BRICKS WITH TOTAL REPLACEMENT

OF CLAY BY FLY ASH MIXED WITH

DIFFERENT MATERIALS

J.N Akhtar1 J.Alam2 and M.N Akhtar3

1

Assistant Professor in Civil Engineering Section, University Polytechnic, Aligarh Muslim University Aligarh, 202002, India.

2

Associate Professor in Civil Engineering Department Aligarh Muslim University Aligarh, 202002, India

3

P.G Student Civil Engineering Department, Aligarh Muslim University. Aligarh, 202002, India. Abstract:

Fly ash is a powdery substance obtained from the dust collectors in the Thermal power plants that use coal as fuel. From the cement point of view the mineralogy of Fly ash is important as it contains 80% - 90% of glass. The impurities in coal-mostly clays, shale’s, limestone & dolomite; they cannot be burned so they turn up as ash. The Fly ash of class C category was used as a raw material to total replacement of clay for making Fly ash bricks. In present study the effect of Fly ash with high replacement of clay mixed with different materials were studied at a constant percentage of cement i.e 10%. Three Categories of bricks were to be studied namely Plain Fly ash brick (FAB), Treated Fly ash brick (TFAB) and Treated Fly ash stone dust brick (TFASDB).In all the above mentioned categories the quantity of Fly ash was kept constant as 80%. It is found that the compressive strength of plain Fly ash brick (15FAB) and Treated Fly ash brick (15TFAB) was found to be higher with 5% coarse sand and 15% sand combination at 10% cement. The gain in strength continues for Treated Fly ash Stone dust Brick (10TFASDB) and found to be higher with 10% stone dust and 10% sand combination. A variation in the quantity of Fly ash was also attempted and it was found that the 25TFASDB with 50% flyash, 25% stone dust and 25% sand combination at 10% cement achieved highest compressive strength.

Key words: Fly ash, Compressive strength, Lime

Corresponding Author: jannisar_akhtaramu@rediffmail.com

1. Introduction

Maureen T. etal[1]studied for the potential use of Fly ash as final cover over a landfill and as a soil stabilizing agent. From geotechnical tests, including permeability, strength and shrinkage were performed on mixture of ash with local quarry tailings for the land fill final cover. In conclusion the combination of Municipal Solid Waste (MSW) ash and lime, as a soil stabilizer, improved the workability of soil mixtures by drying effect and decrease of the plasticity index. The swell potential was reduced by increase of soil rigidity and water-resistance. The strength was increased by formation of cementations materials.

disposal and allocation of site for this solid waste, but also provide low cost, light-weight, self-hardening construction material for various application in port and harbour areas.

A.V.S.R. Murty etal [3] work was related to the construction of roads and embankments by using Fly ash. From their study they found out that, since the coal ashes usually vary from plant to plant, the proper characterization of ashes should be done to ascertain their suitability for road works. The bottom ashes and pond ashes after mixing with local soils could be used as sub base material. The soil-lime-Fly ash could be used as a base course materials provided the compacted layer is not subjected directly under the abrasive action of the traffic.

Kazuya Yasutiara [4] they carried out model tests of a coal based pulverized fuel ash (PFA) with a view to its use for land reclamation. The bearing capacity characteristics were investigated by plate loading and cone penetration tests on model reclaimed PFA. The conclusions from the result were:

An increase in bearing capacity of PFA is caused by both increased dry density and enhanced or added cementation.

In this respect, the slurry disposal method for PFA is best suited for producing stable reclaimed land.

Terzaghi’s classical theory of bearing capacity is sufficient for predicting the bearing capacity of PFA i.e. laboratory model tests under low confining pressures and with a small diameter of loaded area

Samiullah Khan et al [5]this study analyses effect of Fly ash on physico-chemical properties and Nutrient status of soil. The effect of varying levels of ash on pH, electrical conductivity and available major plant nutrients such as nitrogen, phosphorus and potassium was investigated in an alkaline fine sandy loam soil. The result show a decrease in soil pH and increase in electrical conductivity with the increasing does of Fly ash.

The Shrike Brick Industries [6] manufactures investigation for Fly ash bricks, blocks, for building construction as an eco friendly green environment product. The fly ash bricks are promoted as an alternative to burnt clay bricks with in the construction sector in India.

2. Experimental Set Up and Procedure

Materials Used

Present Fly ash used in the study was the portion of the ash collected through electrostatic precipitators of Dadri thermal power station, Dadri (U.P.), India. Locally available Lime was used to augment the cementitious properties of Fly ash. The physical properties of raw materials used in the study are given in Table 2, as the coal is supplied from different mines of Bihar the chemical properties also vary a great extent and the results of Chemical analysis of fly ash along with their range for different materials are given in Table 1. The finely ground Calcium Hydroxide, was used to augment the cementitious properties of the Fly ash. Its optimum amount with respect to Optimum Moisture Contents (OMC) and Maximum Dry Density (MDD) was determined in Table 3. It was done through Standard Proctor's Test.

3. Determination of OMC and MDD

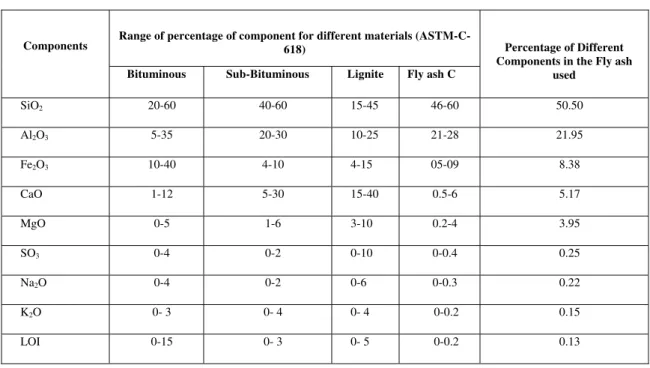

Table 1. Chemical analysis of fly ash along with the range for different materials

Components Range of percentage of component for different materials (ASTM-C-618) Percentage of Different Components in the Fly ash

used Bituminous Sub-Bituminous Lignite Fly ash C

SiO2 20-60 40-60 15-45 46-60 50.50

Al2O3 5-35 20-30 10-25 21-28 21.95

Fe2O3 10-40 4-10 4-15 05-09 8.38

CaO 1-12 5-30 15-40 0.5-6 5.17

MgO 0-5 1-6 3-10 0.2-4 3.95

SO3 0-4 0-2 0-10 0-0.4 0.25

Na2O 0-4 0-2 0-6 0-0.3 0.22

K2O 0- 3 0- 4 0- 4 0-0.2 0.15

Table 2.The physical properties of materials used in the study

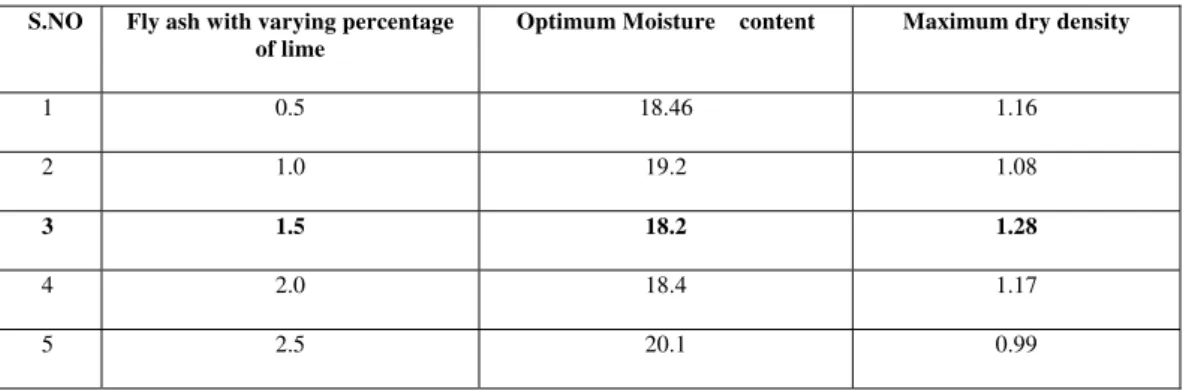

Table 3. Optimization of Lime with respect to OMC and MDD

S.NO Fly ash with varying percentage of lime

Optimum Moisture content Maximum dry density

1 0.5 18.46 1.16

2 1.0 19.2 1.08

3 1.5 18.2 1.28

4 2.0 18.4 1.17

5 2.5 20.1 0.99

Table 4. (a) Mix proportions of FAB

Designation

Cement (%age)

Mix Proportion

Stress (Kg/cm2) Plain Fly ash(%age) Coarse Sand (%age) Sand (%age)

SFCB - - - - 105.50

00FAB 10 80 20.0 00.0 34.15

05FAB 10 80 15.0 05.0 37.69

10FAB 10 80 10.0 10.0 44.09

15FAB 10 80 05.0 15.0 53.81

S. No. Materials Physical Properties Value

1. Plain Fly ash

Specific Gravity 1.86 at 28 0C

Optimum Moisture Content (Standard Proctor Test)

With 1.5% Lime 18.0%

Maximum Dry Density with 1.5% Lime 1.28g/cc

Coefficient of uniformity, Cu 2.0

Coefficient of Curvature, Cc 1.13

Cohesion 0.0

Angle of shear resistance 27o

2.

Cement

Initial Setting time Final setting time Normal consistency Compressive Strength (1:3 cement sand mortar) Tensile Strength (1:3 cement sand mortar)

32 min

389 min

28%

19.2 MPa (3 days) 28.5 MPa (7 days) 1.90 MPa (3 days) 2.45 MPa (7 days)

3. Coarse Sand

Specific Gravity

Water Absorption (30 min) Fineness Modulus Silt Content 2.62 0.39% 2.87 2.46% 4. Sand Specific Gravity

Water Absorption (30 min) Fineness Modulus Silt Content 2.60 0.42% 2.88 2.49%

5. Stone Dust

Specific Gravity

*FAB – Fly ash Brick *SFCB – Standard First Class Brick

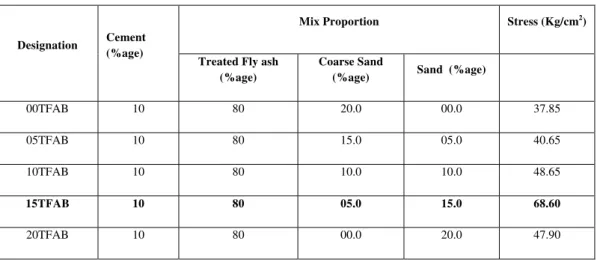

Table.4 (b) Mix proportions of TFAB

Designation Cement (%age)

Mix Proportion Stress (Kg/cm2)

Treated Fly ash (%age)

Coarse Sand

(%age) Sand (%age)

00TFAB 10 80 20.0 00.0 37.85

05TFAB 10 80 15.0 05.0 40.65

10TFAB 10 80 10.0 10.0 48.65

15TFAB 10 80 05.0 15.0 68.60

20TFAB 10 80 00.0 20.0 47.90

TFAB – Treated Fly ash Brick

Table 5. (a) Mix proportions of TFASDB

Designation Cement (%age)

Mix Proportion

Stress (Kg/cm2) Treated Fly ash

(%age)

Stone dust (%age)

Sand (%age)

00TFASDB 10 80 20.0 00.0 36.66

05 TFASDB 10 80 15.0 05.0 42.35

10 TFASDB 10 80 10.0 10.0 71.56

15 TFASDB 10 80 05.0 15.0 65.69

20 TFASDB 10 80 00.0 20.0 47.90

*TFASDB – Treated Fly ash stone dust Brick

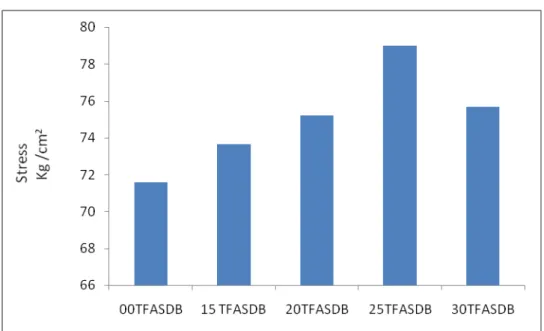

Table 5. (b) Mix proportions of TFASDB

Designation Cement (%age)

Mix Proportion

Stress

(Kg/cm2) Treated Fly ash

(%age)

Stone dust (%age)

Sand (%age)

10TFASDB 10 80 10.0 10.0 71.56

15 TFASDB 10 70 15.0 15.0 73.63

20 TFASDB 10 60 20.0 20.0 75.20

25 TFASDB 10 50 25.0 25.0 79.00

30 TFASDB 10 40 30.0 30.0 75.68

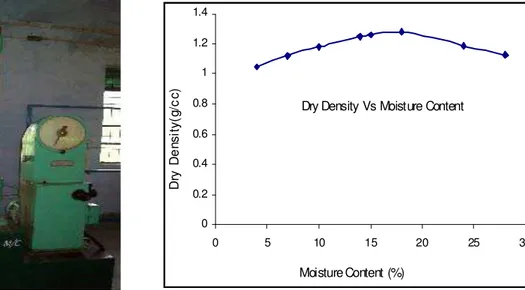

Dry Density Vs Moisture Content

0 0.2 0.4 0.6 0.8 1 1.2 1.4

0 5 10 15 20 25 30

Moisture Content (%)

Dr

y

De

n

s

it

y

(g

/c

c

)

Fig.1. Test under progress. Fig. 2. Dry Density vs. Moisture Content for Fly ash

Fig. 3. Particle size distribution curve

Fig. 5. Compressive strength variation of Treated Fly ash Bricks

Fig. 6. Compressive strength variation of Treated Fly ash stone dust Bricks

Results and Discussion

(1) Fig.3 shows the particle size distribution curve for the flyash used in the study. The values of uniformity coefficient and coefficient of curvature shall very with the type of coal used.

(2) A perusal of Fig.2 shows that at 1.5% addition of lime in the plain flyash gives the maximum dry density and minimum optimum moisture content. This happens because lime increases the cementatious property of flyash.

(3) Fig.4and Table 4(a) shows the variation of compressive strength of plain flyash bricks mixed with coarse sand (20-0%) and sand (0-20%) at constant percentage of cement (10%).Flyash percentage is kept constant as 80%.It is observed that a combination of 15% sand and 5% coarse sand, designated as 15FAB gives maximum compressive strength.

(4) Fig.5and Table 4(b) shows the variation of compressive strength of treated flyash bricks mixed with coarse sand (20-0%) and sand (0-20%) at constant percentage of cement (10%) Flyash percentage is kept constant as 80%.It is observed that a combination of 15% sand and 5% coarse sand, designated as 15TFAB gives maximum compressive strength.

(5) Fig.6and Table 5(a) shows the variation of compressive strength of treated flyash bricks mixed with stone dust (20-0%) and sand (0-20%) at constant percentage of cement (10%). Flyash percentage is kept constant as 80%.It is observed that a combination of 10% sand and 10% stone dust, designated as 10TFASDB gives maximum compressive strength.

(6) Fig.6and Table 5(b) shows the variation of compressive strength of treated flyash bricks mixed with stone dust (10-30%), sand (10-30%) and flyash (80-40%) at constant percentage of cement (10%).It is observed that a combination of 25% sand, 25% stone dust and 50% treated flyash designated as 25TFASDB gives maximum compressive strength.

(7) Flyash based brick designated as 25TFASDB gives maximum compressive strength as compared to10TFASDB, 15TFAB and15FAB.

4. Conclusions

(1) The addition of lime to the fly ash increases the cementitious properties of Fly ash and it was found that at 1.5% of lime, the OMC is minimum and dry density maximum.

(2) The compressive strength of Treated Fly Ash Brick (15TFAB) is more than Plain Fly Ash Brick (15FAB).

(3) The compressive strength of Treated Fly Ash Stone Dust Brick (10TFASDB) is more than 15FAB and 15TFAB.

(4) Treated Fly Ash Stone Dust Brick designated as (25TFASDB) achieved highest compressive strength (79Kg/cm2) with 25% stone dust, 25% sand and 50% treated flyash combination at 10 % cement as compared to15FAB, 15TFAB, 10TFASDB.

5. References

[1] Maureen., T. Lee., Ding, Mingxun and Nicholson, Peter G. (1996): “A study of use of H-Power ash mixtures as a land fill final cover and a soil stabilizing agent”, Environmental Geotechnics, Kaman, pp. 803-80 .

[2] Masaki Kitzume., Tomohiro Ikeda and Nobuyuki Yamane. (1996): “Failure pattern and earth pressure of cement treated flyash’

Environmental Geotechnics, Kamon (ed.) pp. 773-778.

[3] Murty, A.V.S.R., “Flyash in construction of Roads and, Embankments”, Central Road Research Institute India, (1996).

[4] Yasuharo., Kazuya. Horiuchi. Sumio., Hirao., Kazutoshi and Yasufuku., Nariyuki. (1996) “Bearing capacity of reclaimed coal flyash” Environmental Geotechnics, Kamon (ed.) pp. 951-956.

[5] Khan., Samiullah. Begum. Tahira and Singh, Jaibir. (1996): “Effect of flyash on physico-chemical properties and nutrient status of soil “Indian. J. Eviron HLTH. vol. 38 No.1 pp. 41-46.

[6] The Shrike Brick Industries (1990): manufacturers and suppliers of fly ash bricks, fly ash blocks under the reference of IS: 4139:1989 & 12894.

[7] I.S. 2720-VII Methods of Test for Soil Part VII Determination of Water content- Dry Density Relation using Light Compaction (Second Revision).

[8] I.S. 3812. (1983): Specification for Fly ash as pozallana and admixture (First Revision). [9] I.S. 8112- (1989): 43 Grade ordinary Portland cement specifications (First Revision).