclusions

……..………...

25

xi

Index of Figures

Figure 2.1: glass fragments used in the present work ...

5

Figure 4.1: distribution of experimental results/ nominal reference

compositions ratios for Corning Glass Standards (CGS) B and D. ...

9

Figure 4.2: distribution of the sum of analysed elements and total of all

concentrations, calculated by WinFund. ...

13

Figure 4.3: K2O vs Na2O concentrations determined by IBA techniques for

each of the fragments; the legend indicates the fragments’ order numbers

preceded by each respective context. ...

20

Figure 4.4: elemental distribution maps of Si, Ca and Mn on glass fragment

195. ...

22

Figure 4.5: XRF spectra of fragment 195

–

superimposition of data from a

xiii

Index of Tables

Table 2.1: typical average composition of Roman glass (expressed as weight

percentages)...

3

Table 2.2: description of the fragments used in the present work ...

5

Table 4.1: results obtained by IBA and reference values for CGS B (wt %) ...

10

Table 4.2: results obtained by XRF and reference values for CGS B (wt %) ...

11

Table 4.3: results obtained by IBA and XRF and reference values for CGS D

(wt %) ...

12

Table 4.4: compositions obtained by IBA for fragments from context 19

(µg/g except where % is indicated) ...

14

Table 4.5: compositions obtained by IBA for fragments from context 17

(µg/g except where % is indicated) ...

15

Table 4.6: compositions obtained by IBA for fragments from context 15

(µg/g except where % is indicated) ...

16

Table 4.7: compositions obtained by XRF for fragments from context 19

(µg/g except where % is indicated) ...

17

Table 4.8: compositions obtained by XRF for fragments from context

17(µg/g except where % is indicated) ...

18

1

1.

Introduction

The glass fragments studied here belong to 3 three different archaeological contexts, at the

Roman villa of Quinta da Bolacha: two of well determined chronology and a third one, a

revolved context of unknown chronology. This study aims are twofold: i) it intends to

contribute to the material characterisation of the occupation periods by analysing and

comparing the compositions of glass fragments recovered from the different contexts. It also

intends to associate the fragments of the revolved context with those of the other contexts,

trying this way to determine its possible chronological attribution; ii) it intends to compare

measurements made on the same set of samples by different but related spectrometry

techniques, PIXE, PIXE/PIGE and XRF, laying the starting grounds for their usage as

complimentary, taking advantage of and building on the specific character of each technique.

As such, a closely related goal of this work is to ascertain a dependable process which can

provide qualitative and quantitative analysis and be applicable to this particular type of objects,

the archaeological/museological glass.

The unearthed glasses were in a poor state of conservation showing clear delamination of

the glass surfaces, implying that these objects could not be analysed in vacuum. Given this and

the museological nature of the objects analysed, sampling was also not indicated. The use of

non-destructive analytical techniques was thus absolutely imperative.

The new external microbeam line in the Ion Beam Laboratory at Instituto Tecnológico e

Nuclear now in use, MicroFEx, allows non-destructive and quantitative analysis in air, resorting

to PIXE, PIGE and Rutherford Backscattering Spectrometry (RBS), without requiring any

sampling or otherwise special preparation. The analysis by PIGE is, in this case, of vital

importance since Roman glasses are normally characterised by having significant

concentrations of Na which is not detected properly in normal in-air operating conditions by

other non-destructive techniques.

The results of Ion Beam Analysis (IBA) should then be confronted with other existing

techniques, in order to allow a critical comparison. Because IBA techniques are limited

regarding the depth of penetration of the particles used as exciting radiation, XRF technique

was also used for elemental analysis since primary X rays can penetrate deeper in materials

making this technique less dependent on the state of the sample surface [1]. ArtTAX set-up in

the Department of Conservation and Restoration (DCR) at Faculdade de Ciências e Tecnologia,

Universidade Nova de Lisboa (FCT-UNL), has been in use since 2003 providing very useful and

3

2.

Archaeological background

2.1.

Roman glass

During Roman Empire and also through part of Middle Age, glass production was divided in

two phases: primary and secondary. Primary production refers to glass production based on

the fusion of its base components, the raw materials, these being, fundamentally, sand and

natron. Sand would provide the network former – silica – as well as the stabiliser – lime –

together with some contaminants. Natron would provide soda which acted as flux allowing the

decrease of melting temperatures. Primary production of glass is now believed to have happened

mainly in the Syro-Palestine region and in Egypt, where the prime matters were easier to reach

and the technique of glass production had been found and perfected [5]. Some authors defend

the existence of factories of raw glass also in Italy and Gallic and Spanish provinces confirming

Pliny’s writings [6]. The result of this first stage of glass production was then sold and distributed as ingots or chunks throughout the Empire to local workshops where secondary

production took place i.e. the transformation of the ingots or chunks to finished artefacts [5].

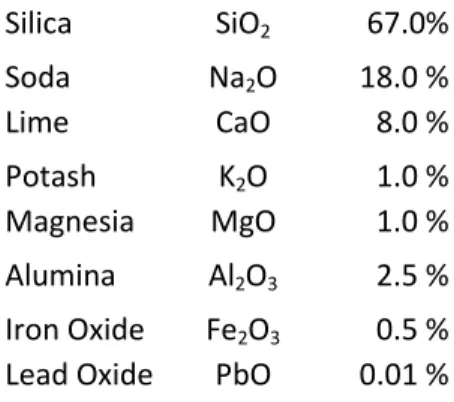

Roman glass was, in its majority, soda-silica-lime glass. Table 2.1 shows the typical average

composition of this historical material [7].

Table 2.1. Typical average composition of Roman glass (expressed as weight percentages)

Silica SiO2 67.0%

Soda Na2O 18.0 %

Lime CaO 8.0 %

Potash K2O 1.0 %

Magnesia MgO 1.0 %

Alumina Al2O3 2.5 %

Iron Oxide Fe2O3 0.5 %

Lead Oxide PbO 0.01 %

Characteristically, Roman glass is considered a low magnesia type when it presents contents

below 1.5 % of MgO and K2O which indicate the use of natron as source of flux. Glasses with

higher contents of magnesia and potash would indicate the use of plant ashes as flux sources

[8]. Prior to the beginning or middle of the I millennium BC, plant ash was the main source of

flux, especially in Egypt and Mesopotamia. At this point, the use of natron became regular

around the Mediterranean and in Europe, until the IX century AD, when it was replaced by

4

2.2.

The villa

The Roman villa of Quinta da Bolacha in Amadora, Portugal, was discovered in 1979 during

prospection of a Roman aqueduct that had already been identified. The archaeological works,

centred in Sectors I and III [9] where structures had been identified, made possible identifying

sealed contexts, which are attributed to III and IV centuries AD, together with revolved

contexts of uncertain dating. The excavation campaigns recovered numerous objects among

which the glass fragments of the present study, which belonged to different contexts. In

general, the objects unearthed from the sealed contexts and the available historical

information consistently point to III and IV centuries AD as the main occupation periods of the

villa. There is the possibility, still under study, of an earlier occupation period too, possibly

dating back to I/II centuries AD. This is as yet subjected to confirmation.

The fragments analysed during this study belong to contexts identified as 19, 17 and 15,

which are briefly described below.

Context 19, attributed to a 1st occupation during 2nd half of the III century/1st half of IV

century, corresponds to a burnt level, where there was a fire. During this occupation, the

structure corresponded to a large room of a habitation. The walls were covered with painted

stuccoes and the room had a central stuccoed pillar and a drain next to the wall.

Context 17 is attributed to a 2nd occupation, after the fire, during the second half of the IV

century. At this time, the room was remodelled, a wall having been built to divide it. The

central pillar was destroyed and 3 more drains and a fireplace were built in that space. These

new structures and the objects collected, such as anforae, common ceramics and terra sigillata

recipients, indicate that the new space was used as a kitchen. The context is mainly composed

of fragmented ceramic shingles, suggesting a sudden event, corresponding to the ruin phase of

the space, which is ascribed to the end of the IV century.

In context 15, very fragmented archaeological materials of diverse chronologies, including

Roman, were gathered. This context was formed recently and is situated exactly above the

sealed Roman contexts [9].

2.3.

The glass fragments

The fragments studied here were chosen as the most representative of each context. Figure

2.1 displays pictures of the glass fragments where they appear identified and grouped by

5

Context 19 Context 17 Context 15

Figure 2.1: glass fragments used in the present work

Most of the fragments are of undermined typology, with exception of the blue tesserae–

id.193/03 – and a bead fragment – id.90/01. All the fragments of undetermined typology are

concave, except fragment 195 which is completely flat.

Table 2.2 resumes the objects' description.

Table 2.2: description of the fragments used in the present work

Order number Context

Fragment

Typology

Details

1

19

26-09-00

Undetermined

Border with cannelures

2 and 3*

19

92/01

Undetermined

-

4

19

172

Undetermined

Border

5

19

193/03

Tesserae

Blue

6

19

195

Undetermined

Flat

7

17

55

Undetermined

Handle (possibly)

8

17

72/01

Undetermined

-

9

17

90/01

Bead

-

10

17

274

Undetermined

Bottom

11

17

283

Undetermined

-

12

15

21-05-00

Undetermined

-

13

15

20-06-00

Undetermined

Border

14

15

27-06-00

Undetermined

-

15

15

28-06-00

Undetermined

Border

16

15

19-07-00

Undetermined

Border

* Larger and smaller, respectively.

1

7

3.

Experimental details

As the recovered glass fragments displayed areas with distinctive corrosion features, care

had to be taken when selecting representative zones. For bulk analysis, all the areas were

chosen in order to be able to get a good flat surface with no apparent major alterations.

The objects were analysed resorting to the IBA (Ion Beam Analysis) techniques referred to

above, PIXE and PIGE, and XRF.

3.1.

Ion Beam Analyses

Particle Induced X ray Emission (PIXE) combined with Particle Induced Gamma Emission

(PIGE), were simultaneously used to determine the elemental compositions of the Roman glass

pieces. Excitation of both target atomic and nuclear levels yielding characteristic X and gamma

rays was provided by a 2 MeV proton beam from a 2.5 MV Van de Graaff accelerator, focused

by a OM50 triplet quadrupole system onto the target, 3 mm away from a 100 nm thick Si3N4

vacuum extraction window. The 1 nA beam focused on target illuminated a spot measuring

60 × 65 µm2. Helium gas was made to flood the analysis region with a flow of 4.5 L/min, at

normal atmospheric pressure, in order to i) reduce energy losses of the incoming beam and

attenuation of the emitted X rays, and ii) remove Ar, thus eliminating it as a source of spectral

interference. The OM-DAQ beam steering control allowed scanning up to 1 × 1 mm2 target area

in synchronism with spectral data acquisition. Accurate target positioning was assured by two

converging laser beams intersecting each other at the beam spot, 3 mm distant from the beam

exit nozzle. A mini-video camera assists the whole procedure.

The PIXE and PIGE spectra were simultaneously collected using one 30 mm2 Bruker AXS

Xflash SDD (silicon drift) X rays detector of 145 eV energy resolution at 5.9 keV, and one large

volume HPGe detector with 45% efficiency and 1.9 keV energy resolution (at 1.3325 MeV). The

SDD detector was placed at 45º to the incoming beam direction and HPGe detector was placed

at 90º.

The PIXE spectra were analysed with the AXIL [10] program for line deconvolution and

DATTPIXE [11] for quantification. Although He was sprayed into the volume in front of the

beam exit nozzle and SDD detector, aiming at reducing the energy losses of beam protons and

attenuation of X rays, the quantification of Na was only possible through PIGE, by measuring

the yield of the 440 keV gamma emission line resulting from the 23Na (p, p´γ) 23Na reaction. A

rotating metallic vane was used for normalising charge collection, by measuring the X rays

produced when intercepting the proton beam. Placed inside the microprobe vacuum chamber,

8

were compared for each sample with those obtained with Corning glass standards, allowing

assessment of the quality of the detection system calibration, and control of experimental

parameters.

3.2.

Energy Dispersive X Ray Fluorescence Spectrometry

The energy dispersive XRF was performed with ArtTAX, a portable spectrometer equipped

with a SDD detector and a CCD camera and laser light diode for sample positioning. The

primary X rays are produced by a Mo anode and the beam spot size is c.a. 100 µm across. This

device also allows He flooding for lower Z elements detection enhancement [12].

Spectra were collected at 40 kV voltage and 600 µA current with typically 360 s acquisition

time and normalised to the compositions of Corning Glass standards [13]. The XRF spectra

were analysed resorting to WinAxil© software package, allowing spectra display, manipulation,

deconvolution and, with WinFund© module, quantification based on fundamental parameters

9

4.

Results and Discussion

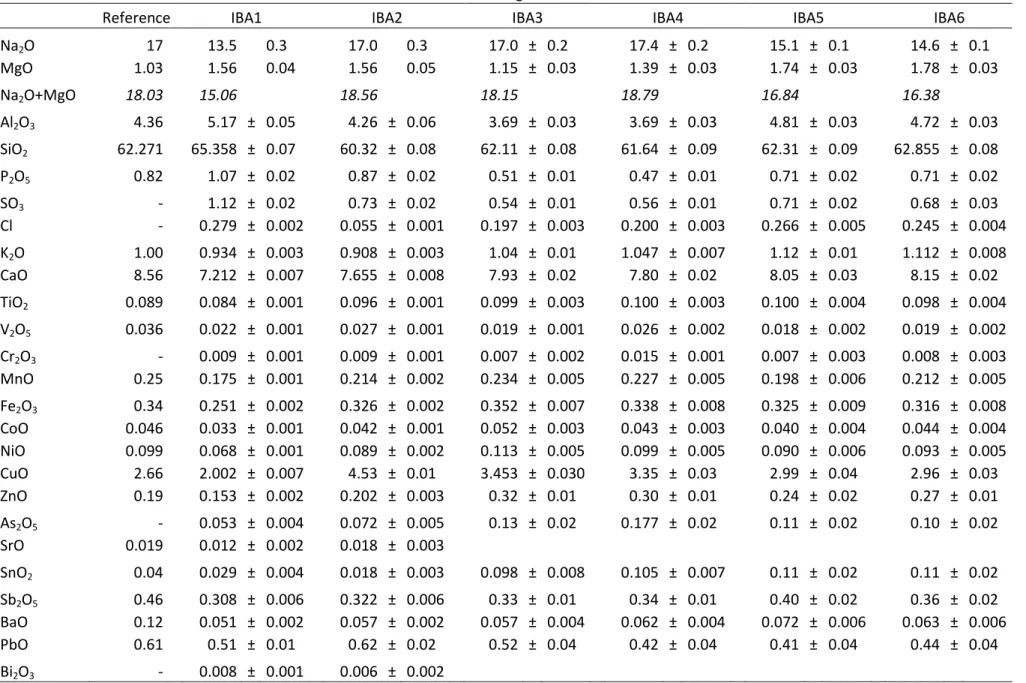

Both IBA and XRF results were analysed by resorting to the comparison with the Corning

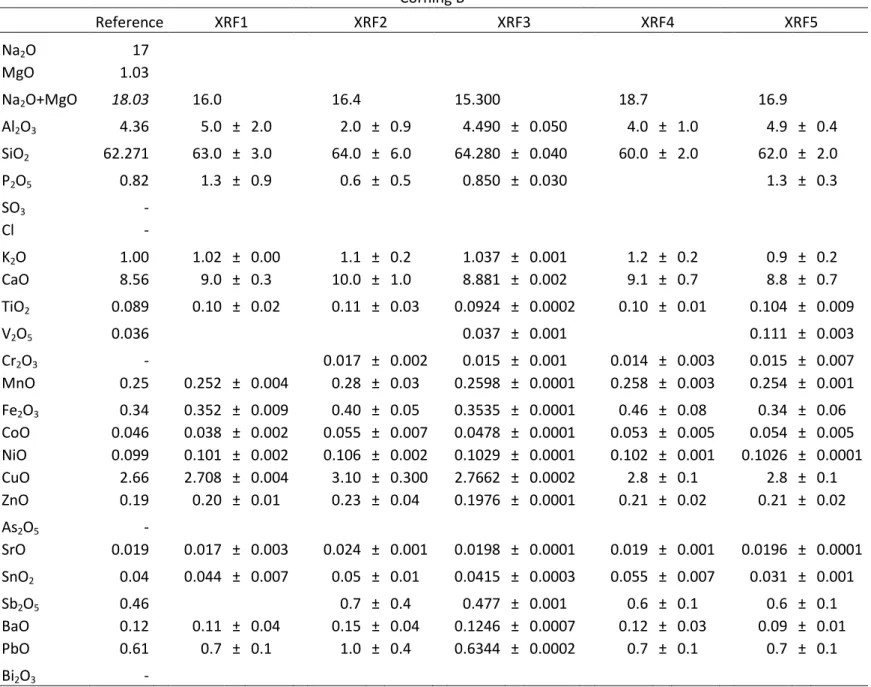

glass standards, following the same procedure as Wobrauschek et al. [15]. Tables 4.1 to 4.3

(next pages) show the quantitative results for these standards, obtained by both techniques.

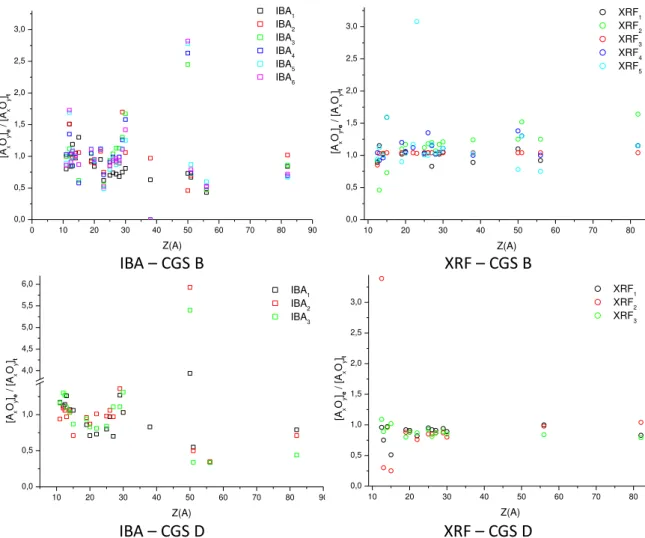

The plots in Fig. 4.1 display the distribution of the ratios of the experimental results to the

nominal reference compositions for each of the oxides identified by the atomic number of the

cation [13], allowing the quality of the analytical procedure and solutions to be evaluated.

IBA

–

CGS B

XRF

–

CGS B

IBA

–

CGS D

XRF

–

CGS D

Figure 4.1: distribution of experimental results/ nominal reference compositions ratios for Corning Glass Standards (CGS) B and D.

Clearly, for both CGS B and CGS D, the scattering of the ratios is significantly higher with IBA

techniques than with XRF, especially for the oxides of elements present in concentrations of

the order of µg/g. As the distributions do not follow systematic patterns, these results may

indicate fluctuations related to the experimental conditions, e.g. the state of the analysed

surfaces, presenting areas free from corrosion, together with areas partially affected by

corrosion to various degrees. Also the high concentrations of some metal oxides, such as tin

and copper or zinc and tin/antimonyseen on the IBA plots, as well as the presence of some

0 10 20 30 40 50 60 70 80 90

0,0 0,5 1,0 1,5 2,0 2,5 3,0 [Ax Oy ]e / [A x Oy ]t Z(A) IBA1 IBA2 IBA3 IBA4 IBA5 IBA6

10 20 30 40 50 60 70 80

0,0 0,5 1,0 1,5 2,0 2,5 3,0 [A x Oy ]e / [A x Oy ]t Z(A) XRF1 XRF2 XRF3 XRF4 XRF5

10 20 30 40 50 60 70 80 90

0,0 0,5 1,0 4,0 4,5 5,0 5,5 6,0 [A x Oy ]e / [A x Oy ]t Z(A) IBA1 IBA2 IBA3

10 20 30 40 50 60 70 80

10

Table 4.1: results obtained by IBA and reference values for CGS B (wt %) Corning B

Reference IBA1 IBA2 IBA3 IBA4 IBA5 IBA6

Na2O 17 13.5 0.3 17.0 0.3 17.0 ± 0.2 17.4 ± 0.2 15.1 ± 0.1 14.6 ± 0.1

MgO 1.03 1.56 0.04 1.56 0.05 1.15 ± 0.03 1.39 ± 0.03 1.74 ± 0.03 1.78 ± 0.03

Na2O+MgO 18.03 15.06

18.56

18.15

18.79

16.84

16.38

Al2O3 4.36 5.17 ± 0.05 4.26 ± 0.06 3.69 ± 0.03 3.69 ± 0.03 4.81 ± 0.03 4.72 ± 0.03

SiO2 62.271 65.358 ± 0.07 60.32 ± 0.08 62.11 ± 0.08 61.64 ± 0.09 62.31 ± 0.09 62.855 ± 0.08

P2O5 0.82 1.07 ± 0.02 0.87 ± 0.02 0.51 ± 0.01 0.47 ± 0.01 0.71 ± 0.02 0.71 ± 0.02

SO3 - 1.12 ± 0.02 0.73 ± 0.02 0.54 ± 0.01 0.56 ± 0.01 0.71 ± 0.02 0.68 ± 0.03

Cl - 0.279 ± 0.002 0.055 ± 0.001 0.197 ± 0.003 0.200 ± 0.003 0.266 ± 0.005 0.245 ± 0.004

K2O 1.00 0.934 ± 0.003 0.908 ± 0.003 1.04 ± 0.01 1.047 ± 0.007 1.12 ± 0.01 1.112 ± 0.008

CaO 8.56 7.212 ± 0.007 7.655 ± 0.008 7.93 ± 0.02 7.80 ± 0.02 8.05 ± 0.03 8.15 ± 0.02

TiO2 0.089 0.084 ± 0.001 0.096 ± 0.001 0.099 ± 0.003 0.100 ± 0.003 0.100 ± 0.004 0.098 ± 0.004

V2O5 0.036 0.022 ± 0.001 0.027 ± 0.001 0.019 ± 0.001 0.026 ± 0.002 0.018 ± 0.002 0.019 ± 0.002

Cr2O3 - 0.009 ± 0.001 0.009 ± 0.001 0.007 ± 0.002 0.015 ± 0.001 0.007 ± 0.003 0.008 ± 0.003

MnO 0.25 0.175 ± 0.001 0.214 ± 0.002 0.234 ± 0.005 0.227 ± 0.005 0.198 ± 0.006 0.212 ± 0.005

Fe2O3 0.34 0.251 ± 0.002 0.326 ± 0.002 0.352 ± 0.007 0.338 ± 0.008 0.325 ± 0.009 0.316 ± 0.008

CoO 0.046 0.033 ± 0.001 0.042 ± 0.001 0.052 ± 0.003 0.043 ± 0.003 0.040 ± 0.004 0.044 ± 0.004

NiO 0.099 0.068 ± 0.001 0.089 ± 0.002 0.113 ± 0.005 0.099 ± 0.005 0.090 ± 0.006 0.093 ± 0.005

CuO 2.66 2.002 ± 0.007 4.53 ± 0.01 3.453 ± 0.030 3.35 ± 0.03 2.99 ± 0.04 2.96 ± 0.03

ZnO 0.19 0.153 ± 0.002 0.202 ± 0.003 0.32 ± 0.01 0.30 ± 0.01 0.24 ± 0.02 0.27 ± 0.01

As2O5 - 0.053 ± 0.004 0.072 ± 0.005 0.13 ± 0.02 0.177 ± 0.02 0.11 ± 0.02 0.10 ± 0.02

SrO 0.019 0.012 ± 0.002 0.018 ± 0.003

SnO2 0.04 0.029 ± 0.004 0.018 ± 0.003 0.098 ± 0.008 0.105 ± 0.007 0.11 ± 0.02 0.11 ± 0.02

Sb2O5 0.46 0.308 ± 0.006 0.322 ± 0.006 0.33 ± 0.01 0.34 ± 0.01 0.40 ± 0.02 0.36 ± 0.02

BaO 0.12 0.051 ± 0.002 0.057 ± 0.002 0.057 ± 0.004 0.062 ± 0.004 0.072 ± 0.006 0.063 ± 0.006

PbO 0.61 0.51 ± 0.01 0.62 ± 0.02 0.52 ± 0.04 0.42 ± 0.04 0.41 ± 0.04 0.44 ± 0.04

11

Table 4.2: results obtained by XRF and reference values for CGS B (wt %) Corning B

Reference XRF1 XRF2 XRF3 XRF4 XRF5

Na2O 17

MgO 1.03

Na2O+MgO 18.03 16.0

16.4 15.300 18.7 16.9

Al2O3 4.36 5.0 ± 2.0 2.0 ± 0.9 4.490 ± 0.050 4.0 ± 1.0 4.9 ± 0.4

SiO2 62.271 63.0 ± 3.0 64.0 ± 6.0 64.280 ± 0.040 60.0 ± 2.0 62.0 ± 2.0

P2O5 0.82 1.3 ± 0.9 0.6 ± 0.5 0.850 ± 0.030 1.3 ± 0.3

SO3 -

Cl -

K2O 1.00 1.02 ± 0.00 1.1 ± 0.2 1.037 ± 0.001 1.2 ± 0.2 0.9 ± 0.2

CaO 8.56 9.0 ± 0.3 10.0 ± 1.0 8.881 ± 0.002 9.1 ± 0.7 8.8 ± 0.7

TiO2 0.089 0.10 ± 0.02 0.11 ± 0.03 0.0924 ± 0.0002 0.10 ± 0.01 0.104 ± 0.009

V2O5 0.036

0.037 ± 0.001 0.111 ± 0.003

Cr2O3 -

0.017 ± 0.002 0.015 ± 0.001 0.014 ± 0.003 0.015 ± 0.007

MnO 0.25 0.252 ± 0.004 0.28 ± 0.03 0.2598 ± 0.0001 0.258 ± 0.003 0.254 ± 0.001

Fe2O3 0.34 0.352 ± 0.009 0.40 ± 0.05 0.3535 ± 0.0001 0.46 ± 0.08 0.34 ± 0.06

CoO 0.046 0.038 ± 0.002 0.055 ± 0.007 0.0478 ± 0.0001 0.053 ± 0.005 0.054 ± 0.005

NiO 0.099 0.101 ± 0.002 0.106 ± 0.002 0.1029 ± 0.0001 0.102 ± 0.001 0.1026 ± 0.0001

CuO 2.66 2.708 ± 0.004 3.10 ± 0.300 2.7662 ± 0.0002 2.8 ± 0.1 2.8 ± 0.1

ZnO 0.19 0.20 ± 0.01 0.23 ± 0.04 0.1976 ± 0.0001 0.21 ± 0.02 0.21 ± 0.02

As2O5 -

SrO 0.019 0.017 ± 0.003 0.024 ± 0.001 0.0198 ± 0.0001 0.019 ± 0.001 0.0196 ± 0.0001

SnO2 0.04 0.044 ± 0.007 0.05 ± 0.01 0.0415 ± 0.0003 0.055 ± 0.007 0.031 ± 0.001

Sb2O5 0.46

0.7 ± 0.4 0.477 ± 0.001 0.6 ± 0.1 0.6 ± 0.1

BaO 0.12 0.11 ± 0.04 0.15 ± 0.04 0.1246 ± 0.0007 0.12 ± 0.03 0.09 ± 0.01

PbO 0.61 0.7 ± 0.1 1.0 ± 0.4 0.6344 ± 0.0002 0.7 ± 0.1 0.7 ± 0.1

12

Table 4.3: results obtained by IBA and XRF and reference values for CGS D (wt %) Corning D

Reference IBA1 IBA2 IBA3 XRF1 XRF2 XRF3

Na2O 1.20 1.41 ± 0.07 1.13 ± 0.05 1.39 ± 0.01

MgO 3.94 4.4 ± 0.2 4.3 ± 0.1 5.13 ± 0.01

Na2O+MgO 5.14 5.81

5.44 6.52

4.94

17.40

5.610

Al2O3 5.30 6.69 ± 0.08 5.13 ± 0.08 5.82 ± 0.02 4.0 ± 1.0 1.6 ± 0.7 4.700 ± 0.400

SiO2 55.46 59.5 ± 0.1 58.4 ± 0.2 57.12 ± 0.06 54.0 ± 3.0 53.0 ± 5.0 53.000 ± 2.000

P2O5 3.93 4.15 ± 0.03 2.78 ± 0.05 3.42 ± 0.02 2.0 ± 1.0 1.0 ± 1.0 4.000 ± 1.000

SO3 - 0.22 ± 0.02 0.309 ± 0.007

Cl - 0.067 ± 0.002 0.209 ± 0.008 0.243 ± 0.003

K2O 11.30 9.72 ± 0.01 10.88 ± 0.05 10.6 ± 0.02 10.43 ± 0.05 10.0 ± 1.0 9.000 ± 2.000

CaO 14.80 10.56 ± 0.01 12.91 ± 0.07 12.22 ± 0.03 13.4 ± 0.4 13.0 ± 2.0 13.000 ± 1.000

TiO2 0.38 0.277 ± 0.003 0.38 ± 0.02 0.308 ± 0.005 0.31 ± 0.06 0.29 ± 0.07 0.330 ± 0.030

V2O5 - 0.012 ± 0.001

Cr2O3 -

MnO 0.55 0.442 ± 0.003 0.54 ± 0.02 0.463 ± 0.007 0.52 ± 0.01 0.47 ± 0.06 0.504 ± 0.001

Fe2O3 0.52 0.505 ± 0.004 0.55 ± 0.02 0.82 ± 0.01 0.48 ± 0.01 0.44 ± 0.06 0.420 ± 0.070

CoO 0.02 0.016 ± 0.001 0.022 ± 0.006 0.026 ± 0.002 0.021 ± 0.001 0.020 ± 0.003 0.020 ± 0.002

NiO - 0.044 ± 0.001 0.08 ± 0.01 0.049 ± 0.003 0.045 ± 0.001 0.039 ± 0.001 0.042 ± 0.000

CuO 0.38 0.482 ± 0.005 0.52 ± 0.03 0.42 ± 0.01 0.356 ± 0.002 0.33 ± 0.03 0.340 ± 0.010

ZnO 0.10 0.103 ± 0.003 0.14 ± 0.02 0.13 ± 0.01 0.089 ± 0.007 0.08 ± 0.01 0.085 ± 0.008

As2O5 - 0.067 ± 0.005 0.12 ± 0.01

SrO 0.057 0.047 ± 0.005

0.06 ± 0.01 0.053 ± 0.001 0.052 ± 0.000

SnO2 0.10 0.39 ± 0.01 0.59 ± 0.05 0.54 ± 0.01 0.09 ± 0.01 0.07 ± 0.02 0.093 ± 0.004

Sb2O5 0.97 0.53 ± 0.01 0.48 ± 0.0 0.33 ± 0.01 2.0 ± 2.0 1.3 ± 0.6 0.800 ± 0.200

BaO 0.51 0.173 ± 0.003 0.18 ± 0.02 0.175 ± 0.006 0.51 ± 0.07 0.50 ± 0.06 0.430 ± 0.050

13

elements which are not specified in the reference compositions, may indicate contamination

from laboratory tools used to handle the standards or the sample positioning system.

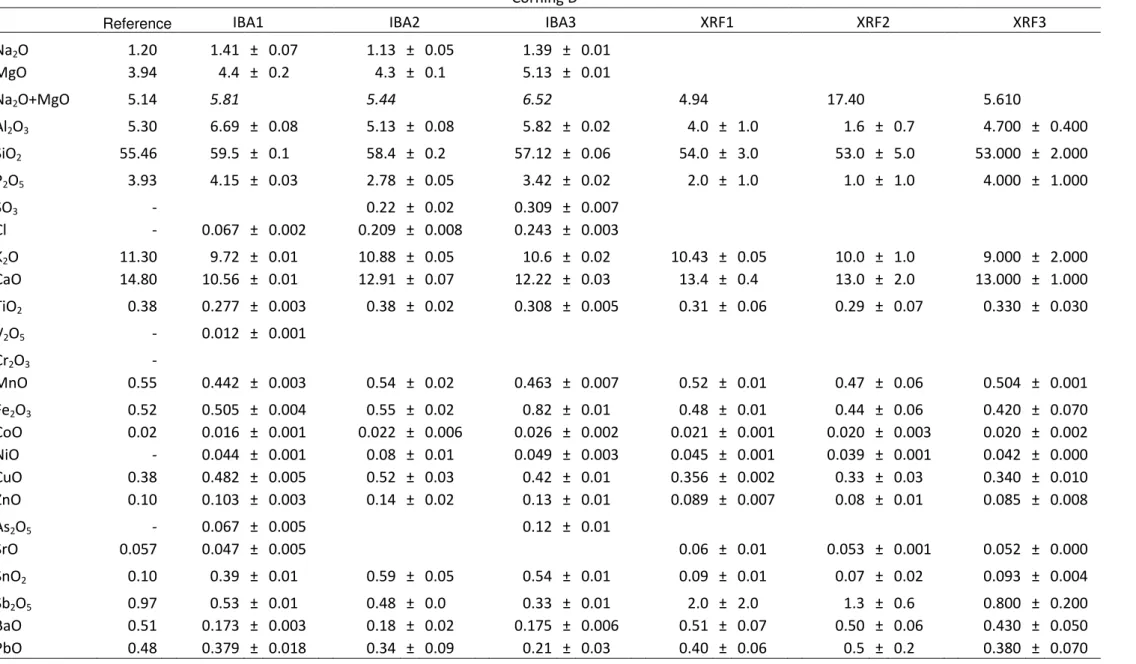

Regarding the calibration used with XRF spectra and the WinFund© software, it is possible

to see in Fig. 4.2 that, by calibrating with two glass standards instead of one – even if this one is

more similar in composition to the analysed samples – the sum of analysed elements comes

closer to 100% for the majority of the samples. This means that the lack of a second standard,

in this case, affects the values calculated by difference for the oxides of light elements, Na2O

and MgO (given as Na2MgO2), as well as those of oxides not present in the standard’s

composition.

Figure 4.2: distribution of the sum of analysed elements and total of all concentrations, calculated by WinFund.

Tables 4.4 to 4.9 (next pages) summarise the compositions of the glass fragments from the different contexts, as obtained by both techniques.

0 2 4 6 8 10 12 14 16 18

55 60 65 70 75 80 85 90 95 100 Su m o f a n a lys e d e le m e n ts ( % )

Fragment order nr.

Calibration w/ CGS B and D Calibration w/ CGS B

0 2 4 6 8 10 12 14 16 18

94 95 96 97 98 99 100 T o ta l o f a ll co n ce n tr a tio n s

Fragment order nr.

14

Table 4.4: compositions obtained by IBA for fragments from context 19 (µg/g except where % is indicated)

Fragment nr. 1 2 3 4 5 6

Na2O 0.37% ± 0.04% 0.8% ± 0.1% 14.4% ± 0.7% 17.0% ± 0.8% 9.6% ± 0.8% 10.9% ± 0.9%

MgO 1.8% ± 0.3% 2.0% ± 0.3% 1.1% ± 0.2% 1.8% ± 0.3% 1.5% ± 0.2% 0.8% ± 0.1%

Na2O+MgO 2.20%

2.81% 15.50% 18.74% 11.13% 11.63%

Al2O3 9.60% ± 0.06% 7.45% ± 0.06% 7.63% ± 0.04% 7.54% ± 0.05% 7.98% ± 0.04% 6.38% ± 0.05%

SiO2 82.69% ± 0.08% 70.21% ± 0.07% 67.44% ± 0.06% 64.98% ± 0.06% 69.48% ± 0.06% 73.23% ± 0.07%

P2O5

1.01% ± 0.02% 0.204% ± 0.009%

0.098% ± 0.009%

SO3 1654 ± 110 4924 ± 148 0.401% ± 0.008% 0.629% ± 0.012% 0.392% ± 0.005% 2569 ± 79

Cl 3765 ± 26 0.362% ± 0.003% 0.794% ± 0.003% 0.823% ± 0.003% 0.375% ± 0.002% 0.713% ± 0.003%

K2O 0.602% ± 0.002% 1.579% ± 0.004% 0.446% ± 0.002% 0.675% ± 0.002% 0.506% ± 0.002% 0.480% ± 0.002%

CaO 3.640% ± 0.006% 14.27% ± 0.01% 4.175% ± 0.005% 5.186% ± 0.006% 4.916% ± 0.005% 5.335% ± 0.006%

TiO2 416 ± 9 0.25% ± 0.00% 0.518% ± 0.002% 575 ± 9 304 ± 6 691 ± 9

V2O5

56 ± 8 0.013% ± 0.001%

27 ± 5

Cr2O3 49 ± 6 93 ± 9 61 ± 5 24 ± 6 48 ± 3

MnO 63 ± 4 250 ± 7 1.284% ± 0.003% 0.769% ± 0.003% 0.221% ± 0.001% 1.291% ± 0.004%

Fe2O3 0.386% ± 0.003% 1.290% ± 0.005% 1.496% ± 0.004% 0.522% ± 0.003% 0.728% ± 0.003% 0.447% ± 0.003%

CoO 64 ± 5 148 ± 8 101 ± 6 36 ± 5 0.158% ± 0.001% 27 ± 5

NiO 8 ± 2 56 ± 7

63 ± 4 56 ± 5

CuO 23 ± 3 42 ± 4 58 ± 4 34 ± 4 0.229% ± 0.002% 19 ± 3

ZnO 22 ± 3 44 ± 4 37 ± 4 43 ± 4 299 ± 8 60 ± 5

As2O5 36 ± 10 26 ± 10 26 ± 7 41 ± 9 0.117% ± 0.003%

Br 73 ± 12

184 ± 15 18 ± 6

Rb2O

SrO 142 ± 26 135 ± 24 243 ± 26 329 ± 34 185 ± 20 291 ± 31

SnO2 121 ± 32

520 ± 22

Sb2O5 0.235% ± 0.006% 0.144% ± 0.007%

3.478% ± 0.007%

BaO 94 ± 12 383 ± 19 0.043% ± 0.002% 141 ± 12 150 ± 7 217 ± 12

PbO

1212 ± 62

Bi2O3

22 ± 8

15

Table 4.5: compositions obtained by IBA for fragments from context 17 (µg/g except where % is indicated)

Fragment nr. 7 8 9 10 11

Na2O 19.8% ± 1.6% 11.5% ± 0.9% 0.59% ± 0.09% 24.8% ± 2.0% 3.6% ± 0.4%

MgO 1.2% ± 0.2% 0.8% ± 0.1% 3.4% ± 0.5% 1.3% ± 0.2% 1.2% ± 0.2%

Na2O+MgO 20.96% 12.35%

4.02% 26.10% 4.74%

Al2O3 3.56% ± 0.05% 3.87% ± 0.05% 6.64% ± 0.07% 2.39% ± 0.03% 11.26% ± 0.06%

SiO2 65.37% ± 0.08% 72.57% ± 0.08% 80.47% ± 0.10% 64.19% ± 0.07% 75.23% ± 0.08%

P2O5

0.155% ± 0.013%

SO3 4810 ± 147 6752 ± 144 6350 ± 159 5684 ± 76 4005 ± 55

Cl 1.401% ± 0.005% 0.914% ± 0.003% 0.396% ± 0.003% 1.347% ± 0.004% 0.328% ± 0.002%

K2O 0.357% ± 0.002% 0.589% ± 0.002% 0.275% ± 0.002% 0.237% ± 0.001% 0.382% ± 0.002%

CaO 6.363% ± 0.008% 7.333% ± 0.008% 3.696% ± 0.007% 3.875% ± 0.006% 6.032% ± 0.007%

TiO2 584 ± 11 660 ± 11 0.412% ± 0.003% 688 ± 10 1497 ± 13

V2O5 31 ± 6

59 ± 12

16 ± 3

Cr2O3

21 ± 6 20 ± 7

43 ± 3

MnO 1.065% ± 0.004% 1.110% ± 0.004% 1.837% ± 0.006% 0.785% ± 0.003% 0.599% ± 0.003%

Fe2O3 0.341% ± 0.003% 0.446% ± 0.003% 1.330% ± 0.006% 0.392% ± 0.003% 0.833% ± 0.004%

CoO 24 ± 5 26 ± 5 73 ± 9 33 ± 4 60 ± 4

NiO

22 ± 5 9 ± 2 8 ± 2

CuO 12 ± 3 37 ± 5 73 ± 6 26 ± 3 18 ± 3

ZnO 75 ± 6 37 ± 5 44 ± 5 20 ± 3 18 ± 3

As2O5 29 ± 10 40 ± 13

16 ± 6

Br

28 ± 11

20 ± 7

Rb2O 38 ± 14

SrO 163 ± 30 411 ± 46 266 ± 40 254 ± 33 169 ± 28

SnO2

Sb2O5

BaO 88 ± 14 258 ± 15 732 ± 28 110 ± 9 44 ± 6

PbO

Bi2O3

34 ± 13

16

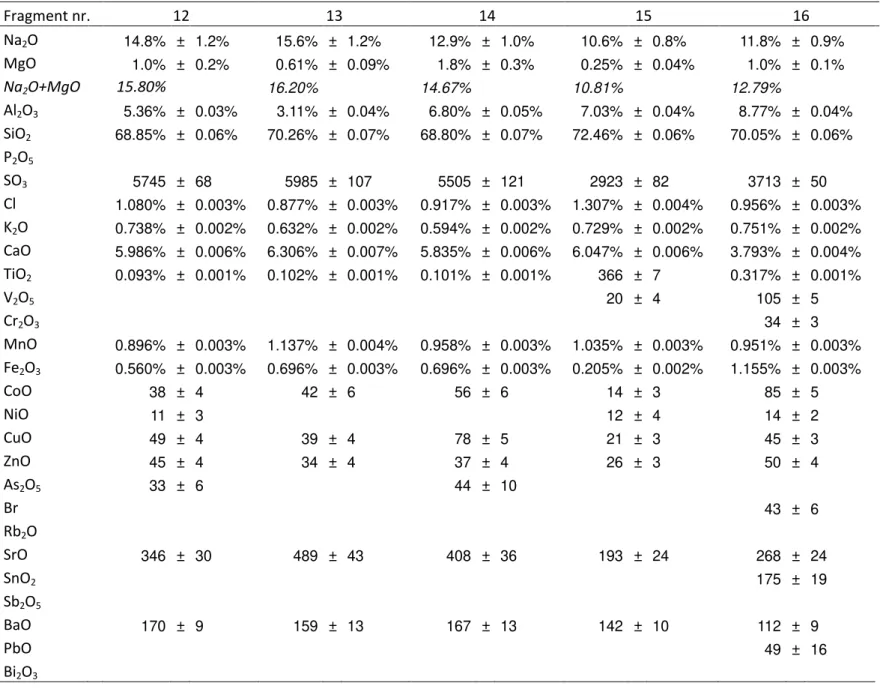

Table 4.6: compositions obtained by IBA for fragments from context 15 (µg/g except where % is indicated)

Fragment nr. 12 13 14 15 16

Na2O 14.8% ± 1.2% 15.6% ± 1.2% 12.9% ± 1.0% 10.6% ± 0.8% 11.8% ± 0.9%

MgO 1.0% ± 0.2% 0.61% ± 0.09% 1.8% ± 0.3% 0.25% ± 0.04% 1.0% ± 0.1%

Na2O+MgO 15.80%

16.20%

14.67%

10.81%

12.79%

Al2O3 5.36% ± 0.03% 3.11% ± 0.04% 6.80% ± 0.05% 7.03% ± 0.04% 8.77% ± 0.04%

SiO2 68.85% ± 0.06% 70.26% ± 0.07% 68.80% ± 0.07% 72.46% ± 0.06% 70.05% ± 0.06%

P2O5

SO3 5745 ± 68 5985 ± 107 5505 ± 121 2923 ± 82 3713 ± 50

Cl 1.080% ± 0.003% 0.877% ± 0.003% 0.917% ± 0.003% 1.307% ± 0.004% 0.956% ± 0.003%

K2O 0.738% ± 0.002% 0.632% ± 0.002% 0.594% ± 0.002% 0.729% ± 0.002% 0.751% ± 0.002%

CaO 5.986% ± 0.006% 6.306% ± 0.007% 5.835% ± 0.006% 6.047% ± 0.006% 3.793% ± 0.004%

TiO2 0.093% ± 0.001% 0.102% ± 0.001% 0.101% ± 0.001% 366 ± 7 0.317% ± 0.001%

V2O5 20 ± 4 105 ± 5

Cr2O3 34 ± 3

MnO 0.896% ± 0.003% 1.137% ± 0.004% 0.958% ± 0.003% 1.035% ± 0.003% 0.951% ± 0.003%

Fe2O3 0.560% ± 0.003% 0.696% ± 0.003% 0.696% ± 0.003% 0.205% ± 0.002% 1.155% ± 0.003%

CoO 38 ± 4 42 ± 6 56 ± 6 14 ± 3 85 ± 5

NiO 11 ± 3 12 ± 4 14 ± 2

CuO 49 ± 4 39 ± 4 78 ± 5 21 ± 3 45 ± 3

ZnO 45 ± 4 34 ± 4 37 ± 4 26 ± 3 50 ± 4

As2O5 33 ± 6 44 ± 10

Br 43 ± 6

Rb2O

SrO 346 ± 30 489 ± 43 408 ± 36 193 ± 24 268 ± 24

SnO2 175 ± 19

Sb2O5

BaO 170 ± 9 159 ± 13 167 ± 13 142 ± 10 112 ± 9

PbO 49 ± 16

17

Table 4.7: compositions obtained by XRF for fragments from context 19 (µg/g except where % is indicated)

Fragment nr. 1 2 3 4 5 6

Na2O+MgO 5.93%

1.25%

3.47%

20.63%

15.23%

20.63%

Al2O3 11.4% ± 1.0% 6.3% ± 0.6% 7.8% ± 0.7% 9.8% ± 0.8% 5.3% ± 0.6% 5.3% ± 0.4%

SiO2 72.3% ± 2.3% 62.0% ± 2.0% 72.7% ± 2.7% 59.0% ± 2.0% 62.0% ± 2.0% 73.3% ± 3.0%

P2O5 0.32% ± 0.08% 0.29% ± 0.07% 1.0% ± 0.3% 0.33% ± 0.09% 0.32% ± 0.09% 0.5% ± 0.1%

SO3 70 ± 15 475 ± 30 0.25% ± 0.01% 0.43% ± 0.02% 0.18% ± 0.01% 393 ± 23

Cl 245 ± 12 0.11% ± 0.01% 0.67% ± 0.03% 0.23% ± 0.01% 0.24% ± 0.02% 0.61% ± 0.03%

K2O 1.1% ± 0.2% 1.4% ± 0.2% 0.50% ± 0.08% 1.0% ± 0.2% 0.47% ± 0.08% 0.7% ± 0.1%

CaO 4.2% ± 0.3% 20.0% ± 1.3% 6.9% ± 0.5% 5.6% ± 0.4% 6.6% ± 0.5% 8.6% ± 0.6%

TiO2 467 ± 40 0.23% ± 0.02% 0.90% ± 0.08% 600 ± 53 900 ± 87 667 ± 57

V2O5 160 ± 10 0.30% ± 0.01% 590 ± 15 770 ± 20 0.163% ± 0.005%

Cr2O3 113 ± 5 49 ± 3 231 ± 9 14 ± 1 19 ± 1 30 ± 2

MnO 114 ± 1 488 ± 2 2.63% ± 0.01% 0.705% ± 0.002% 0.401% ± 0.002% 1.66% ± 0.01%

Fe2O3 0.49% ± 0.08% 1.7% ± 0.3% 2.43% ± 0.40% 0.50% ± 0.08% 1.1% ± 0.2% 0.41% ± 0.07%

CoO 41 ± 4 117 ± 10 163 ± 17 31 ± 3 0.29% ± 0.03% 40 ± 4

NiO 4.1 ± 0.2 12.9 ± 0.2 18.7 ± 0.2 98 ± 3

CuO 28 ± 1 48 ± 2 103 ± 4 35 ± 1 0.36% ± 0.01% 20 ± 1

ZnO 54 ± 5 79 ± 8 85 ± 8 52 ± 5 433 ± 40 50 ± 5

As2O5 39 ± 2 75 ± 3 22 ± 1 0.15% ± 0.01%

Br 51 ± 3 40 ± 2 36 ± 2 124 ± 6 34 ± 4 27 ± 1

SrO 447 ± 2 756 ± 4 734 ± 4 498 ± 3 428 ± 5 573 ± 3

SnO2 158 ± 5 0.1% ± 0.4% 220 ± 8 262 ± 8 263 ± 9 377 ± 10

Sb2O5 0.24% ± 0.05% 0.26% ± 0.05% 6.7% ± 1.0%

BaO 613 ± 73 420 ± 50 0.18% ± 0.02% 333 ± 40 620 ± 77

PbO 124 ± 20 45 ± 8 137 ± 23 120 ± 20 967 ± 233 453 ± 77

Sum of analysed elements 90.07% 92.90% 95.70% 77.80% 83.93% 77.80%

18

Table 4.8: compositions obtained by XRF for fragments from context 17(µg/g except where % is indicated)

Fragment nr. 7 8 9 10 11

Na2O+MgO 6.92% 20.70%

6.28%

15.30%

40.57%

Al2O3 4.8% ± 0.4% 4.7% ± 0.4% 7.7% ± 0.7% 3.8% ± 0.3% 3.7% ± 0.3%

SiO2 68.7% ± 2.3% 62.3% ± 2.0% 71.7% ± 2.3% 72.0% ± 3.0% 43.3% ± 1.7%

P2O5 500 ± 200 0.5% ± 0.1% 0.9% ± 0.2% 600 ± 200 0.5% ± 0.1%

SO3 937 ± 47 710 ± 40 0.14% ± 0.01% 0.11% ± 0.01% 343 ± 27

Cl 0.90% ± 0.04% 0.45% ± 0.02% 0.23% ± 0.01% 0.92% ± 0.04% 0.47% ± 0.02%

K2O 0.44% ± 0.08% 0.6% ± 0.1% 0.32% ± 0.05% 0.28% ± 0.05% 0.28% ± 0.05%

CaO 9.3% ± 0.7% 8.5% ± 0.7% 5.4% ± 0.4% 5.7% ± 0.4% 7.3% ± 0.5%

TiO2 837 ± 67 613 ± 50 0.53% ± 0.04% 880 ± 70 0.27% ± 0.02%

V2O5 3853 ± 97 3487 ± 90 2825 ± 70 2810 ± 80 2323 ± 70

Cr2O3 39 ± 2 4 ± 1 136 ± 6

108

MnO 1.90% ± 0.01% 1.332% ± 0.004% 2.54% ± 0.01% 1.169% ± 0.004% 1.69% ± 0.01%

Fe2O3 0.49% ± 0.08% 0.43% ± 0.07% 1.5% ± 0.2% 0.48% ± 0.08% 1.2% ± 0.2%

CoO 41 ± 4 40 ± 4 98 ± 9 32 ± 3 67 ± 6

NiO

28.3 ± 0.2

CuO 28 ± 1 38 ± 1 81 ± 3 23 ± 1 44 ± 2

ZnO 71 ± 7 51 ± 5 83 ± 8 47 ± 4 56 ± 5

As2O5

Br 28 ± 1 32 ± 1 30 ± 1 37 ± 2 31 ± 2

SrO 582 ± 3 595 ± 3 513 ± 3 506 ± 3 597 ± 3

SnO2 437 ± 13 377 ± 13 218 ± 8 219 ± 7 298 ± 9

Sb2O5 145 ± 30 390 ± 80

BaO 490 ± 60 603 ± 77 0.23% ± 0.03% 730 ± 90 293 ± 40

PbO 513 ± 87 537 ± 83 467 ± 80 450 ± 80 120 ± 23

Sum of analysed elements 87,70% 79,27% 91,30% 84,70% 59,43%

19

Table 4.9: compositions obtained by XRF for fragments from context 15 (µg/g except where % is indicated)

Fragment nr. 12 13 14 15 16

Na2O+MgO 19.83%

20.63%

14.23%

33.03%

18.70%

Al2O3 4.77% ± 0.40% 5.13% ± 0.43% 5.53% ± 0.50% 4.10% ± 0.40% 7.3% ± 0.6%

SiO2 64.00% ± 2.00% 63.00% ± 2.00% 66.67% ± 2.00% 54.00% ± 2.00% 64.3% ± 2.0%

P2O5 800 ± 300 1.07% ± 0.27% 0.70% ± 0.20% 0.70% ± 0.20% 0.26% ± 0.07%

SO3 845 ± 40 1760 ± 85 995 ± 50 337 ± 23 880 ± 50

Cl 0.53% ± 0.03% 0.42% ± 0.02% 0.61% ± 0.03% 0.50% ± 0.02% 0.55% ± 0.03%

K2O 0.52% ± 0.09% 0.57% ± 0.09% 0.67% ± 0.10% 0.39% ± 0.07% 0.46% ± 0.08%

CaO 7.23% ± 0.50% 6.87% ± 0.53% 8.60% ± 0.63% 5.27% ± 0.40% 4.5% ± 0.3%

TiO2 0.10% ± 0.01% 0.11% ± 0.01% 0.14% ± 0.01% 297 ± 23 0.40% ± 0.03%

V2O5 0.46% ± 0.01% 0.25% ± 0.01% 0.35% ± 0.01% 0.23% ± 0.01% 720 ± 20

Cr2O3 14 ± 1 30 ± 2 19 ± 1 120 ± 6

MnO 1.38% ± 0.00% 1.21% ± 0.00% 1.55% ± 0.01% 1.12% ± 0.00% 1.512% ± 0.005%

Fe2O3 0.70% ± 0.10% 0.67% ± 0.10% 0.90% ± 0.17% 0.18% ± 0.03% 1.5% ± 0.2%

CoO 51 ± 5 46 ± 4 68 ± 7 24 ± 3 102 ± 9

NiO 7.2 ± 0.2 6.7 ± 0.2 8.2 ± 0.2 22.2 ± 0.2

CuO 71 ± 3 42 ± 2 107 ± 4 18 ± 1 49 ± 2

ZnO 52 ± 5 47 ± 4 58 ± 5 28 ± 2 60 ± 5

As2O5 9 ± 1 10 ± 1

Br 32 ± 2 26 ± 1 32 ± 2 18 ± 1 29 ± 1

SrO

833 ± 4

490 ± 3

SnO2 353 ± 10 315 ± 10 387 ± 10 258 ± 8 184 ± 6

Sb2O5 327 ± 67 180 ± 40 430 ± 80

BaO 563 ± 67 317 ± 40 550 ± 70 340 ± 43 637 ± 70

PbO 490 ± 83 337 ± 60 397 ± 67 327 ± 57 71 ± 13

Sum of analysed elements 80.17% 79.37% 85.73% 66.97% 81.27%

20

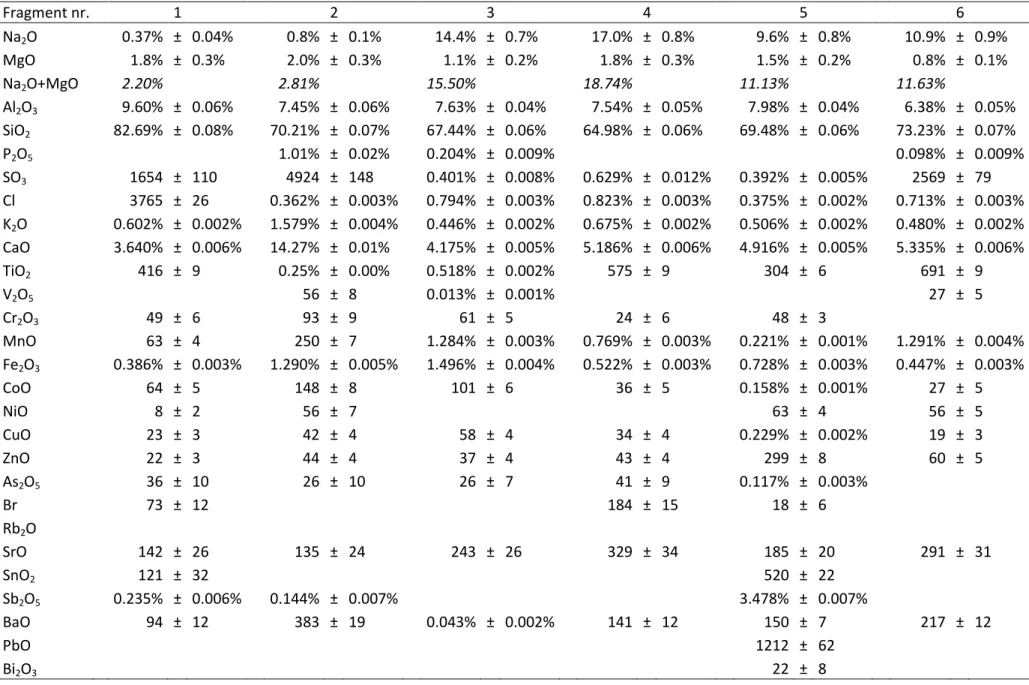

From simple observation of the results presented, several remarks can be made: in what

concerns the K2O and Na2O contents, K2O is generally below 1%, with few exceptions which

probably correspond to more corroded glass fragments, and this is consistently seen by both

techniques, IBA and XRF. On the contrary, although Na2O concentrations obtained by IBA

present variations from 0.37% up to 24.8% (cf. Fig. 2.3; XRF was totally unable to provide any

values for these concentrations) the overall values – obtained by IBA and calculated by

differences in XRF for the joint Na2O+MgO concentrations – scatter equally through large

intervals, namely 2.20-26.1% as seen by IBA vs 1.26-40.6% by XRF.

0 5 10 15 20 25 30

0,0 0,2 0,4 0,6 0,8 1,0 1,2 1,4 1,6 1,8 2,0

[K

2O

]/

wt%

[Na

2O]/ wt%

19-1 19-2 19-3 19-4 19-5 19-6 17-7 17-8 17-9 17-10 17-11 15-12 15-13 15-14 15-15 15-16

Figure 4.3: K2O vs Na2O concentrations determined by IBA techniques for each of the fragments; the

legend indicates the fragments’ order numbers preceded by each respective context.

Furthermore, [CaO] values vary from 3.64% to 14.27% while [MgO] stays below 2%. At this

point – given the relatively low content of MgO which as such has no significant influence in

the overall variation imposed by Na2O – what is surprising is the comparatively much larger

scatter of results that may be inferred from XRF for Na2O. This means that, as expected from

Roman glasses [16], the analysed fragments are soda-lime-silica glasses showing different

extents of surface corrosion, which is responsible for the removal of Na and Ca. Figure 4.3,

together with the low contents of MgO presented in the presented tables, further indicate that

these glasses were produced by resorting to natron as a flux [8].

It is to be noticed from inspection of the tables that all the glass fragments analysed by XRF –

21

– show a consistently high content of Sr (expressed as SrO), between 400 µg/g and 800 µg/g,

across contexts. Even the IBA results (that probe more shallow layers of the glasses) show

consistently high contents of Sr, in the range 130 µg/g to 500 µg/g. Such results clearly indicate

that Sr cannot be used as a distinctive fingerprint that might allow associating particular

fragments with definite contexts in this case. They point, however, to a common source, most

probably of coastal nature, either local or imported, especially if their low MgO content and

noticeable absence of Zr is taken into account. In fact, according to Paynter [17], and also to

Freestone [18], higher Sr concentrations, around 400 µg/g, associated with low contents of Zr

60 µg/g [17] or low MgO contents, below 2% [18], indicate use of Mediterranean coastal

sands to produce the glasses, while lower Sr values, closer to 150 µg/g, and higher

concentrations of Zr, ca. 160 µg/g [17] or MgO contents above 2% [18], would suggest the use

of inland sands.

Although at an earlier stage of results processing it seemed possible that grouping by

similarity of composition would emerge allowing an unambiguous association between samples

and contexts of origin, this proved not to be so. In spite of the apparent scattering of the results,

very much influenced by the strong variation in Na contents most probably due to varying

degrees and extent of glass surface corrosion, the results are fairly homogeneous in that they

do not characteristically associate with any context. This is very interesting as it indicates that

essentially no significant distinction exists – from the point of view of chemical/elemental

composition – between samples from different contexts. As such, the reasonable conclusion

that presents is that the analysed glass fragments are common to the different occupations of

the archaeological site.

Fragment 193/03 from context 19 showed significant concentrations of Sb and Pb,

indicating usage of opacifying agents (mixed oxides as Ca2Sb2O7, Ca2Sb2O6 and Pb2Sb2O7), which

are known to have been used until IV century AD [19], in agreement with the time interval of

the villa’s occupation.

Fragment 92/01-Larger is abnormally rich in K, comparing to other samples, while low in Na

contrarily to 92/01-Smaller from the same context. Therefore these two fragments should not

be considered as belonging to the same original object (as opposed to what was initially

accepted).

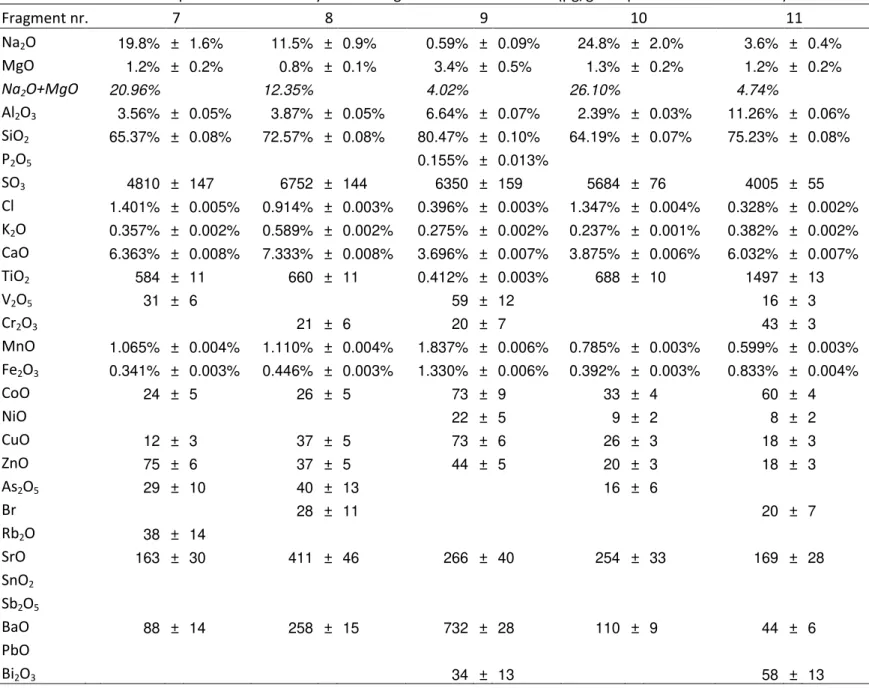

Performing beam scanning and elemental distribution mapping with IBA techniques further

helped in identifying the most corroded areas of the samples.

This possibility is demonstrated for glass fragment 195 in Fig. 4.4, showing the elemental

distribution maps of Si, Ca and Mn. Clearly corroded versus clean, non-attacked areas can be

22

Si and Ca in correlation with corresponding regions displaying enhanced Mn contents. This is

also seen by XRF in the spectra of a corroded area versus non-corroded area as seen in Fig. 4.5.

The Mn rich regions in the PIXE maps correlate to a visible dark brown thin layer on the glass

surface, probably corresponding to MnO2, as the result of redeposition of Mn on the glass

surface, after oxidation by atmospheric O2, which in turn is subsequent to the leaching of Mn

from the glass matrix [20].

Figure 4.4: elemental distribution maps of Si, Ca and Mn on glass fragment 195.

Figure 4.5: XRF spectra of fragment 195 – superimposition of data from a corroded and non corroded area.

Contact of glass with water leads to leaching of alkali and alkaline earth ions and their

substitution by hydronium ions in the glass structure. This creates a hydrated layer at the

1 mm

23

surface, causing more leaching and silica dissolution in the presence of water [21]. This

mechanism may explain the low contents of both Na and K found in some of the fragments.

As expected, XRF results generally present higher contents of SiO2, CaO and K2O and lower

concentrations of Mn and Cl in apparent opposition to the IBA results. This can be explained by

the deeper penetration of the X rays beams in the glass, and thus larger volumes of probed

material.

Finally a word about processing and analysing large volumes of data as was the case of the

present work and all works of similar nature.

The presently available XRF spectra processing software, although adequate for processing

individual spectra or small numbers of spectra, is much less fit or adequate to handle a large

number of spectra. In such cases, its use becomes difficult, even cumbersome, without proper

planning and adequate knowledge of the package full possibilities. At present this is not yet an

optimised process at DCR, most probably due to the fact that the necessity has not posed itself

so far. Fully exploring the package’s capabilities became an understandably important aim of

this work, one that has also been successfully achieved. With this purpose in mind, the focus

was first set in understanding the formats used for information storage and retrieval, both

spectral and operational, concerning the data acquisition and analysis software. Inspecting and

understanding these formats lead to realising that all pertinent experimental data is stored in

block structured XML format – an ASCII format that is easily and readily machine readable and

user readable – in the form of SPX files. Secondly, and equally important due to its practical

implications, was the realisation that – since WinAXIL does not provide any means to directly

read or accept the SPX files from the ArTAX acquisition system (or otherwise XML formatted

data) – the best working format to use for conveying spectra and relevant data to WinAXIL is

the SPE format. This is a well-documented block structured ASCII format, sponsored by the

International Atomic Energy Agency (IAEA) and also used with previous versions of the AXIL

code. Contrary to the plain ASCII format TXT commonly used at DCR, SPE formatted files store

and convey relevant data to WinAXIL, in particular system times – live and real (clock) times –

necessary for e.g. dead time calculations, not just the spectral data. Using these SPE format not

only eliminates the need of manually entering the system times for each individual spectrum

but also enables large number batch processing by means of WinAXILBatch: spectral line

deconvolution and background correction can be performed unattended, automatically, for any

number of spectra. Furthermore, automatic data handling also minimizes the chance for error.

In order to make this possible and practical, creation of the SPE data files from the original SPX

24

imposed by this work and the understanding gained about the data formats and usage, an

existing batch format conversion program was implemented to accommodate batch conversion

of SPX (XML) to IAEA/AXIL complying SPE format. In all, the combined use of the format

conversion program and the SPE files with WinAXILBatch, allow a reduction of the overall

processing time to less than 6 minutes per 60 spectra.

After the spectra have been processed – deconvoluted and background corrected – by

WinAXIL or WinAXILBatch, calculations must be performed by WinFund. Here, and very much

unfortunately some shortcomings of the present form of the program prevent practical fully

automatic calculations on a set of spectra. Parameters’ setting is totally inadequate for batch

calculations. However, after an initial painstaking stage of cumbersome, individual spectrum,

parameter setting, automatic calculations can finally be performed on the set. The results have

to be manually copied to a worksheet and then sorted or organised in a useful form. Due to the

peculiar way in which WinFund outputs the results of its calculations, a routine was developed

as an Excel VBA coded macro to automatically sort and organise the WinFund output data,

transforming it in numerical values that can be used for further calculations. As a final remark,

in spite of all enhancements WinFund is still the bottleneck since it only allows “one file loading at a time” including the specification of the oxides that are to associate to each element present in the sample, element by element, one element at a time. This is a very time

consuming task, one that also increases the chance for error enormously.

As a result of the time invested in understanding the software operation, a description of

the procedures to be followed, as well as the file format conversion program and the Excel

macro enabled worksheet for WinFund data transformation will be made available for the

25

5.

Conclusions

Considering the comparison of the two types of techniques used in this study, IBA and XRF,

it is possible to state that, despite the results obtained with each technique for the

archaeological samples showed significant differences between themselves, these differences

are consistent with the physical principles of the techniques and to the conservation state of

the objects. Although apparently obvious, it is nonetheless worth mentioning that these

techniques do not replace each other, except of course in the unlikely case of pristine unaltered

homogeneous objects. Instead they do complement, allowing a more complete and

encompassing characterisation of the objects under analysis. Stated otherwise the techniques

compare well, taking into account their specific probing depths and sensitivity to the state of

the surface region of the artefacts and, as such, both are needed, either individually or in

combination to the greatest advantage of the analyst.

Nevertheless, there is room for improvements and these may be considered. The geometry

and intensity of He flow used in MicroFEx external beam end station should be better defined

in order to systematically guarantee a relatively stable Ar free He atmosphere. This is an

improvement of major importance since setting the proper He atmosphere enables detection

of Na X rays, as recent experiments have shown. And that is by all means a notable achievement,

especially in external, non-vacuum environment.

Also, improvement in beam charge monitoring will make the system less sensitive to beam

intensity fluctuations contributing to better precision and reliability of the quantification of

spectral data.

In what concerns XRF, one major improvement would focus as well on setting a better He

atmosphere, one that may also potentiate Na X rays collection (provided that the detector

window is not too thick to absorb almost entirely those X rays). Another suggestion is to

correctly determine the sample-to-detector real distance and state it to the analysis software,

since attenuation of X rays in air is of importance, particularly for the lighter elements, and can

significantly affect the results (this is less of a problem in a He pure atmosphere).

In line with the general conclusions stated above, the use of nuclear microprobe based PIXE

and PIGE techniques in external analysis, complemented by in air micro-XRF, allowed

characterising Roman glasses from different occupation periods of the same settlement, the

one of Quinta da Bolacha in the centuries IV to II AD, establishing:

– The elemental compositions and conservation state. Although XRF and IBA techniques

produce apparently different sets of results particularly in glasses with significant surface

26

characterised by the low contents of Na and K and the high contents of Mn in clearly

identifiable corroded regions – these are, however, glasses with essentially moderate to high

Na contents, low in K and Mg, consistent with the general soda-lime-silica compositions known

to Roman glasses.

– Natron was used as a source of flux for the production of these glasses.

– Significant levels of Sb and Pb found on one fragment indicate that the opacifying

agents used were those characteristic of historical periods until the IV century AD, confirming

the time interval of the villa’s occupation. No specific elements were found that could be used

as fingerprints for attributing a chronology to the objects from revolved contexts. Instead, no

distinction between the two sealed contexts could be made based on the bulk composition of

the glass fragments collected therefrom, leading to state that most probably manufacture

27

References

[1] A Comparison of the Depth of Analysis of Three Experimental Techniques, SEM-EDS, PIXE

and XRF, http://ion.asu.edu/depth/depth2.htm, 2010.

[2] FERNANDES, P, VILARIGUES, M., ALVES, L. C., SILVA, R. C. da, “Stained glasses from

Monastery of Batalha: Non-destructive characterisation”, Journal of Cultural Heritage, 9,

(2008), 5–9.

[3] LOPES, F., Uranium Glass in Museum Collections– Dissertação de Mestrado, DCR,

FCT-UNL, 2008.

[4] RUIVO, A., GOMES, C., LIMA, A., BOTELHO, M. L., MELO, R., BELCHIOR, A., MATOS, A. P.

de, “Gold nanoparticles in ancient and contemporary ruby glass”, Journal of Cultural

Heritage, 9, (2008), 134–137.

[5] CRUZ, Mário, O Vidro Romano no Noroeste Peninsular, Um olhar a partir de Bracara

Au-gusta, Volume I, O Vidro Romano no Noroeste Peninsular– Tese de Doutoramento,

Insti-tuto de Ciências Sociais, Universidade do Minho, 2009.

[6] DEGRYSE, P., SCHNEIDER, J., “Pliny the Elder and Sr-Nd isotopes: tracing the provenance

of raw materials for Roman glass production”, Journal of Archaeological Science 35 (2008)

1993–2000.

[7] Chemistry of Glass, http://www.cmog.org/dynamic.aspx?id=5664&terms=composition%20roman,

Corning Museum of Glass, 2011.

[8] SHORTLAND, Andrew, SCHACHNER, Lukas, FREESTONE, Ian, TITE, Michael, “Natron as a

flux in the early vitreous materials industry: sources, beginnings and reasons for decline”,

Journal of Archaeological Science 33 (2006) 521–530.

[9] MIRANDA, J. A., ENCARNAÇÃO, G., Villa Romana da Quinta da Bolacha, Campanha de

Abril/Maio de 1997, Relatórios-4, Gabinete de Arqueologia Urbana, Associação de

Arqueologia da Amadora, 1998.

[10] VAN ESPEN, P., NULENS, H., ADAMS, F., Nucl. Instr. And Meth. 145 (1977) 579.

[11] REIS, M. A., ALVES, L.C., “DATTPIXE, A Computer Package for TTPIXE Data Analysis”, Nucl.

Instr. and Meth. B68 1-4, (1992), 300–304.

[12] BRONK H, RÖHRS S, BJEOUMIKHOV A, LANGHOFF N, SCHMALZ J, WEDELL R, GORNY HE,

HEROLD A, WALDSCHLÄGER U. “ArtTAX – a new mobile spectrometer for

energy-dispersive micro X ray fluorescence spectrometry on art and archaeological objects”,

Fresenius J Anal Chem. 2001 Oct 371(3):307–16.

[13] BRILL, Robert H., Chemical Analysis of Early Glass – Table of Analysis, Volume 2, The

Corning Museum of Glass, New York; 1999.

[14] Model S-5005 WinAxil X ray Analysis Software, http://www.canberra.com/be/pdf/Cpbsp2m6-WinAxil.pdf,

[15] WOBRAUSCHEK, P., HALMETSCHLAGER, G., ZAMINI, S., JOKUBONIS, C., TRNKA, G.,

KAR-WOWSKI, M., “Energy-Dispersive X ray Fluorescence Analysis of Celtic Glasses”, X ray

Spectrom. 29, (2000), 25–33.

[16] REHREN, Thilo, “Rationales in Old World Base Glass Compositions”, Journal of Archaeo-

logical Science 27, (2000), 1225–1234.

[17] PAYNTER, S., “Analyses of colourless Roman glass from Binchester, County Durham”,

28

[18] FREESTONE, I. C. “The Provenance of Ancient Glass through CompositionalAnalysis”, Mater. Res. Soc. Symp. Proc. Vol. 852 © 2005.

[19] DAVISON, Sandra, Conservation and Restoration of Glass, Butterworth-Heinemann,

Elsevier Science, Oxford, 2003, ISBN-0-7506-4341-2.

[20] SCHALM, O., PROOST, K., DE VIS, K., CAGNO, S., JANSSENS, K., MEES, F., JACOBS, P., CAEN,

J., “Manganese staining of archaeological glass: The characterization of Mn-rich inclusions

in leached layers and a hypothesis of its formation”, Archaeometry53, 1 (2011) 103–122.

[21] VILARIGUES, M., SILVA, R. C. da, "Characterization of potash-glass corrosion in aqueous solution by Ion Beam and IR Spectroscopy", Journal of Non-crystalline Solids, 352, (2006),