The Effect of Rapid Microwave Sintering Process on the Electrical Conductivity, Thermal

Conductivity and Mechanical Properties of Al-TiC Composites

Omid Yaghobizadeha*, Maryam Nazaria , Mehri Mashhadib

Received: May 04, 2018; Revised: August 06, 2018; Accepted: August 29, 2018

In this research, electrical conductivity, thermal conductivity and mechanical properties of the Al-TiC composites which were sintered via microwave-assisted process were investigated. The specimens were sintered for 3, 5 and 8 minutes. The results have shown that the sample which contains 4 vol. % TiC and was sintered for 8 minutes, has the highest electrical and thermal conductivities among the other obtained ones. Besides that, the sample which contains 8 vol. % TiC and was sintered for 3 minutes, has dedicated the highest hardness and density to itself. Scanning electron microscopy (SEM) micrographs have illustrated that by increasing the amount of TiC up to 12 vol. %, the agglomeration of particles occurs. The X-ray diffraction (XRD) investigations have shown that due to the short duration of the sintering process in the microwave method, there is no trace of TiO2 and Al4C3 as pernicious phases. According to the obtained results, it becomes clear that increasing the amount of TiC powder leads to the reduction of electrical and thermal properties of the samples and increasing the sintering duration, leads to the increase of the mentioned properties.

Keywords: Microwave-assisted sintering, electrical conductivity, thermal conductivity, Al-TiC composite, Microstructure.

* e-mail: o.yaghobizadeh@edu.ikiu.ac.ir

1. Introduction

Nowadays, metal matrix composites (MMCs) have caught so many attentions due to their unique properties including high specific modulus, high yield stress, wear resistance and good creep and fatigue properties. These composites have been utilized in so many applications such as aerospace industry, automobile industry, military applications and other high-tech innovations.

Among the light weight alloys, aluminum alloys are one of the best candidates for the fabrication of MMCs1-4. Due to the

supreme features of Al, including low density, proper strength, high thermal and electrical conductivities, good strength and hardness, it can improve the final properties of composites if it be located as the matrix phase. Aluminum alloys have been studied from 1920s and various industries take them into great consideration3. Copper and/or aluminum due to

good thermal conductivity, have been utilized usually as the baseplate of power module, but their CTEs are larger than the CTEs of ceramic substrates or semiconductor materials, so the thermal stress leads to the failure of the components. Although Kovar or Invar have compatible CTEs and good welding capacity, they suffer from low thermal conductivity and high density, Mo-Cu also has high density. Therefore, the aluminum-matrix composites which are reinforced with ceramic particles can be appropriate solution for electronic

packaging and thermal management applications due to high thermal conductivity, compatible CTEs and light weight5.

Besides the features of the utilized matrix, one of the crucial factors which affects the mechanical and physical properties of such composites are the type of the utilized reinforcement and the chemical interaction between the reinforcement and matrix6. Various types of ceramic reinforcements have been

used as the reinforcement phase in the aluminum-matrix composites such as oxides (Al2O3, Y2O3), nitrides (Si3N4, AlN), carbides (TiC, SiC), hydrates (TiH2) and borides (TiB2)7,8. Among the mentioned reinforcements, TiC is one

of the best choices, because has unique properties like low density, high hardness, good wettability and negligible tendency to react with Al9.

Casting routes10, powder metallurgy11, in situ synthesis12

and spray forming 13 have been utilized for the fabrication

of AMCs. Each of these methods has its own advantages and disadvantages. For example, the casting route is an economical method, however non-uniform distribution of the reinforcement phase and interfacial reactions are the main disadvantages of it14-19.

Among the press-based methods, powder metallurgy is one of the most popular ones. Reduction of the probable chemical reactions between the matrix and the reinforcement during the fabrication process, uniform distribution of the reinforcement particles in the matrix, good tailoring and requiring inexpensive and available facilities are the main privileges of this method compared to the others.

aDepartment of Materials Engineering, Imam Khomeini International University, Qazvin, Iran

bFaculty of Materials and Manufacturing Engineering, Malek Ashtar University of Technology, Tehran,

One of the stages of fabrication via traditional PM is sintering. As it’s known, in order to gain high density and reach to the culmination of properties, the shaped samples must be sintered at optimum conditions. Inadequate sintering temperature and duration lead to the remaining of the porosities in the structure and eventually the deterioration of the properties. On the other side, increasing the sintering temperature and duration lead to the increased probability of the reactions which can occur between the reinforcement and the matrix. Also, the obtained coarse grains deteriorate the properties of the final composite5,9.

Microwave-assisted sintering method is a novel sintering route which is fundamentally different with the traditional sintering processes. In traditional sintering methods, the sintering driving force is supplied through external elements (resistance heating) and the radiation of them reaches to the sample via conduction and convection mechanism. But in Microwave-assisted sintering process, the sample absorbs the microwave’s power itself and converts its energy to the heat within the sample volume itself 9. So, by decreasing

the sintering duration, the grain growth is under control and reaching to a uniform microstructure, with the optimized properties is completely possible.

According to the best of the author’s knowledge, no report has been published so far which investigates the thermal and electrical conductivities of the Al-TiC composite fabricated through microwave-assisted sintering method. Therefore, in this current research, the Al-TiC composite is fabricated through microwave-assisted sintering method and the electrical, thermal and mechanical properties of sintered Al-TiC composites have been investigated.

2. Experimental Procedure

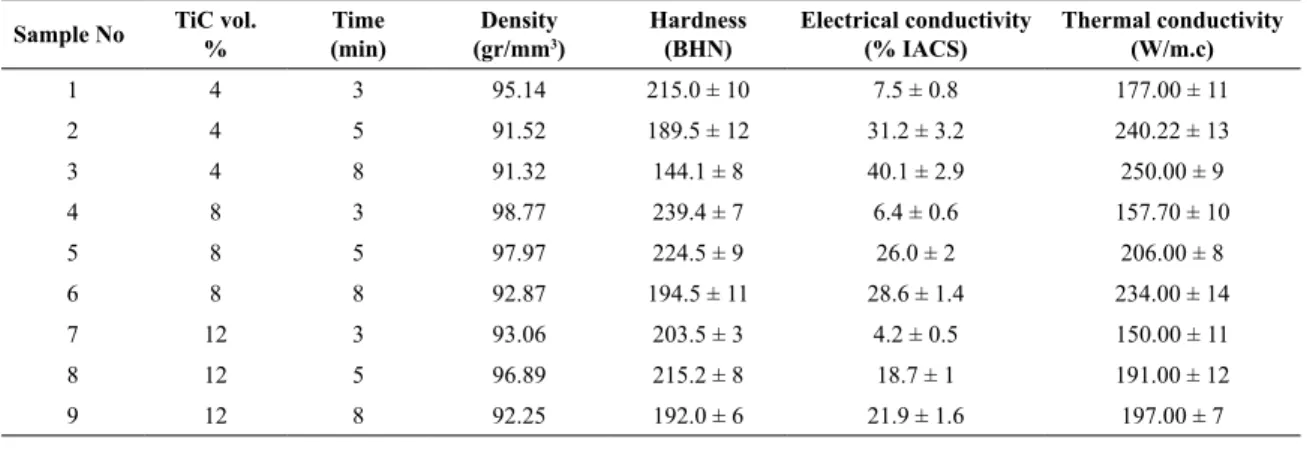

In this research, aluminum powders (Sigma Aldrich, particle size <5 µm, purity: 99.5%) and sub-micron TiC powders (Luoyang Zhengjie Science &Technology Industry Trade Co. Ltd., china, purity: 99.9%) were utilized. In order to investigate the effects of reinforcement’s amount and sintering duration through microwave-assisted sintering process on the electrical, thermal and mechanical properties and also the microstructure of the Al-TiC composites, the samples were prepared according to Table 1 and were sintered through microwave oven. The starting materials were mixed by a planetary ball mill (Retsch PM200, 150 rpm) with the speed of 150 rpm for 1 h in a tungsten carbide cup, under high purity argon atmosphere. The ball: powders ratio was adjusted to 1:10. Then, the suspension was dried at 80/ for 24 hours. The dried and mixed powders were disagglomerated by a 100 mesh sieve and then were pressed by an isostatic press under the load of 120 MPa. Eventually, the samples were embedded at a substrate which contains SiC and graphite and were sintered in a 2.45 GHz microwave furnace for various durations.

After the sintering process, the samples were weighed and their densities were measured according to the Archimedes method. The phase analysis of the samples was conducted via X-ray diffractometry (XRD, X’Pert Pro MPD, PANalytical) via Cu Kα radiation. The microstructure analysis was performed by scanning electron microscopy (SEM, VEGA\\TESCAN-LMU) and also a light microscope which was equipped with a camera (Leica DFC480) and imaging software (Image-Pro MC v6.0). The hardness of the samples was calculated via the Brinell method (GNEHM- SWISS Rock, American) under the load of 30 N and the dwell time of 10 seconds. Electrical resistance of the samples was measured by a 2-point probe method by using a high-resistance meter (model 4339B, Agilent Technologies, Santa Clara, CA, USA).

Thermal conductivity of samples was measured by means of a relative steady-state technique, in an experimental set up (model HT01, Deghat Azma corp). It must be mentioned that all the samples were polished and then etched prior to any analysis. The entire test had been done for 10 times and the average value was reported as the final data for each test. It’s noteworthy that experimental design was carried out via Minitab 14 software.

3. Results and Discussion

The results of the phase analysis of the samples 2 and 8 are illustrated in Fig. 1. Samples contain Al and TiC phases. S. Shimada et al.20 has reported, the oxidation behavior of

TiC in both wet and dry oxygen at 300-400/. Their results have shown that TiC decomposes to TiO2 according to the following equation21,22:

(1)

On the other side, J. Viala23 has also submitted the

following equation for the stability of TiC:

(2)

There are at least two oxygen sources in the microwave-assisted sintering process method: one of them is the entrapped oxygen between Al and TiC particles when the samples pressed and the other is the diffused oxygen to the graphite bed.

The formation of the two phases including Al4C3 and TiO2 not only decreases the mechanical properties of the samples, but also deteriorates the electrical and thermal properties of them.

The Gibbs free energy of the reactions 1 and 2 are shown

in Fig. 2. Although, these reactions are thermodynamically possible, but there is no trace of oxide or intermetallic phase in the composites. The phase analysis of composites (fig. 1) and line scan analysis of interface between matrix and TiC particle for sample 9, confirm this fact (Fig. 3). The

TiC

+

2

O

2=

TiO

2+

CO

2Al

TiC

Al Ti

Al C

shortened sintering duration of this method is the main reason that neither TiO2 nor Al4C3 was formed.

The SEM images and the X-Rays maps of the sample’s surfaces including the samples 4 are illustrated in Figs. 4. The EDS analyses of points 1 and 2 (in fig. 4) are shown in Fig. 5, here white and gray regions belong to TiC and Al phases, respectively. Also, the SEM images and the X-Rays maps of the sample’s surfaces including the samples 7 are illustrated in Figs. 6.

As it’s obvious, the distribution of the reinforcement phase in the samples with 8 vol. % is more uniform and by

increasing its content up to 12 vol. %, their agglomeration is quite visible. As shown in Figs. 4and 6, increasing the amount of reinforcement leads to the increase in the porosity content. In addition, the comparison of the SEM images (Figs.4and 7) has shown that increasing the sintering duration leads to the reduction of the porosity content in the structure. These behavior are in accordance with the submitted values in Fig. 8.

Also, as it’s evident from the light microscope images (Fig. 9 (a, b)), increasing the sintering duration leads to the grain growth of the matrix. As a matter of fact, as long as the submicron TiC particles are distributed over the matrix uniformly, they could act beneficial and inhibit severe grain growth (fig. 9(c)). But, the addition of the TiC, more than 12 vol. % has no effect on the inhibition of grain growth (fig. 9(d)) due to their agglomeration and non-uniform distribution. With respect to the obtained results, it can be concluded that the lowest grain growth and the highest density is related to the sample with 8 vol. % of TiC which was sintered for 3 minutes.

The results of the hardness test are listed in Table 1. The effect of reinforcement content and sintering duration on the hardness are also depicted in Fig. 10. As it’s obvious, the sample contains 8 vol. % of TiC and was sintered for 3 minutes, dedicated the highest amount of hardness. This property has been deteriorated by increasing the reinforcement content up to 12 vol. %. In addition, it can be observed that increasing the sintering duration has a negative effect on the hardness of the samples and the highest hardness was obtained for the sintering duration equal to 3 minutes.

The observed increasing in the hardness by increasing the reinforcement content is attributed to the dispersion strengthening effect of the TiC particles. In fact, by increasing the reinforcement content, the density of the dislocations is increased in the Al matrix24.

Excessive increase in the reinforcement content not only decreases the resistance of the composite’s matrix, but also introduces more crack initiation’s locations and eventually decreases the load-bearing capacity of the composite25,26. As

it can be seen from figs. 4 and 6, by increasing the amount

Table 1. Various properties of samples.

Sample No TiC vol. % (min)Time (gr/mmDensity 3)

Hardness

(BHN) Electrical conductivity (% IACS) Thermal conductivity (W/m.c)

1 4 3 95.14 215.0 ± 10 7.5 ± 0.8 177.00 ± 11

2 4 5 91.52 189.5 ± 12 31.2 ± 3.2 240.22 ± 13

3 4 8 91.32 144.1 ± 8 40.1 ± 2.9 250.00 ± 9

4 8 3 98.77 239.4 ± 7 6.4 ± 0.6 157.70 ± 10

5 8 5 97.97 224.5 ± 9 26.0 ± 2 206.00 ± 8

6 8 8 92.87 194.5 ± 11 28.6 ± 1.4 234.00 ± 14

7 12 3 93.06 203.5 ± 3 4.2 ± 0.5 150.00 ± 11

8 12 5 96.89 215.2 ± 8 18.7 ± 1 191.00 ± 12

9 12 8 92.25 192.0 ± 6 21.9 ± 1.6 197.00 ± 7

Figure 1. Infrared absorption spectra of the PVdF-CTFE 10 % membranes. The inset indicates the temperature and pressure at which the hot pressing process was conducted.

Figure 3. Microstructure and line scan analysis of interface between matrix and TiC particle for sample 9.

Figure 4. (a) SEM images and (b) the X-Rays maps of sample 4.

Figure 6. (a) SEM images and (b) the X-Rays maps of sample 7.

Figure 7. (a) SEM images of sample 6.

Figure 8. The effect of reinforcement content and sintering duration

on the density of samples.

of reinforcements, their uniform distribution in the matrix of the composite have been begun to decrease. Therefore, the contact between the TiC particles is increased and the ductile aluminum of the matrix cannot protect the particles

any more. As a result, the cracks propagated among the TiC particles, easily27.

Although increasing the sintering duration has a positive impact on the density of the samples, it was expected that the reduction of porosity leads to the increase of hardness, but the ultimate result was utterly in the opposition of what was expected. Actually, the negative effect of increasing the sintering duration on the hardness of the composite can be attributed to the growth of the matrix’s grains (fig. 9) due to the increased diffusion of the atoms. According to the Hall-Petch equation, over growth of the grains leads to the decrease of hardness.

The measured electrical conductivity of the sintered Al-TiC composites with different sintering durations and different amount of reinforcements are listed in Table 1. As it’s evident from Fig. 11, the electrical conductivity of the composites is faced with a descending trend by increasing the amount of TiC.

Porosities and slight oxidation are the main reasons behind the low electrical conductivity of the samples without additives28. The interaction of free electrons and nucleus of

metals is weak, therefore, free electrons can move easily without interruption and that’s why the electrical conductivity of metals is quite good. But in carbides, the electrons are bonding firmly to the nucleus and can’t move so easily and that’s why these materials have low electrical conductivity29,30.

So it can be justified that increasing the amount of carbide eventually leads to the reduction of electrical conductivity of the final composite.

the Al-TiC surface and as a result, causes the reduction of the electrical conductivity and at last, (iii) presence of TiC particles actually reduces the size of the matrix’s grains which means the increase of grain boundaries 30 and finally

the reduction of electrical conductivity.

As it’s shown in fig. 11, increasing the sintering duration have a positive impact on the electrical conductivity of the samples and it can be attributed to the reduction of porosity in the structure.

The obtained data for thermal conductivity of the samples are listed in Table 1. The effect of the amount of reinforcement and sintering duration on the thermal conductivity are shown in Fig. 12. It was clarified that increasing the amount of reinforcement and sintering duration have negative and positive effects on the thermal conductivity of the samples, respectively.

With respect to the fact that the thermal conductivity of TiC is lower than metal matrix’s value, it was expected that

Figure 9. Light microscope images of (a) sample 1 (b), sample 3, (c) sample 6 and (d) sample 9.

Figure 10. The effect of reinforcement content and sintering duration

on the Hardness of samples.

Figure 11. The effect of reinforcement content and sintering duration

increasing the amount of reinforcement has a negative effect on the thermal conductivity of the composite. A schematic of heat conduction in metals are shown in Fig. 13.

Several factors can reduce the thermal conductivity, the most important of them are: phonon/defect scattering, phonon/ interface scattering and phonon/phonon scattering. In crystalline structures, presence of defects leads to the phonon scattering, phonon reflection and/or phonon diffraction. Therefore, by shortening the mean free path, thermal conductivity will reduce31,32. In this kind of scattering, each defect acts as an

obstacle in front of phonons transfer.

In phonon/interface scattering mechanism, since the TiC particles have dimensions, so they present an interface or disconnection. In composites, this kind of scattering

in inevitable and depends to the TiC particle’s features. Therefore, increasing the amount of reinforcement provokes more scatterings.

4. Conclusion

In this research, Al-TiC composite was fabricated through rapid microwave process and the following results have been obtained:

• The addition of the TiC, more than 12 vol. % had no effect on the inhibition of grain growth, due to their agglomeration and non-uniform distribution of particles.

• Due to the shortened sintering duration in the microwave sintering method, there was no trace of pernicious phases including TiO2 and Al4C3. • The highest electrical and thermal conductivities

were achieved for the composite containing 4 vol. % TiC which was sintered for 8 minutes. Also the highest hardness and density were achieved for the composite containing 8 vol. % TiC which was sintered for 3 minutes.

• Increasing the sintering duration had a negative effect on the hardness of the composites due to the growth of the matrix’s grains.

• Increasing the amount of TiC, led to the reduction of thermal and electrical conductivities of the samples while increasing the sintering duration increased the mentioned properties.

Figure 12. The effect of reinforcement content and sintering duration

on the thermal conductivity of samples.

• By changing the amount of TiC and sintering duration, electrical and thermal conductivities were variable from 4.2 % IACS to 40.1 % IACS and from 150 W/m.c to 250 W/m.c, respectively, without deteriorating its mechanical properties.

5. References:

1. Kaftelen H, Ünlü N, Göller G, Lütfi Öveolu M, Henein H.

Comparative processing-structure-property studies of Al-Cu matrix composites reinforced with TiC particulates. Composites Part A: Applied Science and Manufacturing. 2011;42(7):812-824.

2. Samer N, Andrieux J, Gardiola B, Karnatak N, Martin O, Kurita H, et al. Microstructure and mechanical properties of an Al-TiC metal matrix composite obtained by reactive synthesis.

Composites Part A: Applied Science and Manufacturing. 2015;72:50-57.

3. Omar AA, El-Shennawy M, Ayad M. Study of Wear Behavior of as Cast TiC/7075 Composite. International Journal of Mechanical Engineering. 2015;4(4):45-52.

4. Veeravalli RR, Ramanaiah N, Sarcar MMM. Mechanical and tribological properties of AA7075-TiC metal matrix composites under heat treated (T6) and cast conditions. Journal of Materials Research and Technology. 2016;5(4):377-383.

5. Zhang Q, Liu D, Chen G, Xiu Z, Wu G. Performance and application of SiCp/Al composites for electronic packaging. In: Proceedings of 16th IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits; 2009 Jul 6-10; Suzhou, Jiangsu, China. p. 252-255.

6. Yaghobizadeh O, Baharvandi HR, Ahmadi AR, Aghaei E.

Development of the Properties of Al/SiC Nano-Composite

Fabricated by Stir Cast Method by Means of Coating SiC Particles with Al. Silicon. 2018; DOI: https://doi.org/10.1007/ s12633-018-9867-3

7. Srivastava A. Recent Advances in Metal Matrix Composites (MMCs): A Review. Biomedical - Journal of Scientific &

Techical Research. [Internet]. 2017. Available from: <http://

biomedres.us/fulltexts/BJSTR.MS.ID.000236.php>. Access

in: 18/04/2018.

8. Kumar A, Mahapatra MM, Jha PK. Fabrication and Characterizations of Mechanical Properties of Al-4.5%Cu/10TiC Composite by In-Situ Method. Journal of Minerals and Materials Characterization and Engineering. 2012;11:1075-1080.

9. Ghasali E, Fazili A, Alizadeh M, Shirvanimoghaddam K, Ebadzadeh T. Evaluation of Microstructure and Mechanical Properties of Al-Tic Metal Matrix Composite Prepared By Conventional, Microwave and Spark Plasma Sintering Methods.

Materials (Basel). 2017;10(11). pii: E1255.

10. Lloyd DJ. Particle reinforced aluminium and magnesium matrix

composites. International Material Reviews. 1994;39(1):1-23.

11. Padmavathi C, Upadhyaya A. Densification, microstructure

and properties of supersolidus liquid phase sintered 6711Al-SiC metal matrix composites. Science of Sintering. 2010;42(3):363-382.

12. Dinaharan I, Murugan N. Dry sliding wear behavior of

AA6061/ZrB2 in-situ composite. Transactions of Nonferrous Metals Society of China. 2012;22(4):810-818.

13. Laha T, Agarwal A, McKechnie T, Seal S. Synthesis and characterization of plasma spray formed carbon nanotube reinforced aluminum composite. Materials Science and Engineering: A. 2004;381(1-2):249-258.

14. Ghasali E, Nouranian H, Rahbari A, Majidian H, Alizadeh M, Ebadzadeh T. Low Temperature Sintering of Aluminum-Zircon Metal Matrix Composite Prepared by Spark Plasma Sintering. Materials Research. 2016;19(5):1189-1192.

15. Kala H, Mer KKS, Kumar S. A Review on Mechanical and Tribological Behaviors of Stir Cast Aluminum Matrix Composites. Procedia Materials Science. 2014;6:1951-1960.

16. Ibrahim IA, Mohamed FA, Lavernia EJ. Particulate reinforced metal matrix composites - a review. Journal of Materials Science. 1991;26(5):1137-1156.

17. Liu YB, Lim SC, Lu L, Lai MO. Recent development in the fabrication of metal matrix-particulate composites using powder metallurgy techniques. Journal of Materials Science. 1994;29(8):1999-2007.

18. Majidian H, Ghasali E, Ebadzadeh T, Razavi M. Effect of

Heating Method on Microstructure and Mechanical Properties of Zircon Reinforced Aluminum Composites. Materials Research. 2016;19(6):1443-1448.

19. Çetin A, Kalkanli A. Effect of solidification rate on spatial

distribution of SiC particles in A356 alloy composites. Journal of Materials Processing Technology. 2008;205(1-3):1-8.

20. Shimada S, Mochidsuki K. The oxidation of TiC in dry oxygen, wet oxygen, and water vapor. Journal of Materials Science. 2004;39(2):581-586.

21. Korablev SF. Chemical and kinetic features of oxidation of powder titanium carbide. Refractories and Industrial Ceramics. 1999;40(11-12):534-536.

22. Das G, Chatterjee DK, Lipsitt HA. Electron irradiation damage

in TiC. Journal of Materials Science. 1981;16(12):3283-3291.

DOI: http://dx.doi.org/10.1007/BF00586288

23. Viala JC, Vincent C, Vincent H, Bouix J. Approche thermodynamique de l'interaction chimique entre l'aluminium et le carbure de titane. Materials Research Bulletin. 1990;25(4):457-464.

24. Lijay KJ, Selvam JDR, Dinaharan I, Vijay SJ. Microstructure

and mechanical properties characterization of AA6061/TiC aluminum matrix composites synthesized by in situ reaction

25. Sivaraj M, Selvakumar N. Experimental Analysis of Al-TiC Sintered

Nanocomposite on EDM Process Parameters Using ANOVA. Materials and Manufacturing Processes. 2016;31(6):802-812.

26. Rizkalla HL, Abdulwahed A. Some mechanical properties of metal-nonmetal Al-SiO2 particulate composites. Journal of Materials Processing Technology. 1996;56(1-4):398-403.

27. El-Amoush AS. Effect of aluminum content on mechanical

properties of hydrogenated Mg-Al magnesium alloys. Journal of Alloys and Compounds. 2008;463(1-2):475-479.

28. Santos SF, De Andrade MC, Sampaio JA, Da Luz AB, Ogasawara T.

Thermal study of TiO2-CeO2 yellow ceramic pigment obtained by the Pechini method. Journal of Thermal Analysis and Calorimetry. 2007;87(3):743-746.

29. Schoenitz M, Patel B, Agboh O, Dreizin EL. Oxidation of aluminum

powders at high heating rates. Thermochimica Acta. 2010;507-508:115-122.

30. Wang QZ, Cui CX, Lu DM, Bu SJ. Fabrication and properties

of a novel ZnO/Cu composite. Journal of Materials Processing Technology. 2010;210(3):497-503.

31. Weisenberger M, Martin-Gullon I, Vera-Agullo J, Varela-Rizo

H, Merino C, Andrews R, et al. The effect of graphitization

temperature on the structure of helical-ribbon carbon

nanofibers. Carbon. 2009;47(9):2211-2218.