ublished qur trterty as the , organ of ihd

Special Issue

112008

137-1 42

E E R I N G

Sciences 11 !he Polish

Chosen

aspects

of thermo-mechanical

phenomena

in

resin bonded sands

by

use

of Hot

Distortion tests

Z.

Fgnaszak"

~aboratorium

CADICAE

Technologii

Matcriatowych, Zaklad

Odiewnictwa,Politechnika

Poznaitska, ul.Piotrowe

3,60-965

Poznati,Polska

Otrzy mano

14.03.2008;

zaakceptowano

do

druku

25.03.2008

Abstract

In prcscnted article the problems on thermo-mechanical phenomena. which occur in mould submitted 20 zhcrmal choc.

arc discussed.

The author t r i d to answer rhe question concerning thc uscfulncss o f Hot Distorzion tests (HD) for estimation of parametcrs necessary in data basc oTsimulation codes. which permit forecasting both strcss ficlds and location olzones mcnaccd by tcars in castings. The total Iack oh these paramcrcrs which shouId bc acccssiblc as rcmpcra!ure F~rnct ion, csp~cially in high tcrnpcm!i~rc rangc 41T rnoi~ld hcating was should,Usability of typical mcthods serving to mctal alloys (clast icily modulus, yicld. Poisson coelficicnt, dilatation cocfficicnt) is limired.

Bc-

sides sinplc cxccptions, thc rncchanical characteristics 01" mould sands (R compression, R tcnsion.R

hcnding) docsn? obhrain the elabo-rated mc!hndology and cotrespanding apparatus. Thc mc~hndotocy and cquipment. being propscd in thc

'70s

hv RCIRA, allowed to study rnnuld sand feature callcdHot

Distortion.In

this p a v r the I ID methodological basis of BClRA mcthod arc showcd. Thc modernapparatus DMA bascd on BCIRA mczhod was claboratcd and manulacturcd n fcw

ycars

ago in Poland. The author of this pawr makesrcccntIy a modification

of

DMA. Two thcrmic sources (clcctric and gascous) tosarnplc

hcating was testcd and analyscd. I t was intmduced the cxtended measurement and recording of choscn parameters. i.e, variability of tcmpraturc field in hcated sample.by

trsc o f pyromctcr and thermal camera. The analysis or rcsulrs according lo the interpretation or bchavior of quartz sands bonded by fzlranio rcsin was donc.Key

words: thcrmo-mechanical paramclcrs OF mould. test Hot Distortion, quanz sands. dcstnrcrion o f rcsin bond. ihcrmal tlilarnt ion.1. Introduction

Virtual methods in foundry and used simuln~ion sonware spwad widcr and wider. Rerativcly slowly arc dcvcloping applica-

tions

of systcms that forecasting stresses in castings and arcas of crack risk. An important reason of that situation i s unccdainly concerning high-tcmperaturc thermo-mechanical data necessary in rhese phenomena modcling. It concerns especial1 y mould materials. Mould material and mndc non-permanent moulds and corcs alwaysfulfilled important mlc in affccling on phenomena which are dcci-

sive in nspcct of casting quality. Uesemhes on materials for

moulds and corcs arc not cohcrcnt and not systematic, in nppsitc

to castinns

-

and alloys. Standard tests lor mould materials do notgive sufficicnk basis to forrnulatc its bchavior description in rhcr- ma1 conditions during mould lilling m d cas~iog solidification. Methods that turn otrt lrr hc ~ l s c f i ~ l lor alroys (modulus OF elasticity. yield limit. Poisson cocfficicnt. dilatation coefficicnk) arc not use-

ful for rnouId sand. Evcn changes in strength (Rc, Rg, Rb) in func- tion o f temperature has got any normnlizd rncthods and apparatus. Therc is Iack of parametcrs dctcrmincd in high-tcmvrature range. Somc hopc i s putting long timc an tlot Distortion (HD) tcst. well known since 30 years 14.51.

Sirnultancously the suggestion

for

apparatus, which has beenproposed

as

an

DMA

instrument, worked out in Poland, gives the opportunity for pmressionally conductedHD

research. This in- strument in original vcrsion and in vcrsionmodified

byZ.

Ig-

naszak, was applied for cornparativc studics.

In thc paper it has bccn rcfcrced to

IID

methodicalbasis,

that

were the basics of prototype instrumentBCIRA.

It

has been

tcsted and analyzed two kinds of heat sources forheating

theBCIRA

specimen. It has been introduced and widcn the range or paramc- ters recording, mainly for changes in temperature Fieldsof

heatedspecimen, mcasured by pyrornetcr and thcrmovision-camera. t t

has

been analyzed and interpreted results, for thc bchavior

OF

silica sand with furanic binder.2.

Analysis

of the thermo-mechanical

phenomena

for

sand mouId in

aspect

of

HI)

method

Thermo-mechanical interactions between casting and mould are known mainly intuitively. It is well known, that thcsc phcnom- ena determine intermediate and final statc of stresscs in casting.

In

individual cases, it can appcar thc dcformation or cvcn crackof

casting. The situation depends on alloy kind and castingshape

(blocking of contraction) and ~ h c technology of mould prcpma~ion and mould materials. Rigid moulds (permanent moulds) areequivalent to practical lack of flcxibit ity. Non-pcrrnancnt moulds (sand moulds) characterize with divcrw flexibility, depending on kind of mould marerial,

and are

made by use of conccntrated (and hardened) mould sand. It canbe

found in literature only citations for classical sources the descriptionof

rigidity withrange

fromvery high

(ccmcnt

mould-

practcaicatly not usedin

foundries) to very low (green sand conccntrated by classical mould machines, with low pressure). There arc not announced any numerical valucs.Thc bchavior

of

mould mawrialdepends

on

changeabilityof

properliesof

its components with temperature and applied load. Sintering temperalure. rcfractorincss coefficient, roasting tosses, permeability in conditions of hot air flow and hcat radiation on mould surface, that is few normalized (sometimes standardized)measures

in increased and in high temperatures, They do not allow ,to estimate searched, enumerated above thcrmo-mechanical valucs and charactcrinics.

Measure methods inspired e.g. by static compression or tension rest

for

testing o f mould materials behavior, put on test by tem- peraturc or both temperature and strcss, are rather rare [ 1,231.In fact, rcconstn~ction of ~hcrrno-mechanical conditions put on mould or

core

(heated by the liquid alloy) and study rhc assump- tions to construct suitablc apparatus, it must bc bascdon

scrics of simpIificat ions, together with sirnultancous tcst for standardization and repeatabilityof

the tests,Bctwcen methods workcd out by thc British Institutc

BCIRA,

for spccial artcntion dcscrvc this method,in

which ithas

bccn u s d heating by thcgas

and Bunscngas

burncr

.

This contact mcrhod, in which thc spccimcn was hcatcd using the block of 950'C tcmpera-rure, has

failcd.

In [4,51 it has bccn presentcd rncthodical basicsand iotcrprctation of

Hot

Distonion tests rcsultsHeating by gas burner is favourable in aspcct of high heat transfer coefficient between the Rame and thc specimen. Corre-

sponding and rcpeatable intcnsity of gas flow. constant distance of

gas

burner

to spcimen. itis a

conditionfor

stabilityof

transferred energy to each studied spccimcn.The principle

of RCIRA

testis

cmployed asan

assumption to construct polish professionalDMA

apparatus, callcdby

itscon-

structors "apparatusfor high-temperature

phenomena

testing in corcs"[6,7].

It

is

innovative

solution

fulfilling complex functionsof

meas-ure

automat It contains among olhcrs microproccssos systcm for programming heating parameters. automatic drive For specimen rnovcrnent with auto-positioning, super prccise converter for specimen position (precision t it1I

rnicromcter). Bcsidcpossibilities

of programmingusing

kcyboard belongingto

apparatus, dircct controlof

test coursc and data recording is taking place by con- nccrcdPC,

using spocial soitwarc.An

important

methodical novclty in this apparatus is applica- tionof

thc hear sourccas

an

haIogcn radiator withI

kW powcr (possibility of specimen hcating from its bclow andabovc).

Thcsecond new proposal is temperaturc measuring in area above the halogen radiator (thermocouple). Unfortunately, mcasurcd

[em-

pcraturc has not any rcfcrcncc (bcsidc thc fact of radiator working) to the temperaturc filcd of the spccirncn. The issue the author

of

thc paper has got informed and discussed with crcatorsof

DMA.

The auihor h&prcscn~cd to crcators thc rcsults of studics with mcas- ured real temperature using thermocouple locatcd insidc spccimcn6 9 1 ,

and showing small utility of such rcalized measurement.3.

Testing of thc

apparatus

and concep-

tion of its functionarity broadening

There are known

fmm

litcraturc thc typical deiormationof

BCIRA

s ~ c i m e n . The only one rcsult ofHD

tcst is thc dcforma- tion-time diagram.as

presentcd in standard BCIRA test(fig. 2)

[41.14

0

J E

ii

.-1 R

.

w s mFig. I .

Characteristic hot distortion curves Tor various resin bonded sands- original scsults from [4]. (order from left to right:Furanic, Shell-Croning. Hot Box, Cold Box)

Despite applied tcmpcraturc mcasurcmcnt

in

opcralion arca ofDMA

apparatus, it does not pcrform conditionsof

reprcscntativc samplefor

tcmpcraturcficld

in

spccimcn. Itcan

not bc prcparcd reliable relationship between spccimen dcforrnation and Icrnpera-ture.It should bctakcn mrc attcntion for ihc tcmpcraturc ficld in spcimen.

Thc

spximcn with dimcnsions I 14x25~6 rnm is put toheat radiation from lwo halogen radiators, with regulated p w c r ( 1

m900

W).Thc author o f ppcr has rcalizcd many studics (or mould sands

wilh

divcrsc

sand grains, boundcd by chemical and lhcrmal bind-crs.

Initially, rhc studics wcrc c~nductcd using awn constructedcquipmcnt. rnodeted on

BClRA

(wirh gas heating). Aftcr obtaining possibility of studies with DMA, i t has bccn continued comparativc studics. It is not known fromDMA

appararvs dcscription. how rherc wcrc dctcrmined boundary tcmpcmturcs o l spccirncn hcating, by heat radiation from 100 do 950"C.

Thc ohscwarions takcn during I ID mcasurcrncnt on DMA ap- paratus has dcrnonstmtcd, that for thc

same

kind o f bindcrarc

proceeding two pcflurhing and out-of-contml phcnomcna:influcncc of sand grains (kind of matrix), mcnning cmission cocfficicnt (c.g color and granularity) o l tcstcd moitld

sand

onamount of absorbcd cncrgy, and that causes somc rcslrictions for

methodology I-ID studics.

influence of thickness mlucc o f the spccimcn in arca o l long-

t imc hcating (e.g for mould sand with Suranic bindcr) in rcsult o l

gravitational descending o f sand grains, acquitted from bindcr constraints. which has lost its bond forcc.

I t rcsults. that [or gelting rcpcatahilizy of radiation cncrgy ab-

sorW

by

thc specimen, it is ncccssary to takc somc assumptions.If it will not bc takcn hn!o consideration. it should not bc co~nnarcd c.g bchavior o f mould sand madc o f ncw sand and regcnerntcd sand. Such restrictions do not occur by using gas burncr. as a hcat

SOUTCC.

The decrcasc in activc

s p i m c n

cross-scc~ion. in cffcct of sand grains loss. burdcn rhc rcsult o f spccimcn dcformation in thc sec-ond

gage o l hcating with largc dcfcct.Thc

phcnomcna Iikc this do not occur when using hcnting by gas burncr.This siruation induccs preparation of additional mdulc, which

makc possible heating

by

gas. This conception.mmains

idcntical mcchnnical configuration: working kngth of the spccimcn (From holdcr to load o f displaccmcnr sensor). I r is equal wirh possibility to spccimcns dcformation compnrison for both kinds nf hcating.Thc

spcimcn

is loadd by its own wcight. dcpcnding on kind of sand grains and levd o f density (for silica sand i t i s ahout 0.03Nlcm). Additionally. in place o l the loading of the sensor flangc.

point wise, i t is l o d c d thc Sorcc o f about 0, I N (fig. 2). Maximal

bending momcnt and strcsscs will occur naturally in placc OF

clamping. The quickcst dccrcasc of specim.cn strcngth Idcgcncra-

tion of resins bonds

-

joints) will occur in area o f maximal tcm- pcnturc. To draw comparativc conclusion, by using onc kind of healing, it is necessary 10 crnphasizc that changcnbil ity o f strcngth- plastic characteristics will hc prcciscly conncctcd with cxpcrimcn- ta2 conditions (spccimcn wcipht. amount o f cncrgy absorbcd by spccimcn and variability o f volumetric tcmpcraturc ficld. and that willdcpnd

on subst iiutc cocrficicnts o f ibcrmal conductivity and hcat capacity).Thc

sccondimponnnt

mtionaliza~ion o f IID mcasurcmcnt,which has bcen restcd. i s introduction of spccimcn tcmpcrnrurc rccording on oppsirc to hcatcd st~rfncc. It was acbicvcd using radiating pyromctcr Raytck. located on stand. Somc of studics wcrc

additionally instmmcntcd by thcrmovision-camera, which has

allowcd continuous rccording tcmpcralurc

ficld

onspccimcn

sur- face. T h c x rationalizations has nllowcd to conduct scrics o f stud- ies.Pip. 2. Scheme o f BCIRA test loads and chnrac~cr of tcmpcraturc curve in hcating zonc of sand sample.

4.

Study using

the

modificd

methodology

of

HD

tcsts

and analysis

of

results

Aficr achicvcmcnt o f neccssnry rnodificntions o f DMA appa- rarus (introduction o f addit ionnl gas hcat ing, with spccimcn tcm- pmturc mcasuremcnr) i t has hccn rcalizcd thc scrics of

scvcrnl

srudics. BcIow, in the first pan. it

has

hccn prcscntcd sclcctcd rcsuIts gaincd by gas heating. for rurnnic mould sands by i~sc of rcclnirncd sand and ncw sand (also silica snnd). RcsuIts (fig. 3 and5 ) hns bccn prcscnred in scqucnccs: Ax=i{t)

i

T=f(t) o m dx=f(T).I t has bccn also shown rcsu21s adcquatc to mould rcgencmtcd sand. obtaincd wirh thcmavision-camcn (irnapc and rcmwrdturc pmfilc

on

fraction of sccond bcforc destroying nF spccimcn and the coursc o f maximal rcmpcraturc during !hc wholc hcating (fig.4).On the following figurcs (fig. 5 , 6 m d 7) i t has bccn shown idcntical scqlicncc o f rcsults, for the same mould sands. making a!lowancc for that

IID

studics wctc madc using hcn~ing hy hcnrradiation, adequate for original DMh.

Whcn comparing fitst 1 ID rcsults (gas heating) for two kinds oS sand grains bondcd with thc samc kind or r~tnnic rcsin bindcs. it

can bc obsctvcd cvidcnt infltrcncc o f Ihc stdc o l emin for rcpcncr- atcd sand on character of st~rdicd phcnomcnn. It has hccn ohtaincd thc cffcct of flcxibility o f thc sysrcm grain-rcsio bindcr (s11ic:i- f u m i c ) in final stagc o f dcrormntion.

Furanic sand with ncw sand has bccn sight lcss rcsislam on thermal dcgradntion. I t tcstifics on significant contribulion of adhe- sion phenomena conncctcd with thc stntc o f rcclnimcd snnd grains.

not only for strcngth in arnbicnl tcmpcrafurc (lowcr Kflcx for this mould sands than Tor mould sands with ncw sand).

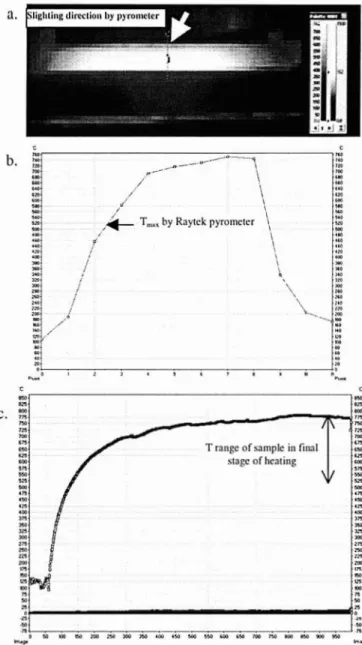

Fig. 3. Hot Distortion curvcs obtained by gas heating

for

lir-ranic quartz

sandsby

usc o f rcclaimcrl foundrysand

as

thc matrix.a)

Ax

= f(t) iT

= f(t), b) Crx=f(T).Fig. 4. 7hcmal imaging

by

V50

camera. a) thermal image,b)

temperature

prolilc invenical

middle linc of snrnple, c) ct~rvcof

maximal sarnplc lernperaturc recorded during wholc limc tcsl

( I 88

s).

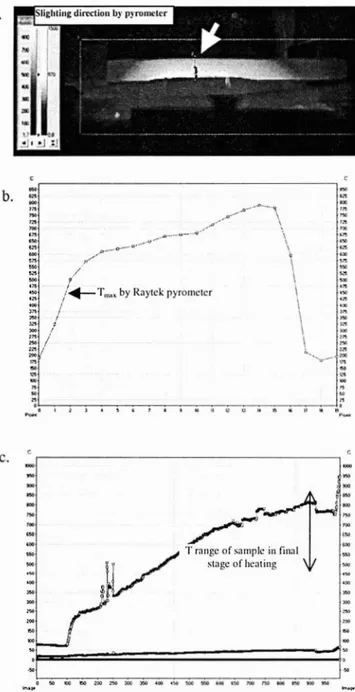

Fig.5. Hot Distortion curves obtained by gas hcating for

furanic sands

by useof

ncw quartz sand as the matrix. a) Ax = 1(2)i

T

= f(t),

b)Ax

=

f(T)

The rcsulrs o l

rcrnvnturc

ficld in erca offlarnc

operation orintensive hcat radiation indicates

on

diffcrcnt incrcasc a lT=f(t)

and different rcrnpcnture fields in thc final rnomcnt of the spccimenusing

gasbumcr

Sor hcn~ing. It wilt nor procccd thc perturbationarrccting

on deformationrcsitl!

(dccrcnsing in spccirncn thickness).dcsrruczion. ~ n d

this

the reasonfor

diffcrcnt dynamic o fthc

Ax=f(t).

Thc inRtlcnccof

kind of thc hcat sourcc on I I D studicsresult

is

wclE

visiblc.11 wouId bc ncccssary to achicvc stabilizalion of I ID wudics conditions. Tbc sclcction of thc rest with radiation

(halogn

) bcnt- ing catlscs accclcratcd destruction o f layers wirh rhc highcst tcm- pcra!urcs and falling "rnin ofsand

grains", with lowering of spcci- rncn rhickacss(cf. fig.7n).

If

this

phcnomcnon wile occur (nl ways insccond

halfof

hcat- ing period) valucsof

rcgislcrcd sinccthis

momentdeformation, do

not conccrn ~ h c wholc

cross-scction

o f 1h.c specimen (6x25mrn) andarc

in

principle Tcw valuahlc.Fig.

6.llot

Distortion curves obtained hy radiation hcnting for furanic quanz sands by use o f rcclairncd Foundry sand as n matrix.a

-

bx=f(t) iT=i(!).

b-

Ax=f(T).

5.

Summary

Thc studics has provcd, that modifications rcalizcd by

thc

author

of

pnpcr, about which wcrethc

crcatorsof

DMA inlorrncd (may 200S), sIlows to makcthc

comparison both kinds of hcating (by gas hurncr and halogen hcat radiation). This modification allows quick cxchangc o f hcating systcm. Applicationof

pyromctcrand thcrmovision-cnmcra, with irs own recording sysrcrns, allows

analysis of tcmpcraturc ficld

changcs

in spccimcn.If

we considcr thc rcsults o fI

ID. ilhas

bccn proved,that the

Full analysis

of

behavior of furanic mould sands is possihle only byFig. 7. Thermal imaging by V50 camcra for, a

-

thcrrnal irnagc, h-

zcrnpcraturc. profile in vcrtical middtc linc of snmplc, c-

curvc

or

maximalsarnplc tcmpcnturc

recordcd during wholc iimc tcn(16.4 s).

Thc

~ n u r b a t i o n likc [hisoccurs

always whcn i tis

npplicd rii-diation heating. If

docs

il occtjs. vatucs of rccordcd dcfortnalions will not allowthc

whotc spccirncn cross-scclion. and dcformnt ions arc in fact fcw valuahlc.Quickcr

dcgcncrntion of mould sand can be conncctcd with prcscncc ofoxygen

form a~mosphcric air inarca

o f rcsin dcgcncrotian.

I t has bccn provcd ;in significant influcncc or kind o f origin o f

]Litcratusa

the silica sand grains on thcrmo-mcchanicat

rcsponsc

of

mould material, Mouldsand

ohtaincd from rcpncrazcd s A d from foundry with 100% application of furanic rcsin hinders and mcchanical rcgencntion (dry, bywcak

Mction o f grains)is

chamrcrizcdby

anothcr

coursc

o f dcgmdation o f mechanical characteristic w i ~ h ternFraturc.Thc

dcgradationproceeds

in longcr timc and with diffcrcnl dynamics.Such ohscrvat ion only partially can

he

confirmed for classical hcating by radiation. likc this applicd in original DMA. The wholccurvc in

IIQ,

cspccially its sccond half,can

not bc thc basisro

cstimatc thcrmo-mcchanicnl fcarurcs o f mould sand. P ~ i a l l y , thc h a ~ i s likc this can

hc

1 ID curvc obtain4 from gas burncr hcating. with thc rcscrvation. that dcgradation occurs in conditions o fflame

atmosphcrc (dilficult acccss of oxygen).

I t has hccn provcd ples~icity o f firranic mouId sand obtaincd from 1006 rcclairncd sand. 'Thc fcalurc likc this was not obscrvcd when spccimcns madc using o f this sand wcrc tcstcd using classi-

cal DMA mclhorl. AT1 1hc carlicr crfcctuatcd studies with

applica-

tion o f rhis clnssical rncthodology. cnn bcc anaEyzcd sincc the rnomcnt o f starting dccrcasing o f spccimcn thickness.[I] S.N.Ramnttan and olhcrs, ThcrmaI Distort ion in Prnccss Con-

arol o f ChcmicaIly-Bondcs Sands. AFS Transact ions 1997. pa-

p r

no 152,152-165.121 L.Lcwandowski: Masy

formicrskici

rd7cniowc.PWK

Wnr- szawa (1991 ).[3J

Z.Samsonowicz : Porniay przcpuszc7.lnoSci mas furmicrskich wwysokich

tempcmmrach. Zcsqty Naukoic 1'01. \Vroclnw- skicj, Mcchanika IX. Nr 56.1963.93,

[4] A.D.Morgan, E.W.Fasham. A ncw hot distortion tcstcr for chcrnicatly bondcd sands. Rcport o f BCIRA. 1974.

[ 5 ]

BCIRA EFot distortion tcslcr. Opcraling ins~ructions. 1975.[6] hrtp://www.multiscrw-morcl;.pl/p1/indcxpl.h~m.

[7] J-Jakubski, St.M.Dobosz Annliza rltcrorrnacjl cicplncj mas

z zasrosownnicm aparatu

DM

A -Archiw~rn Odlcwnictwn =Archivcs o f Foundry. 2003

K.

3 nr 9.241+25 1.IS]

Z.lgnaszak. Privalc infnrma~ion SorS.I>oht)sz.

AGI 1 Krak6w. 2000,[9]

Z.lgnaszak, Tcsts 1 ID dcs sablcs lurnniqi~cs ct plyourcrancs Rcscarch rcpotTs. Fcrry-Capitain Foundry. 2000-2007.[I01

J.Jakubski. St.M.Dobosa: Wplyw powloki ochronncj nnzjawiska cicplnc w rdzcninch odlcwniczych, Archivcs oh Fo- undry. 2006,. nr 18 (2/2), 453-458,

Wybrane aspckty

zjawisk terrno-mcchanicznych

m

masach wiqzanych Qwicq furanowq

podczas realisacji

tcst6w

Hot Distortion

Streszczcnie

W artykulc ombwiono zagadnienia odnosyce sic do zjaivisk ~crmorncchanictnych jakic aachodL~ w poddancj szokorvi cieplnernu formic piaskoivej. Starano sic odpow-icdzicc na pyanic d o r y c ~ ~ c c pmydatnoSci hadah I lot Distortion (I !I)) do uscowania dohon~ paramc- trbw niczbednych w 'bazie danych w systcmach syrnulacyjnych, prognozujqcych napn$cnia \v odlcwvach i polotcnic strcf 7agroionycli p~knivciami. Stlvicrdzono calkorviry b n k tych parametrciiv. kldrc por\@inny

hyi:

dost~pnc w funkcji lcmpentuv, z\rrtaszcm w rakrcsic wysokotrmperaiurowym, do jakich nagrxwn sic Sur~na, I'rzydntnoSC ~ncrocl j:!kic spri!\vdirAi,jq sic dtn mctnli (modut sprt;@stoSci. grmicn ptastycznoSci, wsp6lczynni k I'oissonn, \vsr.spblcqnniL dylarac.ji) jcsl znikoma. ZrniennoiC \vytrzymnloScC mas I'urrnicrskich(k.,

R,. R,) w litnkcji tcmperatury. porn pqjedynczymi wviqtkami, nic doczckaly siq unormowanych mcrod i sloso\vnej aparatup. Mctodologia i npnra-tura jaka pojawita sic w tatach 70-rych. opracowanc przcz BCIRA. pozwalaty na przcprowadzcnia hadail ccchy masy zwanej I lot Distor- tion. W artykuIe naSwicilono podstawy mctodycznc I I!) jnkiu lcgly u podstaw mctody UCIRA. W knju pnrq lat tcmu zostnt y p r u d ~ r k o -

wany nowoczcsny aparat

![Fig. I . Characteristic hot distortion curves Tor various resin bonded sands- original scsults from [4]](https://thumb-eu.123doks.com/thumbv2/123dok_br/18198542.333202/2.893.456.842.687.948/characteristic-distortion-curves-various-resin-bonded-original-scsults.webp)