Fiabilitate si Durabilitate - Fiability & Durability Supplement no 1/ 2012 Editura “Academica Brâncuşi” , Târgu Jiu, ISSN 1844 – 640X 276

FACILITES FOR ELECTRIC DETONATORS TESTING, ON HIGH

TECHNICAL LEVEL AND IN SAFETY CONDITIONS REGARDING

OF REQUIREMENTS OF EUROPEAN STANDARDS

Eng. Edward GHEORGHIOSU, INCD-INSEMEX, Edward.Gheorghiosu@insemex.ro Phd.Eng., Attila KOVACS, INCD-INSEMEX, Attila.Kovacs@insemex.ro

Eng. Sorin BORDOŞ, INCD-INSEMEX, insemex@insemex.ro

Abstract: To place on the market of explosives for civil use must comply with the essential safety requirements applicable. The evaluation of products with the essential safety requirements, is achieved by comparing the obtained results do the tests on laboratory, equipment test conditions required ensure

by the harmonized European standards.

Keywords: explosives for civil use, electric detonators, harmonized standard, the test stand

1. Foreword

To place on the market of explosives for civil use (including detonators) shall be in accordance with applicable essential safety requirements specified in the "Directive 93/15/CE" and "Decision no.207/2005".

The products with the essential safety requirements, is achieved by "notified bodies" by evaluating the obtained results do the laboratory tests performed by applying the harmonized European standards of families 13630-112 Explosives for civil uses – Detonating cords and safety fuses, 13631-1 16 Explosives for civil uses – High Explosives 13631-1 25 Explosives for civil uses – Detonators and relays, standards were taken as the SR EN "ASRO – Standardization Association in Romania".

On basis of the experience gained during the development of specific activity in explosives for civil use, INCD-INSEMEX certification body meet minimum criteria and the European Commission was notified as competent in evaluating products in this area.

To obtain notification required infrastructure to test by developing stands and purchase equipment with which can be to checked the performance and characteristics of explosives for civil use, in accordance with harmonized European standards.

Test conditions imposed by standards for testing electric detonators, has led to a stand, presented the contents of this article.

2. Design requirements

Fiabilitate si Durabilitate - Fiability & Durability Supplement no 1/ 2012 Editura “Academica Brâncuşi” , Târgu Jiu, ISSN 1844 – 640X 277

2.1. Design for ergonomics and user safety

Design for user safety. Laws and regulations on labor protection leads the designer to act responsibly. Security of personnel and the environment are essential requirements to respond to any technical equipment. The designer must consider the subjective aspects related to personnel, such as misunderstanding the correct or fatigue, that the equipment designed to avoid causing injury to a possible mishandling.

Ergonomics. In making the stand was given to maintenance and easy handling, goodlighting and ventilation of the workplace, the possibility of surveillance equipment operating parameters, noise, dustiness etc.

The main health and safety requirements in operation of the stand trial are related to: avoid falling lid, providing work and movement space, to avoid danger of uncommanded explosion of the electric detonators, excluding the false orders or incorrect handling; ensure adequate lighnting and visibility; good opportunities handling subassemblies, stability, risk of rupture of mechanical assemblies, risks due to surface corners and edges, explosion hazard, avoid gas formation during handling.

2.2. Structure rezistence calculation

The main condition which prevails in the new method is that the test material, in this case, electric detonators, is necessary to be thermally conditioned at a temperature of 20± 2 C.

Given this requirement, the test stand was built in an area that can be thermally conditioned according to ambient temperature (heated in winter and cooled in summer).

This led to a partitioning of a building located in a warehouse

In this space to set the location of the stand, separate from the control table by a soundproof wall.

Stand to gain visibility during the tests was provided in an insulating glasspartition. Since the tests resulting toxic explosiones, it was necessary to provide for the introduction of a fan to absorb gases inside the stand and to evacuate to the outeratmosphere.

The initiation of electrical detonators is as a result, the production ofexplosive gases, and some splinters from desintegretion of detonator tube and pressure generated by the explosion.

When designing the test stand to experience while in the field, was taken into account the phenomena described above.

For this stand has collaborated with specialists from the UM Sadu – Bumbeşti Jiu, for the design, and specialists from UPSROM Petroşani for the construction.

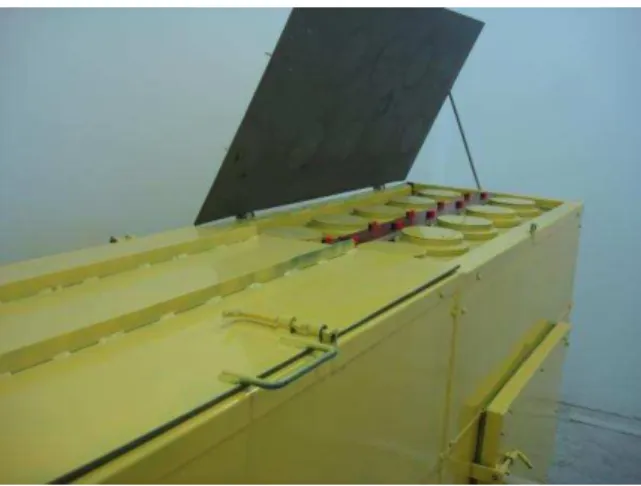

Since they took large safety factors, and has provided a massive construction, the stand has been built modular and assembled on-site, (Fig. 1-2).

Fiabilitate si Durabilitate - Fiability & Durability Supplement no 1/ 2012 Editura “Academica Brâncuşi” , Târgu Jiu, ISSN 1844 – 640X 278

Fig. 1. Components of the test stand

The stand walls are lined with expanded polystyrene 5 cm thick to reduce blast noise and of the outside stand is wrapped in iron sheets of thick 2 mm.

Stand resistance calculation was calculated by the mass of explosive that detonates, the pressure developed by the explosion, explosive density, stand volume.

From calculations showed that the test bench as a whole has to withstand a pressure 0.096 kgf/cm2.

Stand construction is modular, with two sizes of surfaces, the modules being symmetrical. Front and back surfaces have a size S = 160 cm2, and the side of 74 cm2. Side surfaces are attached with 10 screws (Fig. 2).

Fig. 2. Construction of stand modules

3. The electric current in the circuit and designing the wires

For each of the 20 cylinders (masks) which detonate electric detonators were installed two electrical terminals on an isulated support to link wires (conductors) of detonators.

Fiabilitate si Durabilitate - Fiability & Durability Supplement no 1/ 2012 Editura “Academica Brâncuşi” , Târgu Jiu, ISSN 1844 – 640X 279

Fig. 3. The stand equipped with electric conductors

From the literature, is considered a resistance of wires take into account themaximum value of 5 .

In this case the circuit 20 electric detonators in series will have a maximum resistance of 100 .

Knowing that the resistivity of copper is 1.7 x 10-8 x m, and have used 80 m of wire cross section S = 1.5 mm2 in the circuit connecting the power terminals and control panel was calculated resistance of this circuit as 0.113

4. Ventilation and microclimate conditions

4.1. Description of site

Test stand for detonators was placed inside a building in test polygon in this site by creating a partitioned room dividers insulated plaster and mineral wool.

4.2. Designing of air conditioning

The test procedure requires maintaining a constant temperature of 20 ± 20 C both in the room and stand. Following test resulting in stand gas and smoke which to be discharged into the atmosphere without them enter the room

To ensure regularity test required ventilation is necessary to stand out in approx. 3 minutes.

From the literature, outdoor temperatures for calculating ventilation installations and air conditioning in cold and warm periods of the year for Petrosani are:

• 29°C in summer; • - 7°C in winter.

For the design of ventilation and air conditioning were considered calculation the following parameters: the amount of heat came from outside or released on site, heat losses and consumption of the enclosure, the release of moisture from the site, the release of gases, vapors and dust, ventilation air flow required for winter season, summer season.

Fiabilitate si Durabilitate - Fiability & Durability Supplement no 1/ 2012 Editura “Academica Brâncuşi” , Târgu Jiu, ISSN 1844 – 640X 280

4.3. Choice of ventilation system

Given the recommendations of the literature on the number of air changes for ventilation of testing, determining factor for general ventilation air exchange (Cs) as of 4 to 6 V (V - volume of the enclosure).

Given the fact that ventilation must stand out in approx. 3 minutes, and stand volume (approximately 6 m3) that is required to develop a fan flow between 16.5 ÷ 22.5 m3/min.In this respect it is best to choose a type centrifugal fan Vortice Lineo can achieve, that flow at a maximum pressure of 520 Pa.

4.4. Construction details on the test stand ventilation eyelets

To connect the fan to stand is necessary to perform 250 mm circular cuttings in both wall and stand in the building wall. The relationship between fan and stand will be a circular steel pipe 250 mm linear going beyond wall outside the building with approx. 600 mm. The hole was practiced so that its horizontal diameter corresponds to halfway up the stand, To reduce the influence of external temperature on the temperature required to be maintained in the stand and to protect the fan from the dynamic effect of the tests, it achieved a construction shown in detail 1 (Fig. 4).

Fig. 4. Vent installation location of the stand

Inner wall of the booth, located in the room, saw a circular hole diameter max. 250 mmalso provided with a shutter operated by sliding. This hole is the same height I will practice the outside, and in the diagonally opposite to it.

Sealing both shutters will be to not allow dissipation of the stand that temperature andgas migration in the tower room.

After each test sequence to perform maneuvers should be as follows: • Start the fan and shutter partially open while inside;

• After stabilizing the direction of movement of air inside the booth interior shutter is fully open;

• After, making ventilation cycle is going to stop opening covers masks and ventilation

5. Conclusion

Fiabilitate si Durabilitate - Fiability & Durability Supplement no 1/ 2012 Editura “Academica Brâncuşi” , Târgu Jiu, ISSN 1844 – 640X 281

6. References

[1] Buzdugan, Gheorghe., "Strength of Materials", Technical Publishing, 1980.

[2] Cristea, A., Niculescu, N., "Ventilation and air conditioning." Technical Publishing House, Bucharest, 1971, Volumes I, II and III.

[3] Bordos Sorin, "Design and implementation of a test stand staples staples electricalpower requirements detonanteconform harmonized European standards" – Draft diploma

Universitatea din Petroşani, 2009.

[4] SR EN 13763-1: Explosives for civil uses. Detonators and relays. Part1:Requirements