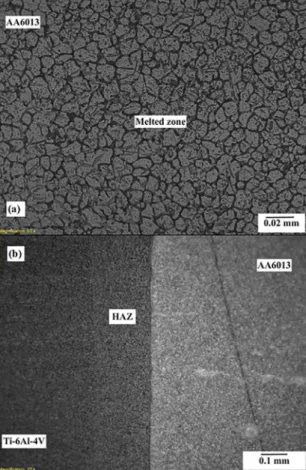

Influence of Si Coating on Interfacial Microstructure of Laser Joining of Titanium and Aluminium Alloys

Texto

Imagem

Documentos relacionados

The probability of attending school four our group of interest in this region increased by 6.5 percentage points after the expansion of the Bolsa Família program in 2007 and

As expected, the analysis of the drivers referred by respondents for the selection of their co-opetition partners matched in great extent those described in literature as fitting

between temperate and continental climatic zones and 1.4 t·ha -1 between continental and Mediterranean climatic zones. The results of DEA analysis of energy efficiency in

Remelted zone of the probes after treatment with current intensity of arc plasma – 100 A, lower bainite, retained austenite and secondary cementite.. Because the secondary

Para Estrela (2002, p.17) “o conceito de indisciplina relaciona-se intimamente com o de disciplina e tende normalmente a ser definido pela sua negação ou privação ou pela desordem

The results of the welding of wrought (6063) aluminium alloy with the above given chemical composition and welding conditions revealed that the control sample has the best

(a) Open circuit potential curve of the AA2524-T3 aluminium alloy in aerated 0.05 mol L -1 NaCl aqueous solution and (b) image of AA2524-T3 aluminium alloy by optical microscopy

The structure of the remelting zone of the steel C90 steel be- fore conventional tempering consitute cells, dendritic cells, sur- rounded with the cementite, inside of