Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

Effects of the addition of red berries flavor in barley malt production of the

Pilsen type

Efeitos da adição de aroma de frutas vermelhas na produção de malte de

cevada do tipo Pilsen

DOI:10.34117/bjdv6n8-198

Recebimento dos originais:08/07/2020 Aceitação para publicação:14/08/2020

Rodolfo Heitor Vargas Rebelo

Master in Chemical Engineering/ Doemens Brewmaster/ Doemens Beersommelier Malteria Blumenau, Special Malts, 4680 Gustavo Zimmermann Street, 89063 000 Blumenau,

Brazil

rodolfo@malteriablumenau.com.br

Lisiane Fernandes de Carvalho

PhD in Engineering and Food Science

University of Blumenau, Department of Chemical Engineering, 3250 São Paulo Street, 89030-000 Blumenau, Brazil

lfcarvalho@furb.br

Carolina Krebs de Souza

PhD in Chemistry and Toxicology of Foods

University of Blumenau, Department of Chemical Engineering, 3250 São Paulo Street, 89030-000 Blumenau, Brazil

carolinakrebs@furb.br

ABSTRACT

The consumption of beers produced with different raw materials is rising, because different flavors can be obtained. The emerging of new beer products is motivating researches in the area. For this reason, this study objective is to produce flavored barley malt by adding a flavored solution of red berries during malting production. For this purpose, barley of the Pilsen type was submitted to the malting process with the presence of a red berries flavored solution, where three different flavor concentrations (1.5, 3.0 and 4.5 mL kg-1) and kilning temperatures (75, 80 and 85 °C) were evaluated concerning the flavor retention. In order to quantify the flavor present in barley malt at each stage of malting production, chromatographic analyzes were performed. Results showed that of the 20 flavor components present in the flavor solution, 4 were found at the end of the flavored malt production. Flavors of grapes, apricot, melon and red wine remained in the barley malt produced with 4.5 mL kg-1 of red berries solution and kilned at 75 °C due to the 4 flavor compounds present. The production of flavored malt provides novel ingredients for breweries and contribute to the production and development of different flavored beers.

Keywords: red berries flavor, flavor concentration, flavored barley malt, kilning drying

temperature, malting process.

RESUMO

O consumo de cervejas produzidas com diferentes matérias-primas está aumentando, pois promove a obtenção de diferentes sabores. O surgimento de novas cerveja está motivando pesquisas na área.

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

Por esse motivo, o objetivo deste estudo é produzir malte de cevada aromatizado, adicionando uma solução aromatizada de frutas vermelhas durante a produção do malte. Para isso, a cevada do tipo Pilsen foi submetida ao processo de maltagem com a presença de uma solução aromatizada de frutas vermelhas, onde três concentrações diferentes de aromas (1,5, 3,0 e 4,5 mL kg-1) e temperaturas de

moagem (75, 80 e 85 °C) foram avaliados quanto à retenção de aroma. Para quantificar o aroma presente no malte de cevada em cada estágio da produção, foram realizadas análises cromatográficas. Os resultados mostraram que dos 20 componentes aromatizantes presentes na solução inicial, 4 foram encontrados no final da produção de malte aromatizado. Os aromas de uvas, damasco, melão e vinho tinto permaneceram no malte de cevada produzido com 4,5 mL kg-1 de solução de frutas vermelhas e seco a 75 °C devido aos 4 compostos aromatizantes presentes. A produção de malte aromatizado fornece novos ingredientes para as cervejarias e contribui para a produção e o desenvolvimento de diferentes cervejas aromatizadas.

Keywords: aroma de frutas vermelhas, concentração de aromas, malte de cevada aromatizado,

temperatura de secagem, malteação.

1 INTRODUCTION

Beer is a beverage rich in useful compounds for human health (vitamins, polyphenols, minerals, fiber, as well as antioxidants) (Bamforth, 2002). In beer production, barley grain (Hordeum vulgare L.) is mainly used as a source of starch. According to Beleti, Duarte and Georg-Kraemer (Beleti; Duarte; Georg-Georg-Kraemer, 2012), the barley grain is the 5th most used cereal in the world. However, for socio-economic reasons, other sources of starch are also applied in beer production, such as rice, corn, sorghum, oats and wheat. The barley grain is widely used in breweries, mainly because it has a good starch-protein ratio, which provides better technical characteristics in sensory and physico-chemical properties of beer.

The use of barley grains in beer production follows the German purity law (Reinheitsgebot), which is legally applied in Germany, Norway and Sweden (Oser, 2015). The law was decreed on the 23rd of April, 1516 in Bavaria by Duke William 4th of Bavaria; and aimed to reduce toxic

ingredients in beer and to protect the cultivation of some specific grains for beer and baking (Kunze, 2011).

For use in beer production, barley undergoes a malting process. This process is summarized in the following stages: steeping, germination, kilning, deculming and storage until use. The steeping consists of increasing the moisture content of the barley grains to favor germination. During germination, occurs the enzyme formation and activation and the endosperm modification. The subsequent stage, the kilning process, reduces the moisture content from grains and provides stabilization of enzymatic activity, which grants flavor and color to malt. The deculming is applied to remove culms from grains; and finally, the malt is stored until use in beer production (Montanuci et al., 2014; Pinto, 2013; Kleinwächter; Meyer; Selmar, 2011).

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

Barley malt has a direct influence on the production of different styles of beers; and is responsible for the color change, amount of fermentable sugars, as well as sensory characteristics in beer (Fix, 1999; Oser, 2015). The type of malt influences the aroma and flavor of the beer. The addition of flavorings in the malting process, also enhance the flavor and aroma properties and enables the production of different flavored types of beer (Oliveira; Faber; Plata-Oviedo, 2015; Tozetto, 2017).

With the increasing consumption of flavored beers and the constant evolution in this market segment, the objective of this study was to provide an alternative to obtain flavored barley malt for flavored beer production. For this purpose, barley of the Pilsen type was submitted to the malting process with the presence of a red berries flavored solution. Also, tests were performed during malt production to quantify and identify flavoring components after each stage of the malting process.

2 MATERIALS AND METHODS

2.1 MATERIALS

Barley grain used in this study was the BRS Cauê from the 2015 harvest, registered by EMBRAPA (Brazilian Agricultural Research Corporation), and provided by Malteria Blumenau, from Santa Catarina state, in Brazil. The flavoring solution was gently donated by Duas Rodas Industrial Ltda, located in Santa Catarina state, in Brazil. The flavoring was prepared with 20 chemical components that characterize red berries flavor, and propylene glycol was applied as the flavor carrier.

2.2 DESIGN OF EXPERIMENTS (DOE)

The concentration of red berries flavoring and kilning temperature applied in malt production were studied in three different conditions. For this end, both variables were evaluated according to the full factorial design 32, present in table 1. The design of experiments resulted in 11 treatments, with triplicate in the central point.

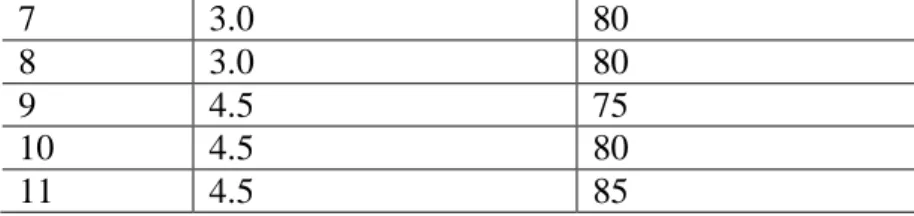

Table 1. Flavoring concentrations and kilning temperatures applied in the production of flavored malt.

Tests Flavoring concentration (mL kg-1) Kilning temperature (°C) 1 1.5 75 2 1.5 80 3 1.5 85 4 3.0 75 5 3.0 80 6 3.0 85

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761 7 3.0 80 8 3.0 80 9 4.5 75 10 4.5 80 11 4.5 85

The definition of the concentration of red berries flavoring was based on the recommended dosage for the use in candy/drops/lollipops industry, which is 300 mL of flavor solution for 100 kg of the food product, according to the Duas Rodas Industrial Ltda. This flavor concentration was considered in this study because barley grains can lose flavor molecules during the malting process, once it is a volatile product. Other two concentrations values of flavor solutions were also evaluated. While, the kilning temperature was selected based on malt production of the Pilsen type. This process consists of the use of lower temperatures during the kilning stage. According to Briggs (1998) and Kunze (2011), the kilning stage of the malting production of the Pilsen operates at 80 °C. Considering this, the temperature of 80 °C was set as a central point in this study, and a range of ± 5 °C from the central point was evaluated.

2.3 FLAVORED MALT PRODUCTION

The flavored malt production was performed according to the standardized malting process based on barley malt of the Pilsen type (Kunze, 2011). The malting process was carried out according to the following stages: steeping with the addition of the flavoring solution, germination, kilning, deculming and storage. Figure 1 presents the stages of flavored malt production.

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

2.3.1 Steeping process

Initially, 3 kg of barley grains were submerged in 5 L of water in a steeping vessel. Then, the bathwater was drained to wash the grains. New bathwater (5 L) was provided in addition to the flavored solution. This steeping process was maintained for 140 min with aeration every 15 min. The aeration was supplied by a compressor connected to a flexible duct made of silicone. The duct was placed inside of the steeping vessel and operated with an airflow rate of 0.005 m3.min-1. A second bath was prepared with a hydration period of 90 min and aeration every 15 min. After every hydration process, barley grains were placed in a dry location, for 320 min, with aeration every 45 min to remove CO2. Subsequently, baths were prepared according to the last one, until barley grains

moisture content reaches 43%, where moisture content in barley grains was evaluated during the steeping process using a portable moisture analyzer (AL-101, Agrologic). The steeping process operated with constant temperature (20 °C), using a thermostatic bath.

2.3.2 Gemination process

The germination process was conducted with periodical humidification with flavored water (every 12 h) and under controlled temperature (19 °C ± 1°C), for 3.5 days. During germination, grains were turned over in regular intervals (12 h) to ensure its growth, properly aeration and avoid the lack of oxygen (important extrinsic factor in germination of barley grains). The germination rate measurement was performed by quantifying the percentage of barley grains that germinated in a sample of 200 g.

2.3.3 Kilning process

The kilning process was carried out in a forced convection oven (320E model, FANEM®), operating according to the following temperature steps: the grains were initially kept at 50 °C in the first 2 hours; then, the temperature was raised in steps of 5 °C, each step was maintained for 2 hours in the new temperature until 70 °C was reached. After that, grains were submitted to the last step of temperature increased, where the temperature was set according to table 1 (75, 80 and 85 °C) and maintained for 2 hours.

2.3.4 Deculming process

After the kilning process is completed, culms are removed from grains during the deculming process. This process consists in to sieve the grains with coarse mesh (1.8 mm).

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

2.3.5 Storage conditions

At the end of each stage of the production of the flavored malt, samples were collected, packaged in a plastic bag and stored under freezing conditions (-6 °C) for further analysis in the laboratory. In a total, 33 samples were collected, which corresponds to samples after steeping and germination process (22 samples) and after the drying process at different temperatures (11 samples).

2.4 ANALYSIS OF SOLID PHASE MICROEXTRACTION (SPME) AND GAS CHROMATOGRAPHY

The analytical technique applied to extract the volatile compounds of the malt samples was the solid phase microextraction (SPME). Briefly, 3 grams of the crushed sample was placed in contact with a silica fiber coated with an extracting phase (divinylbenzene/carboxen/polydimethylsiloxane). The fiber, previously conditioned at 300 °C for 45 minutes, was injected in contact with the sample, at 80 °C for 15 minutes, to adsorb the analytes. The analyte in the sample is directly extracted onto the fiber coating. SPME technique is based on the partition equilibrium of the analytes between the sample and the extraction phase. Once equilibrium is reached, the quantity of analyte extracted by the fiber is proportional to its concentration in the sample.

Subsequently, the SPME fiber was inserted into the heat injection port of the gas chromatograph (GC) to quantify the analytes present in the sample. For this analysis, a GC (7890A model, Agilent) was applied coupled to a quadrupole mass spectrometer (5975C model, Agilent). The oven temperature was maintained initially at 50 °C for 2 minutes and, afterwards, increased to 240 °C at a rate of 4 °C min-1. The column used in the analysis was the VF-WAXms (polyethylene glycol, 30 m x 0.25 mm x 0.25 µm) from Agilent, with polar characteristics. The column flow was set constant at 2.5 mL s-1. The sample injector used was the multimode inlet (MMI), which operates at a temperature of 230 °C.

2.5 STATISTICAL ANALYSIS

The experimental data were analyzed by analysis of variance (ANOVA) using the Statistica 7.0 software. The difference was considered statistically significant if p < 0.05.

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

3 RESULTS AND DISCUSSION

The increase in flavor concentration from 1.5 to 3.0 mL kg-1 affected the germination process

by reducing the germination rate to 65%. Different from tests performed with the lowest flavoring concentration (1.5 mL kg-1), where germination reached 95% in grains; and is in agreement with

Brazilian Regulation for barley identity and quality (691/1996). The reduction in germination rate results in a malt that is not characterized as barley malt of the Pilsen type. Results collected from tests with 4.5 mL kg-1 of flavoring concentration show a higher reduction in germination rate, where only 50% of the grains germinated.

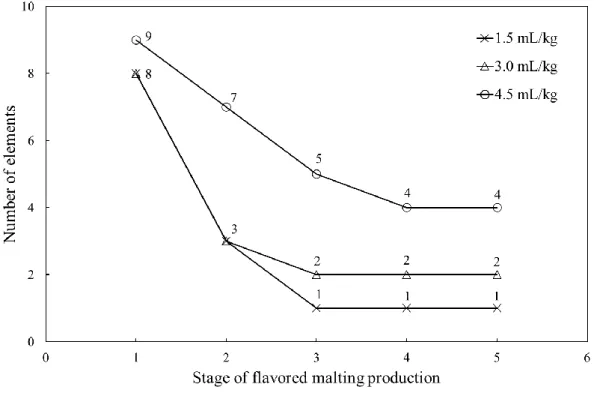

Figure 2 presents the number of chemical elements in each stage from flavored malting production, according to the tests from table 1. The flavor present in malt is notably reduced during malt production. The tests performed with the lower flavor concentration (1.5 mL kg-1) showed to have just 1 element from flavor solution at the end of malt production, even after different kilning temperatures. However, the element present was propylene glycol, the flavor carrier, which does not characterize flavor to the final product. As a result, the barley malt produced with the lowest concentration evaluated in this study did not present aromatic characteristics at the end of the process. Therefore, the addition of the flavored solution in this concentration (1.5 mL kg-1) did not interfere in the final product.

However, in contrast with the tests carried out with 1.5 mL kg-1, the kilning stage from the

tests with 3.0 mL kg-1, showed the presence of 2 elements: propylene glycol (flavor carrier) and

benzyl alcohol. The benzyl alcohol element refers to flavor sensory characteristics of flowers, roses, black plums and jasmine. Thus, the increase in the concentration of the flavored solution provided better flavor retention at the end of the malting process. However, by the same way, the kilning temperatures (75, 80 and 85 °C) did not show influence in flavor final concentration.

At the highest flavor concentration evaluated (4.5 mL kg-1), the number of elements found after steeping and germination was higher than the ones observed from the other flavor concentrations. Consequently, after the kilning stage, the number of elements present in barley malt was also higher. The lower kilning temperature (75 °C), with this flavor concentration (4.5 mL kg

-1), presented an extra element when compared to the final product obtained after other kilning

temperatures (80 and 85 °C). The extra element observed was the ethyl butyrate, which has flavor characteristics that refer to pineapple, fruity, cognac and tutti frutti. Propylene glycol, benzyl alcohol, isoamyl butyrate and isobutanol were the elements observed after all the kilning temperatures stages. Isoamyl butyrate presents fruity, grape, apricot and melon flavor perceptions; while, isobutanol is associated with red wine, grape and fruity flavors.

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

The tests carried out at the central point of this study showed the same results concerning the number of elements present. Therefore, the results do not present an experimental deviat ion.

A further analysis was performed in the test that provided 5 elements at the end of the malting process, to quantify the intensity of the elements. According to the table 1, the test with the best performance to produce flavored malt was the test 9, which presents the higher flavor concentration (4.5 mL kg-1) and operated with the lower kilning temperature (75 ºC). In Figure 3 the results of the GC-MS analyses of test 9 are presented. Notably, the carrier is present in a higher proportion. Also, the flavors with remarkable presence are the isoamyl butyrate and isobutanol. Thus, the flavored barley malt produced is mainly characterized by flavors of grapes, apricot, melon and red wine.

Figure 2. The number of flavor elements present in each stage of flavored malting production. Stage 1: steeping. Stage 2: germination. Stage 3: kilning at 75 °C. Stage 4: kilning at 80°C. Stage 5: kilning at 85 °C.

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

Figure 3. The intensity of each element presents at the end of the production of the flavored malt by the gas chromatography analysis.

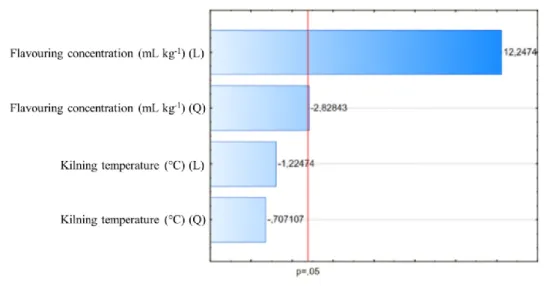

The statistical analysis of the results related to the number of flavor components at the end of the malting production showed that the flavoring concentration has statistical significance (p < 0.05), as presented in figure 4. While, the kilning temperature variable did not show a statistically significant effect (p > 0.05).

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

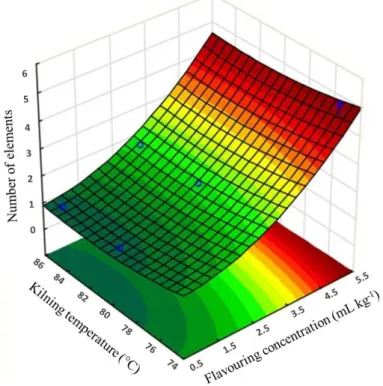

Figure 5. Response surface based on the statistical model for the number of elements presents after malting production.

The response surface is presented in figure 5, where it is observed that the increase in the number of elements is favored when there is a significant increase in the concentration of flavoring. While, the temperature range studied in the kilning stage did not show significant influence in the number of elements.

4 CONCLUSION

The production of flavored malt was evaluated based on the retention of flavoring elements at the end of the malting process. Results showed the presence of flavoring elements from red berries flavoring solution in barley malt produced according to the standardized malting process based on barley malt of the Pilsen type. However, once the germination rate was lower (less than 95%) in barley malt with the higher flavoring concentrations (3.0 and 4.5 mL kg-1), the malt produced is not characterized as the Pilsen type. From the variables evaluated, flavoring concentration (1.5 to 4.5 mL kg-1) and kilning temperature (75 to 85 °C), only flavoring concentration presented statistical significance in flavor retention in the final product. The barley malt, produced with 4.5 mL kg-1 of

flavoring concentration and 75 °C in kilning temperature, presented the best performance in flavor retention. Analysis by gas chromatography, in the best condition, presented 4 flavoring elements (isoamyl butyrate, isobutanol, benzyl alcohol and ethyl butyrate) and the flavor carrier (propylene glycol). Thus, the flavored barley malt produced is mainly characterized by flavors of grapes,

Braz. J. of Develop.,Curitiba, v. 6, n. 8, p.56977-56987 aug. 2020. ISSN 2525-8761

apricot, melon and red wine. This study support and provide information for breweries by presenting a novel flavored malt production, which contribute to the production of different flavored beers.

REFERENCES

Bamforth, C. W.: Nutritional aspects of beer – a review, Nutrition Research, 22 (2002), no. 1/2, pp. 227-237.

Beleti, M. A.; Duarte, F.; Georg-Kraemer, J. E.: Temperatura no desenvolvimento da atividade das enzimas (1-3, 1-4) - Beta-glucanases e degradação de Beta-glucanos durante a malteação, Ciência Rural, 42 (2012), no. 3, pp. 467-473.

Briggs, D. E.: Malts and Malting, Blackie Academic & Professional, 1998.

Fix, G. J.: Principles of Brewing Science, 2 ed., Boulder: Brewers Association, 1999.

Kleinwächter, M.; Meyer, A. K.; Selmar, D.: Malting revisited: Germination of barley (Hordeum vulgare L.) in inhibited by both oxygen deficiency and high carbon dioxide concentrations, Food Chemistry, 132 (2011), no. 1, pp. 476-481.

Kunze, W.: Technologie Brauer und Mälzer. Berlim: Versuchs - und Lehranstalt für Brauerei in Berlin (VLB), 2011.

Montanuci, F. D.; Perussello, C. A.; Jorge, L. M. M.; Jorge, R. M. M.: Experimental analysis and finite element simultion of the hydration process of barley grains, Journal of Food Engineering, 131 (2014), pp. 44-49.

Oliveira, M.; Faber, C. R.; Plata-Oviedo, M. S. V.: Elaboração de cerveja artesanal a partir da substituição parcial do malte por mel, Brazilian Journal of Food Research, 6 (2015), no. 3, pp. 1-10.

Oser, H. H.: Producing quality barley for the malting industry, Plant Health Program, Nebraska University, Doctoral Dissertation, 2015.

Pinto, A. R. M.: Avaliação do processo de secagem no fabrico de malte, Food Engineering – Food Processing, Technical University of Lisbon, Masters Thesis, 2013.

Tozetto, L. M.: Produção e caracterização de cerveja artesanal adicionada de gengibre (Zingiber officinale), Engineering Production, Federal Technological University of Paraná, Masters Thesis, 2017.