Abstract

The use of a gouging abrasion test to evaluate the wear of jaw crushers is revised in terms of its procedures, considering the effects of the most signiicant variables, such as the minimum amount of crushed material and the minimum opening between the jaws during the crushing cycle (minimum discharge aperture). A correlation between the work hardening of jaws and the amount of crushed material is presented. The wear of stationary and movable jaws is compared, being the results dependent on the jaw’s material and the discharge aperture. The abrasiveness of several rocks was evaluated, showing a good correlation with their Mohs hardness.

Keywords: jaw crusher; gouging abrasion test; work hardening; abrasiveness. Giuseppe Pintaude

Professor

Universidade Tecnológica Federal do Paraná - UTFPR Curitiba – Paraná – Brasil

giuseppepintaude@gmail.com

Nilson Mar Bartalini

Mestre em Engenharia Mineral

Supervisor Regional da Clariant S/A - CMS São Paulo – São Paulo – Brasil

nilson.bartalini@clariant.com

Revisiting gouging

abrasion test for jaw crushers

Mining

Mineração

http://dx.doi.org/10.1590/0370-44672017710060

1. Introduction

Around 40 per cent of the total en-ergy used in mineral processing operations is due to the crushing and grinding steps. The wear of crushing and grinding media corresponds approximately to 50 per cent of process costs in these operations (Radziszewski, 2002; Aldrich, 2013).

In this context, it is worthwhile to mention that there only exists rela-tively scarce literature on the wear of jaw crushers. Basically, most of wear data was produced by two research groups: the US Bureau of Mines (closed in March

1996) in EUA (Blickensderfer et al.,

1985; Tylczak et al., 1999; Hawk et al.,

1999), and Commonwealth Scientiic and Industrial Research Organisation (CSIRO) in Australia (Sare et al., 1980;

Sare and Arnold, 1989; Sare and Con-stantine, 1991; Sare and Arnold, 1995; Sare and Constantine, 1997).

Before these publications, the Cli-max Molybdenum Company presented signiicant investigations for the inter-pretation of results obtained in tests to estimate the wear of jaw crushers (Borik and Sponseller, 1971a; Borik and Spon-seller, 1971b).

The contributions of these research groups promoted a consolidation of an ASTM standard for a gouging abrasion test using jaw crushers, edited for irst time in 1997 and reapproved in 2002, 2007 and inally in 2013.

More recently, a research group from Chalmers University (Lindqvist and Evertsson, 2003) studied the wear of jaw crushers, but their goal was to transfer a developed wear model for cone crushers.

As austenitic manganese steel is widely used as material to manufacture jaws. Some recent investigations

de-served attention for the microstructural aspects of this alloy and its performance being tested in terms of wear (Silva, 2004; Olawale et al., 2013; Magdaluyo et al., 2016). Considering the wear

per-formance of a wide range of materials and hardfacing deposits during gouging abrasion test, the indings described by Llewellyn et al. (2006) can be considered

a very useful guide.

In Brazil, academic studies were conducted at the University of São Paulo, being the irst one a thesis (Siriani, 1973), whose detailed data was extracted directly from mining operations, and two Master’s Dissertations (Pintaúde, 1998; Bartalini, 1999), which used a small machine, a lab prototype of a jaw crusher. This article is a historical summary of the main con-tributions given by these researches for understanding wear of jaw crushers.

2. Materials and methods

Three sets of experiments were performed using a small lab jaw crusher, with sample dimensions of 135 mm X 75 mm X 25 mm. For the irst and second ones, the same crushed material, granite with particle size between 1” and ¾” was used. Details of its mineralogical charac-terization can be found in Pintaude

et al. (2001). In these experiments,

the work hardening of worn surfaces

was evaluated for different amounts of crushed material, to establish a mini-mum of cycles to measure wear in the steady-state regime. The procedures to determine hardness were described by Pintaude et al. (2003). In the second

set, two materials were used for this, a high silicon (2Cr-1.5Si-0.5Mo) and a manganese cast steel, evaluating the effect of the closed side set (CSS) - the minimum opening between the jaws

Set Crushed material Jaw material CSS, mm Objective

1st Granite High Si cast steel 3.2*

Evaluation of minimum amount of crushed

material and work hardening of stationary jaw

2nd Granite

High Si cast steel 0, 3.2*

Evaluate the effect of CSS, compare materials, and the wear of different jaws High Mn cast steel 1.8, 4.5, and 7.2

3rd Eight rocks** High Mn cast steel 4.5 Evaluate the

abrasiveness of rocks

*recommended by ASTM G81-97(2013). **basalt, diabase, quartzite and five granites.

Table 1

Main parameters used in each set of experiments.

3. Results

First set of experiments

Figure 1 shows the wear of the sta-tionary jaw manufactured in high Si cast

steel as a function of the crushing batches. In the same Figure, the microhardness of

each step is presented, and was used to evaluate the work hardening.

Figure 1

Variation of mass loss (g)

a stationary jaw (high Si cast steel) for different crushing cycles of granite, using CSS = 3.2 mm. Values of superficial microhardness (HV0.1) are shown.

One can clearly observe that the wear reached a steady-state regime when the values of microhardnessa at the worn surfaces did not present any variation. In this fashion, the description made by Blickensderfer et al. (1985) for a minimum

crushed material to reach a steady-state

regime of wear in a similar lab equip-ment can be considered as suitable. They recommended a minimum of 90 kg, while ASTM G81-97(2013) requires 900 kg, but in this case the dimensions of the equip-ment are higher.

The extension of plastic

defor-mation was also evaluated, as shown in Figure 2. One can observe that the level of deformation is suficient to alter up to 1 mm below the worn surface. Similar results were reported by Borik and Sponseller (1971) for austenitic manganese steel.

Figure 2

Second set of experiments

Figure 3 shows the variation of wear rates in terms of CCS (mm). In a general way, the smaller the CSS, the higher the wear. This is an expected result (Borik and Sponseller, 1971), since the compression forces increase with the reduction of discharge aperture.

In addition to the effect of CSS on the wear rates, other observations can be discussed from this set of experiments. The first one is related to the tested materials, which were dependent on

the position of jaw. High Mn cast steel performed much better when a station-ary jaw is considered, but for a movable one, the high Si cast steel presented a better behavior in terms of wear resis-tance. This difference explains, from the numerical point of view, the wear of stationary jaws in relation to those determined for the movables, which was much superior in case of the experiments conducted using high Si cast steel.

The wear of a stationary jaw tends

to be increasingly higher than that de-termined for movable side as the CSS diminished. In an indirect way, one can conclude that the increase of compres-sion forces can cause an increase on the gouging action on the stationary jaw, but this extension will depend on the tested material. More accurate conclu-sions with this issue could be treated in future investigations, helping to select in a better way for the materials with different jaws.

Figure 3 Variation of wear (g/t) in terms of CSS (mm), crushing granite.

Third set of experiments

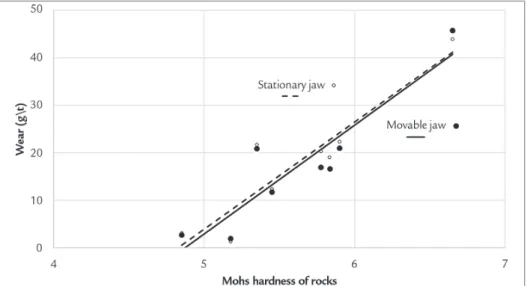

Figure 4 shows the relationship be-tween the wear rates and the Mohs hard-ness of several rocks, tested under the same

conditions. Good correlations are found (R2 ~ 0.85), being the increase of hardness, consequently the abrasiveness, attributed to

the increase of quartz content. This relation-ship was pointed out previously by Siriani (1973) and conirmed here in another way.

Figure 4 Variation of wear rate (high Mn cast steel) in terms of Mohs

hard-ness of crushed rocks. (CSS = 4.5 mm).

4. Conclusions

This article summarizes results obtained in a gouging abrasion test obtained with a lab jaw crusher ma-chine. The following conclusions can be presented:

- The minimum amount of

crushed material to achieve the steady-state regime of wear was closely related to the work hardening of the worn surface;

- The wear rate of jaws increases for smaller close sided sets, but this

variation depends on the material of the jaws; and

Acknowledgments

Authors acknowledge Embu S.A. for supplying rocks for lab tests. Special

thanks are to the advisors, professors A. Sinatora, D. K. Tanaka and F. Fujimura.

References

ALDRICH, C. Consumption of steel grinding media in mills–A review. Minerals

Engineering, v. 49, p. 77-91, 2013

ASTM G81-97a(2013), Standard Test Method for Jaw Crusher Gouging Abrasion Test, ASTM International, West Conshohocken, PA, 2013, www.astm.org

BARTALINI, N. M. Desgaste abrasivo em britadores de mandíbulas. São Paulo:

Escola Politécnica da Universidade de São Paulo, 1999. 158 p. (Dissertação de Mestrado em Engenharia de Minas).

BLICKENSDERFER, R., MADSEN, B. W., TYLCZAK, J. H. Comparison of several types of abrasive wear tests. In: INT. CONF. ON WEAR OF MATERIALS, 1985. Vancouver. Proc. of Wear of Materials 1985. ASME, 1985. v. 1, p. 313-323, 1985. BORIK, F., SCHOLZ, W. G. Gouging abrasion test for material used in ore and rock

crushing. Part 2: effect of metallurgical variables on gouging wear. Journal of

Materials, v. 6, n. 3, p. 590-605, 1971.

BORIK, F., SPONSELLER, D. L. Gouging abrasion test for material used in ore and rock crushing. Part 1: description of the test. Journal of Materials, v. 6,

n. 3, p. 576-589, 1971.

HAWK, J. A. et al. Laboratory abrasive wear tests: investigation of test methods and alloy correlation. Wear, v. 225, p. 1031-1042, 1999.

LINDQVIST, M., EVERTSSON, C. M. Liner wear in jaw crushers. Minerals

Engineering, v. 16, n. 1, p. 1-12, 2003.

LLEWELLYN, R. J., HALL, R. A., DU, J. R. Assessment of materials for gouging abrasion applications. In: AUSTRIB 2006, 2006. Brisbane. Proc. of Austrib:

National Reseach Council, 2006. v.1, p. 1-8.

MAGDALUYO Jr, E. R., AUSA, M. S., TINIO, R. J. Effect of titanium on gouging abrasion behavior and hardness of austenitic manganese steel. In: Transactions on Engineering Technologies. Springer Singapore, 2016. p. 73-81.

OLAWALE, J. O., IBITOYE, S. A., SHITTU, M. D. Work hardening behaviour and microstructural analysis of failed austenitic manganese steel crusher jaws.

Materials Research, v. 16, n. 6, p. 1274-1281, 2013.

PINTAÚDE, G. Estudo do regime transiente em desgaste abrasivo: ensaios em

britador de mandíbulas. São Paulo: Escola Politécnica da Universidade de São

Paulo, 1998. 126 p. (Dissertação de Mestrado em Engenharia Mecânica). PINTAUDE, G. et al. The particle size effect on abrasive wear of high-chromium

whi-te cast iron mill balls. Wear, v. 250, n. 1, p. 66-70, 2001.

PINTAUDE, G., TANAKA, D. K., SINATORA, A. The effects of abrasive particle size on the sliding friction coeficient of steel using a spiral pin-on-disk apparatus.

Wear, v. 255, n. 1, p. 55-59, 2003.

RADZISZEWSKI, P. Exploring total media wear. Minerals Engineering, v. 15, n. 12,

p. 1073-1087, 2002.

SARE, I. R. et al. The determination of gouging abrasion resistance by jaw crusher tests. In: CONFERENCE ON LUBRICATION, FRICTION AND WEAR IN ENGINEERING 1980, Melbourne: Preprints of Papers, Institution of Engine-ers, Australia, 1980. p. 94.

SARE, I. R., ARNOLD, B. K. Gouging abrasion of wear-resistant alloy white cast irons. Wear, v. 131, n. 1, p. 15-37, 1989.

SARE, I. R., CONSTANTINE, A. G. Design and analysis of jaw crusher gouging abrasion tests. Journal of Testing and Evaluation, v. 19, n. 2, p. 115-122, 1991.

SARE, I. R., CONSTANTINE, A. G. Development of methodologies for the evaluation of wear-resistant materials for the mineral industry. Wear, v. 203,

p. 671-678, 1997.

SARE, IR S., ARNOLD, B. K. The effect of heat treatment on the gouging abrasion resistance of alloy white cast irons. Metallurgical and Materials Transactions A,

v. 26, n. 2, p. 357-370, 1995.

nióbio--boro em aços Hadield no desempenho ao desgaste abrasivo. Ouro Preto:

Universidade Federal de Ouro Preto, 2004. 122 f. (Dissertação de Mestrado em Engenharia de Materiais).

SIRIANI, F. A. Características gerais de desgaste de mandíbulas em britadores. São

Paulo: Escola Politécnica da Universidade de São Paulo, 1973. 281 p. (Tese de Dou-torado em Engenharia de Minas).

TYLCZAK, J. H., HAWK, J. A., WILSON, R. D. A comparison of laboratory abra-sion and ield wear results. Wear, v. 225, p. 1059-1069, 1999.