110

PROPRIEDADES ESTRUTURAIS, MAGNÉTICAS E

HIPERFINAS DAS LIGAS Fe86Co14-yCuy

STRUCTURAL, MAGNETIC AND HYPERFINE PROPERTIES

OF Fe86Co14-yCuy ALLOYS

PROPIEDADES ESTRUCTURALES, MAGNÉTICAS E

HIPERFINAS DE LAS ALEACIONES DE Fe86Co14-yCuy

Caroline Knapp Cavalini1 Flavia Stephanie Wentz2 João Carlos Krause3

Carlos Ariel Samudio Pérez4

Resumo: As propriedades estruturais, hiperfinas e magnéticas das ligas de Fe86Co14-yCuyforam investigadas com diversas técnicas experimentais e cálculos teóricos em função do at% Cu (y=1, 3 e 5). Em trabalho experimental, as amostras foram produzidas por fusão a arco sob atmosfera de argônio inerte. A análise de XRD mostrou que todas as amostras estudadas são monofásicas e são bem cristalizadas com a estrutura A2 (BCC), com parâmetros de rede típicos de bcc-ferro. Foi observado que a adição de cobre é um impedimento para a magnetização total, enquanto a adição de cobalto é benéfica. Os cálculos de DFT foram realizados com o método de ondas planas aumentadas lineares (LAPW), conforme implementado no código WIEN2K. Os cálculos foram realizados utilizando uma super célula de 3x3x3 com 54 átomos em simulação de estrutura bcc e a mesma estequiometria do estudo experimental em ligas de Fe-Co-Cu. Nossos resultados indicaram que a magnetização e o campo hiperfino magnético não estão linearmente correlacionados neste sistema.

Palavras-chave: Ligas Fe-Co-Cu. Magnetização. Campo hiperfino. Estrutura eletrônica.

Abstract: The structural, hyperfine and magnetic properties of Fe86Co14-yCuy alloys have been investigated with several experimental techniques and theoretical calculations as a function of the at.% Cu (y=1, 3 and 5). In experimental work, the samples were produced by arc melting under inert argon atmosphere. The XRD analysis showed that all the studied samples are single phase and are well crystallized with the A2 (BCC) structure, with lattice parameters typical of bcc-iron. It has been observed that the copper addition is deterrent for the total magnetization, while the cobalt addition is beneficial. DFT calculations were performed with the linear augmented plane-wave method (LAPW) as implemented in the WIEN2K code. Calculations were performed using a 3x3x3 supercell with 54 atoms in bcc structure simulation the same stoichiometry of experimental study in Fe-Co-Cu alloys. Our results indicated that the magnetization and the magnetic hyperfine field are not linearly correlated in this system.

Keywords: Fe-Co-Cu alloys. Magnetization. Hyperfine field. Electronic structure.

1 Graduanda Engenharia Elétrica – Bolsista PIBIC/CNPQ. URI. E-mail: carolknappcavalini@gmail.com 2 Graduanda Engenharia Elétrica – Bolsista PIITI/URI. URI. E-mail: flaviawentz@outlook.com 3 Doutor. URI. E-mail:krause@san.uri.br

111

Resumen: Las propiedades estructurales, hiperfinas y magnéticas de las aleaciones Fe86Co14-yCuyse han investigado con varias técnicas experimentales y cálculos teóricos en función del at% Cu (y=1, 3 y 5). En el trabajo experimental, las muestras se produjeron mediante fusión por arco en atmósfera de argón inerte. El análisis XRD mostró que todas las muestras estudiadas son monofásicas y están bien cristalizadas con la estructura A2 (BCC), con parámetros de red típicos de bcc-hierro. Se ha observado que la adición de cobre es disuasiva para la magnetización total, mientras que la adición de cobalto es beneficiosa. Los cálculos de DFT se realizaron con el método lineal de ondas planas aumentadas (LAPW) implementado en el código WIEN2K. Los cálculos se realizaron utilizando una supercelda 3x3x3 con 54 átomos en la simulación de la estructura bcc, la misma estequiometría del estudio experimental en aleaciones de Fe-Co-Cu. Nuestros resultados indicaron que la magnetización y el campo hiperfino magnético no están correlacionados linealmente en este sistema.

Palabras-clave: Aleaciones de Fe-Co-Cu. Magnetización. Campo hiperfino. Estructura electrónica..

112

IntroductionA brief search in the specialized literature reveals a series of studies to verify the stability and formation of alloys in immiscible systems, being the Fe-Cu (Yavari et.al, 1992; Eckert et.al, 1992; Ambrose et.al, 1993; Kimura e Takaki, 1997) and Co-Cu (Egry et.al, 2010; Yoo et.al, 1999) systems some of the widely investigated through several experimental techniques. Likewise, ternary systems involving these elements have also been studied in this line, both in Cu-rich (Wada et.al, 2015) alloys and in other concentrations (Prieto et.al, 1999; Liu et.al, 2011).Many of these studies have gone beyond the interest related to the miscibility between the elements, investigating the most relevant magnetic properties related to local order (Gay et.al, 1999) as well as their dependence on temperature (Prieto et.al, 1999), for possible applications in magnetic recording devices.

Among the Fe-alloys, the Fe-Co system shows a high permeability and the highest magnetization saturation. Binary Fe-Co alloys can be obtained in a wide range of concentrations, the (FCC) phase can be obtained for high concentrations of Co, the (BCC) phase for concentrations above 30wt% Fe, and the ordered ' phase in the equiatomic region (Nishizawa e Ishida, 1984).

The formation of Fe-based and Co-based binary alloys is possible with almost all the metallic elements of the periodic table, but, Fe and Co are immiscible with some, being a case of Cu. This immiscibility in Fe-Cu and Co-Cu systems was first observed by Nakagawa (Nakagawa, 1958). But, the Fe-Cu and Co-Cu phase diagrams indicate the possibility of very low solubility. In the Co-Cu system an alpha phase can be obtained at high temperature up to

about 20 at% Cu. For Fe-Cu system the solubility can reach about 2at% Cu at about 700oC. Considering this tendency of immiscibility in the Co-Cu and Fe-Cu binary systems, it is expected the same to occur in the Fe-Co-Cu ternary system (Liu et.al, 2011; Nakagawa, 1958; Hasebe e Nishizawa, 1980; He e Zhao, 2005; He e Zhao, 2005; He e Zhao, 2005; He e Zhao, 2006; Curiotto et.al, 2007; Ik e Abbaschian, 2000).

The phase diagram of the Fe-Co-Cu system is very complex varying its possible phases in an extensive region of temperature (basically and ), but in almost all of them with the

113

precipitation of copper. Around 800oC its noticeable a region where we can obtain a bcc phasefor alloys rich in iron (Bein et.al, 2000). However, for a concentration greater than 3wt.% Cu there may be possibility of copper precipitation. This precipitation can be observed at various temperatures for various compositions and phases (Liu et.al, 2013; Ik e Abbaschian, 2000; Munitz et.al, 2006; Bamberger et.al, 2002; Banda et.al, 2008).

In the present work, the structural, magnetic and hyperfine properties of ternary alloys

Fe86Co14-yCuy (y = 1, 3 and 5) are investigated to characterize the effect of a relatively high

concentration of copper in the alloy. In the next section the details of sample preparation, experimental analysis x-ray diffraction (XRD), Mössbauer Spectroscopy (MS), magnetization, scanning electron microscopy (SEM), and energy dispersive spectroscopy (EDS)) and first principles electronic structure calculations are presented. Subsequently the results obtained are discussed and finally commented on the most relevant conclusions.

Materials and methods

The Fe86Co14-yCuy alloys were prepared by melting several times the nominal mixtures of the electrolytic elements with high purity (above 99.5%) under argon atmosphere in an arc furnace. Were chosen three different compositions following a straight line of constant Fe concentration by increasing the concentration of copper (Liu et.al, 2011) from bcc single phase region in the phase diagram until the region with a possible precipitation of copper, namely, y = 1, 3 and 5. The alloys were subsequently encapsulated in quartz tubes filled with

argon, annealed for three days at 800oC and then quenched in iced water. The samples for experimental analysis were taken from the central part of each alloy. The XRD analysis were carried out by using a Rigaku MiniFlex 600 diffractometer and CuKradiation. A scanning electron microscopy (SEM) JEOL JSM-IT100 with energy dispersive spectroscopy (EDS) was used to determine the chemical composition of the alloys. Magnetization measurements were performed by using a SQUID MPMS-XL magnetometer from Quantum Design allowing measurements between temperatures from 5K to 380K. The hysteresis loops were registered at RT. The powder absorbers for the MS were obtained by crushing the central part of each sample. The MS spectra were collected at room temperature (RT=300K), in transmission geometry with a conventional spectrometer, operating with constant acceleration mode, using

114

a 50mCi Co/Rh source. The standard is natural -iron, for which all quoted isomer shifts arereduced to its centroid ((Fe)).

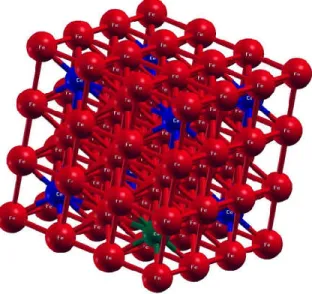

Fig. 1. Crystal structure of 3x3x3 supercell with 54 atoms constructed with a bcc unit cell for Fe46Co7Cu1 alloy. Red balls are iron atoms, blue balls are cobalt atoms and green balls are cooper atoms.

For the theoretical study was used the linearized augmented plane wave (LAPW) method within the framework of the Density Functional Theory (DFT) as implemented in the WIEN2k code. Theoretical calculations were performed for Fe86Co14-yCuy alloys modeled with a 3x3x3 supercell, with 54 atoms, constructed with a unit cell of body-centered cubic (BCC) type. The same stoichiometry of experimental study were simulated in Fe-Co-Cu alloys. Calculations in three cluster were performed: Fe46Co7Cu1, Fe46Co6Cu2 and Fe46Co5Cu3. The supercell structure for Fe46Co7Cu1 alloy is shown in Fig. 1 to illustrate.

Results and Discussions

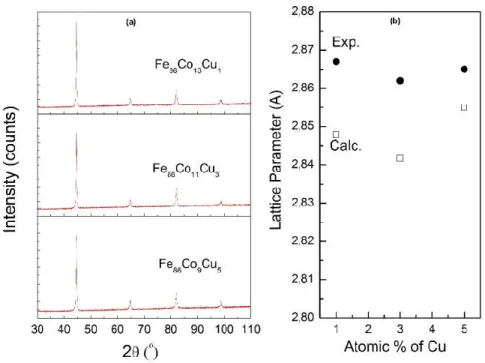

The XRD patterns of the samples are composed by well-defined lines characteristic of BCC structure, Fig.2. This result seems to indicate that all the studied samples are single phase and are well crystallized with the A2 (BCC) structure. Although two samples are in the region

115

of the phase diagram in which precipitation of copper is expected, that is not observed. Thelattice spacing for the three samples Fe86Co13Cu1, Fe86Co11Cu3 and Fe86Co9Cu5 were 2.867Å, 2.862Å and 2.865Å, respectively. These values are comparable to that of pure BCC iron (2.866Å), indicating that the inclusion of atoms of cobalt and copper practically does not change the repulsive part of the potential energy of the BCC iron matrix. These results for the lattice parameter are in agreement with that found by experimental studies in FeCo alloys. According to Sundar and Deevi (Sundar e Deevi, 2005) for concentrations around 30at% Co in Fe, the lattice parameter variation is very small. The calculated lattice parameter as function of the Cu concentration indicated the same behavior which experimental results (see Fig. 2-b).

Fig. 2. (a) X-ray diffraction pattern of the BCC structure for the Fe86Co14-yCuy alloys. (b) Experimental lattice parameter and calculated.

The SEM-EDS measures show the concentrations of each alloy and do not indicate the presence of impurities. Data for the concentrations for each of the alloys obtained by EDS are shown in Table 1. It can be seen from this table that the iron concentrations is higher than 85at. % Fe, this confirms the formation of iron-rich samples with Co and Cu.

116

Table 1Average atomic concentrations obtained by EDS for the constituents of each sample investigated.

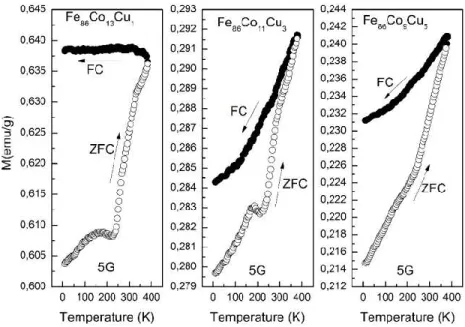

The temperature dependence of the magnetization (M(T) curve) can be observed in Fig. 3. For the measurements of the M(T) curves the samples were zero-field-cooled (ZFC) down to 5K, then a field of 5G was applied and the data was collected by heating the samples at a rate of 0.2k/min to 380 K. Afterwards, the field-cooled (FC) M(T) curves were obtained while cooling the samples down to about 5K. Because the maximum magnetometer temperature was 380 K, obtaining the Curie temperatures of these samples was not possible. The ZFC curve exhibits a peak at 150 K and 175 K for samples with y = 1 and 3, respectively. Is observed also a pronounced irreversibility between ZFC and FC M(T) curves. These features observed in the M(T) curves suggest a competition between ferromagnetic and anti-ferromagnetic exchange interactions indicating the presence of spin-glass-like behavior.

To determine the saturation magnetization of the alloys hysteresis loops measurements were performed at RT (Fig. 4). From these one can see that the alloys show features of soft magnetic material. No remanence and no coercive field are observed for the alloys at RT. The estimated saturation magnetization values are 239, 232, and 223 emu/g, for Fe86Co14-yCuy alloys with y =1, 3, and 5, respectively. As can been observed the specific magnetization of alloys decreases slightly as the amount of copper increases in the composition. From the saturation magnetization values were calculated the average local magnetic moments considering only the contributions of Fe and Co atoms. According to several works (Bardos, 1969; Di Fabrizio et.al, 1989; Kulkova et.al, 2002; Paduani e Krause, 1999)in binary Fe-Co alloys, cobalt atoms keeps their magnetic moment constant (1.7 mB), and the iron atoms varies its moment from 2.22mB (pure) to 3mB (50wt.%Co). So we calculate the average values of the iron magnetic moment considering the magnetic moment of Co atoms 1.7mB and obtain the

117

values of 2.43mB, 2.41mB and 2.37mB for Fe atoms in alloys Fe86Co13Cu1, Fe86Co11Cu3and Fe86Co9Cu5, respectively. This result indicates that the average magnetic moment of iron atoms in the studied alloys decrease slightly with the increase of copper concentration.

Fig. 3. Field-cooled (FC) and zero field-cooled (ZFC) magnetization vs temperature curves (measuring under magnetization field of 5G).

118

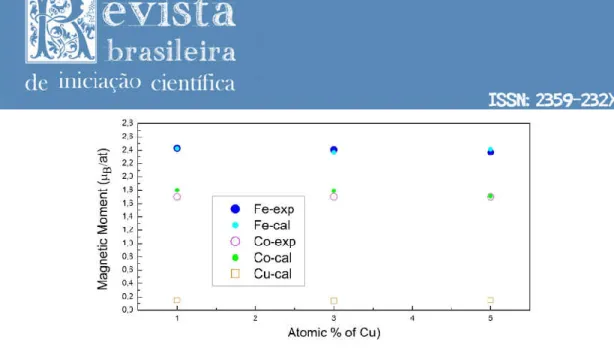

Fig. 5. Comparison between magnetic moments of atoms from each alloy obtained by

experimenting and calculating.

The DFT calculations through the code WIEN2k corroborate the experimental results obtained for the magnetic moments. In Fig. 5 there are the results obtained from the theoretical calculations compared to the results obtained experimentally. The weak magnetization of the Cu atoms and the slight dependence of the magnetization on the Fe and Co atoms with the Cu concentration are observed. Since the Cu atoms are not magnetic in their pure state it can be concluded that the local magnetic moment observed at the Cu sites in the structure of the studied alloys is induced by the Fe and Co atoms. On other hand, the positive sign of the magnetic moment of Cu atoms is an indicative that these atoms couple ferromagnetically to the Fe and Co atoms.

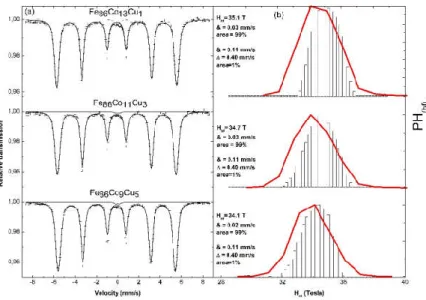

Figure 6.a shows the Mossbauer spectra of the alloys taken at RT. All the spectra were fitted with a distribution (histograms) of hyperfine magnetic fields (Bhf) which uses a block of 75 sextets with a linewidth =0.22mm/s and electric quadrupole having the value 0,0 mm/s. In figure 6(b), the corresponding distribution profile is shown. In order to improve the fit of Mossbauer spectra it was necessary to use a paramagnetic doublet. The relative area under the doublet in the spectra of the alloys is approximately constant (~1%). The electrical quadrupole (0,40 mm/s) and isomer shift (0,11mm/s) are also approximately constant. These results may suggest the presence of a Cu-rich phase with diluted Fe in the studied alloys.

119

The fitting procedure of the Mössbauer spectra shows that with increasing concentrationof Cu in the alloys there is a slight decrease of the Bhf , being the average hyperfine magnetic fields found of 35.1T, 34.7T and 34.1T for Fe86Co13Cu1, Fe86Co11Cu3 and Fe86Co9Cu5 alloys, respectively.

In order to improve the reliability of the Bhf distribution profiles obtained from the Mössbauer spectra, and consequently its interpretation, we used a binomial distribution for the theoretical estimation of the occupation probability of the neighborhood of the Fe atoms by Co and Cu atoms. In this theoretical estimation, we consider the distribution of solute atoms in the first and second neighborhoods, estimating the probability for each possible configuration for a given stoichiometry (Pi). A given hyperfine field (Bi) value was associated for each arrangement. The average hyperfine field ( ) was calculated through the equation:

= + ∑ (1)

where B0 is the hyperfine field of pure iron.

To calculate the values of the Bi were used the experimental values obtained by Idczak for the contribution of Co atoms and Błachowski to the contributions of Cu atoms (Idczak et.al, 2015; Blachowski et.al, 2011). The fit of the theoretical distribution to those obtained from the fitting of the experimental data was obtained by considering a variation of 0.9T for 1 Co nearest neighbor (NN) and 0.9T for 1 Co next-nearest-neighbor (NNN), and -1T for 1 Cu NN and 0.3T for 1 Cu NNN. In Fig. 6(b) both experimental (columns) and theoretical (red lines) Bhf distributions are shown, for the sake of comparison. Although the experimental curve is broadened by a Lorentzian function the theoretical one was made just by connecting points.

The first principles calculation results indicate that Fe atoms with only Co NN and NNN experience a field of 32.5, 32.5 and 32.6 T, whereas for those with at least one Cu NN the hyperfine field is of 31.0, 29.7, and 29.7 T in the alloys Fe86Co13Cu1, Fe86Co11Cu3 and

Fe86Co9Cu5, respectively. Since the field theoretically determined for bcc-Fe is 30.6 T, these

120

Fig. 6. (a) Mössbauer spectra at 300K. (b) The histograms shown at the right depict themagnetic hyperfine field distributions (bars) from the fits to the respective experimental spectra. For each case is also indicated a theoretical distribution profile (red lines).

Conclusion

An experimental investigation of the structural and magnetic properties of the Fe86Co14-yCuy alloys has been performed as a function of the at.% Cu (y=1, 3 and 5). Results of the X-ray diffraction analysis confirm that the A2 (BCC) structure exists in all the alloys. SEM-EDS measurements show that the Fe, Co and Cu concentrations are very near to nominal compositions; this confirms the formation of Fe-rich samples with Co and Cu. Magnetic measurements suggest a spin-glass-like behavior in the alloys and that the presence of Co atoms in the neighborhood of Fe atoms increase the iron magnetic moment relative to that of pure Fe.

The fitting procedure of the Mössbauer spectra showsthat with increasing concentration of Cu in the alloys there is a slight decrease of the hyperfine magnetic field at the Fe nuclei. The results indicate also that 1 Co NN (or NNN) contributes to increase the hyperfine magnetic field of Fe atom, whereas 1 Cu NN (or NNN) contributes to decrease the field.

The performed DFT calculations through the code WIEN2k seems to corroborate the experimental results obtained in the present study.

121

The authors declare that they have no conflict of interest.Acknowledgements Thanks to Dr. Jacob Schaf for the measurements of magnetization and Dr. J. D. Ardisson for the mesurements of Mössbauer spectropy.

References

AMBROSE, T.; GAVRIN, A.; CHIEN CL. Magnetic properties of metastable fee Fe-Cu alloys prepared by high energy ball milling. Journal of Magnetism and Magnetic Materials 124, p. 15-19, 1993.

BACHMAIER A.; ABOULFADL H.; PFAFF M.; MÜCKLICH F. MOTZ C. Structural evolution and strain induced mixing in Cu– Co composites studied by transmission electron microscopy and atom probe tomography. Materials Characterization 100, p. 178–191, 2015.

BAMBERGER A.; MUNITZ A.; KAUFMSN L.; ABBASCHIAN R. Evaluation of the Stable and Metastable Cu-Co-Fe Phase Diagrams. Calphad 26(3), p. 375-384, 2002.

BANDA W.; GEORGALLI GA.; LANG C.; EKSTEEN JJ.; Liquidus temperature determination of the Fe-Co-Cu system in the Fe-rich corner by thermal analysis. Journal of Alloys and

Compounds 461, p. 178-182, 2008.

BARDOS DJ. Mean Magnetic Moments in bcc Fe-Co Alloys. Journal of Applied Physics 40, p. 1371-1372, 1969.

BEIN S.; COLINET C.; DURAND-CHARRE M. CVM calculation of the ternary system Co–Cu– Fe. Journal of Alloys and Compounds 313, p. 13-143, 2000.

BŁACHOWSKI A. Spin- and charge density perturbations and short-range order in Fe– Cu and Fe–Zn BCC alloys: A Mossbauer study. Journal of Physics and Chemistry of Solids 72, p. 1537– 1542, 2011.

CHIEN C L. Granular magnetic solids. Journal of Applied Physics 69, p. 5267-5272, 1991. https://doi.org/10.1063/1.348946

CHONG-DE C.; GÖRLER GP. Direct Measurement of the Metastable Liquid Miscibility Gap in Fe–Co–Cu Ternary Alloy System. Chinese Phys. Lett. 22(2), p. 482-484, 2005.

CURIOTTO S.; BATTEZZATI L.; JOHNSON E.; PRYDS N. Thermodynamics and mechanism of demixing in undercooled Cu-Co-Ni alloys. Acta Materialia 55, p. 6642-6650, 2007.

DI FABRIZIO E.; MAZZONE B.; PETRILLO C.; SACCHETTI F. Spin density of ordered FeCo: A failure of the local-spin-density approximation. Physical Review B 40(14), p. 9502-9507, 1989. ECKERT J.; HOLZER JC.; KRILL CE.; JOHNSON WL. Reversible grain size changes in ball-milled nanocrystalline Fe-Cu alloys. J. Mater. Res. 7(8), p. 1980-1983, 1992.

122

EGRY I.; HERLACH D.; KOLBE M.; RATKE L.; REUTZEL S.; PERRIN C.; CHATAIN D.Surface Tension, Phases Separation, and Solidification of Undercooled Cobalt-Copper Alloys. Advanced Engineering Materials 5(11), p. 819-823, 2003.

EGRY I.; RATKE L.; KOLBE M.; CHATAIN D.; CURIOTTO S.; BATTEZZATI L.; JOHNSON E.; PRY N. Interfacial properties of immiscible Co–Cu alloys. J Mater Science 45, p. 1979–1985, 2010.

GAY-SANZ N.; PRIETO C.; MUNÕZ-MARTÍN A.; DE ANDRÉS A.; VÁZQUEZ M.; SEONG-CHO YU. Time evolution of the structural short-range order during the mechanical milling of Fe–Co–Cu nanocrystalline alloys. Journal of Materials Research 14(10), p. 3882-3888, 1999. GENTE C.; OEHRING M.; BORMANN R. Formation of thermodynamically unstable solid solutions in the Cu-Co system by mechanical alloying. PHYSICAL REVIEW B 48 (18), p. 13244-13253, 1993.

HASEBE M.; NISHIZAWA T. Calculation Of Phase Diagrams Of The Iron-Copper And Cobalt-Copper Systems. CALPHAD 4(2), p. 83-100, 1980.

HE J.; ZHAO J. Microstructure Evolution in a Rapidly Solidified Cu85Fe15 Alloy Undercooled

into the Metastable Miscibility Gap. Materials Science & Technology 21(05), p. 759-762, 2005. HE J.; ZHAO JZ.; RATKE L. Solidification microstructure and dynamics of metastable phase transformation in undercooled liquid Cu-Fe alloys. Acta Materialia 54, p. 1749-1757, 2006. HE J.; ZHAO JZ.; WANG XF.; GAO LL. Microstructure Development in Finely Atomized Droplets of Copper-Iron Alloys. Metallurgical And Materials Transactions 36(A), p. 2449-2454, 2005.

HE J.; ZHAO JZ. Behavior of Fe-rich phase during rapid solidification of Cu-Fe hypoperitectic alloy. Materials Science and Engineering A 404(1-2), p. 85-90, 2005.

IDCZAK R.; KONIECZNY R.; CHOJCAN J. Hyperfine fields at 57Fe in dilute iron-based alloys determined by Mössbauer spectroscopy. Phys. Scr. 90, 2015, p. 045801.

IK KIM D.; ABBASCHIAN RJ. The metastable liquid miscibility gap in Cu-Co-Fe alloys. Journal of Phase Equilibria 21(1), p. 25-31, 2000.

KIMURA Y.; TAKAKl S. Phase Transformation Mechanism of Fe-Cu Alloys. ISIJ International 37(3), p. 290-295, 1997.

KULKOVA SE.; VALUJSKYA DV.; KIM JS, LEE G.; KOOB YM. The electronic properties of FeCo, Ni3Mn and Ni3Fe at the orderâ “disorder transition”. Physica B, 322, p. 236-247, 2002. LIU N.; LIU F.; YANG W.; CHEN Z.; YANG GC. Movement of minor phase in undercooled immiscible Fe–Co–Cu alloys. Journal of Alloys and Compounds 551, p. 323–326, 2013. LIU N.; YANG GC.; YANG W.; LIU F.; YANG CL.; ZHOU YH. Microstructure evolution of undercool ed Fe–Co–Cu alloys. Physica B 406, p. 957–962, 2011.

123

MUNITZ A.; BAMBERGER AM.; WANNAPARHUN S.; ABBASCHIAN R. Effects ofsupercooling and cooling rate on the microstructure of Cu-Co-Fe alloys. Journal of Materials Science 41, p. 2749-2759, 2006.

NAKAGAWA Y. Liquid immiscibility in copper-iron and copper-cobalt systems in the supercooled state. Acta Materialia 6(11), p. 704-711, 1958.

NISHIZAWA T.; ISHIDA K. The Co-Fe (Cobalt-Iron) System. Bulletin of Alloy Phase Diagrams 5(3), p. 250-259, 1984.

PADUANI C.; KRAUSE JC. Electronic structure and magnetization of Fe-Co alloys and multilayers. Journal of Applied Physics 86(1), p. 578-583, 1999.

PÉREZ CAS.; SANTOS AV DOS. Electronic Effect of V, Ti, and Sc Impurities on the Hyperfine Interactions of Fe Atoms in α-Fe: A First Principles Study. Materials Research-Ibero-american Journal of Materials, v. 20, p. 523-531, 2017.

PRIETO C.; DE BERNAB A.; GAY-SANZ N.; VÁZQUEZ M.; SEONG-CHO YU. Structural study of the mechanically alloyed Fe-Co-Cu nanocrystalline system. Journal of Non-Crystalline Solids 246, p. 169-176, 1999.

SUNDAR RS.; DEEVI SC. Soft magnetic FeCo alloys: alloy development, processing, and properties. International Materials Reviews 50(3), p. 157-192, 2005.

WADA N.; KUWADA K.; KIM JS.; TAKEGUCHI M.; TAKEDA M. Precipitation Behavior and Magnetic Properties of Cu-Fe-Co Alloys Containing Nanogranular Ferromagnetic-Element Particles. Advances in Condensed Matter Physics, p.1-7, 2015.

YAVARI A R.; DESRE PJ.; BENAMEUR T. Mechanically Driven Alloying of Immiscible Elements. Physical Review Letters 68(14), p. 2235-2240, 1992.

YOO YG.; YANG DS.; YU SC.; KIM WT.; LEE JM. Structural and magnetic properties of mechanically alloyed Co20Cu80 solid solution. Journal of Magnetism and Magnetic Materials 203, p.