Developments from CSIRO

TC-Y'T'TT '.

S

Serdang

Hospital in Kuala

Lumpur

Interview with MSSA President

Profile on SSSS President

Radar as nondestructive testing tool for concrete

Non-destructive Tests On Concrete

Cubelnfo

Controls equipment for Mapei

France lab

f"'f"' T{

E TECHNOLOGY

ConstructiVision

ConcreteKiosk

Termacol

Recycled aggregates for precast concrete

INCORPORATING

STRUCTURAL

STEEL

JUL-SEP 2002 FREE COpy FOR QUALIFIED READERS

Cone rcrc cornpressivc "trength of

vi andnrd samples curing under vtnndard conditions are of urmovr importance for quality control of concrete as It ISproduced, Ilow ever, those values can only be at veptcd as mdrcarmg the 'porcnnal "rength' of concrete and rnav <lIt" kr from the acrual1S1siru concrete

cornprcwrve vrrcngrh.

I he knowledge, a, close a,

1)()'~Jblc.

of

the ,"-~I(Uconcretecornpressrvc vtrcngth

i,

.

In somexuuanonv, necessary in order [0 evrrmure, for instance, the time when precast concrete rucmberv can be moved andtransported, rhe lime of prestressing, removal of mould, or propping. etc,

14

~UL-SEPT 2002

b

y

Migu

e

l

C.

S.

Nepomuceno,

Lecturer,

U

niv

e

r

s

it

y o

[B

e

irn Im

e

r

i

or

,

Portugal and

se

rgi

o

M. R.

L

o

p

es

,

Ass

i

S

IlIIJl

P

ro

f

esso

r

,

U

tliv

e

r

s

it

yo{Coi

mbra

,

P

or

w

g

al

concrete

tests on

Non-destructive

'EVENTS'CONCRETE: F"EATURE'CONCRE:TE EQUIPMENT'CONCRETE APPLICATIONS'

.JUL-SEPT 2002

1 5

This fact isa direct consequence of thehigh number

of practical factors that can affect therebound of the incident mass,due tothe difficulty of takinginto

ac-count the correct influence of such factors or to re

-produce similar condirions as those using onc alibra-rion test.

Someprofessionals have pointed out that even in

situations wheretheseconditions are weUreproduced in-situ and specifically developed correlations are used,the 95 percent confidence limits on theestima

-tion ofcompressive strength deviate

2

5

percent from the mean value [4,6].Under ideal laboratory condi-Lionsit is probable that this difference would be re -duced to 15 percent [4.6J.

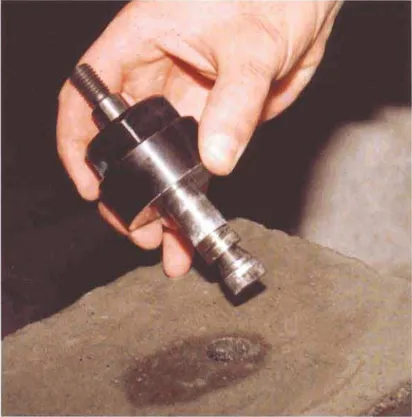

Figure 2-Loading

Schmidt Rebound Hammer.

Figure 1 - SchmidtRebound Hammertype N.

Surface Hardness Test

This type ofresring hasbeing applied[0concretesinee

the 30'Sand from the earlyattempts different meth -odsand techniques havebeen proposed. The method proposed by the Swiss engineering Ernst Schmidt in the 40'Sisbased on the rebound of an incident mass

has been recognised asthemost reliable and it isstill used nowadays (3,6).

The Schmidt hammer hasbeen used with success

to evaluate the surface hardness, withspecial evidence

forsuch apparatus type

N

,

with an impact energy of2..207N.m <FigureIand Figure 2). Its use iscovered by various national standards suchasthe Recommen

-dations from BritishStandards BS:1881:Part202{4) The surface hardness res

i

s

easytooperate, onlyrequires afree surface,is cheap,and causesLessdam -age than the majorityof the other non destructive tests. However its use to estimate directlythe in-situ

compressive strength using general established cor

-relations isnot recommended by manyauthors [6}.

Non-destructive tests(NUT) have been increas

-ingly usedin the last few decades for the assessment of in-situ quality anti integrity of concrete elements,

especially for estimation of in-situ concrete compressive strength. National standards are avail

-able in a number of countries, notably in the UK and USA,detailing procedures for the most firmly estab-lished testing methods. It is important to mention that procedures from different national standards presentsmalldifferences.

Non-destructive tests present some significant advantages such as speediness of operation, immedi

-ate availabili ty of results.less costs and,above all,less damage forconcrete elements under test. The NDT methods arcspeciallydesigned for estirnarion of the

in-situ concrete compressive strength and donot al-Iowa direct quanrirarivc measurement ofsuch prop-erty. Therefore, it would be necessary to develop and

useempiricalcorrelations.Such correlations introduce

uncertainties on the results,which represent the maio disadvantage of these testswhencompared tothose

methods basedon drilledcores.10spiteofthat,when based on fum correlations, the accuracy of such esti-mations improves significantlyand itcould overcome

such drawbacks [3].

Tbe NDT techniques actually availablevarysig

-nificantly in terms of accuracy;degree of destruction

causedtoconcreteelements, speed of test,immediacy

of results and costs involved. Those methods have been traditionally usedon normalstrengthconcrete.

Although, since highstrength concrete isbeing

in-creasingly used all over the world. many research works havebeen developed during rhe lase tenyears to rest the applicability of such methods to high

strength concrete.

Tbe use of NDT methods on normal and high

strength concrete clements willbequalitatively dis-cussed on this paper, taking as reference fivediffe r-em test methods, which imply the measurement of other fivedifferent properties. Such properties in

-dude the measurement of the surface hardness, ul-tra-sonic pulsevelocity, penetration resistance,

pull-out force and direct tensile strength (pull-off test).

-EVENTS-CONCRETE FEATURE-CONCRETE EQUIPMENT-CONCRETE APPLICATIONS

-Figure4-Windsor ProbeTest

System.

Ultra

-

sonic Pulse Ve

l

ocity

Test

The ultra-sonic pulse velocity test iswellstudied and its use isgener

-alised worldwide. This method docs not cause any damages on

concrete surfaceand it is believed tobe oneof themethods that can be used to evaluarc the interior mass of concrete elements(6}.One of themost generalised equipment used onconcrete is the Portable Ultra-sonic Non-destructive Dig

-rralIndicating Tester

(p

UND

T

n

Withelectro-acoustical transducersof natural frequency of 54 k Hz (Figure 3)[3). Recommendations

forItsusc can befound, forexam

-ple, on British Standards Institu

-tion BS:1881:Part203 [2]

The factors which affect the test results have been studied for many yearsand,insomecases, cor

-recrion factorswere developed to

take into account, for example, the

presence of reinforcement bars.

The ultra-sonic pulse velocityde

-pends on themodulusofelasticity of the material which isrelated [0

The experiencehassbown that the surface hardness test can be veryuseful insituations in which

correlations arc not needed, for

example,tomonitor large surfaces

for comparative analysisand locali -sation of crrtical zones, where other more reliable tests can be

applied, which unfortunately causes more surface damage and arcmore expensive.

Penetration

R

esistance Test

Penetration resistance tests havebeen used for many years mainly supported by the Wmdsor Probe

Test System (WPTS) and its usc has been more generalised in North America [6]. USAStand

-ards ASTM C803-90 [I] or BS:1881:Parr207[5) havebeen used as reference. For normal strength ·EVENTS·CONCRETE FEATURE·CONCRETE EQUIPMENT·CONCRETE APPLICATIONS'

16

concrete compressive strength.

Despite all [he recognised practi

-caladvantages. the CPV test has some of the problems referred to

rbe penetration resistance test, i.

e.,this rcsr doe ..notgivea direct reading of the concrete compressive strength, andthe cor

-relation..are affected bya large

number of factors. There exist

some correction factors,but prac

-rice hasdemonstrated that it in

-troduces largeuncertainties on the result, with consequences on the accuracy of rhc estimation value.

It has been pointed out that, even usingcorrelauons specifically

developed fora givenconcrete un

-der good in-situ conditions, it is

unlikelythat the 95 percent confi

-dence limits for the estimation of the compressive strength arebet

-ter than 20 percent of the mean

value[2,6]. Usinggeneral correla

-tion curves. thi' difference could

ariseto 50percent [2,6]. Using spe

-cific correlation curves developed in the laborarory such 95percent

confidence hmirs could dcviarc 10

percent from the estimated mean

value (2.6).

Correlation between

compressive strength and pulse

velocity has shown exponential behaviour [2,6,12],which leadsto theloss ofsensibilityof thelest for highstrength concrete, I.c.,a lit

-tleincrease on pulsevelocitycor

-responds to a great increase on

compressive strength. For this rea -son the applicability LO high

Figure 3-Ultra-sonicPulse VelocityTest Equipment.

·NEWS·COVER STORY·STEEL FEATURE·CONCRETE MATERIALS·STEEL APPLICATIONS·

strength concrete needs tobe fur-ther investigated. A first attempt wasmade bythe authors [12]and the obtained correlation curves

have shown aconsiderable varia

-tion on estimation of concrete compressivestrength when dealing

with concrete elements of

compressive strength of morethan

70 MFa. Probably, it is a natural

consequence of exponential corr

e-lation which increases consider

-ably at this level of strength.

As for surface hardness test,

unlessaspecific calibration curve can be obtained, it

is

virtually im-possible to predict the absolute

strength of a massof in-situ con -crete by pulse velocity measure

-ments [2,6,u]. However, this test isuseful forcomparative and uni -formiryassessments.

.JUL-SEPT 2002

..JUL-SEPT 2DD2 Figure 6•Removing the drilled core In Its full 65 mmlength.

17

Figure 5 -Drilling a 18mm centre hole with a

drill unit.

Pull

-

Out Test

Pull-out Test isrecognised. among

themain non-destructive tests. as

that which offers moreaccuracy on the estimntion of the in-situ con

-crete compressive strength [),6].

Recommendations for its useare

provided byBritish Standards BS

188[:Part 207 (5l

Onc of thetechniques used for this purpose isthe CAPO.:rEST System developed by 'Germann IJ1

-struments

AlS'

(Figures 5torr),TheLoadisapplied tothe capo-insert by

means of an hydraulic jack and a

reaction ring of 55mm inner diam -eter.The capo-insert (2.5mm diam

ererring)isplaced atadepth of15 rom.

In the last few decades, inde

-pendent analytical and experimen

-talstudies havebeen developed to understand how failuremechanism

worksduring thepull-out tests. A

consensus has been achieved re

-garding the existence of atriaxial state ofstress highlynon uniform on the concrete involved thecapo

-insert during extraction [6,7]. In spite ofsome divergence as far as

tribute toa more extensive appli -cation of thismethod.

testcan produceon the surfaceand the highcostof ammunitions and probes are the reasons why this

method has not been extensively

used [9,10,11).For this reasonit is

unlikely that penetration resist

-ancereplaces thesurface hardness

or the ulna-sonic pulse velocity

tests for comparative analysis of

concrete.

The traditional WPT system has shown to be limited to con -crete compressive strength ofless than 40 MPa (on cylinders)

[5,9,IO,lT].However, the authors

have confirmed that the measure

-ment ofpenetration resistance can be extended to concrete

compressive strength of atleast85

MPa (on cubes of 150 mm side)

using anewtechnique supported by anewequipment named 'Alter -native FiringApparatus' [9.10,11].

Thisnew techniquehasalso shown

tobe adequate for normalstrength

concrete offering the advantages of reducing the damages incom

-parison to the rraditional WPT

system [o.ro.n]. It isalso impor

-tant to note that the application

costs of this new equipment is

lower compared tothe traditional \VPT system. This (act may con -concrete the WPT system isused

with silver coloured probes of hardened steel alloy With6.35mm diameter. 79.;mm length. blunt

conical endwith a plastic guideand the standard power (Figure4).

The

WPT

Systemcauses somedamages on the concrete surface

and. in some circumstances its

reparation can be necessary. On

the other hand its application is

limitedbyrestrictions of minimum

edge distances (to prevent split

-ting) and minimum distance be

-tween rwo probes (to avoid over

-lapping ofzones ofinfluence).This maylimitthe use ofthetechnique

In some situations. Usually this

method isrecommended for cl

e-ments of large surfaces likeslabs orclements oflarge cross sections [3]·

The penetration resistance tests can be used in the situations

mentioned above for comparative analysis of similar concrete el

e-ments, showing asan advantage, comparatively to the surfacehard

-ness and ultra-sonic pulse velocity tests.moreaccuracy onestimation

of the concrete compressive strength (3].

However,the damages that this

'EVENTS'CONCRETE F'EATURE'CONCRETE EQUIPMENT'CONCRETE APPLICATIONS' 'NEWS'COVER STORY'STEEL F'EATURE'CONCRETE MATERIALS'STEEL APPLICATIONS'

The Lok-tesr and Capo-test were developed in Denmark and have the same rest geometry and are a reference test inEurope.

Both tests havean apexangle

of 61"and measure the forcewith which a 15 mm diameter disc

placedat 15 mm depth is extracted fromconcrete bymeans of an hy

-draulic jack reacting over bearing

ring of 55 mm interior diameter.

placed onconcrete surface.

The pull-out

r

es

t

probes can beintroduced in freshconcrete apply

-ing the lok-tcst system, whichre

-quires the previous test planning.

The capo-test system can bealter

-natively usedinhardenedconcrete at any time, through the opening

and wideness of an inside hole,

where anexpansive ring wirh me same diameter at the same depth as the lok-rest systemisplaced

The capo-testsystem produces

some surface damageson concrete elements and, in some circum

-stances, its reparation may be

needed. The lok-rest system may

be optionallyapplied with or wrrh

-out fullextraction of the insert.

The second option does nor ere

-ate visible surface damages. The

1 B

methods. Examples of which are

the excellentcorrelation curves for thecompressive concrete strength

versus thepull-out force; the facr that the number of factors that affect the results arc considerably

reduced compared to other non destructive tests;thepossibilityof the correlation curves to be gen

-eralised to natural aggregate classes;the costand theprocedure

of this methods, which is cheap and relativelyquick to operate;and finally,(he fact that the resultsarc

immediately available. Its applica

-bility has been mainly recom

-mended insituations where a high accuracy of resultsisneeded[5,6,7).

Using specifically developed

correlations (0 the studied con -crete, the 95 percent confidence Lirnirs of in-situ compressive strength estimation in a location could be anticipated in the [0per

-cent deviation interval from the mean value,obtained through the

4valid readings of pull-our test [5,6). Usinggeneral correlations, such as those suggested byLok

-testandCapo-test manufacturers,

that interval would probably be

widened to20percent [5,6}.

Figure 8-The expansion unit is inserted In the hole and the capo

-Insert is fully expanded to 25 mm diameter.

.JUL-SEPT 2002

thebasicfailure mechanism is

con-cerned, a consensus exists regard

-ingthe factthat the last pull-our load is influenced by the same properties that influence the con -crete compressive strength [6,7].

.Manyfactorshave contributed

to the dissemination and to the generalised use of pull-out test

Figure 9 - Coupling and the 55 mm inner diameter

counterpressure.

Figure 7- Using the diamond recess router to open an

Inside hole at25mm depth.

-EVENTS-CONCRETE FEATURE-CONCRETE EQUIPMENT'CONCRETE APPLICATIONS'

19 .JUL-SEPT 2002 Figure 11 - Failure type Is observed for validation of resulL

minimum distances usuallyrequired for locations are lim-iting forsmallelements asfor penetration resistance tests.

Figure 10-Loading the instrument by turning the loading handle.

Pull

-

Off Test

The pull-off tests enable the dcrerminarion of direct ten

-sile strength in-situ (Figures 11 and 13).The possibility of using this method with partial coring enables the meas

-urement of such property ar different depths. For this rest method, recommendations arc available on British Stand

-ards BS1881:Parr 207[5]. Figures

I;

and 16 show a tech-nique developed by' Germann Instruments AIS' to s up-port

rhr

s

method andcalledBOND

-

TEST System.Thissystem Includes aportable handoperated hydraulicjack,

acircularsteel rusk with75mm diameter and

30

mm thick-nessand the equipment for preparation of surfaces and partial coring ofconcrete.

The possibihry ofesrabhshing, for a given test equip-ment and a givenconcrete. acorrelation between the

pull-off test and the compressive strength has shown to be useful forestimation of the In-)I(Uconcrete compressive

strength [5,6).Inspite ofother practical factors that can affect rhe results, one fact that should nor be forgorren is

thar pull-off test resultson thesurface differ (rom those usingpartial conng and that the depth of partial coring

should be also taken into account (5.6].

A research workcarriedour bytheauthors hasshown that the applicability of pull-out rem, using the Bond

-restsystem,islirmrcd toconcreteclements ofcompressive

strength of no more then 45MPa (oncubes of')0mm

side) [to). It was also found OUt that rhe usc of partial

coring causesconsiderable surface damages and needs a

considerabletime to operate. Ilowever,partialcoring ena

-bles the evaluationofconcrete strength at deeper layers Figure 12-Loading the Instrument

'EVENTS'CONCRETE FEATURE'CONCRETE EQUIPMENT' CONCRETE APPLICATIONS'

20

.JUL-SEPT 2002

[I]ASTM C80)-90 - Standard Test Method for Penetration Resistance ofHardened Concrete, Philadelphia, AmericanSociety for Testing and Materials, 1990.

[21British Standard BS1881:Part203: 1986-Testing Concrete: Recommendations for Measurement of Velocity of Ultrasonic Pulses inConcrete, London, British Standard Institution.

(3) British Standard BS1881:Part 201:1986-Tesnng Concrete: Guide to the Use ofNon-dcscructive Methods of Test forI Iardened Concrete. London, BritishStandards Institution.

[41

B

ritish

StandardB

S

1881:P

art

202:1986-Testing Concrete: Rccommendations for SurfaceHardnessTesting byRebound Hammer, London, Brirish Standards Institution.

(5)

British StandardBS

J881:P

art

207:1992-Testing Concrete. Recommendations for the Assessment of Concrete Strength by Ncar-to-surface Tests. London, BritishStandards institution. [61 BUNGEY,J. H.iMILLARD, S. G. -Testing of Concrete in Structures. 3.' ed., London, Chapman&llall, 1996.

[7] CARINO,). Nicholas -Pullout Test, to«Handbook onNon- destructive Testing of Concrete»,

Florida (EUA). CRC Press Inc., I991,p.39-82.

[8] KRENCHEL. H.;PETERSEN. C. G.-ln-situ Pullout Testingwith Lok-rest,Ten

Years'

Experience .•International Conference onInsirulNon-destructive Testing of Concrete», Ottawa, 2-5 OC<.I984·

[9) LOPES, sergio; NEPOMUCENO, Miguel-A Comparative Study of Penetration Resistance Apparatus onConcrete, in«Proceedings ofrCCE/4'). Hawaii,David Hui Edition, Jut 1997, p.

6J5-616.

[LO]LOPES, Sergio, NEPOMUCENO, Miguel-Evaluation ofIn-place Concrete Strength by Near

-to-surface Tests. «rath European Ready MixedConcrete Congress»,Lisbon, APEB.June 1998, p.338-347·

en] LOPES, Sergio; NEPOMUCENO, Miguel- High Strength Concrete: Penetration Resistance Tests on HighStrength Concrete, in"First International Conference on High Strength Concrete.july 13-18,1997",ASCE, USA, 1999,ISBN 0-7844-0419- 4,p. 42,-433.

[12J LOPES, Sergio; NEPOMUCENO, Miguel- Non-Destructive Tests on NormalandI ligh Strength Concrete, in"Proceedings of 26thConference on Our World inConcrete & Structures, August

27-28, 2001,volume XX (20Ot)~, Singapore, ISBN 981-04-25'3-9. p. 53-67'

and probably, asaconsequence of that, the obtained correlation curves for normal strength con -crete couldshowagoodagreement between pull-off force and con -crete compressive strength.

For tests performed under

Figure13-Failuretypeis observed forvalidation of result.

About

th

e

au

t

h

o

r

s

MiguelCostaSantosNepomuceno isa Lecturer at the University of Beira Interior, Portugal .He hasa First Degree inCivil Engineering from the University of BeiraInt e-rior.1994;MSc. Concrete Mat eri-als, University of Beira Interior, 1999;Ph.DSrudenr; I Ieis aMem -berof the Portuguese Association of Engineers since T992.Jlis area of specialisation is in Concrete Materials.

Sergto Manuel Rodrigues Lopes is an Assistant Professor,

University of Coimbra, Portugal.

IIehas afirst Degree inCivil En -laboratory conditions and using 6 valid readings ineach location, the BritishStandards BS1881:

P

an

107 [51 points our that the 95percent confidence limits for the estim a-tion of compressive strength the values couldvary (15percent from the meanvalue).gineering from the University of Coirnbra, IC)84;MSe InStructural

Engineering, Technical University of Lisbon, 1988;Ph.D from the Universityof Leeds, England, U.K., 1991. He is Senior Member of the Portuguese Association of Engi

-neers, 1992,was Nominated for Ferry BorgesPrize as one ofbest papers in International Journals, 1999.His area ofspecialisation is

inStructural Concrete. He isa Member of FIP Commission 10 Management, maintenance, and strengthening of concrete struc

-tures;Mem bel'0f Porruguese Mir

-rorgroups for thenorrnalizarionof both European Structural Con -crete Code, Eurocodc 2,andof Eu- .

ropcan Concrete Standard, ENV206; and Individual member of ACI, Portuguese Structural Concrete Group (Portuguese Charter of fib) and Portuguese Group of Structural Engineering <portuguese Charter oflABSE). 'EVENTS'CONCRETE FEATURE-CONCRETE EQUIPMENT-CONCRETE APPLICATIONS' -NEWS-COVER STORY-STEEL FEATURE'CONCRETE MATERIALS'STEEL APPLICATIONS'