Vol-7, Special Issue3-April, 2016, pp2344-2350 http://www.bipublication.com

Research Article

Experimental Investigations on the Efficiency Coefficient of Pile Groups

Sara Darsi, Abolfazl Soltani* and Mohammad Ali Arjomand 1

(MSc Student in Geotechnics)

Shahid Rajaee Teacher Training University, Tehran, Iran Email:darsi8890@yahoo.com

2(Corresponding Author)

Email: Abolfazl_soltani2003@yahoo.com 3Email:Arjomand@srttu.edu

Shahid Rajaee Teacher Training University, Tehran, Iran

ABSTRACT

Several factors influence on behavior of piles group such as type of soil, number of piles in the group and the distance between piles. In this paper, using a small laboratory model, the influence of these factors on the behavior of piles group has been examined.For this purpose a group of piles in different distances and variable number of piles was allocated in sand under anpressure axial load. The piles are preferably metal; thus to reduce weight a hollow type has been selected.In order to calculate the coefficient of piles group efficiency, a single pile has been experimented. Experimental observations show that the number of piles in the group and the distances between piles in sand have considerable effect on bearing capacity and the coefficient of pile group efficiency and the coefficient of efficiency in this type of soil have constantly been more than 1 and limited to 1 by increasing the distance between piles.

Keywords : Efficiency Coefficient, Number of Piles, Pile Group, Distance of Piles, Cap

INTRODUCTION

In order to transfer the load of structures to ground an intermediate element known as foundation is essential. In fact, such foundation transfers all loads of a structure including vertical loads such as gravity load and lateral loads such as wind, earthquake, landslide into the soil below the structureand this acts in a manner to preventany excessive subsidence and detachment in the soil.Various types of foundations are available but in order to use the bearing capacity of more powerful and deeper layers of soil in majority of structuresa deep foundation (piles) is used.Piles are usually applied in a group and it is less likely to be used as a single one in structures. Depending on the application of a pile group, the number of piles in a group may vary. The pile

bearing capacity of piles. For this purpose, a large number of different equations are applied and rarely the calculation of bearing capacity in two equations is the same.

Due to the uncertainties involved in predicting the bearing capacity of piles, it is necessary to determine the bearing capacity in situ. Pile loading test is the best way to determine the bearing capacity of the load on pile, and in most large projects, a number of such tests are carried out. It is very expensive to test at actual size, so laboratory models are often used. If a pile loading test is done for a single pile and a group pile, oftenultimate is not the same in both cases.This difference is due to various reasons including the existence of caps and joint displacement of piles. According to the above-mentioned differences, effective coefficient of group (efficiency coefficient )is defined as follows:

Efficiency coefficient of group is mainly dependent on the changes of pile lateral resistance. Therefore, the factors that affect this ratio and the performance of pile group differ from effective factors in the performance of a single pile. In general, factors affecting the performance of piles and efficiency coefficient can be named as follows:

1. Soil type and density,

2. The method of installation of pile, 3. How to sort piles,

4. The ratio of insertion length to diameter pile, 5. Pilesdistance from each other,

6. Coefficient of friction between the pile and soil.

In sandy soils, the efficiency coefficient of pile groups at different distances of piles from one another is variable and is between 1 and 2. This performance increase is due to the interference of piles pressure in a pile group which increases the frictional resistance of piles wall. According to research conducted on pile group in sandy soil it has been indicated that the performance of a group of piles is related to following factors.

1- The concentration of banging,

2- The degree of overlap of the pressure that resulted from piles distance from one another. The closer the piles are together the more they increase the degree of overlap and therefore they have more effect on each other, thus the distance should not be less than 2 times of the diameter of the piles.

The studies by Meyerhof and Nishia (1965)showed that the coefficient of performance is always greater than one. They also reported that the efficiency of group piles in very dense sand (φ> 40) is less than 1 and distance of 7 times of the diameter, the coefficient of efficiency of Group is 1.This can be raised to justify that when banging pile, the impact of density on piles and overlapping the volume of pressure is minimal. When the pile is banged into a loose soil, the soil compacts, resulting in increased φ and when it is very dense, banging it makes it loose and causes adverse effects.

pointed out to some practices undertaken by NabilF. Ismael (2001) who did experiments on sandy soil inworkshop and came to the conclusion that the piles, away from each other with a diameter of 2 the efficiency coefficient is1.22and 1.93 is the efficiency coefficient for piles away from each other with a diameter of 3.Using numerical methods, Comodromos et al. (2003) stated that efficiency coefficient of pile group depends on the space between piles. The efficiency coefficient of piles increases with increasing distance.Hanna and Nguyen (2003) studied the frictional resistance of a vertical and slant pile. This experiment was performed on two different steel piles with a diameter of 76 mm and 38 mm both in the sand with relative density of 65.3 percent. To calculate the ultimate strength of the pile in the experiments, a graph to show load shift was designed and the point where the slope of the graph changed would be considered as ultimate strength of the pile. Dividing the ultimate strength into the pile length determines the final amount of frictional resistance (fs).With increasing the L/D ratio, the length frictional resistance(fs) increases in critical depth, and after this depth the resistance continues to increase slowly. In addition, by increasing the angle of inclination of piles ratio to a vertical angle, length frictional resistance reduces. By increasing the angle of inclination of piles from zero to 30 degrees, pile resistance decreases.

The main objective of this research is to model some single pile and pile group experiments and to compare load curve – displacement of piles with different number of piles in the group and the space between them. With this test the efficiency coefficient of pile groups was calculated and compared for different scenarios.

Methodology

To search for static loading tests and control the quality of piles integrity, and how to perform axial static loading testthis work refers to ASTM standards. According to this standard to determine the bearing capacity and behavior of

the force - displacement of piles is the most important issue in designing and implementing piles. Static load test as a reliable method can be used in designing stage and before installing the main piles as (Test Pile), or during the operation on the main piles to ensure the expected design and implementation of quality control be carried out.Static axial compressive load test in piles should be planned and implemented in accordance with ASTM D-1143 instructions. Since metal piles with circular cross sections are usually used in Iran, this work only determines the type of such piles. Aspreviously indicated, the loads on the pile are axial, lateral and bending loads. But often the most important factor in designing piles in terms of loading capacity, is to design piles against axle load.In other words, in most cases, the axial force on the piles is the main cause to determine the bearing capacity of piles. In this paper, the bearing capacity of single pile and pile group under axial loading, digging in a granular soil will be discussed. For the experiments of this study, a particular device was designed. Experiments were done in the Faculty of Civil Engineering, Shahid Rajaee Teacher Training University, Tehran, Iran. At least 5 different modes were tested in these experiments.An experiment was conducted on a single pile that was used to gain control capacity and 4 modes of the experiments were on the group piles with a different number and various spacing of the piles.

In the following explanations, more details regarding the test equipment may be considered.

Loading device

During the experiment, a universal device for the changes in addition to some equipment, according to regulations, was used. The Universal device used in these experiments has the following specifications and features:

1. Ball Screw axis servo motor system

3. Carefully measuring the displacement of ± 5 Micrometer

4. Measuring the force ± 1kg

5. Windows software allows devices to collect data from testing strength and elongation by sensors, calculation, preparation and publication of the results and creating a graph with the following features:

• Ability to draw deflection and stress-strain curve• Ability to store test data in Microsoft Excel format

Sand chamber

To perform laboratory tests a chamber was designed and built. The chamber has dimensions of 100 × 60 × 70 cm.

Soil

To conduct this study, a type of sand from Firoozkooh region, NE Tehran was prepared with different granularities that are used in Sandblasting and casting industry.

Sand bags are supplied in 50 kg bags, the grains have a diameter ranging from 0.7 to 1.4 mm. In order to determine the physical and mechanical properties of the coarse-grained soil some laboratory tests including Atterberg limits, density, particle size, have been made based on the ASTM standards.

Piles

Piles are steel and black pipes and especially hollow to reduce the weight and a type of quality cement has been used to block the end.Theoutside diameter ofpiles is 33 mm, and their inner diameter is 30 mm while a length of 70 cm was chosen.

Cap

Most Piled foundations consist of several piles rather than a single one, and as a result, an integrated cap is installed on the top. In this experiment a plank of wood with suitable

dimensions has been used as a cap for each stage according to the number of piles in every group.

Overall stages in the test

After preparing the necessary equipment and materials as well as guidelines, the experiments were performed. To investigate the effect of number and spacing of piles on the performance, tests were performed on groups of 2 × 1 piles with a distance of 3 times the diameter of the piles and 6 times the diameter of the pile and groups of2 × 2 piles at a distance of 3 times the diameter of piles and 6 times the diameter of the piles, respectively. According to previous studies, this distance can better show the influence on the behavior of pile group.With the distance of 3 times the diameter of the piles was considered as the closest distance between piles because less stress bubbles were overlapping and 6 times the maximum distance was also considered because from this limit on piles turn to act as a single pile and go out of a pile group.And also to compare results and determine the efficiency coefficient of pile groups, single- pile tests were also conducted.

Following is the general trend in this test:

First 5 cm-thick layer of soil is poured and compress and continue with a second layer, so the final layer thickness reaches 40 cm. Under these conditions, the density in soil is 75%. Put the piles on the ground, put the cap on pile group and then continue with pouring and compressing the soil down to a 75 cm height. Upper jaw of the device is set in such a way so that the metal plate is placed on the center of cap. Universal device is turned on and begins loading piles. The force has been set to press the cap at 1 mm per second and the cap distributes the force among the piles. The results are displayed by this device in Excel.

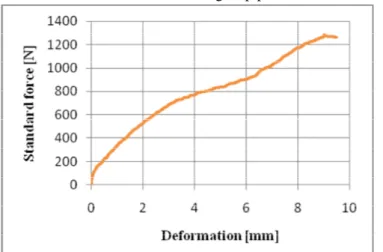

Figure 1: Test results of single pile

In follow, test results of group pile with different distances have been shown.

Figure 2: Test results of groups of 2 × 1 piles with a distance of 3 times the diameter of the piles

Figure 3: Test results of groups of 2 × 1 piles with a distance of 6 times the diameter of the piles

Figure 4: Test results of groups of 2 × 2 piles with a distance of 3 times the diameter of the piles

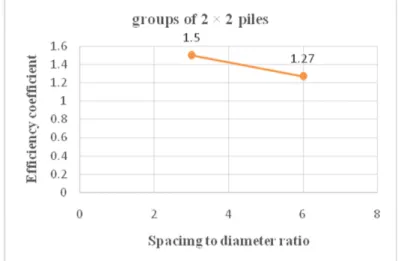

According to the model presented in the previous section, efficiency coefficient of group pile have been calculated by load capacity and their results have been brought inthe Fig. 6-9.

Figure 6: Efficiency coefficient groups of 2 × 1 pile at various distances

Figure 7: Efficiency coefficient groups of 2 × 2 pile at various distances

Figure 8: Efficiency coefficient for groups pile different Figure 9: Efficiency coefficient for groups pile different

DISCUSSION AND CONCLUSION

In general, according to the conducted tests, the following results can be obtained:

1. On sandy soil the efficiency of pile group is always more than 1.

2. The number of piles in the group and the distance between the piles has a significant impact on the capacity of bearing and coefficient of performance in pile group. 3. The coefficient of performance in a distance

of 3 times the diameter of the pile has had the

highest amount of 1.5 and by increasing the distance to 6 times the diameter of the pile tends towards 1. In other words, the distance factor will reduce the efficiency of the group and the piles lose their joint performance and act as a single pile.

5. In the specified distance between the piles, with the number of piles from 2 to 4 ones, the coefficient of efficiency and loading capacity increases from 1.33 to 1.5. This reflects the impact of the number of piles on the efficiency coefficient.

REFERENCES

1. Moradi, Gh. Pashayan, M and Alizade, M. (1391). “Experimental investigations ofinfluence of distanceon the efficiency coefficient of pile groups, Isfahan University of Technology, Tehran, Iran.

2. Comodromos, E.M., Anagnostopoulos, C.T., and Georgiadis, M.K., (2003). Numerical assessment ofaxial pile group response based on load test, Journal of Computers and Geotechnics, Vol. 30, pp. 505-515

3. Nabil F.Ismael. (2001). Axial load tests on bored piles and pile groups in cemented sands. Journal of geotechnical and geoenvironmental engineering, PP.766-773

4. Lo, K.Y. (1967). Discussion to paper by Orrje and Broms. J.S.M.F.D, ASCE, vol.94, SM2: 606-608.

5. Kishida, H. (1967). Ultimate Bearing Capacity of Piled Driven into Loose Sand. Soil andFoundations. vol.7 No.3:20-29 6. Vesic, A.S. (1969). Experiments with

instrumented pile groups in sand. Performance of deepfoundations. ASTM STP 444, ASTM, West Conshohocken.PP.177–22