ADSORPTION OF CELLULASES ONTO SUGAR BEET SHREDS AND MODELING OF THE EXPERIMENTAL DATA

Darjana Ž. Ivetić*, Radovan P. Omorjan, Mirjana G. Antov

University of Novi Sad, Faculty of Technology Novi Sad, Bulevar Cara Lazara 1, Novi Sad, Serbia This study investigated the adsorption of cellulases onto sugar beet shreds. The experiments were carried out using untreated, as well as dried and not dried dilute acid and steam pretreated sugar beet shreds at different initial enzyme loads. Both dilute acid and steam pretreatment were beneficial in respect of cellulases adsorption providing 8 and 9 times higher amounts of adsorbed proteins, respectively, in comparison to the results obtained with the untreated substrate. Although the use of higher solids load enabled by drying of pretreated substrates, could be beneficial for process productivity, at the same time it decreases the adsorption of enzymes. The obtained experimental data were fitted to five adsorption models, and the Langmuir model having the lowest residual sum of squares was used for the determination of adsorption parameters which were used to calculate the strength of cellulases binding to the substrates.

KEY WORDS: adsorption, cellulases, modeling, sugar beet shreds, pretreatment

INTRODUCTION

Lignocellulosic biomass, the most abundant organic material in nature, consists of three major polymers: cellulose, hemicelluloses and lignin. These polymers could be transformed into many valuable products rather than use biomass as cattle feed or burnt, which is the most common practice. Having in mind the value and significance of its main degrading product – glucose, cellulose is a compound of special interest in all ligno-cellulosic materials (1, 2). However, due to the complex structure of lignocellulose, some type of pretreatment must be conducted prior to its degradation. As far as degradation is concerned, hydrolysis of cellulose via cellulases enzymatic activity is a process of choice because of mild process conditions, environmental benefits and efficiency. Thus, pret-reatment should prepare recalcitrant biomass for the enzymatic hydrolysis through phy-sical and/or chemical alteration of the material (1, 3). Adsorption of cellulases on the solid cellulose substrate is one of the most important parameters that govern the rate of cellulose enzymatic hydrolysis. Considering that, pretreatment should open up complex lignocellulosic matrix in order to expose cellulose and allow contact with cellulases and their consequent binding (4, 5).

As lignocellulosic biomass, sugar beet shreds are by-products from the sugar industry which is widely available in Serbia (6). In addition, besides pectin (24-32%), sugar beet shreds have high carbohydrate content (cellulose 22-30% and hemicellulose 22-30%), and low lignin content (1-3%) (7), which makes them a feedstock potentially susceptible to biochemical transformation to glucose and other sugars.

The aim of this study was to investigate the adsorption of cellulases onto sugar beet shreds. The investigation encompassed adsorption onto untreated, as well as dried and not dried dilute acid and steam- pretreated sugar beet shreds at different initial enzyme loads. The obtained experimental data were fitted to five adsorption models in order to reveal which one best describes adsorption of cellulases onto the investigated substrates. The best fitting model determined by the residual sum of squares (RSS) was Langmuir`s mo-del, which was used for the determination of adsorption parameters from which the strength of cellulases binding to the substrates was calculated.

EXPERIMENTAL

Sugar beet shreds

In this study, sugar beet shreds, a kind gift from A.D. Šajkaška, Žabalj, Serbia, were used as raw material. Sugar beet shreds were milled on a laboratory mill and sieved as previously reported (8)and particles in the range 224-400 m were used for adsorption or subjected to pretreatments.

Pretreatment of sugar beet shreds

Dilute acid pretreatment was applied in order to remove pectic substances. Suspen-sion of sugar beet shreds in dilute HCl solution was subjected to treatment according to Sun and Hudges (9). After cooling down the mixture was filtered through laboratory filter paper Macherey - Nagel MN 651/120 and the filter cake was water washed (10) to remo-ve present HCl. Steam pretreatment was conducted in a laboratory autoclaremo-ve at a pressure of 2.1 bars for 15 minutes. Sugar beet shreds were suspended in distilled water and sub-jected to treatment. After pretreatment, the obtained solids were washed with distilled water until filtrate did not contain sugars. The materials obtained after both pretreatments were used as is (not dried) or dried at 60oC until achieving 100% of dry matter and then subjected to adsorption.

Cellulases adsorption

investiga-ted substrates and the lowest value of the range that is preseninvestiga-ted in this work was the first load that gave measurable adsorption, while the highest value was the one after which the increase in the initial protein load did not give a measurable increase in the protein ad-sorption.

The content of proteins in the supernatant after adsorption was determined as free cel-lulases in the solution. The amount of enzymes adsorbed onto the substrate, q, was cal-culated as a difference between the total amount of proteins initially added to the reaction mixture and the amount of free (unadsorbed) proteins in the solution, and is expressed per gram of material dry weight.

The concentration of the enzymes was determined through the determination of pro-teins using Bradford method (11) with BSA as a standard.

Adsorption modeling

The experimental data were fitted to the different adsorption models: Langmuir`s, Freundlich`s, Halsey`s, Henderson`s and Oswin`s (12), and adsorption parameters were estimated by a direct nonlinear regression using Euler Math Toolbox (12).

The residual sum of squares (RSS) presented in equation [1] was used to determine which of the investigated models best describes obtained the experimental results of cel-lulases adsorption onto sugar beet shreds.

RSS = (qexp-qpred)2 [1]

where qexp is the amount of adsorbed cellulases obtained experimentally and qpred the amount of the adsorbed cellulases predicted by the applied model.

RESULTS AND DISCUSSION

Previous investigations have been concerned with pretreatments with dilute acid and steam of sugar beet shreds and other lignocellulosic substrates as a step prior to enzyma-tic hydrolysis (8, 13, 14). In this work, those pretreatments were perceived in respect of the adsorption of cellulases onto the surface of the obtained sugar beet shreds. Sugar beet shreds, due to their very complex and intact structure, generally are not being used with-out treatment as substrate for enzymatic hydrolysis (8). However, the investigation of the cellulases adsorption onto them was conducted in order to have a reference for compa-rison of the influence of pretreatments on enzymes adsorption.

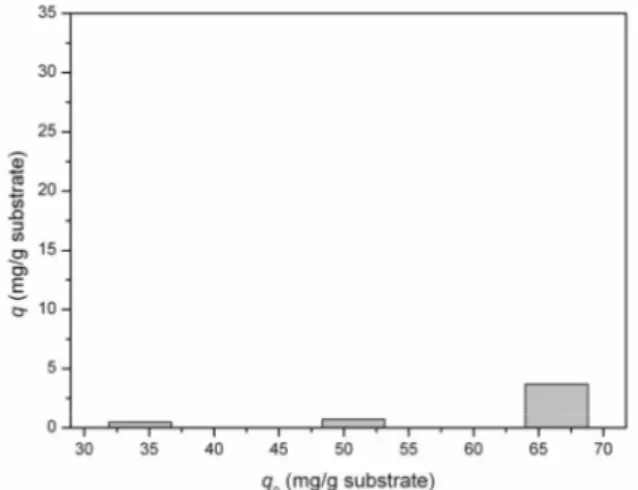

Adsorption of cellulases onto untreated sugar beet shreds

per gram of substrate was adsorbed. This could be explained as a result of the complex structure of untreated substrate in which cellulose is covered by other material constitu-ents and thus limitedly available for contact with the enzymes (15).

Figure 1. Cellulases adsorption onto untreated sugar beet shreds. q0 – initial enzyme load, q – amount of adsorbed enzymes

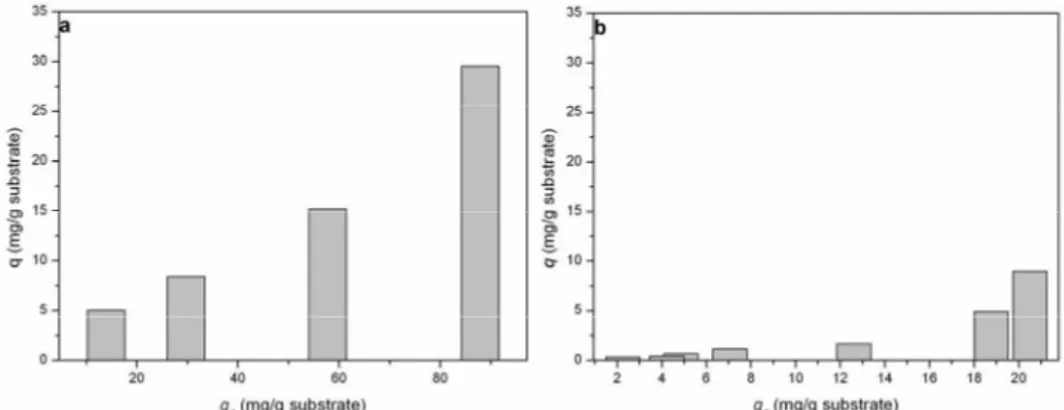

Adsorption of cellulases onto dilute acid pretreated sugar beet shreds

As mentioned before, dilute acid pretreatment should remove pectin from sugar beet shreds and generally disturb the complex lignocelluloses matrix (9). As a result, cellulose should be more exposed for contact with the enzymes, allowing better adsorption and, consequently, better enzymes performance during the next degradation step - hydrolysis. The results of the investigation of the cellulases adsorption onto not dried dilute acid pre-treated sugar beet shreds are shown in Figure 2a. In the examination the enzymes loads were in the range from 13.9 to 87.9 mg/g. The highest amount of adsorbed proteins was achieved at the highest applied initial load and it amounted 29.54 mg of proteins per gram of substrate dry weight. Thus, dilute acid pretreatment had a positive effect on the adsorp-tion of cellulases onto the substrate, increasing it by 8 times in comparison to the untrea-ted sugar beet shreds.

Figure 2. Cellulases adsorption onto dilute acid pretreated sugar beet shreds – (a) not dried, (b) dried. q0 – initial enzyme load, q – amount of adsorbed enzymes

Figure 2b showed results of the cellulases adsorption onto dried dilute acid pretreated sugar beet shreds, at the initial enzymes loads from 2.3 to 20.5 mg/g. It can be noticed that the highest yield of adsorption amounted 9.01 mg of proteins per gram of substrate (dry weight). Although that amount of adsorbed enzymes was higher than the one obtai-ned for untreated substrate, on the other hand it was 3.3 timeslower than the highest one achieved during the adsorption onto not dried dilute acid pretreated sugar beet shreds. The results indicated that drying of dilute acid pretreated substrate had a negative effect on the cellulases adsorption, which consequently would negatively reflect on the hydro-lysis performance and yield. The decreased adsorption of cellulases upon drying might be a result of the pore shrinking and collapsing - phenomena known as hornification (17, 18), and it was also noticed for other dried pretreated lignocellulosic substrates (18, 19).

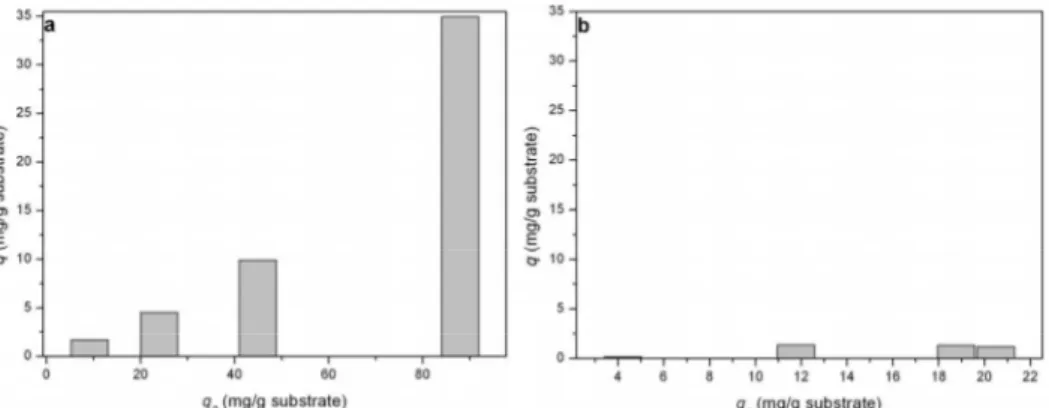

Adsorption of cellulases adsorption onto steam pretreated sugar beet shreds

The adsorption of cellulases onto dried steam pretreated sugar beet shreds was also investigated and the obtained results are shown in Figure 3b. In this experiment, the initi-al proteins loads ranged from 4.3 to 20.5 mg/g, and the highest adsorption yield obtained at 11.8 mg of proteins per gram of substrate amounted 1.37 mg/g. Thus, for the steam pretreated sugar beet shreds in respect of enzymes adsorption drying had a more negative effect than for dilute acid pretreated ones, which resulted in the lowest adsorption yield of the all investigated substrates. This might be the result of the previously mentioned hornification (17) which in this, more disrupted substrate (after steam pretreatment), had a more pronounced effect after drying, making adsorption very ineffective.

Figure 3. Cellulases adsorption onto steam pretreated sugar beet shreds – (a) not dried, (b) dried. q0 – initial enzyme load, q – amount of adsorbed enzymes

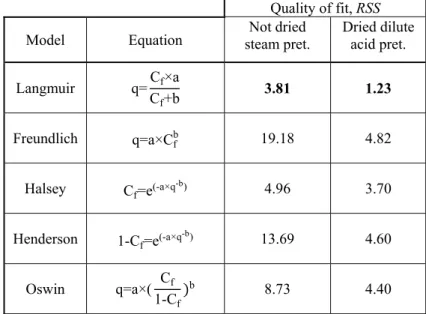

Modeling of the adsorption results

The results obtained for the cellulases adsorption by varying initial enzymes loads were fitted to the five adsorption models, while residual sum of squares calculated using equation [1] was used to perceive which of investigated models best describes adsorption of the cellulases onto differently treated sugar beet shreds. The models used for adsorp-tion modeling and results obtained for RSS of models for adsorpadsorp-tion onto not dried steam pretreated and dried dilute acid pretreated sugar beet shreds are shown in Table 1.

For both not dried steam pretreated and dried dilute acid pretreated, as well as for other investigated substrates (data not shown), the best fit (the lowest RSS) was obtained by the Langmuir model. Furthermore, the Langmuir model is known to be used for ad-sorption of molecules onto solid adsorbents in monolayer, which is the case with the cel-lulases adsorption onto (ligno)cellulosic substrates (21, 22).

Due to that, the parameters denoted as a and b in the Langmuir model may be used to represent the maximum adsorption coefficient (qmax) and adsorption dissociation constant (Kd), respectively. These parameters could be combined in one parameter called the strength of binding, which is calculated as follows (3, 5):

R=qmax×c [2]

Table 1. Models used for modeling of adsorption, corresponding equations and RSS of the models for not dried steam pretreated and dried dilute acid pretreated sugar beet

shreds

Quality of fit, RSS

Model Equation steam pret. Not dried Dried dilute acid pret.

Langmuir q=Cf×a

Cf+b 3.81 1.23

Freundlich q=a×Cfb 19.18 4.82

Halsey Cf=e(-a×q

-b)

4.96 3.70

Henderson 1-Cf=e(-a×q

-b)

13.69 4.60

Oswin q=a×( Cf 1-Cf)

b 8.73 4.40

a and b are model parameters, Cf is the concentration of free enzyme at equilibrium

Using the Langmuir model and equation, the adsorption parameters were determined, and the strength of binding for all investigated substrates was calculated and presented in Table 2.

Table 2. Strength of binding for all investigated substrates

Substrate Untreated

Not dried Dried

Dilute acid pret.

Steam pret.

Dilute acid pret.

Steam pret. R (mL/g substrate) 14.17 16.67 40.91 11.22 2.63

CONCLUSION

The subject of this study was the adsorption of cellulases onto untreated, dried and not dried dilute acid and steam pretreated sugar beet shreds. For all investigated substrates, the amount of adsorbed enzymes increased with the increase in enzymes load to some extent, although the highest yields of adsorption were obtained at different initial loads. Both dilute acid and steam pretreatment were beneficial in respect of cellulases adsorp-tion, providing multiply higher amounts of adsorbed proteins in comparison to the one obtained for substrate without pretreatment. Although the use of dried pretreated subs-trates, which allows achieving higher solids loads, could be beneficial for the process productivity, it decreased the adsorption of cellulases. Among the five models that were applied on the experimental data fitting Langmuir`s had the lowest value of residual sum of squares, and it was used for the determination of adsorption parameters and strength of cellulases binding onto the substrates. Both pretreatments increased the strength of cellulases binding to the obtained substrates, while drying had a negative effect on this parameter, as well as on the amount of adsorbed enzymes. Steam pretreatment provided a substrate that allowed not just adsorption of the highest amount of cellulases but also the highest strength of their binding, making this sugar beet shreds more favorable in respect of the adsorption of cellulases.

Acknowledgement

Financial support from the Ministry of Education, Science and Technological Deve-lopment of the Republic of Serbia (Grant No. TR 31002) is gratefully acknowledged.

REFERENCES

1. Galbe M. and Zacchi G.: A review of the production of ethanol from softwood. Appl. Microbiol. Biotechnol. 59 (2002) 618-628.

2. Sarkar N., Kumar Ghosh S., Bannerjee S. and Aikat K.: Bioethanol production from agricultural wastes: An overview. Renew. Energ. 37 (2012) 19-27.

3. Pareek N., Gillgren T. and Jönsson L.J.: Adsorption of proteins involved in hydrolysis of lignocellulose on lignins and hemicelluloses. Bioresour. Technol. 148 (2013) 70-77.

4. Alvira P., Tomás-Pejó E., Ballesteros M., Negro M.J.: Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: A review. Bioresour. Technol. 101, 13 (2010) 4851-4861.

5. Lee S.B., Shin H.S., Ryu D.D. and Mandels M.: Adsorption of cellulase on cellulose: Effect of physicochemical properties of cellulose on adsorption and rate of hydrolysis. Biotechnol. Bioeng. 24, 10 (1982) 2137-2153.

7. Statistical Office of the Republic of Serbia. 2010. Realized yield of late crops, plums and grapes in the Republic of Serbia, as of 10.11. 2010. Communication, Agriculture statistics. Number 330, Year LIX, 25.10.2011.

8. Zheng Y., Yu C., Cheng Y.-S., Zhang R., Jenkins B. and VanderGheynst J.S.: Effects of ensilage on storage and enzymatic degradability of sugar beet pulp. Bioresour. Technol. 102, 2 (2011) 1489-1495.

9. Ivetić D.Ž., Šćiban M.B. and Antov M.G.: Enzymatic hydrolysis of pretreated sugar beet shreds: statistical modeling of the experimental results. Biomass Bioenerg. 47 (2012) 387-394.

10.Sun R. and Hughes S.: Extraction and physico-chemical characterization of pectins from sugar beet pulp. Polym. J. 30, 8 (1998) 671-677.

11.Ivetić D.Ž., Vasić V. ., Šćiban M.B. and Antov M.G.: Analysis of pretreatments of sugar beet shreds for bioethanol production in respect of cellulose hydrolysis and waste flows. APTEFF 42 (2011) 223-230.

12.Bradford M.M.: Rapid and sensitive method for the quantitation of microgram quanti-ties of protein utilizing the principle of protein-dye binding. Anal. Biochem. 72 (1976) 248-254.

13.Euler Math Toolbox, http://euler.rene-grothmann.de/ (accessed May 2014).

14.Yang M., Kuittinen S., Zhang J., Keinänen M., Pappinen A.: Effect of dilute acid pretreatment on the conversion of barley straw with grains to fermentable sugars. Bio-resour.Technol. 146 (2013) 444-450.

15.Han G., Cheng H.W., Deng J., Dai C., Zhang S. and Wu Q. Effect of pressurized steam treatment on selected properties of wheat straws. Ind. Crop. Prod. 30 (2009) 48-53.

16.Balat M.: Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energ. Convers. Manage. 52, 2 (2011) 858-875.

17.Galbe M. and Zacchi G.: Pretreatment of lignocellulosic materials for efficient bio-ethanol production. Adv. Biochem. Eng. Biot. 108 (2007) 41-65.

18.Fernandes Diniz J.M.B., Gil M.H. and Castro J.A.A.M.: Hornification-Its origin and interpretation in wood pulps. Wood Sci. Technol. 37, 6 (2004) 489-494.

19.Wang Q.Q., He Z., Zhu Z., Zhang. Y.-H.P., Ni Y., Luo X.L. and Zhu J.Y.: Evalua-tions of cellulose accessibilities of lignocelluloses by solute exclusion and protein ad-sorption techniques. Biotechnol. Bioeng. 109, 2 (2012) 381-389.

20.Luo X, and Zhu J.Y.: Effects of drying-induced fiber hornification on enzymatic saccharification of lignocelluloses. Enzym. Microb. Technol. 48 (2011) 92-99. 21.Hendriks A.T.W.M. and Zeeman G.: Pretreatments to enhance the digestibility of

lignocellulosic biomass. Bioresour. Technol. 100 (2009) 10-18.

22.Dabrowski A.: Adsorption–from theory to practice. Adv. Colloid Interfac. 93 (2001) 135-224.

ȺȾɋɈɊɉɐɂȳȺɐȿɅɍɅȺɁȺɇȺɊȿɁȺɇɐɂɆȺɒȿȶȿɊɇȿɊȿɉȿɂ ɆɈȾȿɅɈȼȺȵȿȿɄɋɉȿɊɂɆȿɇɌȺɅɇɂɏɉɈȾȺɌȺɄȺ

. , . .

, , 1, ,

.

,

. ђ

ђ 8 9

-, . ,

,

,

-. ,

ђ

ђ , ђ 18,3%

-.

-. Langmuir-

ђ

-.

,

.

,

.

Ʉʂɭɱɧɟɪɟɱɢ: , , , ,