EFFECTS OF CIRCULAR CORNERS AND ASPECT-RATIO

ON ENTROPY GENERATION DUE TO NATURAL CONVECTION

OF NANOFLUID FLOWS IN RECTANGULAR CAVITIES

by

Mahmoud SALARIa*, Ali MOHAMMADTABARb,

and Mohammad MOHAMMADTABARc

a Department of Mechanical Engineering, Imam Hussein University, Tehran, Iran b Department of Mechanical Engineering, Azad Islamic University Branch

Tehran, Iran

c Department of Mechanical Engineering, University of Alberta, Edmonton, Alb., Canada

Original scientific paper DOI:10.2298/TSCI130201034S

In this paper, entropy generation induced by natural convection of Cu-water nanofluid in rectangular cavities with different circular corners and different as-pect-ratios were numerically investigated. The governing equations were solved using a finite volume approach and the SIMPLE algorithm was used to couple the pressure and velocity fields. The results showed that the total entropy genera-tion increased with the increase of Rayleigh number, irreversibility coefficient, aspect ratio or solid volume fraction while it decreased with the increase of the corner radius. It should be noted that the best way for minimizing entropy gener-ation is decreasing Rayleigh number. This is the first priority for minimizing en-tropy generation. The other parameters such as radius, volume fraction, etc. are placed on the second priority. However, Bejan number had an inverse trend compared with total entropy generation. As an exception, Bejan number and total entropy number had the same trend whenever solid volume fraction increased. Moreover, Nusselt number increased as Rayleigh number, solid volume fraction or aspect ratio increased whereas it decreases with the increase of corner radius. Key words: entropy generation, nanofluid, circular corners, rectangular cavity,

natural convection, numerical analysis

Introduction

Natural convention heat transfer has various applications in many practical fields such as cooling system of electronic components, solar collectors, wall insulations, thermal systems of building, and natural circulation in the atmosphere. Minimization of entropy gen-eration is the optimal design criteria for various practical thermal systems such as electronic cooling, turbo-machines, heat exchangers, etc. Bejan [1] showed that flow parameters should be designed to minimize the irreversibility related to a specific convective heat transfer. Abu-Hijleh et al. [2] numerically studied the entropy generation of natural convection in a horizon-tal cylinder. They showed, for a range of Rayleigh numbers, entropy generation decreased with the increase of the cylinder diameter. Zahmatkesh [3] investigated entropy generation of natural convection in a porous enclosure and indicated that the generation rate was maximum

––––––––––––––

for uniform heating/cooling and minimum for non-uniform heating/cooling. Olivesli et al. [4] considered entropy generation in a rectangular cavity which was submitted to a horizontal temperature gradient and showed variation of entropy generation in relation to Rayleigh num-ber, aspect ratio and irreversibility coefficient. Salari et al. [5] studied numerical study of en-tropy generation for natural convection in rectangular cavity with circular corners. Khanatee

et al. [6] introduced a new class of fluid with higher thermal conductivity and called it nanofluids which consisted of suspended nanoparticles with better suspension stability com-pared with millimeter and micrometer sized particles. Natural convection of different nanoflu-ids in cavity has been numerically carried out by many investigators [7-13]. Feng and Klein-strener [14] studied entropy generation of nanofluids flow between parallel disks. Li and Kleinstrener [15] analyzed entropy generation in trapezoidal microchannels when the used nanofluids were a combination of water and CuO nanoparticles. They determined the most suitable channel aspect ratio and Reynolds number range by minimizing entropy generation. Singh et al. [16] studied entropy generation in micro-channel, mini-channel and a convection-al channel with convection-alumina-water nanofluids. They reported an optimum diameter for mini- mizing entropy generation rate. Mahmoudi et al. [17] simulated a numerical study of entropy generation in a square open cavity heated with a protruded heat source and showed that the position of open boundary and location of the heater had considerable effects on heat transfer characteristics and irreversibility. The entropy generation due to flow and heat transfer of nanofluids between co-rotating cylinders with constant heat flux on the walls is studied ana-lytically by Mahian et al. [18]. In other work, the mixed convection flow between two vertical concentric pipes with constant heat flux at the boundaries and MHD flow effects is considered by Mahian et al. [19]. In the study by Selimefendigil and Oztop [20], a square cavity with two ventilation ports in the presence of an adiabatic fin of different lengths placed on the walls of the cavity is numerically analyzed for the mixed convection case. Also a good review about the entropy generation due to flow and heat transfer of nanofluids in different geometries and flow regimes is presented by Mahian et al.[21]. The objective of this work is to investigate entropy generation due to natural convection in a rectangular cavity with different circular corners. Based on the knowledge of authors, there has been no paper on the effects of circular corners on Nusselt number and total entropy generation. This paper presents dependence of total entropy generation, Bejan number and Nusselt number on various parameters such as Rayleigh number, solid volume fraction, aspect ratio and corner radius.

Mathematical model

equilibrium. Thermo-physical properties of nanofluid are constant, except the density ob-tained by the assumption of Boussinesq approximation. Table 1 [16, 22] shows properties of the base fluid and diverse nanoparticles used in this paper at reference temperature 25 °C. However, at the procedure of computation and for each computation cell all the parameters presented at tab. 1 are depending on temperature and their amounts are updated for each cell.

Table 1. Thermo-physical properties of water and nanoparticles [22]

The governing equations of continuity, momentum, and energy with the assumptions can be obtained:

0

u v x y ∂ +∂ =

∂ ∂ (1)

2 2

nf 2 2

nf 1

u u p u u

u v

x y ρ x µ x y

∂ + ∂ = −∂ + ∂ +∂

∂ ∂ ∂ ∂ ∂ (2)

2 2

nf 2 2 nf c

nf 1

( ) ( )

v v p v v

u v g T T

x y ρ y µ x y ρβ

∂ + ∂ = −∂ + ∂ +∂ + −

∂ ∂ ∂ ∂ ∂ (3)

2 2

nf 2 2

T T T T

u v

x y α x y

∂ + ∂ = ∂ +∂

∂ ∂ ∂ ∂ (4)

The effective density of nanofluid can be achieved:

nf (1 ) f p

ρ = −f ρ +fρ (5)

where ϕis the solid volume fraction of nanofluid. Thermal diffusivity of nanofluid is determined:

nf nf

nf ( p)

k C α

ρ

= (6)

Heat capacity of the nanofluid is obtained:

nf

(ρCp) = −(1 f ρ)( Cp)f +f ρ( Cp p) (7)

Also, the thermal expansion coefficient of the nanofluid is expressed:

nf

(ρβ) = −(1 f ρβ)( )f +f ρβ( )p (8)

The effective dynamic viscosity of the nanofluid presented by Brinkman [23] is giv-en:

β · 105 [K–1]

k [Wm–1K–1]

Cp

[Jkg–1K–1] ρ

[kgm–3]

21 0.613

4179 997.1

Pure water

1.67 401

385 8933

f nf 2.5 (1 ) µ µ f = − (9)

The effective thermal conductivity of the nanofluid calculated by Abu-Nada and Chamkha [24] is:

0.3690 0.7476

0.7640 0.9955 1.2321

nf f f

p

T

f p

1 64.7 Pr Re

k d k

k f d k

= +

(10)

where kf is the thermal conductivity of pure fluid and kp is the thermal conductivity of dis-persed nanoparticles. PrT and Re are defined:

f T f f Pr µ ρ α = (10-1) f 2 f f Re 3π b k T l ρ µ = (10-2)

The symbol kb is the Boltzmann constant = 1.3807·10–23 J/K, and lf – the mean path of fluid practices given as 0.17 nm [24].

The mentioned governing equations are converted to the following dimensionless form by introducing the dimensionless parameters:

2 c

2

h c nf

3

f f

h c

f f f

, , , , , ,

g

, Ra , Pr

T T

x y uL vL pL

X Y U V P

L L T T

L T T T T

θ

α α ρ α

β u

u α α

− = = = = = = − ∆ ∆ = − = = (11)

Using these dimensionless parameters, the governing eqs. (1)-(4) could be written:

0

U V

X Y

∂ +∂ =

∂ ∂ (12)

2 2

f

2.5 2 2

nf Pr

(1 )

U U P U U

U V

X Y X X Y

ρ ρ f ∂ + ∂ = − ∂ + ∂ +∂

∂ ∂ ∂ − ∂ ∂ (13)

2 2

f nf

2.5 2 2

nf nf f

( )

Pr

Ra Pr

(1 )

V V P V V

U V

X Y Y X Y

ρ ρβ θ

ρ f ρ β

∂ + ∂ = − ∂ + ∂ +∂ +

∂ ∂ ∂ − ∂ ∂ (14)

2 2

nf

2 2

f

U V

X Y X Y

α

θ θ θ θ

α

∂ + ∂ = ∂ +∂

∂ ∂ ∂ ∂ (15)

The local Nusselt number of the nanofluid on left wall can be determined:

l f Nu hL

k

= (17)

The convection heat transfer coefficient h is also obtained by:

h c

"

q

h

T T

=

− (18)

and the average Nusselt number (Num) can be achieved by integrating the local Nusselt num-ber (NuS) along the heat source:

l 0 1

Nu Nu ( )d

H

m Y Y

H

=

∫

(19)In the natural convection process the entropy generation is associated with the heat transfer and to the fluid flow friction. The entropy generation for an incompressible flow sys-tem was previously developed by Bejan [25]. The volumetric entropy generation in flow, due to the heat transfer and fluid friction, can be written:

l l,h l,f

S =S +S (20)

The heat transfer contribution of the volumetric entropy generation of the nanofluid in a system of 2-D flow is:

2 2

nf l,h 2 0

K T T

S

x y

T

∂ ∂

= +

∂ ∂

(21)

where To = (Th + Tc)/2 is the bulk temperature, and knf – the thermal conductivity of nanofluid. The fluid friction contribution of the volumetric entropy generation of the nanofluid in a system of 2-D flow is determined:

2 2

2 nf

l,f 0

2 u 2 v u v

S

T x y y x

µ ∂ ∂ ∂ ∂

= + + +

∂ ∂ ∂ ∂

(22)

where μnf is the dynamic viscosity of nanofluid.

These equations in dimensionless form for the nanofluid can be determined:

l,a l, ,ha l, ,fa

S =S +S (23)

2 2

nf l, ,h

f a

K S

K X Y

θ θ

∂ ∂

= +

∂ ∂

(24)

X = 0, on left wall: U = V = 0, θ = 1,

X = 0, on half parts of corner radii linked to left wall: U = V = 0, θ = 1,

X = 1, on right wall: U = V = 0, θ = 0,

X = 1, on half parts of corner radii linked to right wall: U = V = 0, θ = 0,

Y = 0, on bottom wall: U = V= 0, ∂θ/∂Y = 0,

Y = 1, on top wall: U = V= 0, ∂θ/∂Y = 0,

on half parts of corner radii linked to top and bottom walls: U = V= 0, ∂θ/∂n = 0

2 2 2

l, ,f 2.5 2 2

(1 )

a

U V U V

S

X X Y X

ϕ f

∂ ∂ ∂ ∂

= + + +

∂ ∂ ∂ ∂

−

(25)

where φ is the ratio between viscous and thermal irreversibility and is defined: 2

f 0 f

f ( h c) T

k L T T

µ α

ϕ=

−

(26)

The dimensionless total entropy generation of the nanofluid is achieved by getting integral over the entire volume of the dimensionless local entropy generation:

, l, d

T a a

S =

∫

Sν

(27)The Bejan non-dimensional number of the nanofluid (Be) is also expressed:

l, ,h

l,

Be a

a S

S =

(28)

Grid generation

Figure 2 schematically shows grid generation processes, which was done according to the following steps:

– a structured grid was generated algebraically for the rectan-gular cavity (first, without considering the circular corners). Accordingly, all cell geometries had a rectangular form. Clustering could be also used near the cavity walls,

– the rectangular cells in vicinity of the circular boundaries were totally selected as computational domain (i. e. where their pieces were placed in the physical domain). Then, the remaining cells between circular corner and the rectangular cavity walls were withdrawn, and the required boundary condition could be imposed to the extra cell boundaries, (fig. 2).

It can be seen in fig. 2 that the circular boundaries were approximated with broken lines. However, this error can be reduced by decreasing mesh sizes.

Numerical method and validation

The non-dimensional governing eqs. (12)-(15) were numerically solved based on the finite volume approach presented by Pa-tankar [26]. For coupling the pressure and velocity

fields, the SIMPLE algorithm was applied. A non-uniform grid mesh which was thinner in the vicinity of walls was used to increase accuracy of the results. The effect of grid resolution was studied in order to find suitable grid density. The results of the grid study on average Nusselt number are reported in tab. 2. Based on the results presented in this table, a 100 × 100 non-uniform grid was selected for the numerical simulation of this research. The convergence Figure 2. Structured grid

features

Table 2. Grid study results (Cu-water, A = 1, r = 0.3, ϕ = 0.1, φ = 10–2, Ra = 105)

125 × 125 100 × 100

75 × 75 50 × 50

25 × 25 Grid

2.4765 2.4767

2.4782 2.4815

2.5532 Nu

6.5972 6.5972

6.5971 6.5917

criteria were satisfied when maximum mass re-siduals of the grid control volume was less than about 10–9. For validation of the present numeri-cal code, U velocity profile of a mixed convec-tion flow within a lid-driven square enclosure ob-tained by this code was compared with that of the numerical results presented by several investiga-tors [27-29]. As shown in fig. 3, these results were in good agreement with each other. Moreo-ver, the results of averaged Nusselt number in this research were compared with those present-ed by Oliveski et al., [4] and Davis de Vahl [30], as shown in tab. 3. In addition, tab. 4 shows the comparison of non-dimensional total entropy generation (STa) obtained by this code with

oth-er investigations [4, 31]. Both tabs. 3 and 4 demonstrate that both avoth-erage Nusselt numboth-er and non-dimensional total entropy generation obtained by the present numerical code had very good agreement with the results presented by other investigators.

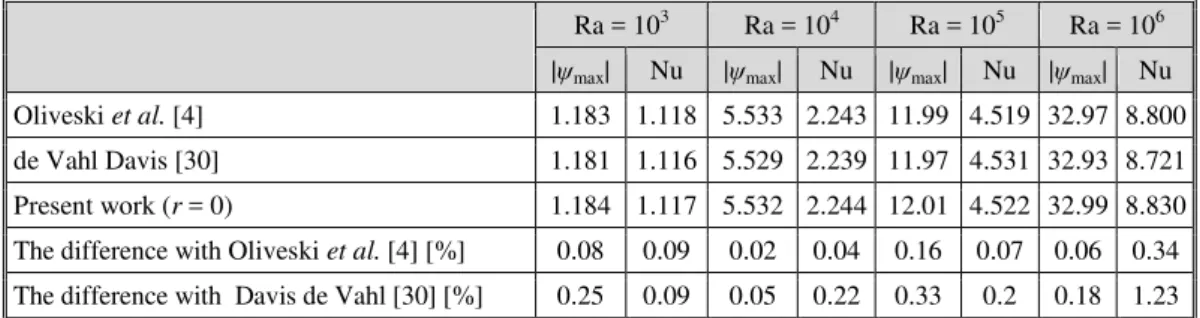

Table 3. The comparison of averaged Nusselt number of present study with others

Results and discussion

Entropy generation, due to natural convection in a rectangular cavity with cir-cular corners filled by Cu-water nanofluid is numeri-cally studied for a range of solid volume fraction [29,

32] (0 ≤ ϕ≤ 0.1), Rayleigh number (103≤ Ra ≤ 106), aspect ratio (1 ≤ A≤ 4), irreversibility coefficient (10–4≤ φ≤ 10–2), and corner radius (0 ≤ r≤ 0.5).

Figure 4 shows the effects of different Rayleigh numbers and corner radii on iso-therms. Isotherm lines are parallel whenever Rayleigh number is 1000 which mean conduc-tion is dominant. When Rayleigh number increases, the isotherm lines would be distorted. Dimensionless temperature increased with augmenting Rayleigh number while it decreased with increase of the corner radius. Also two last rows show the percent difference of existing data in table 3 between present paper from Davis de Vahl [30] and Oliveski et al. [4] which show a good accuracy.

Figure 3. Comparision of the U-velocity profile of the present study with those of the other investigators [27-29]

Ra = 106 Ra = 105

Ra = 104 Ra = 103

Nu |ψmax|

Nu |ψmax|

Nu |ψmax|

Nu |ψmax|

8.800 32.97 4.519 11.99 2.243 5.533 1.118 1.183 Oliveski et al. [4]

8.721 32.93 4.531 11.97 2.239 5.529 1.116 1.181 de Vahl Davis [30]

8.830 32.99 4.522 12.01 2.244 5.532 1.117 1.184 Present work (r = 0)

0.34 0.06 0.07 0.16 0.04 0.02 0.09 0.08 The difference with Oliveski et al. [4] [%]

1.23 0.18 0.2 0.33 0.22 0.05 0.09 0.25 The difference with Davis de Vahl [30] [%]

Table 4. The comparison of total entropy generation of present study with others

Ra = 105, φ = 10–4 Ra = 103, φ = 10–2

22.863 4.557

Oliveski et al. [4]

22.863 4.558

Magherbi [31]

22.865 4.559

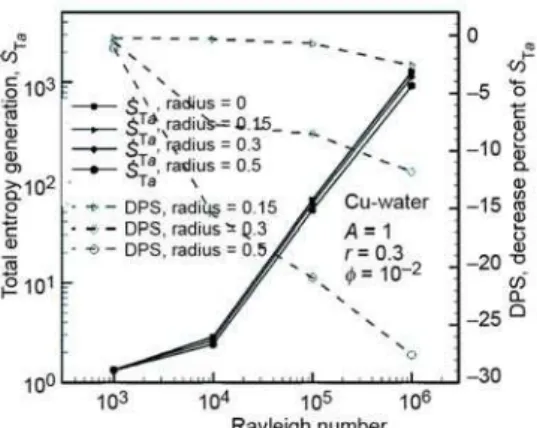

Figure 5 illustrates effects of different corner radii on total entropy generation. As shown in the figure, total entropy generation increased with augmenting Rayleigh number. The behavior of total entropy generation, due to corner radii, was rather vague. For showing the behavior, another co-ordinate system was used, which was located on the right side. This axis was called decrease of percent of STwhich presented the difference between all the cas-es, except first case. Using this axis, it is clear that total entropy generation decreased as corner radius was en-hanced. Figure 6 presents effects of different solid vol-ume fractions on total entropy generation. Total entropy generation increased by augmenting solid volume frac-tion. The right axis was called increase of percent of ST,a

which showed the percent of increase between all the cases, except first case. This behavior was expectable be-cause, by adding more nanoparticles, solid volume frac-tion increased and it was directly proporfrac-tional to total en-tropy generation, as shown in eq. (22).

Figure 7 indicates effects of different irreversibility ratios on total entropy generation. It is obvious that total entropy generation was enhanced as irreversibility ratio augmented. Figure 8 demonstrates effects of different as-pect ratios on total entropy generation. As shown in this figure, total entropy generation in-creased by increasing aspect ratio.

Figure 5. Effects of different corner radii on total entropy generation

Figure 6. Effects of different solid volume fractions on total entropy generation

Figure 9 presents effects of different corner radii on Bejan number. As shown in fig. 8, it is clear that Bejan number decreased by increasing Rayleigh number. Whenever Rayleigh number increased, heat transfer increased; so dimensionless temperature decreased, then it caused Bejan number to decrease. Moreover, using, increase of percent of Bejan number (IPB), it is obvious that Bejan number increased as corner radius was enhanced. Also, the per-cent of this increase was augmented by increasing Rayleigh number. Figure 10 shows that Figure 4. Isotherms for enclosures

Figure 7. Effects of different irreversibility ratios on total entropy generation

Figure 8. Effects of different aspect ratios on total entropy generation

Bejan number increased as solid volume fraction increased. For better understanding, IPB was also depicted. Figure 11 illustrates that Bejan number decreased by boosting irreversibility ra-tio. Figure 12 demonstrates that Bejan number decreased as aspect ratio increased. Whenever aspect ratio increased, Nusselt number increased; so, dimensionless temperature decreased and then caused Bejan number to decrease.

Figure 9. Effects of different corner radii on Bejan number

Figure 10. Effects of different solid volume fractions on Bejan number

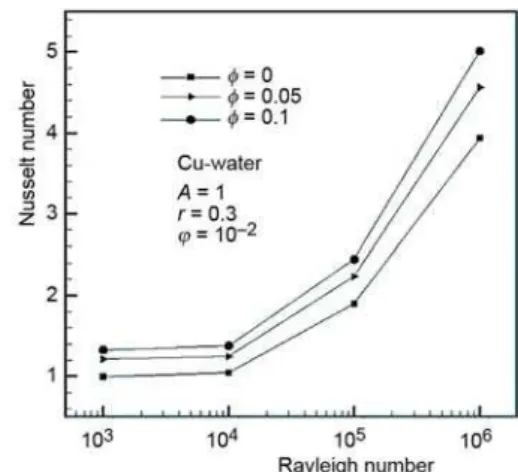

Figure 13 presents effects of different corner radii on Nusselt number. Using de-crease of percent of Nu (DPN), it is clear that Nusselt number dede-creased as corner radius in-creased. The percent of this decreasing was enhanced by augmenting Rayleigh number. Fig-ure 14 shows that Nusselt number increased whenever solid volume fraction was augmented. In fig. 15, effects of different aspect ratios on Nusselt number is depicted. Nusselt number was boosted by increasing aspect ratio.

Conclusions

• Total entropy generation increased by augment-ing Rayleigh number, irreversibility coeffi-cient, aspect ratio or solid volume fraction while it decreased with the increase of corner radius. It should be noted that the best way for minimizing entropy generation is decreasing Rayleigh number. This is the first priority for minimizing entropy generation. The other pa-rameters such as radius, volume fraction, etc.

are placed on the second priority.

• Bejan number was enhanced by augmenting corner radius or solid volume fraction while it decreased by boosting Rayleigh number, irre-versibility coefficient or aspect ratio.

Figure 12. Effects of different aspect ratios on Bejan number

Figure 11. Effects of different irreversibility ratios on Bejan number

Figure 14. Effects of different solid volume fractions on Nusselt number

Figure 13. Effects of different corner radii on Nusselt number

• Nusselt number was an increasing function with the increase in Rayleigh number, solid volume fraction or aspect ratio while it was a decreasing function whenever corner radius was enhanced.

• The percent of decreasing of total entropy generation and Nusselt number and the percent of increasing of Bejan number via corner radius increased by augmenting Rayleigh ber. Stream function and dimensionless pressure increased by augmenting Rayleigh num-ber while dimensionless temperature decreased. However, by boosting corner radius, stream function and dimensionless pressure were a decreasing function while dimension-less temperature was an increasing one.

Nomenclature

A – aspect ratio, (= H/L) Be – Bejan number, (=Sl, , ha /Sl,a) Cp – specific heat, [Jkg–1K–1]

d – diameter, [m]

g – gravitational acceleration, [ms–2] H – height of cavity, [m]

h – heat transfer coefficient, [Wm–2K–1] k – thermal conductivity, [Wm–1K–1] L – length of cavity, [m]

Nu – Nusselt number

P – dimensionless pressure (=p p U/ nf 02) Pr – Prandtl number (vf/αf)

p – pressure, [Pa]

Ra – Rayleigh number (= gBfL3ΔT/vfαf)

r – dimensionless radius [–] S – entropy generation, [Wm–3K–1] T – temperature, [K]

To – bulk temperature, [K]

U, V – dimensionless velocity components (= u/U0, v/U0)

u, v – velocity components in x-, y-directions, [ms–1]

X, Y– dimensionless co-ordinates (= x/H, y/H)

x, y– Cartesian co-ordinates, [m] Greek symbols

α – thermal diffusivity, (= k/ρCp), [m2s–1]

� – thermal expansion coefficient, [K–1]

θ – dimensionless temperature, [= (T – Tc)/(Th – Tc)] μ – dynamic viscosity, [kgm–1s–1]

� – kinematic viscosity, (μ/ρ), [m2s–1]

ρ – density, [kgm–3]

� – solid volume fraction

φ – irreversibility, {(μT0/k)[α/L(Th – Tc)]2} ψ – stream function

Subscripts

a – dimensionless c – cold f – pure fluid h – hot l – local nf – nanofluid p – solid particle T – total

References

[1] Bejan, A., A Study of Entropy Generation in Fundamental Convective Heat Transfer, ASME J. Heat Transfer, 101 (1979), 4, pp. 718-725

[2] Abu-Hijleh, B. A. K., et al., Numerical Prediction of Entropy Generation due to Natural Convection from a Horizontal Cylinder, Energy, 24 (1999), 4, pp. 327-333

[3] Zahmatkesh, I., On the Importance of Thermal Boundary Conditions in Heat Transfer and Entropy Gen-eration for Natural Convection Inside a Porous Enclosure, Int. J. Therm. Sci., 47 (2008), 3, pp. 339-346 [4] Oliveski, D. C., et al., Entropy Generation and Natural Convection in Rectangular Cavities, Applied

Thermal Eng., 29 (2009), 8-9, pp. 1417-1425

[5] Salari, M., et al., Numerical Study of Entropy Generation for Natural Convection in Rectangular Cavity with Circular Corners, Heat Transfer Engineering, 36 (2014), 2, pp. 186-199

[6] Khanafer, K., et al., Buoyancy Driven Heat Transfer Enhancement in a Two-Dimensional Enclosure Uti-lizing Nanofluids, Int. J. Heat Mass Trans., 46 (2001), 19, pp. 3639-3653

[7] Aminossadati, S. M., Ghasemi, B., Natural Convection Cooling of a Localized Heat Source at the Bottom of a Nanofluid-Filled Enclosure, European Journal of Mechanics-B/Fluids 28 (2009), 5, pp. 630-640 [8] Ghasemi, B., Aminpssadati, S. M., Periodic Natural Convection in a Nanofluid-Filled with Oscillating

Heat Flux, International Journal of Thermal Science 49 (2010), 1, pp. 1-9

[10]Mahmoudi, A. H., et al., Numerical Study of Natural Convection Cooling of Horizontal Heat Source Mounted in a Square Cavity Filled with Nanofluid, Int. Comm. Heat Mass Transfer, 37 (2010), 8, pp. 1135-1141

[11]Alloui, Z., et al., Natural Convection of Nanofluids in a Shallow Cavity Heated from Below, Int. J. Therm. Sci., 50 (2011), 3, pp. 385-393

[12]Sheikhzadeh, G. A., et al., Natural Convection of Cu-Water Nanofluid in a Cavity with Partially Active Side Walls, Eur. J. Mech. B/Fluids 30 (2011), 2, pp. 166-176

[13]Mahmoudi, A. H., et al., Modeling of Conjugated Heat Transfer in a Thickwalled Enclosure Filled with Nanofluid, Int. Commu. Heat Mass Trans., 38 (2011), 1, pp. 119-127

[14]Feng, Y., Kleinstreuer, C., Nanofluid Convective Heat Transfer in a Parallel-Disk System, Int .J. Heat Mass Trans., 53 (2010), 21, pp. 4619-4628

[15]Li, J., Kleinstreuer, C., Entropy Generation Analysis for Nanofluid Flow in Microchannels, J. Heat Trans., 132 (2010), 12, pp. 122401.1-122401.8

[16]Singh, P. K., et al., Entropy Generation due to Flow and Heat Transfer in Nanofluids, Int. J. Heat Mass Transfer, 53 (2010), 21, pp. 4757-4767

[17]Mahmoudi, A. H., et al., Entropy Generation Due to Natural Convection in a Partially Open Cavity with a Thin Heat Source Subjected to a Nanofluid, Num. Heat Transfer, Part A, 61 (2012), 4, pp. 283-305 [18]Mahian, O., et al., Analysis of Entropy Generation between Co-Rotating Cylinders using Nanofluids,

Energy, 44 (2012), 1, pp. 430-446

[19]Mahian, O., et al., Design of a Vertical Annulus With MHD Flow using Entropy Generation Analysis, Thermal Science, 17, (2013), 4, pp. 1013-1022

[20]Selimefendigil, F., Oztop, H. F., Effect of an Adiabatic Fin on the Mixed Convection Heat Transfer in a Square Cavity with Two Ventilation Ports, Thermal Science,18, (2014), 2, pp. 377-389

[21]Mahian, O., et al., A Review of Entropy Generation in Nanofluid Flow, International Journal of Heat and Mass Transfer, 65, (2013), Oct., pp. 514-532

[22]Salari, M., et al., Mixed Convection of Nanofluid Flows in a Square Lid-Driven Cavity Heated Partially from Both the Bottom and Side Walls, Num. Heat Transfer, Part A, 62 (2012), 2, pp. 158-177

[23]Brinkman, H. C., The Viscosity of Concentrated Suspensions and Solution, J. Chemical Physics 20 (1952), 4, pp. 571-581

[24]Abu-Nada, E., Chamkha, A. J., Effect of Nanofluid Variable Properties on Natural Convection in Enclo-sures, International Journal of Thermal Science, 49 (2010), 3, pp. 479-491

[25]Bejan, A., Entropy Generation through Heat and Fluid Flow, Wiley, New York, N. Y., USA, 1982 [26]Patankar, Von S. V., Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Corporation,

McGraw Hill Book Company, New York, N. Y., USA, 1980

[27]Abu-Nada, E., Chamkha, A. J., Mixed Convection Flow in a Lid-Driven Inclined Square Enclosure Filled with a Nanofluid, Eur. J. Mech. B/Fluids, 29 (2010), 6, pp. 472-482

[28]Iwatsu, R., et al., Mixed Convection in a Driven Cavity with a Stable Vertical Temperature Gradient, Int. J. Heat Mass Trans., 36 (1993), 6, pp. 1601-1608

[29]Khanafer, K., Chamkha, A. J., Mixed Convection Flow in a Lid-Driven Enclosure Filled with a Fluid-Saturated Porous Medium, Int. J. Heat Mass Trans., 42 (1999), 13, pp. 2465-2481

[30]Davis, de Vahl G., Natural Convection of Air in a Square Cavity: a Bench Mark Numerical Solution, Int. J. Num. Methods Fluids, 3 (1983), 3, pp. 249-264

[31]Magherbi, M., et al., Entropy Generation at the Onset of Natural Convection, Int. J. Heat and Mass Trans., 46 (2003), 18, pp. 3441-3450

[32]Oztop, H. F., et al., Computational Analysis of Non-Isothermal Temperature Distribution on Natural Convection in Nanofluid Filled Enclosures, Science Direct, Superlattices and Microstructures, 69 (2011), 4, pp. 453-467

![Table 1. Thermo-physical properties of water and nanoparticles [22]](https://thumb-eu.123doks.com/thumbv2/123dok_br/18247198.341870/3.892.151.743.385.477/table-thermo-physical-properties-water-nanoparticles.webp)