various

thermomechanical

processing

Mohammad

Masoumi

∗,

Cleiton

Carvalho

Silva,

Hamilton

Ferreira

Gomes

de

Abreu

FederalUniversityofCeará,DepartmentofMetallurgicalandMaterialsEngineering,CampusdoPici,Bloco729CEP60.440-554,Fortaleza,Ceará,Brazila

r

t

i

c

l

e

i

n

f

o

Articlehistory:

Received29January2016

Receivedinrevisedform3May2016 Accepted4May2016

Availableonline4May2016

Keywords: API5LX70steel Crystallographictexture Thermomechanicalprocessing Hydrogen-inducedcracking

a

b

s

t

r

a

c

t

Inthisstudyathermomechanicalprocessingwassuggestedtoimprovethehydrogen-inducedcracking (HIC)resistanceinX70pipelinesteel.Proposedthermomechanicaltreatmentproducedfavorable crys-tallographictexturesandsignificantlyincreasedHICresistancewhichisofgreatinteresttopetroleum industry.TheresultsshowedthatthehighanglegrainboundariesandKernelparametervaluesactedas hydrogen-trappingsites,leadingtoincreasedHICsusceptibility.HighestHICresistancewasobtainedin samplerolledisothermallyat850◦C,duetothehighproportionofgrainsorientedwith{110}planes

par-alleltothenormaldirectionand{111}//NDfibersaccompaniedbynegligiblefractionofgrainsoriented in{001}//ND.

©2016ElsevierLtd.Allrightsreserved.

1. Introduction

The continuously increasing demand for crude oil and gas requiresthesteelmakingindustrytoimprovethecorrosion resis-tanceinharshandaggressiveenvironments.Lowcarbonsteelsfor sourservicepipingarewidelyusedfortransportationofnatural gasandcrudeoilacrosslongdistancesbecauseofthelowalloying elementscontent,economicmanufacturingandeasyinstallation

[1–3].Stresscorrosioncracking(SCC)andhydrogen-induced crack-ing (HIC), are considered as the main damage modes in the sourenvironment[4–6]andcauseaconsiderableamountof eco-nomiclosstothepetroleumindustry.Therefore,manystrategies havebeenproposedtoreduceHICsusceptibilityincludingadding micro-alloying elements such as titanium, niobium and vana-dium,decreasingsulphurandphosphoruscontents,controllingthe morphologyofmanganesesulphides,removingprecipitationand segregationzonesduring solutionheat treatmentand reducing thenumberof hydrogentrapping [7–9].However,these strate-gieshavenoteffectivelysucceededtocontrolHICsusceptibility. Therefore,crystallographictextureandgrainboundary distribu-tionsengineeringseemstobealogicalstepforenhancementof HICresistance.

∗Correspondingauthor.

E-mailaddress:mohammad@alu.ufc.br(M.Masoumi).

Grainsorientedin preferredcrystallographicorientationthat develop during manufacturing process can influence both the mechanical properties and theHIC resistance. The textureof a rolledsheetisrepresentedbyacombinationofcrystallographic planeanddirection{hkl}<uvw>,whichmeansthat{hkl}arethe planesparalleltotherollingplaneandthe<uvw>arethe direc-tionsparalleltotherollingdirectionwhichisshowninFig.1[10]. Venegaset al. [11,12]studied influence of textureonHIC sus-ceptibilityinAPIX46steel.Theyshowedthatthepreferredgrain orientedwithplane{111}paralleltonormaldirection({111}//ND) produced viawarmrollingbellowrecrystallisationtemperature increasedtheHICresistance.Ghosh etal.[13]reportedthatthe cleavage{001}//NDgrainsgeneratedduringrollingathigh tem-peraturebyrescrystallisationofaustenitegrainsfollowedbyferrite transformation,provideaneasycrackpathandreducesignificantly boththemechanicalpropertiesandtheHICresistance.Verdejaetal.

[14]documentedthatthecrystallographictexturesassociatedwith {110}//NDand{332}//NDreducethesensitivitytoHICin ferritic-pearliticsteels,while{001}//NDand{112}//NDtextureshavethe oppositeeffect.Recently,Mohtadi-Bonabetal.[15–17]reported that there is no preferred directionfor hydrogencrack propa-gation,andthat crackcanpropagatealongvariousorientations. However,differentfactorssuchasgrainorientation,grain bound-arydistributions,specialcoincidencesitelattice(CSL)boundaries, and distributionofrecrystallisedgrainsplay significantrolesin HICresistancebyprovidinggoodlatticefitwithlowstoredenergy ahead of thecrack tip [18,19]. It is worth mentioningthat the

Fig.1.Schematicrepresentationofcrystalorientationwithrespecttosampleaxes [10].

crystallographictextureinterpretationisnotstraightforwardand afundamentalunderstandingofcorrosionisrequired.

Inthepresentwork,firstlymicrostructureandmicrotexturein thevicinityofhydrogeninducedcracks,inaplatetakenfroman in-servicesourgaspipelinewereexaminedtofindacorrelation betweencrackpropagationandcrystallographictextures.Then,a similarmaterialwithcomparablechemicalcompositionwascut andsubjectedtothermomechanicalprocessingwithvarious fin-ishrollingtemperaturestoproduceasimilarmicrostructurewith differentcrystallographictextures. Then, tostudytheeffects of differentthermomechanicalprocessingonmicrostructure, macro-textureandmicrotexturewereinvestigatedbyscanningelectron microscopy (SEM), X-rayenergy dispersive spectroscopy (EDS), electronbackscatterdiffraction(EBSD),andX-raydiffraction(XRD). Finally,electrochemicalhydrogenchargingtestswerecarriedout toshowtheHICresistanceimprovementviaappropriate thermo-mechanicalprocessing.

2. Experimentalprocedure

AnAPI5LX70platewastakenfromanin-servicepipelinewhich wasusedforabout20yearsforsourgastransportationand con-tainedseveralhydrogeninducedcracks.Thechemicalcomposition ofthissamplewas0.105C,1.664Mn,0.018P,0.006Sand0.204Si (wt.%).Inaddition,anothersimilarplatewithcomparablechemical composition(0.099C,1.604Mn,0.014P,0.011Sand0.180Si(wt.%)) wascutfroma9mmplateandthensubjectedtofourdifferent thermomechanicalprocessingroutes,asshowninFig.2.

Inordertodissolve inclusionsand eliminateprobable segre-gationzones,thesamplesweresolutionannealedat1200◦Cfor

onehour.Then, thesampleswererolledina Stanatmodel TA-315rollingmachinewith273rpmrotationalspeed,inthreepasses toreachthe3mmthickness(9mm→7mm→5mm→3mm), fol-lowedbyaircoolingtoroomtemperature.Temperaturetracking during the rolling operation was carried out by Minolta/Land Cyclops152InfraredThermometer.Itisworthmentioningthatthe mainideaforthedifferentstartandfinishrollingtemperatures, lowerthantherecrystallisationtemperature(inbothausteniteand austenite-ferriteregions),wastoobtainasimilarmicrostructure withdifferentcrystallographictextures.

Microstructuralstudieswerecarriedoutalongthecrosssection (RD-ND)onallsamples.Therolledsampleswerepreparedfor met-allographicanalysisbygrindingwithSiCpapersupto1200gritand thenpolishingwith6,3and1mdiamondpaste.Finally,the spec-imenswereetchedwith2%nitalsolutionforapproximately40s andexaminedusingSEM.Also,themicro-hardnesstestwas per-formedbasedontheASTME-384standardalongthemid-thickness ofspecimenswith4.903Nindentationloadfor15s(HV0.5).

Macrotexturesweremeasuredinmid-thicknessalongthe RD-TDsections(rollingplane).Thesestudieswereperformedusing PanalyticalX’PertProdiffractometerequippedwithCuradiation

sourceandtexturegoniometer.Threeincompletepolefigures,i.e. {110},{200}and{211}wereobtainedinthereflectionmodeona 5◦gridupto85◦sampletilt.Theorientationdistributionfunction

(ODF)ofsampleswascalculatedfromthemeasuredpolefigures usingMTEX-freeandopensourcesoftwaretoolbox.The2=45◦

sectionofEulerspacewasusedtodisplay thecomputed ODFs. Moreover,electronbackscattereddiffraction(EBSD)analysiswas conductedintheRD-NDplaneofinvestigatedsamplesusingFEI Quanta FEG 450 scanning electron microscope operating at an accelerationvoltageof20kV,sampletiltangleof70◦,working

dis-tanceof12mmand0.5mstepsize.TheChannel5softwareand MTEXwereusedtoanalyseanddisplaythedata.

InordertoestimatetheHICresistance,twospecimensofeach sheetwerepreparedfromthemid-thicknessregion,consideredas themostsusceptibleareatoHIC,andweresubjectedtothe elec-trochemicalhydrogenchargingtest.Thesamplesweregroundup to1200grit paper,and then polishedwith 6,3 and 1m dia-mondpastetoeliminate flux-limitingsurface impedances[20]. 0.2Msulphuricacidsolutionwasusedforhydrogencharging,in theelectrochemicalhydrogen-chargingtest.Moreover,toprevent theformationofhydrogenbubblesonthesurfaceofthespecimen andtoincreasetheamountofhydrogenenteringthesteel,3g/l arsenictrioxide(As2O3)wasaddedtothesolution.Eachsample

wasthenelectrochemicallychargedfor6hwithaconstantcurrent of20mA/cm2.

3. Resultsanddiscussion

3.1. MicrostructureofHICsample

The in-servicesour material with severalhydrogen-induced crackspresentedapearlite/ferritebandedmicrostructure.The typ-icalstepwisehydrogencrackpropagationisshowninFig.3aandb andisorientedparalleltotherollingdirection,besidessome deflec-tiontowardsthenormaldirection.Therewasnosegregationzone foundin thesample bySEMandEDS analysis.However, differ-enttypesof inclusionswerefoundinthevicinityofthecracks. Somecomplexcarbonitrideprecipitatessuchas(Ti,Nb,V)(C,N) wereidentified byEDS. As shown in Fig. 3,the ferrite/pearlite phaseboundariesalsoenhancedthecrackspread.Micro-hardness measurementsintwodifferentregions(withandwithoutcracks), demonstratedthesignificanthardnessvariation.Thehardnesswas measuredasabout200±5HVin thenon-crackedregion,while 235±7HVwasmeasuredaroundthecrackedarea,whichindicated acorrelationbetweenhardnessandHICsusceptibility.

3.2. MicrotextureanalysisofHICsample

Fig.4showsthenormaldirectioninversepolefigure(IPF)maps oftheHICcracked sample.Themediumanglegrainboundaries (MAGBs)withamisorientationbetween5and15◦andhighangle

grainboundaries(HAGBs)withmisorientationgreaterthan15◦are

markedasthinandthickblacklines,respectively.Asshowninthe IPFmaps,theHICcrackpropagatedalongtheboundariesrelated tothegrainsorientedwith{001}//NDand{111}//NDfibers,which areindicatedwithredandbluecolours,respectively.Sincethehigh anglegrainboundarieshavehigherinternalenergyincomparison tobothlowandmediumanglegrainboundaries,theywere consid-eredasthemainhydrogentrappingsites,providingeasierpathsfor crackpropagation.

Fig.2.SchematicrepresentationofthermomechanicalprocessingofsamplesA–D.

Fig.3. (a)SEMmicrograph,(b)EDSresultoftheparticleinhydrogencrackpath.

hydrogenatomsrecombinetoformhydrogenmolecules,leadingto greaterinternalpressureinmaterial,thuspromotingcrack nucle-ationandpropagation[21].Inaddition,hardnessplaysasignificant rolein HICsusceptibility.Ontheone hand,accordingthe Hall-Petchrelation[22,23],theyield strengthand hardnessincrease withdecreasinggrainsize,leadingtoincreasedHIC susceptibil-ity.On theotherhand, it isbelieved that thegrainboundaries actas obstaclesto crack propagation.In the samesample also fewverycoarsegrains(around18mindiameter)wereobserved inthevicinityof thecracks(Fig.4aandb).Thesecoarsegrains withlow fractionof grainboundaries canfacilitatecrack prop-agation and increase HIC susceptibility. Therefore, there is an optimum grain size at which maximum HIC resistancecan be achieved.

AlthoughtheIPF orientationmap is anexcellent methodto presentgrainorientation,ithasanunavoidablelimitationinthe Eulerscheme[24].Tocorrectthislimitationandfindacorrelation betweencrackpropagationandgrainorientations,orientation dis-tributionfunctionwascalculatedandshowninFig.5.Thecube texturecomponentwith(001)[0 ¯10] crystallographicorientation wasthedominanttextureintheHICcrackedsample(regionsAand B).Thecubecomponentthatdevelopedundersheardeformation duringthermomechanicalprocessinghasalowabilitytorelease thestressorstrainconcentration.InFig.5aandb,thelow resis-tancecleavagepathwithorientationwithin15◦oftheidealcube

componentisconsideredasthemaincrackpropagationpath.In addition,highdislocationdensitywasgeneratedduring thermo-mechanicalprocessingdistributedalongdifferentslipsystemsand providedmaximumshearstressaheadofcracktip[25,26].Thus, thezigzag-likecrackpropagationobservedinthissampleisrelated totheabovementionedphenomenon.Also,the(112)[3 ¯1 ¯1] compo-nentisobservedinregionCinthevicinityofthecrack.The(112) planeisconsideredasoneofthemainslipplanesintheBCC lat-tice[27].Asmentionedearlier,dislocationisarrangedalongthis slipplaneandprovidessufficientdrivingforceforcrack propaga-tion.

Another parameter to be evaluated is the Kernel average misorientation(KAM)whichrepresentstherelativeaverage mis-orientationbetweenanypointsthatbelongtothesamegrain[28]. KAMdistributionmapsfortheHICcrackedsampleareshownin

Fig.6. AccordingtoRef. [29], hydrogensegregationis localised nearthegrainboundaries,consideredasdislocationaccumulation sites.Ahighaccumulationofgrainswithrelativemisorientation between0.5–2.5◦ is observed. This accumulation suggests that

strain induced during both manufacturing process and service developseasiersitesandpathstocrackformation.Also,theregions nearthehydrogeninducedcracksshowedlowerKernelparameter valuesduetoreleaseofenergyneartothecracktipwhichprovides sufficientdrivingforceforcrackgrowth.Theresultsrevealedthat thecracktendedtopropagatealonggrainswithhighKernel param-etervalues.The highdislocation densityaroundthecrack path permitstheaccumulationofmisorientationsinsidethegrainsand distortionbetweenneighbouringlattices,leadingtoanincreasein HICsusceptibility.

ItisdeducedthattherearethreepossibilitiesforHICcrack prop-agation.Thefirstisthatthecracktendstopropagatethroughthe deformedgrainswithhighstoredenergywheredynamic recrys-tallisationorrecoverydidnotoccur.Thesecondisthatthecrack propagatedalonggrainorientedwith{001}//ND,wherethelack ofsufficientslip systemshasaharmfuleffectonHICresistance. Besides,deformedgrainsorientedwith{111}//NDand{112}//ND withhighdislocationcanalsoprovideeasierpathstocrack prop-agation. Finally, very fine grains can trap more hydrogen and generatemoreinternalenergytofacilitatecracknucleationand propagation.

3.3. Thermomechanicalprocessing

3.3.1. Microstructuralanalysis

Duringthermomechanicalprocessing,thesampleswerefirstly solutiontreatedinafurnaceat1200◦Cforonehour,thenrolled

aboveand below the recrystallisationtemperature (Fig.2), fol-lowed by air cooling. The microstructure of specimens after different thermomechanical processing is shown in Fig. 7. The ferritemicrostructure withpearlite, martensite-austenite (M/A) constituentsandasmallfractionofbainiteisobserved. Further-more,rollingatalowertemperatureinamixtureofausteniteand ferriteregion(sampleA)ledtotheformationoffinergrainsize. Theferriteisresponsibleforincreasedhardeningandthe austen-itetendingtoundergoadditionalhardeningbyrisingnumberof availablesitesforferritenucleation.Rollingbelowthe recrystallisa-tiontemperaturedevelopedthepancake-shapedaustenitegrains, leadingtoanincrease inthenumber ofnucleationsitesforthe austenite-to-ferritetransitiontoformpolygonalferrite.

Hardnessmeasurementswerecarriedoutatthemid-thickness ofspecimens.Thehardnessincreasedwithdecreasingfinishrolling temperature.ThemeasuredhardnessvaluesinsamplesA,B,Cand Dwere224,211,234and220±5HV0.5,respectively.Accordingto theAPI5LrequirementsforequipmentinseverewetH2Sservice [30],hardnessshallbelowerthan248±6HV(22HRC).Therefore,all specimensmetthehardnessrequirementsoftheAPI5L specifica-tion.Overall,asimilarmicrostructurewasobtainedinallsamples. Thisisessentialhere,becausethedifferentbehaviourofHIC resis-tancecouldbeonlyattributedtothedifferencesincrystallographic texturesproducedviadifferentthermomechanicalprocessing.

3.3.2. Macrotexture

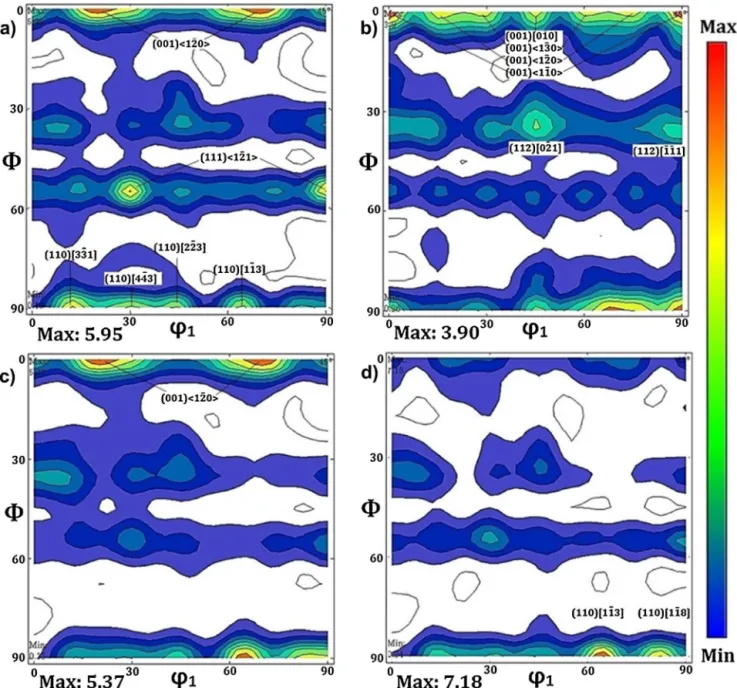

Thecrystallographictextureandgrainboundarydistributionsin fourdifferentthermomechanicalprocessingwerestudiedtofindan appropriatetexturetoattainahigherHICresistance.Fig.8shows theorientationdistributionfunctionat2=45◦intheRD-TDplane

inthesespecimens.(001)<1 ¯20>texturecomponentswithlowHIC resistanceweredevelopedinsampleAduringrecrystallisationin austeniticregionfollowedbyferritetransformation.Also, defor-mationatalowertemperatureinamixtureofausteniteandferrite phasescausedthestrongformationof{111}//NDfiber.However, theshearstraingeneratedbyfrictionbetweentherollsandsurface sheetduringrolling,developedgrainsorientedin{110}//ND direc-tions,whichisshowninFig.8a.Itisworthmentioningthatthe (11)<1 ¯21>texturecomponentsareaconsequenceofthe recrys-tallisationof ferritegrains[31].In addition,thehighesttexture intensityof theODFsbelongs tosampleA, which rolledinthe ferrite-austeniteregion.Raabeetal.[32]showedthatdislocation slidingduringrollingatelevatedtemperature(aboveTm/4)

exten-sivelytookplaceintheBCCstructureonthe{110}and{112}planes, leadingtodecreasingtheintensityofcrystallographictexture.

The cleavage {001}//ND texture components including (001)[0 ¯10],(001)<1 ¯30>,(001)<1 ¯20>and(001)<1 ¯10>were devel-oped in sample B, which was rolled at a higher finish rolling temperature(833◦C),couldbe attributedtorecrystallisation of

austenitefollowedbyferritetransformation.Thepresenceofthese texturesincreasesthenumberofpossiblecrackpropagationsand HICsusceptibility[8].Also, theformationof{112}//ND compo-nents,thatdominatethe(112)[0 ¯21]and(112)[ ¯1 ¯11]orientations, wasobservedinthiscondition.Singhetal.[33]reportedthatthe shearstrainduringplasticdeformationintheaustenitephasecan developthe(112)[1 ¯10]componentdue toitslowstacking fault energy. Then, dynamic recrystallisation and austenite toferrite phase transformation led to the formation of grains with the (112)[0 ¯21]orientation.It isnotablethattheplasticdeformation oftheFCCaustenitephaseoccursbysliportwinningsystem.Hu

Fig.5.Calculatedtexturecomponentsatconstant2=45◦orientationdistributionfunctionsectionfromthreedifferentregionsshowninFig.4.

orientationismostlyrelatedtothetwinningsystem,becauseof lowcrystalsymmetry.Furthermore,thecrystallographictexture in sample C was similar tosample B, but theintensity of the {112}//ND fiber decreased at low finish rolling temperature (737◦C).Interestingly,theisothermalrollingat850◦C(sampleD)

couldhinderthedevelopmentofundesirable{001}//ND compo-nents.The(110)[1 ¯13]texturecomponentwithaspreadtowards theGosscomponentwith(110)[001]orientationwasdominantin sampleD.

Itwasdemonstratedthatthecrystallographicorientationcan improve theHIC resistanceby well-development of {111}//ND and {110}//ND textures, and reducing the number of cleavage {001}//NDcomponents[8].Fig.9presentstheorientationvolume fraction(f(g))offibercomponentssuchas{001},{112},{111},and {110}//NDcalculatedbyMTEXsoftwarewitha2.5◦deflection.For

thepurposeoftexturaldesign,thebestresistanceagainstcrack propagationresultsinminimisingthe{001}cleavageplanesthat areorientedparalleltothenormal direction,andincreasingthe desirable{110},{111}and{112}//NDfibercomponentsthatare closetothecompactplanes.Theformationofstrongcovalentbonds betweentwolatticeslinkedtogetherbyclose-packedplaneleads toobstaclestocrackpropagation,andincreasesHICresistance.As showninFig.9thefirstthreesampleswerenotsuitableforsour

environment,duetothehighvolumefractionofundesired{001} orientedgrains.Incontrast,sampleDpresentedsharp{110}//ND and{111}//NDtexturecomponents,accompaniedbyanegligible volumefractionof{001}//NDorientedgrains,andconsideredtobe suitableforuseinsourenvironment.

3.3.3. Microtexture

AllspecimenswereexaminedbytheEBSDtechniqueinorder to analysecrystallographic orientations, average misorientation angles,grainboundarytypesandTaylorfactor.Theinversepole figure(IPF)mapsofsamplesareshowninFig.10.Itisworth not-ingthatequiaxed,strain-freerecrystallisedgrainssurroundedby highanglegrainboundariesasa resultofhot-rollinghavehigh resistancetocracknucleationandpropagation[35].Conversely, elongatedgrainswithstoredenergyarepronetoHIC.Moreover, thisinhomogeneousmicrostructurecanboosttheHIC susceptibil-ityinthefinalstructure.Thegrainsizeisanotherefficientfactorto controlHICresistance[36].

Thevariousthermomechanicaltreatmentsresultedinawide distributionrangeofgrainorientationsinthespecimens.Rolling atarelativelylowtemperature(i.e.belowAr3)generatedahigher

Fig.6.KernelaveragemisorientationmapinthreedifferentregionsshowninFig.4fromHICsample.

Fig.7.SEMmicrographsshowingmicrostructureofspecimensafterdifferentthermomechanicalprocessing(a)sampleA,(b)sampleB,(c)sampleCand(d)sampleD.

energy which facilitates HICcracking. Furthermore,for sample Bthatwasrolledata relativelyhightemperature(aboveTm/2),

thedegreeof deformationdecreased by recrystallisation inthe austenitephase.Dynamicrecrystallisationtookplaceinthis sam-plegeneratedtheundesirable(001)[0 ¯10]cubetexturecomponent,

Fig.8.Texturecomponentsatconstant2=45◦orientationdistributionfunctionsectionin(a)sampleA,(b)sampleB,(c)sampleCand(d)sampleD.

(112)[2 ¯41]and(110)[1 ¯11]texturecomponentsweredevelopedby isothermallyhotrollingat850◦C(sampleD).

TheanalysisofEBSDmapsledtootherinteresting microstruc-turalinterpretationsregardingthedifferencesofgrain-boundary angles between adjacent grains. The volume fraction of low, mediumandhighanglegrainboundariesforbothHICcrackedand thermomechanically processed specimens was calculated using MTEXsoftwareandisshowninFig.11.Itisclearlyobservedthatthe highstoredenergyasconsequenceofalargefractionofhighangle grainboundariesinHICcrackedsampleledtoincreasingtheHIC susceptibility.Inotherwords,HICresistancedependsonthe abil-ityofmicrostructureandprecipitatestotraphydrogen.Thehigh anglegrainboundarieswithhighdisorderbetweenneighbouring grainsandhighdensityofdislocationsandvacanciesare consid-eredaseffectivehydrogentrappingsites.Itisalsobelievedthat highangleboundarieswithhighlatticedistortionandhighstored energyprovideaneasierpathtocrack nucleationand propaga-tion.Therefore,anincreasednumberoflowangleandcoincidence sitelattice(CSL)boundariesarefavorableforimprovementofHIC

resistance.Althoughthermomechanicalprocessingreduced signif-icantlyproportionofhighanglegrainboundaries,therewasno significantchangeobservedinCSLboundaries.Therefore,itwas confirmedthattheHICsusceptibilityincreaseswithincreased pro-portionofhighanglegrainboundaries,anditsfractionwasfound higherinallregionsofHICsample.

Asmentioned earlier,plastic deformationat crystalscalesis consideredbylatticeorientationalongdislocationarrays,canbe observedbyKernelaveragemisorientation.Thefrequencyof Ker-nelparameterdistributionindeferentregionsofHICsampleand TMCP specimens isshown in Fig.12.The highKernel parame-ter valuesbelong toHICsample. It meansthatthehighKernel parametervaluescorrespondtohigherHICsusceptibility. More-over,thepresenceofveryhighKernelparametervaluesexceeding 2.5◦isobservedinHICsample,facilitatehydrogencrack

propaga-tion.SamplesBandDhavemaximumfrequenciesoflowKernel parametervalues(lessthan0.5◦),whichledtohighHICresistance

sam-Fig.9.VolumefractionsoffibercomponentsinspecimensA–Dafterdifferent ther-momechanicalprocessing.

plesBandD,wherenewrecrystallisedgrainswithlowdislocation densitywerenucleated.Inotherwords,therecoveryanddynamic recrystallisationbyannihilationand dislocationrearrangements cansignificantlyreducetheKernelparametervaluesandHIC sus-ceptibility.Therefore, animprovement of HIC resistancein the mentionedspecimensisexpected.

TheTaylorfactor,whichdemonstrates acorrelationbetween yieldstressandcrystalorientationinmetals,isusedtoanalysethe levelofplasticdeformation,showingthedistributionofgrain ori-entation[37,38].Taylorfactoranalyseswereperformedoncracked andthermomechanicallyprocessedspecimens,showninFig.13.

Fig.11.GrainboundarydistributionsinsamplesA–Dinadditiontosamplewith hydrogeninducedcrackswhereLAGBsmeanslowanglegrainboundaries,MAGBs meansmediumanglegrainboundaries,HAGBsmeanshighanglegrainboundaries andCSLmeanscoincidencesitelattice.

Somegrainsthatarealreadyalignedintheloadingdirectioncan easilyslipanddeform,sincethecriticalresolvedshearstress(crss)

isattained.ThesegrainshavealowTaylorfactorvalue.Secondly, thegrains thatare notalready aligned inslip planes regarding stressstate.Thus,thereneedstobesomekindofrotationintoa newpositiontobringoutminimumcrsstoslip.Thesegrainswith

moderateTaylorfactorvaluearecalledsoftgrains.Finally,there aresomegrainsthatcannotrotatetobringtheappropriateslip systems.Therefore,suchgrainsarecalledhardgrains,withahigh

Fig.12.FrequencydistributionofKernelaveragemisorientationinsamplesA–Din additiontoHICsample.

resistancetodeformation,andarehighlypronetocrackformation andpropagation,asindicatedbytheredcolourintheTaylor fac-tormaps.Fig.13displaysthedistributionofTaylorfactorinthe TMCPsamples.Thegrainsindicatedinlightyellowpresenta rela-tivelyeasypathandmightresistcrackpropagation;whereasthose indarkyellowandredarepronetocrackformation. Transgranu-larcrackpropagationoccursthroughthegrainswithhighTaylor factor and dislocation accumulation,while intergranular cracks propagateduetotheTaylorfactormismatchinneighbouringgrains becauseofdifferencesinactiveslipsystems.Thegrainhavingahigh Taylorfactortendstoberesistanttoyielding,thustransgranular crackingisexpected[39].Intergranularcracksoccurredalongcrack propagationpathsbetweenadjacentgrainsidentifiedbydifferent Taylorfactormismatches.

Activeslipsystemsdependonthecrystallographicorientation andthedifferencesoflocalstressneargrainboundariesbetween adjacentgrains[40].Thefrequency distributionof Taylorfactor valuesinTMCPsamplesispresentedinFig.14.SamplesAandD

Fig.14.TaylorfactordistributioninsamplesA–D.

hadlowTaylorvalues.Thismeansthattherewaslessresistanceto dislocationmovement.Ontheotherhand,samplesBandC devel-opedhigh-stressconcentrationnearthegrainboundariesdueto thehighresistanceagainstdislocationmovement,leadingtocrack formationandprovidinganeasierpathforcrackpropagation.In otherwords,grainboundaryslidingisrestrictedbytheir neigh-bouringgrainswithhighlocalstressdifferences,collaboratedby crystallographicorientation.

Fromthementionedcrystallographictextureandgrain bound-ary characteristic investigations,it couldbeconcluded that the sampleDhadthebestHICresistance.Thismeansthatthehighest HICresistanceresultsinsampleD,whichwasrolledisothermally at850◦C,duetothesharp{110}and{111}texturecomponents

accompaniedbythenegligiblevolumefractionofgrainsoriented with{001}//ND.Also,alargeamountoflowanglegrain bound-arieswithlittlelatticedistortionandlowstoredenergywiththe leastTaylorfactor andKernel parametervalues providedlower traphydrogensites.Finally,toascertaintheroleofcrystallographic textureandgrainboundarycharacteristics,sampleCandDwere

Fig.15.SEMmicrographsofelectrochemicallycharged(a)sampleC,(b)sampleD.

selectedtoconductanelectrochemicalhydrogencharging exper-iment.Fig.15ashowstheHICcrackpropagationinthesampleC after6h.ThesampleDshowedhighresistancetocrackformation, andnoHICcrackswerefoundinthecrosssectionofthissample afterhydrogencharging(Fig.15b).Thissupportsthehypothesis ofbeneficialeffectsofcrystallographictextureonHICresistance. Experimentaldataobtainedinthisworkcanbeusedtoenhance accuracyofnumericalmodels[41,42].

4. Conclusions

Inthiswork,severalanalyseswereusedtoidentifytheeffectsof microstructure,precipitations,andcrystallographicorientationon HICsusceptibility.Then,theinfluenceofdifferent thermomechan-icaltreatmentsonmicrostructure,macro-andmicrotexturewere studied.Finally,anelectrochemicalhydrogenchargingexperiment wasperformedtoverifythehypothesisofbeneficialeffectsof crys-tallographictextureonHICresistance.Thefollowingconclusions canbedrawn:

1.HICcracks propagated not only through {001}//NDoriented grains,butalsoalongthegrainsorientedwith{111}//ND. 2.Thehighdislocationdensityaroundthecrackpropagationpath

permitstheaccumulationofmisorientationsinsidethegrains,or distortionbetweenneighbouringlattices,leadingtoan improve-mentinHICsusceptibility.

3.Grainboundary distributionplayed a significantrole in HIC susceptibility. High angle grain boundaries and high Kernel parametervaluesactedashydrogen-trappingsites,leadingto increasingtheHICsusceptibility.

4.ApoorresistancetoHICwasattributedtothepresenceofstrong {001}//NDtexturecomponents.Conversely,areductioninits volumefractionand developmentof desired texture compo-nentsimprovedHICresistance.

5.Therecoveryanddynamicrecrystallisationbyannihilationand dislocationrearrangementscansignificantlyreducetheKernel parametervaluesandHICsusceptibility.

6.ThehighestHICresistanceresultsinsampleD,whichwasrolled isothermallyat850◦C,duetothesharp{110}and{111}

tex-turecomponentsaccompaniedbythenegligibleproportionof {001}//NDorientedgrains.

Acknowledgements

TheauthorsacknowledgetheBrazilianresearchagenciesCNPq andCAPEs,theresearchboardoftheFederalUniversityofCearáfor thefinancialsupportandLaboratóriodeCaracterizac¸ãode Mate-riais(LACAM)andAnalyticalCenter(CT-INFRA/MCTI-SISNAD)for theprovisionofresearchfacilitiesofthiswork.

References

[1]R.A.Carneiro,R.C.Ratnapuli,V.F.C.Lins,Theinfluenceofchemical compositionandmicrostructureofAPIlinepipesteelsonhydrogeninduced crackingandsulfidestresscorrosioncracking,Mater.Sci.Eng.A357(2003) 104–110.

[2]L.W.Tsay,Y.C.Chen,S.L.I.Chan,Sulfidestresscorrosioncrackingandfatigue crackgrowthofweldedTMCPAPI5LX65pipe-linesteel,Int.J.Fatigue23 (2001)103–113.

[3]V.F.C.Lins,M.L.M.Ferreira,P.A.Saliba,CorrosionresistanceofAPIX52carbon steelinsoilenvironment,JMR&T1(2012)161–166.

[4]Y.Sun,H.Fujii,H.Imai,K.Kondoh,Suppressionofhydrogen-induceddamage infrictionstirweldedlowcarbonsteeljoints,Corros.Sci.94(2015)88–98. [5]M.Stipaniˇcev,O.Rosas,R.Basseguy,F.Turcu,Electrochemicaland

fractographicanalysisofMicrobiologicallyAssistedStressCorrosionCracking ofcarbonsteel,Corros.Sci.80(2014)60–70.

[6]Z.Y.Liu,X.G.Li,C.W.Du,L.Lu,Y.R.Zhang,Y.F.Cheng,Effectofinclusionson initiationofstresscorrosioncracksinX70pipelinesteelinanacidicsoil environment,Corros.Sci.51(4)(2009)895–900.

[7]A.Ikeda,T.Kaneko,Y.Ando,Ontheevaluationmethodofsulfidestress crackingsusceptibilityofcarbonandlowalloysteels,Corros.Sci.27(11) (1987)1099–1115.

[8]K.Matsumoto,Y.Kobayashi,K.Ume,K.Murakami,K.Taira,K.Arikata, Hydrogeninducedcrackingsusceptibilityofhigh-strengthlinepipesteels, Corros.Sci.42(1986)337–345.

[9]D.Hejazi,A.J.Haq,N.Yazdipour,D.P.Dunne,A.Calka,F.Barbaro,Effectof manganesecontentandmicrostructureonthesusceptibilityofX70pipeline steeltohydrogencracking,Mater.Sci.Eng.A551(2012)40–49.

[10]V.Randle,O.Engler,IntroductiontoTextureAnalysis:Macrotexture, MicrotextureandOrientation&Mapping,CRCPress,2009(ISBN-10: 9056992244).

[11]V.Venegas,F.Caleyo,T.Baudin,J.H.Espina-Hernández,J.M.Hallen,Onthe roleofcrystallographictextureinmitigatinghydrogen-inducedcrackingin pipelinesteels,Corros.Sci.53(2011)4204–4212.

[12]V.Venegas,F.Caleyo,T.Baudin,J.M.Hallen,R.Penelle,Roleofmicrotexturein theinteractionandcoalescenceofhydrogen-inducedcracks,Corros.Sci.51 (2009)1140–1145.

[13]A.Ghosh,S.Kundu,D.Chakrabarti,Effectofcrystallographictextureonthe cleavagefracturemechanismandeffectivegrainsizeofferriticsteel,Scr. Mater.81(2014)8–11.

[14]J.I.Verdeja,J.Asensio,J.A.Pero-Sanz,Textureformability,lamellartearingand HICsusceptibilityofferriticandlow-carbonHSLAsteels,Mater.Charact.50 (2003)81–86.

[15]M.A.Mohtadi-Bonab,M.Eskandari,J.A.Szpunar,Texturelocalmisorientation, grainboundaryandrecrystallizationfractioninpipelinesteelsrelatedto hydrogeninducedcracking,Mater.Sci.Eng.A620(2015)97–106. [16]M.A.Mohtadi-Bonab,M.Eskandari,K.M.M.Rahman,R.Ouellet,J.A.Szpunar,

Anextensivestudyofhydrogen-inducedcrackingsusceptibilityinanAPIX60 sourservicepipelinesteel,Int.J.Hydrog.Energy41(2016)4185–4197. [17]M.A.Mohtadi-Bonab,J.A.Szpunar,L.Collins,R.Stankievech,Evaluationof

hydrogeninducedcrackingbehaviorofAPIX70pipelinesteelatdifferent heattreatments,Int.J.Hydrog.Energy39(2014)6076–6088.

[18]M.A.Arafin,J.A.Szpunar,Anewunderstandingofintergranularstress corrosioncrackingresistanceofpipelinesteelthroughgrainboundary characterandcrystallographictexturestudies,Corros.Sci.51(2009)119–128. [19]L.P.M.Santos,M.Béreˇs,I.N.Bastos,S.S.M.Tavares,H.F.G.Abreu,M.J.Gomesda

Silva,Hydrogenembrittlementofultra-highstrength300grademaraging steel,Corros.Sci.101(2015)12–18.

[20]M.A.Mohtadi-Bonab,J.A.Szpunar,S.S.Razavi-Tousi,Acomparativestudyof hydrogeninducedcrackingbehaviorinAPI5LX60andX70pipelinesteels, Eng.Fail.Anal.33(2013)163–175.

[21]N.Yazdipour,A.J.Haq,K.Muzaka,E.V.Pereloma,2Dmodellingoftheeffectof grainsizeonhydrogendiffusioninX70steel,Comput.Mater.Sci.56(2012) 49–57.

ofcoldrolled,ISIJInt.76(8)(1990)1349–1355.

[32]D.Raabe,K.Lucke,G.Gottstein,Textureandmicrostructureofhighpurity tantalum,J.Phys.IVColloque3(1993)523–526.

[33]C.D.Singh,V.Ramaswamy,C.Suryanarayana,Textureevolutioninahot rolledausteniticstainlesssteel,TexturesMicrostruct.13(1991)227–241.

[41]L.Novotn ´y,Simulationofvoidgrowthinductilesteelundermechanical loading,Metalurgija49(2010)416–419(ISSN0543-5846).

![Fig. 1. Schematic representation of crystal orientation with respect to sample axes [10].](https://thumb-eu.123doks.com/thumbv2/123dok_br/15328223.555656/2.918.53.433.85.265/fig-schematic-representation-crystal-orientation-respect-sample-axes.webp)