Marine shrimp farming in the state of Ceará: an analysis of the productive and

economic parameters, in the period 2003-2012

A carcinicultura marinha no estado do Ceará: uma análise dos parâmetros

produtivos e econômicos, no período 2003-2012

DOI:10.34117/bjdv5n12-393

Recebimento dos originais: 30/11/2019 Aceitação para publicação: 27/12/2019

Rommel Rocha de Sousa

Doutor pela Universidade Federal do Ceará

Programa de Pós-Graduação em Engenharia de Pesca, Campus do Pici, Universidade Federal do Ceará, 60.455-760, Fortaleza, Ceará, Brasil

E-mail: rommelpesca@gmail.com

Hudson Makson Rocha Lucena

Graduado pela Universidade Federal do Ceará Celm Aquicultura S/A, 62800-000, Aracati, Ceará, Brasil

E-mail: hudson@maris.com.br

Lívia Rodrigues Guimarães

Graduado pela Universidade Federal do Ceará

Departamento de Engenharia de Pesca, Campus do Pici, Universidade Federal do Ceará, 60.455-760, Fortaleza, Ceará, Brasil

E-mail: liviarguimaraes@yahoo.com.br

Manuella Gazzineo de Moraes

Mestre pela Universidade Federal do Ceará

Programa de Pós-Graduação em Engenharia de Pesca, Campus do Pici, Universidade Federal do Ceará, 60.455-760, Fortaleza, Ceará, Brasil

E-mail: manugazzineom@hotmail.com

Rafael Lustosa Maciel

Doutor pela Universidade Federal do Ceará

Instituto Federal de Educação, Ciência e Tecnologia do Amazonas, 69.800-000, Humaitá, Amazonas, Brasil

E-mail: maciel.rlm@hotmail.com

Ítalo Régis Castelo Branco Rocha

Doutor pela Universidade Federal do Ceará

Instituto Federal de Educação, Ciência e Tecnologia do Ceará, 60.115-282, Morada Nova, Ceará, Brasil

João Felipe Nogueira Matias

Doutor pela Universidade Federal do Ceará

Departamento de Engenharia de Pesca, Campus do Pici, Universidade Federal do Ceará, 60.455-760, Fortaleza, Ceará, Brasil

E-mail: jfn.matias@gmail.com

Elenise Gonçalves de Oliveira

Doutora pela Universidade Estadual de São Paulo

Departamento de Engenharia de Pesca, Campus do Pici, Universidade Federal do Ceará, 60.455-760, Fortaleza, Ceará, Brasil

E-mail: elenisego@yahoo.com.br

José Renato de Oliveira César

Doutor pela University of Hawaii

Departamento de Engenharia de Pesca, Campus do Pici, Universidade Federal do Ceará, 60.455-760, Fortaleza, Ceará, Brasil

E-mail: renatocesarufc@gmail.com

Francisco Hiran Farias Costa

Doutor pela Universidade Federal do Ceará

Departamento de Engenharia de Pesca,Campus do Pici, Universidade Federal do Ceará, 60.455-760, Fortaleza, Ceará, Brasil

E-mail: hiranfcosta@gmail.com

ABSTRACT

Brazil was the third largest producer of white shrimp in Latin America, with 75,000 tons and R$ 600 million, in 2012. The present work focused on the impacts of the IMNV pathogen, the anti-dumping action imposed by USA and the exchange rate appreciation of Brazilian currency in marine shrimp culture in a semi-intensive system in Northeastern region and also on the identification of options for sustainable production. Data were collected on shrimp farms (Compescal and Aquafort) at Ceará state. During the period from 2003 to 2007, these factors affected directly the competitiveness of Brazilian farmed shrimp exportation. However, in 2007 the shrimp producers started to sell on domestic market, which made possible to increase their production, revenue, income and profit levels. In 2007, Compescal had a loss of R$ 2,582,000.00. Although in 2008 it had a profit of R$ 2,353,000.00, while in 2012 the profit has increased to R$ 11,940,000.00. Aquafort was able to successively increase its profit margin, from R$ 865,000.00, in 2007 to R$ 2,583,000.00 in 2012, representing an annual growth rate of 40%. The economic feasibility analysis showed that under simulated conditions, the IRR maintained a direct and more than proportional link to changes in shrimp feed and sales prices, as well to productivity.

Keywords: Shrimp Farming; Myionecrosis; Antidumping; Economic viability.

RESUMO

O Brasil foi o terceiro maior produtor de camarão branco cultivado na América Latina, com 75.000 toneladas e uma receita primária de R$ 600 milhões, em 2012. O presente trabalho teve como foco

da moeda brasileira no cultivo de camarão em regime semi-intensivo na região Nordeste e na identificação de opções para a produção sustentável. Os dados foram coletados em fazendas de camarão (Compescal e Aquafort), no Estado do Ceará. Durante o período 2003-2007, esses fatores afetaram diretamente a competitividade das exportações brasileiras de camarão cultivado. No entanto, durante o ano de 2007, os produtores de camarão iniciaram as vendas no mercado interno, o que possibilitou o aumento dos níveis de produção, receita, rendimento e lucro. Em 2007, a Compescal apresentou seu segundo prejuízo de R$ 2.582.000,00, mas, no período de 2008-2012, mostrou aumento de lucros que variou entre R$ 2.353.000,00, em 2008, e R$ 11.940.000,00, em 2012. Aquafort foi capaz de aumentar sucessivamente a sua margem de lucro, de um lucro de R$ 865.000,00, em 2007, para R$ 2.583.000,00, em 2012, representando uma taxa de crescimento anual de 40% ao ano. A análise de viabilidade econômica mostrou que em condições simuladas a TIR manteve uma ligação direta e mais que proporcional às mudanças no preço da ração, produtividade e preço de venda.

Palavras-chave: Carcinicultura; Mionecrose; Antidumping; Viabilidade econômica.

1 INTRODUCTION

In the early 2000s, Brazilian aquaculture of peneid shrimp was responsible for generating employment for 50,000 people (ROCHA, 2011), which reduced the pressures against the activity. However, the industry started to had a serious collapse due to three different factors: financial losses caused by illnesses, starting in 2003 (POULOS et al., 2006; ANDRADE et al., 2007; TEIXEIRA-LOPES et al., 2011), the anti-dumping action brought by producers shrimp in the Southeast of the United States, starting in 2004 (KEITHLY-JR; POUDEL, 2008), and the appreciation of Brazilian currency, which reduced the competitiveness of the national industry in the world market (ABREU

et al., 2011). In addition, an increase in labor and inputs costs and a reduction on international prices

affected Brazilian shrimp farming, causing a redirection in commercial transactions to this industry. These facts led to a drastic reduction in the number of Jobs, which strengthened movements against the shrimp industry, regarded to environmental degradation and problems with traditional communities (GLASER; OLIVEIRA , 2004).

At the end of 2002, mortality was observed in juvenile and sub-adult individuals from Penaeus

vannamei grown on farms in Northeastern region of Brazil. But only in 2004, it was found that this

fact was caused by a disease caused by a virus origin and that was called as infectious myonecrosis (IMN) (LIGHTNER et al., 2004; TANG et al., 2005; POULOS et al., 2006).

It should be noted that in 2003, the Brazilian national production of farmed shrimp had reached its highest value in history, with 90,000 tons and an annual growth rate of 50%, considering the previous year (ROCHA et al., 2004; RODRIGUES, 2005). According to Eng et al. (1989), Naylor et

cultivation areas and intensification of productive processes, compromise the sustainability and can result in deteriorating ecosystems healthy and increasing the pre-disposition of pathogenic infection. At the end of 2003, a coalition of shrimp producers from the southeastern region of United States filled a petition to the US Department of Commerce accusing China, Vietnam, India, Thailand, Ecuador and Brazil of dumping practices, based on anti-dumping legislation from American law, known as the Byrd Amendment (KEITHLY-JR; POUDEL, 2008). In fact, Brazil was included in this action due to the continued growth of its exports during the period 2000-2003 and its potential to expand areas and not because of its representative participation in the international marine shrimp trade (ABREU et al., 2011).

Another factor that negatively affected the Brazilian farmed shrimp industry in relation to its competitiveness in a globalized market was the exchange rate appreciation of Brazilian currency, compared to American dollar. The exchange rate appreciation reduces the local price of exports, reducing the profit margin and affecting the profitability of the business (NATORI et al., 2011). As a consequence, in the last ten years, Brazilian shrimp farming redirected its sales, reducing its participation in foreign trade and gradually increasing its sales to domestic market (ROCHA, 2011). Thus, the shrimp market in Brazil had passed by a big change that began with the reduction of exportation and with the increase in sales to domestic market, due to the sales of farmed shrimp in retail, food services, restaurants, bars and hotels have become more common in the Country (NATORI et al., 2011; ROCHA, 2011).

The Brazilian shrimp farming industry has been studied from different points of view, considering various aspects such as technical, economic, social and environmental (CARVALHO; NUNES, 2006; SOUSA et al., 2006; ANDRADE et al., 2007; QUEIROZ, 2007; CASÉ et al., 2008; LOPES, 2008; TEIXEIRA-LOPES et al., 2010; ABREU et al., 2011; COSTA et al., 2011; ROCHA, 2011; TEIXEIRA-LOPES et al., 2011; VIEIRA-GIRÃO et al., 2012; DOTE-SÁ et al., 2013). On the other hand, very few is known about the technical aspects and economic profitability, environmental and social costs of Brazilian marine shrimp farms, despite the large number of scientific articles, technical manuals and management protocols (ABREU et al., 2011; DOTE -SÁ et al., 2013).

The present work presents an analysis of the productive and economic aspects of the two main marine shrimp farms in the State of Ceará (Compescal Comércio de Pescado Aracatiense Ltda and Aquacultura Fortaleza Aquafort SA) and their relationship with the disease of infectious myonecrosis (IMN) and the evolution of foreign and domestic trade, in the period 2003-2012.

2 MATERIALS AND METHODS

The study was developed in the two main marine shrimp farms in Brazilian state of Ceará (Compescal Comércio de Pescado Aracatiense Ltda and Aquacultura Fortaleza Aquafort SA). It was analyzed the productive and economic parameters during the period 2003-2012 and their correlations with the infectious myonecrosis virus (IMNV), with the anti-dumping action by north American shrimp producers and with the exchange rate appreciation of Brazilian currency.

The parameters used in this study were selected according to Ling et al. (1999) and Ponce-Palafox et al. (2011), who compared at regional level productive and economic aspects in several shrimp farms in Asian and Latin American countries. The productive parameters analyzed were production area (ha), production (ton), productivity (kg/ha/year), density (post-larvae, PL/m2), average weight (g), weekly growth (g/week), feed conversion factor (FCA), survival rate (%) and number of cycles/year. The economic parameters analyzed were annual cost with post-larvae (R$), annual cost with feed (R$), other annual costs (R$), total annual cost (R$), cost per kilogram (R$/kg), sales price (R$/kg), annual revenue (R$) and annual profit (R$).

Interviews with technicians and managers of the studied shrimp farms were done, and the collected data were analyzed and compared with information from Brazilian Association of Shrimp Farmers (ABCC) and Ministry of Fisheries and Aquaculture (MPA), and after this, they were expressed in tables and graphs.

An economic sensitivity analysis was realized, based on two hypothetical shrimp farms and on the two studied farms. All current values were applied between January 1, 2012 and December 31, 2012; but this period did not include the construction period for each hypothetical farm. For both hypothetical farms, the production system was semi-intensive, while the projected yields were approximately 4,200 kg/ha/year (Aquafort model), and 6,600 kg/ha/year (Compescal model).

Capital, infrastructure, operating costs, total costs, revenues and profits were included as economic parameters. The following assumptions were made for the economic sensitivity analysis: capital costs were R$ 3,200,000.00 for Aquafort model and R$ 6,200,000.00 for Compescal model, including a property acquisition with 200 hectares, which served to build 100 hectares of shrimp ponds and all the necessary equipment for its operation. Licenses and authorizations were also included as capital and infrastructure costs.

Business budgets were prepared for each hypothetical farm according to Jolly and Clonts (1993). The project's cash flow was calculated to a period of 12 years (KUBITZA; ONO, 2004). The internal rate of return (IRR), net present value (NPV) and cash flow were calculated according to Lapponi (2000), Larson et al. (2002) and Kubitza and Ono (2004). IRR, expressed as a percentage, is the discount rate that produces a NPV = zero for an investment (LARSON et al., 2002). The internal

rate of return is the rate used to assess the viability of an investment that reflects the return capacity of the investments done (SOLOMON; PRINGLE, 1977).

The net present value is calculated as the sum of net revenue flow, updated for the year zero, using a discount rate (LARSON et al., 2002). The NPV was calculated considering a discount rate of 8% per year (based on the interest rate in 2012), paid by the savings income of Brazilian banks for an investment of R$ 3,200,000.00 and R$ 6,200,000.00 and the same discount rate was applied to the cash flow analysis. The payback period was defined as the waiting period to recover the value of the initial investment (KUBITZA; ONO, 2004).

The economic sensitivity analysis was realized for two hypothetical farms (Aquafort model and Compescal model), considering six different scenarios and the main risk factors in a business related to aquaculture, which are the increase in the feed costs, the increase in the mortality rate and the reduction in the average commercialization price (SHANG, 1990).

3 RESULTS

The production parameters evolution of both studied companies was described in Table 1. In the studied period, Compescal increased its production area from 288.9 ha (2003) to 624.8 ha (2006), representing an increase of 116 %. In Aquafort, the production area had an evolution from 175.4 ha (2003) to 205.1 ha (2006), representing an increase of 17%. But from 2007 to 2012, it had an expansion to 383.7 ha, representing an increase of 87%.

From 2004 to 2006, even with the IMNV event, Compescal had increased its production volume. However, in 2007, it experienced its lowest level of production. Subsequently, in the period 2008-2012, Compescal reached its highest production level, with a volume of 4.2 thousand tons, in 2012. In case of Aquafort, after a minimum production of 413 tons registered in 2005, it had a continuous increase on its production levels, with a maximum value of 1.6 thousand tons, registered in 2012. In the period between 2003 and 2005, the productivity of Compescal and Aquafort was significantly reduced by 56% and 58%, respectively. During the 2008-2012 period, both Compescal and Aquafort had increased their stocking densities; reaching in 2012, values of 37.6 and 13.8 individuals/m2, respectively. These values were lowers than those observed in 2003 for both companies.

From 2003 to 2006, the average weight of Compescal’s was maintained between 10.2 and 12.1 g, while Aquafort’s was between 10.9 and 15.2 g. The weekly weight gains observed for Compescal ranged between 0.5 and 0.7 g/week, being slightly lower than those observed for Aquafort which ranged between 0.6 and 0.8 g/week, during the period 2003-2012. Survivals rates for Compescal and

Aquafort recorded in 2003 were 69% and 71%, respectively, and were reduced in 2004 to 41% and 46%, respectively.

During the period from 2003 to 2008, the number of production cycles for both Compescal and Aquafort, practically did not have significant oscillations, which means that this parameter was not affected by IMNV. However, from 2009 to 2012, the number of cycles increased significantly.

The economic parameters evolution from Compescal and Aquafort companies was described in Table 2. The annual cost with PLs reached the highest values, both for Compescal (R$ 4,593,000.00) and for Aquafort (R$ 1,931,000, 00), in 2003. During the period 2003-2008, the density was gradually reduced during the epidemiological period of IMN, in an attempt to obtain better zootechnical results. Consequently, the annual costs with PLs were reduced. The annual feed costs for Compescal were reduced from R$ 8,517,000.00 in 2003 to R$ 4,521,000.00 in 2004. During the period from 2005 to 2006, Compescal experienced an increase in annual feed costs, reaching a maximum value of R$ 9,833,000.00, in 2006. While in the period from 2007 to 2012, the annual costs had fluctuated, always influenced by variations in production levels. In the case of Aquafort, the company experienced its lowest level of production in 2006, when it produced only 413 tons of shrimp. However, since this year, it had showed an annual increase in production levels until 2012, when it reached the highest annual cost with feed (R$ 3,640,000.00).

For the 2003-2006 period, Compescal maintained the other annual costs ranging from R$ 7,352,000.00 to R$ 8,542,000.00. On the other hand, during the period 2008-2012, the increase in other annual costs was compatible with production levels. In case of Aquafort, this item was always compatible with production levels, with a minimum of R$ 1,173,000.00 for a production level of 574 tons in 2006, and a maximum of R$ 6,017,000.00 for a production level of 1,626 tons, in 2012. The annual production cost of Compescal ranged between R$ 14,708,000.00 and R$ 21,833,000.00, in the period 2007-2012, reaching a maximum annual production cost in the year 2012. In case of Aquafort, the company obtained a minimum cost of R$ 3,046,000.00 for a production level of 614 tons, in 2007, and a maximum cost of R$ 11,589,000.00 for a production level of 1,626 tons, in 2012. Compescal obtained R$ 33,773,000.00 as a maximum value of revenue for 4,182 tons produced in 2012; while Aquafort obtained R$ 14,172,000.00 as a maximum value of revenue for 1,626 tons produced in 2012. Compescal had showed increasing profits reaching from R$ 2,353,000.00 in 2008 to R$ 11,940,000.00 in 2012. In relation to Aquafort, the company was able to successively maximize its profit margin, going from R$ 865,000.00 in 2007 to R$ 2,583,000.00 in 2012, with an annual growth rate of 60%.

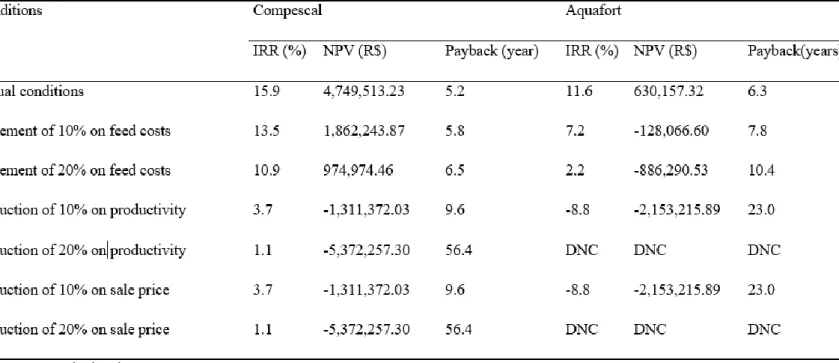

Table 3 presents the results economic sensitivity analysis for both farm models (Compescal and Aquafort). For Compescal model, increases in feed prices had a negative impact on the evaluated

indicators, but did not compromise the project feasibility. IRR values (13.5 and 10.9%) were still higher than the 8% discount, NPVs were R$ 1,862,243.87 and R$ 974,974.46 and payback periods were 5.8 and 6.5 years, for 10 and 20% increases in feed prices.

For Aquafort model, increases in feed prices had a negative impact on the IRR values (7.2 and 2.2%), being lower than the 8% discount rate, NPVs were -R$ 128,066.60 and -R$ 886,290.53, and the payback periods were 7.8 and 10.4 years, for those of 10 and 20% increases in the feed price.

In Compescal model, the impacts of reducing productivity and sales price were similar. For a 10% reduction in both productivity and sales price, the IRR was 3.7%, the NPV was -R$ 1,311,372.03 and the period of return on capital was 9.6 years, for both conditions. For a 20% reduction in both productivity and sales price, the IRR was 1.1%, the NPV was -R$ 5,372,257.30 and the period of return on capital was 56.4 years, for both conditions.

In Aquafort model, the reduction in productivity and sales price followed the same trend as Compescal model. For a 10% reduction in productivity and sales price, the IRR was -8.8%, the NPV was -R$ 2,153,215.89 and the period of return on capital was 23.0 years, for both conditions. For a 20% reduction in productivity and sales price, the IRR, the NPV and the return period could not be calculated, since under these conditions, the company would have an annual loss in the order of R$ 230,436.72, and generating a negative cash flow, without the possibility of a return on invested capital.

4 DISCUSSION

Basically, Compescal has increased its production area during the period 2003-2006, when the infectious myonecrosis virus (IMNV) had its most damaging effect on shrimp production in Ceará state. At the same period, U.S.A. market was closed to import Brazilian farmed shrimp, due to the anti-dumping action and furthermore, the Brazilian shrimp farm industry lost competitiveness due to the exchange rate appreciation of Brazilian currency.

On the other hand, Aquafort only expanded its production area after a significant decrease in the viral outbreaks caused by IMNV and redirection its production to the national market since 2007. According to ROCHA et al. (2013), despite the aforementioned problems, Ceará state has expanded its marine shrimp farmed production area in 95%, from 3,376 ha in 2003 to 6,580 ha in 2011, while other Brazilian states had increased their production area only by 16%. During this period, several authors had reported survival rates between 35% and 55% in earth ponds affected by IMNV, in Brazilian northeastern region (LIGHTNER et al., 2004; POULOS et al., 2006; ANDRADE

The resumption of production levels, after these problems above mentioned, was mainly due to the efforts of the shrimp industry to invest and to adapt itself to domestic market (ROCHA et al., 2011). According to ROCHA et al. (2013), the productivity of shrimp farms in Ceará state, in 2003 reached 7,676 kg/ha/year and in 2011 had decreased to 4,861 kg/ha/year. In shrimp farms from California Gulf, Mexico, the productivity in 2007 was between 1,200 and 6,000 kg/ha/year (PONCE-PALAFOX et al., 2011).

With the reduction of stocking density, the availability of natural food bigger, increasing the growth rate, reducing the cultivation period and the exposure time to pathogen. This strategy reduces the possibility of horizontal transmission of the disease, when a healthy individual eats an infected one (SENAPIN et al., 2011).

The increase in FCA was felt most significantly in Compescal, in 2007, when FCA reached a value of 3.7:1, while in Aquafort, FCA reached a maximum value of 2.6:1, in 2005. According to Andrade (2009), nurseries with a high degree of IMNV infection had a survival rate of 21% and an FCA of 4.4:1, at the beginning of the viral outbreak in Ceará, state, in 2003.

The increase in turnover reduces the mortality risks due to a shorter production process and also reduces the production costs (ROCHA; ROCHA, 2010; ROCHA, 2011). Therefore, the increase in the number of production cycles of both companies seems to be more related to the stocking density and to the average weight of harvest.

According to Wyban (2003), in Thailand, in 2003, the selling price of 1,000 PL15 varied between US$ 3.75 and US$ 6.50 (R$ 11.50 and R$ 19.95, considering an exchange rate of US$ 1.00 = $3.07). Considering the same values in dollars, for 2012, comparatively the values in Brazilian currency would be R$ 7.38 and R$ 12.80 (US$ 3.75 and US$ 6.50, considering an exchange of US$ 1.00 = R$ 1.97). It should be noted that the price of PL was not a cost (considering both the price in Brazilian currency and in American dollars) that had a negative impact through price increases in the total cost, neither during the export phase (2003-2007), nor during the domestic market phase (2008-2012).

Feed is one of the main concerns of shrimp producers and it can represents up to 60% of the total production costs (AKIYAMA et al., 1992; SARAC et al., 1993). In case of Compescal, feed costs varied between 19% and 72% of production costs, while for Aquafort, it varied between 31% and 65%. For the item other annual costs, Compescal was not able to reduce its annual production cost, despite the reduction on its production level. In the period from 2007 to 2012 the company managed to reconcile the production/production cost ratio and the annual production cost had a positive evolution in line with the increase in annual production, reaching a maximum annual

production cost in 2012. In case of Aquafort, as previously mentioned for the item other annual costs, the company has always managed to match its annual production cost with the level of production.

Wyban (2003) reported shrimp farmed prices in Thailand in 2003 as US$ 2.50 for 80/100 shrimp (R$ 7.70, considering an exchange rate of US$ 1.00 = R$ 3.07), US$ 3.00 (R$ 9.20) for 60/70 and U$ 4.00 (R$ 12.30) for 50/60 shrimp. Similar prices have been reported for shrimp sold on farms in Thailand in 2006 (MUANGKEOW et al., 2007). In fact, these prices have remained slightly stabilized in recent years in Asia; with small fluctuations, proving that, mainly, the exchange rate appreciation of Brazilian currency and the increase of some production cost items such as shrimp feed, petroleum and labor costs, reduced the competitiveness of the Brazilian industry with a focus on the export market (ROCHA; ROCHA, 2010).

In the period from 2008 to 2012 the two studied companies experienced an annual increase in marketing prices, as a result of the continuous increase in national per capita consumption, which demanded a greater shrimp supply year by year. As a result of this new market reality, the share of shrimp farmed in Brazil had na increase from 22% in 2003 to 100% in 2012 (ROCHA et al., 2013). At present, price fluctuations in the domestic market are regulated by the seasonality of the shrimp from fisheries and by the periods of low (autumn/winter season) and high consumption (spring/summer season, holidays, traditional festivals) in Brazilian southeastern region, which is the main consumer of shrimp farmed in Northeastern region (ROCHA; ROCHA, 2010).

In cases where IRR values were lower than discount rate, it is more viable to invest in savings accounts than in the shrimp farm models presented for different situations. According to Lonno et al. (2006), a negative NPV value may indicate that an investment is substantially viable, however it would be rejected by the majority of potential investors.

5 CONCLUSIONS

It can be concluded that the infectious myonecrosis virus (IMNV), the anti-dumping action brought by shrimp producers in the Southeastern region of United States and the exchange rate appreciation of the Brazilian currency during the period 2003-2012 had a negative impact both on Compescal and on Aquafort. On the other hand, these companies had the ability to get best practices of management and to reduce production costs, in order to adapt to the new market reality imposed in the period 2008-2012, which was the national market. The economic sensitivity analysis had revealed the possibility of an increase in shrimp feed prices (due to the reduction of the grain harvest in United States), of a reduction in productivity (due to the possibility of a new epizooty for the infectious myonecrosis vírus - IMNV), and of a reduction in commercialization prices (due to the

possibility of Brazil becoming a shrimp importer), may negatively affect the entire Brazilian farmed shrimp industry, based on the evaluated data.

ACKNOWLEDGEMENTS

The authors are grateful to the companies Compescal Ltda and Aquafort S.A. for providing the necessary data for this research. We are indebted to the Coordination for the Improvement of Higher Education Personnel (CAPES) who provided R.R. de Sousa with a scholarship from masters.

Table 1 Production parameters evolution from Compescal Ltda, located in Aracati-Ceará-Brazil and from Aquafort SA, located in Camocim and Granja, State of Ceará-Brazil, during the period 2003-2012.

Table 2 Economic parameters evolution from Compescal Ltda, located in Aracati-Ceará-Brazil and from Aquafort SA, located in Camocim and Granja, State of Ceará-Brazil, during the period 2003-2012.

REFERENCES

ABREU, M.C.S., MATTOS, P., LIMA, P.E.S., PADULA, A.D. Shrimp farming in coastal Brazil: Reasons for market failure and sustainability challenges. Ocean & Coastal Management, v. 54, p. 658–667, 2011.

ANDRADE, T.P. Development and application of novel quantitative and qualitative molecular

techniques for detection of infectious myonecrosis virus (IMNV) in pacific white shrimp Litopenaeus vannamei. Dissertation (Doctor in Philosophy with a major in Pathobiology),

Department of Veterinary Science and Microbiology, The University of Arizona, Tucson, 121 pp, 2009.

ANDRADE, T.P.D., SRISUVAN, T., TANG, K.F.J., LIGTHNER, D.V. Real-time reverse transcription polymerase chain reaction assay using TaqMan probe for detection and quantification of Infectious myonecrosis virus (IMNV). Aquaculture, v. 264, p. 9–15, 2007.

AKIYAMA, D.M., DOMINY, W.G., LAWRENCE, A.L. Penaeid shrimp nutrition. In: FAST, A.W., LESTER, L.J. (Eds), Marine Shrimp Culture: Principles and Practices. Elsevier, Amsterdam, pp. 535–568, 1992.

CARVALHO, E.A., NUNES, J.A.P. Effects of feeding frequency on feed leaching loss and grow-out patterns of the white shrimp Litopenaeus vannamei fed under a diurnal feeding regime in pond enclosures. Aquaculture, v. 252, p. 494–502, 2006.

CASÉ, M., LEÇA, E.E., LEITÃO, S.N., SANT’ANNA, E.E., SCHWAMBORN, R., MORAES-JÚNIOR, A.T. Plankton community as an indicator of water quality in tropical shrimp culture ponds.

Marine Pollution Bulletin, v. 56, p. 1343–1352, 2008.

COSTA, F.H.F, VALENÇA, N.S.M.S., SILVA, A.R.B.P., BEZERRA, G.A., CAVADA, B.S., RÁDIS-BAPTISTA, G. Cloningand molecular modeling of Litopenaeus vannamei (Penaeidae) C-type lectin homologs with mutated mannose binding domain-2. Genetics and Molecular Research, v. 10, p. 650–664, 2011.

DOTE-SÁ, T., SOUSA, R.R., ROCHA, I.R.C.B., LIMA, G.C., COSTA, F.H.F. Brackish shrimp farming in Northeastern Brazil: the environmental and socio-economic impacts and sustainability.

Natural Resources, v. 4, p. 538–550, 2013.

ENG, C.T., PAW, J.N., GUARIN, F.Y. The environmental impact of aquaculture and the effects of pollution on coastal aquaculture development in Southeast Asia. Marine Pollution Bulletin, v. 20, p. 335–343, 1989.

GLASER, M., OLIVEIRA, R. Prospects for the co-management of mangrove ecosystems on the North Brazilian coast: whose rights, whose duties and whose priorities? Natural Resources Forum, v. 28, p. 224–233, 2004.

IONNO, P. N. D.; WINES, G. L.; JONES, P. L.; COLLINS, R. O. A bioeconomic evaluation of a commercial scale recirculating finfish growout system — An Australian perspective. Aquaculture, v. 259, p. 315-327, 2006.

JOLLY, C.M., CLONTS, H.A. Economics of Aquaculture. The Haworth Press, Binghamton. 319 pp, 1993.

KEITHLY-JR, W.R., POUDEL, P. The southeast U.S.A. Shrimp industry: Issues related to trade and antidumping duties. Marine Resource Economics, v. 23, p. 459–483, 2008.

KUBITZA, F., ONO, E.A. Projetos Aquıcolas: Planejamento e Avaliação Econômica, 1st. ed. Fernando Kubitza, Jundiaí. 88 pp, 2004.

LAPPONI, J.C. Projetos de Investimento: Construção e Avaliação do Fluxo de Caixa: Modelos

em Excel. Lapponi Treinamento e Editora, São Paulo. 376 pp, 2000.

LARSON, K.D., WILD, J.J., CHIAPPETTA, B. Fundamental Accounting Principles, 16th edition. McGraw-Hill Irwin Publishing, USA, 2002.

LIGHTNER, D.V., PANTOJA, C.R., POULOS, B.T., TANG, K.F.J., REDMAN, R.M., ANDREAS, T., BONAMI, J.R. Infectious myonecrosis (IMN): a new virus disease of Litopenaeus vannamei. In:

Abstract Book of Aquaculture 2004. Honolulu, Hawaii, EUA, p. 353, 2004.

LING, B.H., LEUNG, P.S., SHANG, Y.C. Comparing Asian shrimp farming: the domestic resource cost approach. Aquaculture, v. 175, p. 31–48, 1999.

LOPES, P.F.M. Extracted and farmed shrimp fisheries in Brazil: economic, environmental and social consequences of exploitation. Environment, Development and Sustainability, v. 10, p. 639–655, 2008.

MUANGKEOW, B., IKEJIMA, K., POWTONGSOOK, S., Yi, Y. Effects of white shrimp,

Litopenaeus vannamei (Boone), and Nile tilapia, Oreochromis niloticus L., stocking density on

growth, nutrient conversion rate and economic return in integrated closed recirculation system.

Aquaculture, v. 269, p. 363–376, 2007.

NATORI, M. M.; SUSSEL, F. R.; SANTOS, E. C. B.; PREVIERO, T. C.; VIEGAS, E. M. M.; GAMEIRO, A. H. Desenvolvimento da carcinicultura marinha no Brasil e no mundo: avanços tecnológicos e desafios. Informações Econômicas, v. 41, p. 61–73, 2011.

NAYLOR, R.L., GOLDBURG, R.J., MOONEY, H., BEVERIDGE, M., CLAY, J., FOLKE, C., KAUTSKY, N., LUBCHENCO, J., PRIMAVERA, J., WILLIAMS, M. Nature’s subsidies to shrimp and salmon farming. Science, v. 282, p. 883–884, 1998.

OIE (Office International des Epizooties/World Animal Health Organization). Immediate

notification report reference: Ref. OIE: 7090, Report Date: 04/06/2007, Country: Brazil, Printed

on: Thu Jun 5 15:21:59 Paris, 3pp, 2007.

PONCE-PALAFOX, J.T., RUIZ-LUNA, A., CASTILLO-VARGASMACHUCA, S., GARCÍA-ULLOA, M., ARREDONDO-FIGUEROA, J.L. Technical, economics and environmental analysis of semi-intensive shrimp (Litopenaeus vannamei) farming in Sonora, Sinaloa and Nayarit states, at the east coast of the Gulf of California, México. Ocean & Coastal Management, v. 54, p. 507–513, 2011.

POULOS, B.T., TANG, K.F.J., PANTOJA, C.R., BONAMI, J.R., LIGTHNER, D.V. Purification and characterization of infectious myonecrosis virus of penaeid shrimp. Journal of General

Virology, v. 87, p. 987–996, 2006.

QUEIROZ, L.S. There is so much mangrove in the life of Cumbe: the influences of the

social-environmental impacts of shrimp farming on the way of life of a coastal community. Dissertation

of Masters in Development and Environment – Graduate Program in Development and Environment, Federal University of Ceará, Fortaleza, 113 pp, 2007.

ROCHA, I.P. Current status and trends in Brazilian shrimp farming. Infofish International, v. 5, p. 24–28, 2011.

ROCHA, I.P., ROCHA, D.M. Análise da produção e do mercado interno e externo do camarão cultivado. Revista da Associação Brasileira dos Criadores de Camarão – ABCC, v. 1, p. 18–23, 2010.

ROCHA, I.P., RODRIGUES, J., AMORIM, L. A carcinicultura brasileira em 2003. Revista da

Associação Brasileira dos Criadores de Camarão – ABCC, v. 1, p. 30–36, 2004.

ROCHA, I.P., BORBA, M.G., MOURA, M. J. N. O censo da carcinicultura em 2011. Revista da

Associação Brasileira dos Criadores de Camarão – ABCC, v. 1, p. 24–28, 2013.

RODRIGUES, J. Carcinicultura marinha – Desempenho em 2004. Revista da Associação Brasileira

dos Criadores de Camarão – ABCC, v. 2, p. 38–44, 2005.

SARAC, Z., THAGGARD, H., SAUNDERS, J., GRAVEL, M., NEILL, A., COWAN, R.T. Observations on the chemical composition of some commercial prawn feeds and associated growth responses in Penaeus monodon. Aquaculture, v. 115, p. 97–110, 1993.

SENAPIN, S., PHIWSAYA, K., GANGNONNGIW, K., FLEGEL, T.W. False rumours of disease outbreaks caused by infectious myonecrosis virus (IMNV) in the whiteleg shrimp in Asia. Journal

of Negative Results in BioMedicine, v. 10, p. 1–5, 2011.

SHANG, Y.C. Aquaculture Economic Analysis: An Introduction. World Aquaculture Society, Baton Rouge. 211 pp, 1990.

SOLOMON, E., PRINGLE, J.J. An Introduction to Financial Management. Goodyear Publishing Company, Santa Monica, California. 614 pp, 1977.

SOUSA, O.V., MACRAE, A., MENEZES, F.G.R., GOMES, N.C.M., VIEIRA, R.H.S.F., MENDONÇA-HAGLER, L.C.S. The impact of shrimp farming effluent on bacterial communities in mangrove waters, Ceará, Brazil. Marine Pollution Bulletin, v. 52, p. 1725–1734, 2006.

TANG, K.F.J., PANTOJA, C.R., POULOS, B.T., REDMAN, R.M.,LIGHTNER, D.V. In situ hybridization demonstrates that Litopenaeus vannamei, L. stylirostris and Penaeus monodon are susceptible to experimental infection with infectious myonecrosis virus (IMNV). Dis. Aquat. Org., v. 63, p. 261–265, 2005.

TEIXEIRA-LOPES, M.A., VIEIRA-GIRÃO, P.R.N., FREIRE, J.E.C., ROCHA, I.R.C.B., COSTA, F.H.F., RÁDIS-BAPTISTA, G. Natural co-infection with infectious hypodermal and hematopoietic necrosis virus (IHHNV) and infectious myonecrosis virus (IMNV) in Litopenaeus vannamei in Brazil. Aquaculture, v. 312, p. 212–216, 2011.

TEIXEIRA-LOPES, M.A., CRUZ, J.E.F., VIEIRA, P.R.N., ROCHA, I.R.C.B., COSTA, F.H.F., RÁDIS-BAPTISTA, G. Differential diagnosis of active hypodermal and hematopoietic necrosis virus based on gene choice and reverse transcription coupled with PCR. Genetics and Molecular

Research, v. 9, p. 2025–2031, 2010.

VIEIRA-GIRÃO, P.R.N., ROCHA, I.R.C.B., COSTA, F.H.F., RÁDIS-BAPTISTA, G. Differential induction of HSP-70 expression in response to IHHNV in white shrimp Litopenaeus vannamei naturally co-infected with IHHNV and IMNV. International Aquatic Research, v. 4, p. 1–13, 2012. WYBAN, J. A. Recent developments in P. vannamei seedstock production Asia. Global

Aquaculture Advocate, v. 6, p. 78-79, 2003.

XU, Z., PRIMAVERA, J.H., DE LA PEÑA, L.D., PETTIT, P., BELAK, J., ALCIVAR-WARREN, A. Genetic diversity of wild and cultured black tiger shrimp (Penaeus monodon) in the Phillipines using microsatellites. Aquaculture, v. 199, p. 13–40, 2001.