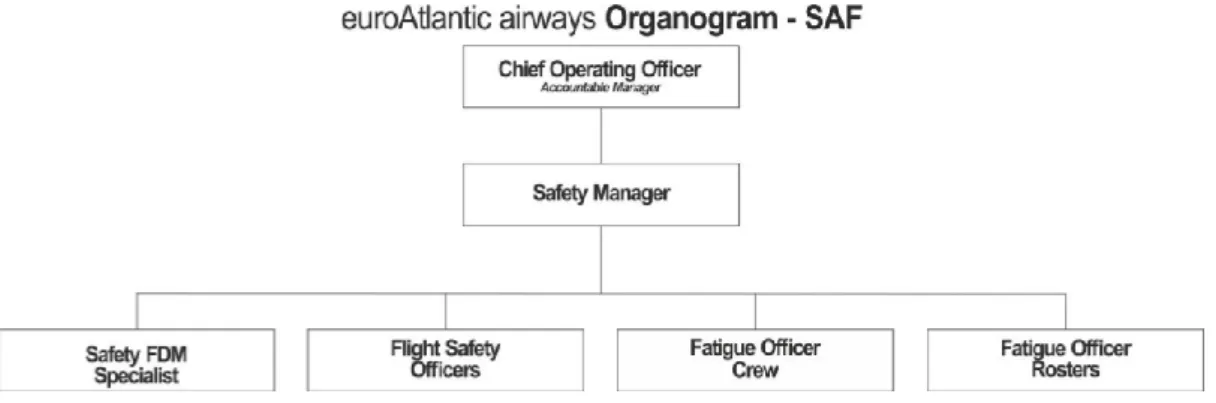

Feasibility Study of a Hazard Identification Process on Daily Operations of a National Airline Operator

Texto

Imagem

Documentos relacionados

Dentro deste grupo terapêutico destacaram-se as reacções adversas aos anti-inflamatórios inibidores específicos da ciclooxigenase-2, que demonstravam existir uma relação entre

Moreover, under this same domain of ‘loss/hurt,’ this connection with mano cornuta is shown for the ASL sign silly (SHAW; DELAPORTE, 2015), as well as for the signs irony and

The Natural theologians of the 18 th and 19 th centuries insisted that the complexity and harmony of a plant or an animal and its place in nature has been designed by its

One such life style adoption is squatting, that is known to change the morphology of the bones especially the lower end of tibia and the superior articulating surfaces of talus..

Oral health education programs targeted at visually impaired people by dental professionals are needed both in dental care and in institutes for blind people, so that

De qualquer forma, por esses e outros debates que ainda provocam a cidade, a “verdade” sobre o que foi e é a história da Estrutural ainda é objeto de

Seguiu para Veneza por um trajecto comum a outros cristãos ‑novos que se deslocavam para o Levante, onde podiam viver como judeus escondidos.. A pedido dos inquisidores de

Em relação à artrite séptica de quadril - forma mais comum e danosa da doença -, o diagnóstico e tratamento precoce é um ponto fundamental para que se evitem danos maiores,