The Eet of Grain-Domain-Size on

Levitation Fore of Melt Growth Proessing

YBCO Bulk Superondutors

W. M. Yang 1;3

, L.Zhou 2

, Y. Feng 2

,P.X. Zhang 2

,C.P. Zhang 2

,

Z.M.Yu 2

,X.D.Tang 2

1:

Departmentofphysis,ShaanxiNormalUniversity, Xi'an,Shaanxi, 710062,China

2

NorthwestInstituteforNonferrousMetalResearh,

P.O.Box51,Xi'an,Shaanxi,710016, China

3

LASUP-Laboratorio deAplia~oesdeSuperondutores,

Depto. de Eletrotenia, Esolade Engenharia,UFRJIlhadoFund~ao,

Cx.P. 68515,21945-970, Riode Janeiro, RJ,Brasil

Reeivedon28February,2002

Eetsofgrain-domain-size(GDS)onlevitationforehavebeendiretlyinvestigatedandidentied

inwell-texturedYBCObulks. A single-grain-domain YBCObulk(=30mm)was preparedbya

topseededmeltgrowthproess,thendividedintotwo,threeandfourgrain-domaintoaquirethe

levitationforesofsampleswithdierentGDS.Itisfoundthatthelevitationforeofthesamples

monotonouslydereaseswiththedereasingoftheaverageGDS(orwiththeinreasingofthetotal

lengthgrain-boundariesofthesample). Themaximumlevitationforeforthesingle-grain-domain

sampleisabout1.68,2.05and2.4timeshigherthanthatofthesampleswithtwo,three,andfour

grain-domains. It is onluded that the levitation fore of a single-grain-domain YBCO bulk is

higherthan that of samples with multi-grain-domains. It is also found that the levitation fore

isproportionaltotheaveragegrain-domainradius,butinverseproportionaltothetotal lengthof

grain-boundariesofthesample, asimplephysial modelhasbeenprovidedandwellinterpretthe

experimentresults.

I Introdution

High levitation foreof single-domainYBCO bulk

su-perondutorshasmadeitpossibleforvarious

applia-tions, suh as non-ontated superonduting bearing

[1,2℄, ywheel[3-8℄,magneti levitationtransport

sys-tems [9,10℄and motors [11,12℄. It isbelieved that the

energylossof superonduting magnetiywheelisas

little as 0.1% per hour, only one tenth of that with

onventional bearings. The ommerialization of this

tehnique will not only redue the energy losses, but

alsomaketheeletriityonsumptionmoreeonomial

andreasonabletomeetourdemands.

Thelevitationforebetweenasuperondutorand

amagnetisloselyrelatedwiththeritialurrent

den-sityJandtheradiusRoftheinduedshieldingurrent

loops(ISCL)inasuperondutor. HigherJandlarger

Rareveryimportanttoahievehigherlevitationfore

[13℄. Nowsingle-domain YBCO bulksuperondutors

anbe fabriated in manylabs [14-21℄,soarelatively

larger R of ISCLan beahievedwhile a magnet

ap-isgenerallyaboutseveralentimetersindiameters,and

limitedto10mforhighqualityYBCObulkuptonow,

beauseof thegrains miss-orientation duringthe melt

growthproess.

The levitation fore is also related with many

pa-rameters, suh as thikness of the sample [22℄,

grain-orientation[15,26-28℄,temperature,magnetield

dis-tributions [23-25℄, and the gap between

superondu-tor/magnet[29℄et. Reently,aneletromaglev

exper-imentperformedonasingle-domainYBCObulk(=

30mm)andamultiple bulkomprisedsmallerdisks(

=10mm) [30℄. It is found that the levitation fore of

asinglelargerYBCOdisksissuperiortoassembliesof

smallerdisks,theexperimentsweredonewithdierent

samplesand espeially the geometri shape of the

as-sembledsmallerdissouldnotwellmaththevolume

shapeof the=30mmsingle-domain YBCO sample.

Butthe physial mehanismsgoverningthe levitation

fore assoiated with the grain-domain-size (GDS) or

ISCL are not learly. We annot see any report

wasdiretlydonebyusingasingle-grain-domainYBCO

bulksuperondutors.Identiationoftherelationship

between the levitation fore and GDS of YBCO bulk

isnotonlyinterested tofundamental studies,but also

veryimportantforpratial.

In this paper, a single-domain YBCO bulk

(=0mm) wasfabriatedanddividedinto two,three,

andfour grain-domains. Thelevitation fore

measure-ments were done on the YBCO samples with a

sin-gle, two, three, and four grain-domainsto investigate

thephysialmehanismsofGDSonthelevitationfore

ofwell-texturedYBCO superondutors,and asimple

physial model has been dedued and well explained

theexperimentaldata.

II Experiments

Samples preparation. X-ray Pure YBa

2 Cu

3 O

y , 4N

purity Y

2 O

3

and PtO

2

powders were weighed and

mixed in the weight ration of 90.5:8.5:1. The

well-mixed powder was uniaxially pressed into

pel-lets of =35mm15mm in a steel mould. The

Nd

1+x Ba

2 x Cu

3 O

y

singlerystalswerepreparedinair

[32℄ and used asseeds in this study. Thepellets with

seedwereputintoafurnaewithatemperature

gradi-ent1-4 o

C/min vertialdiretion. The sampleswere

heated up to 1040-1060 o

C at a rate of 120 o

C/h, and

heldfor2-6hoursforhomogenousmelting. Afterthat,

the samples were ooled to about 1020 o

C at a rate

of 10-30 o

C/h, and further ooled to 940-960 o

C at a

rateofabout1 o

C/h,thenthesampleswere ooledto

room temperature at a rate of 120 o

C/h. Finally the

as-grown samples were annealed at 400-550 o

C for a

week inowingO

2 .

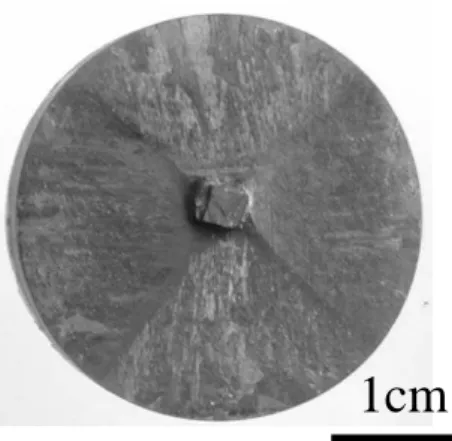

Thetypialphotograph of a single-domain YBCO

bulk (=30mm) is shown in Fig. 1. The

grain-orientation of the sample was investigated by XRD,

optial, SEMand -sanexaminations. All results

in-diate that theYBCO sampleis asingle-domainwith

-axisnormaltoitstopsurfae(resultsnotshownhere).

The sample was rstlydivided into two grain-domain

after levitation fore measurement, and then divided

into three and four grain-domains by a line-saw, so

that we an make four well-textured YBCO samples,

eahof them hasthe samesize (=30mm)and

grain-orientations,butonlywithdierentGDS.Thesamples

with a single, two, three and four grain-domains are

named asa, b, and d respetively, as shematially

shown in Fig. 2. Thevolume and shapeof four

sam-ples are onsidered as the same beause the diameter

1cm

Figure1.Optialphotographofsingle-domainYBCObulk

superondutor.

b

a

c

d

Figure2. ShematidiagramoftheongurationofYBCO

bulksampleswithdierentgrain-domains. a)

Single-grain-domain; b) two grain-domain; ) Three grain-domain; d)

Fourgrain-domain.

Thelevitationforesweremeasuredinahomemade

devie[24,25℄.Amagnetof30mmindiameterwasused

forallthelevitationforemeasurements. Themagneti

eldisabout0.5Tattheenterofthetopsurfae. At

the beginning of eah measurement, the sample was

symmetriallyxedontheaxiallineofthemagnetand

kept50-60mmbelowthemagnet. Afterthesamplewas

ompletelyooledtoliquidnitrogentemperature(zero

eld ooling),then the magnetwasmoved towardsto

andawayfromthesamplebyaontrolledmotor. Thus

the levitation fore as a funtion of distane between

themagnetandthesampleanbeobtained. The

max-imumlevitationforewasmeasuredatagapof0.1mm

III Results and disussion

Thelevitationfore valuesweremeasuredinzeroeld

ooledstateat77Kforthesamplesa,b,andd,shown

in Fig.3. As weansee fromthis gure,thelevitation

foresaremuhdierentforthesampleswithdierent

GDS.Themaximumlevitationforeis67.5Nobtained

inthesingle-grain-domainsamplea,andtheminimum

oneis28.15Nobtainedinthesampledwithfour

grain-domains. Theurveoflevitationforesisshiftingtothe

leftsideandtheslopoftheurvesisgradually

dereas-ing withthe inreasingofgrain-domainnumbersfrom

onetofourorrespondingtotheurvesa,b,anddin

Fig.3. These mean that the levitationfore dereases

withtheinreasinggrain-domainnumbers(orwiththe

dereasingofgrain size),whiletheshape,size and

vol-ume oftheYBCO bulksarethesame.

-1

0

1

2

3

4

5

6

7

0

20

40

60

80

Magnet:

φφφφ

30mm, B=0.5T

YBCO Sample Shape:

a

b

c

d

L

e

v

itati

o

n

f

o

rc

e

(N

)

Distance (cm)

Figure3.Thelevitationforesversesdistaneat77Kforthe

meltgrownYBCObulksamplewithdierentgrain-domain

size.

In order to make learly the relationship between

the levitation fore and the GDS, the maximum

lev-itation fores of the four samples were olleted and

drawnasafuntionoftheorrespondingaverage

grain-domain radius R, as shown in Fig. 4. As we ansee

fromFig. 4,thelevitationforemonotonouslyinreases

from28.15Nto67.5NwhiletheRinreasesfrom0.75m

to 1.5m, theinreasingfatorisaround2.4. The

ex-perimental showed that the levitation fore is nearly

proportional to the average radius of grain size, this

resultsisinagreementwithreferene[13℄. Butthe

lev-itationforewillnotgotozerowhileRisextrapolated

0.6

0.8

1.0

1.2

1.4

1.6

0

10

20

30

40

50

60

70

L

e

v

ita

ti

o

n

fo

rc

e

(N)

Average grain radius R (cm)

Figure4.Maximumlevitationforeversustheaveragegrain

radius of samples with dierent grain-domainnumbersat

liquidnitrogentemperature.

10

12

14

16

18

20

22

0

10

20

30

40

50

60

70

Experimental data

Calculated results

L

e

v

ita

ti

o

n

fo

rc

e

(N

)

ρρρρ

total

(cm)

0.4

0.6

0.8

1.0

30

40

50

60

70

Le

v

ita

ti

o

n

fo

rc

e

(N

)

ρρρρ

min

/

ρρρρ

total

Figure 5. The maximum levitation fore versus the total

grain-boundarylengthtotalofsampleswithdierent

grain-domainnumbersatliquidnitrogentemperature.

Thegrainboundaryofthesampleinreases

gradu-allywiththeinreasingofgrain-domainnumbersafter

eahutting,theboundariesformedbyuttingwill

en-tirely stop the indued shielding urrent to ross the

narrowuttinggap,andleadto somenewandsmaller

induedshielding urrentloop(ISCL) (omparedwith

that before eah utting), and nally result in a

re-dutionin levitation fore. The total length of

grain-domain boundaries inreasesfrom sample ato d with

inreasingofthegrain-domainnumbers. Letusassume

total

representthetotallengthofgrain-domain

bound-ariesofYBCOsample,then

total =R

s ,2R

s +4R

s ,

2R

s +6R

s

and 2R s+8R

s

forsamplesa,b, andd

respetively, where R

s

is the radiusof sample a. Fig.

5showsthe maximum levitation fore of the samples

with dierent

total

. As we an see from Fig.5, the

levitationforedereasesquiklywiththeinreasingof

total

. Theuxpinningforeisverystrongforthe

well-textured YBCO samples under 0.5 T at 77 K, so the

layeralongthegrain-domain-boundariesofthesample.

Here the indued urrent an be regarded as only a

onstantsurfaeurrent,sothetotallengthofISCLis

equalto the

total

. Basedonthis,

total

isrelatedwith

thelevitationforeoforrespondingYBCOsamples.

Thelevitationfore Fisproportionaltotheradius

ofISCL [13℄. Howabouttherelationshipbetweenthe

levitationforeand

total

? Consideringasetofsamples

withdierentGDS.LetA denotethetopsurfaearea

of asingle-grain-domainsuperonduting sample, and

thenthesamplewas

n= R

2

r 2

n

(1)

divided into several equivalent smaller grain-domains

(n=1, 2, 3..., represent the numbers of smaller

grain-domains). R and r

n

denote the radius of the

single-domain sampleand the sampleswith n smaller

grain-domain respetively. Then A=nA

n

, where A

n isthe

top surfaeareaof the smallergrain-domains. Sothe

nanbedesribedas:

Thenthetotalgrain-boundarylengthofthesample

withnsmallergrain-domainsanbewrittenas:

total

=n2r

n

(2)

Substitute equation (1) to (2), the average

grain-domainradiusofthesamplewithmultiple

r

n =

min

total

R (3)

grain-domainsanbeformulatedas:

Where

min

is the grain-boundary length (or

perimeter) of the single-grain-domainsample without

any utting.

min

= 2R =

total

, orresponding to

n=1:

AordingtoRef[13℄,thelevitationforeis

propor-tional to the radius r

n

of thegrain-domains, thus the

levitation foreof samplewith n grain-domainanbe

desribedas:

F

n =

min

total F

1

(4)

Where F

1

is the maximum levitation fore of the

single-domain sample orresponding to

total =

min .

This meansthatthelevitation foreis inverse

propor-tionalto

total .

In this experiment,

min

=2R

s ,

total =2R

s +

L;F

1

=67:5N, and R

s

=15mm. L, the lengthof

in-troduedgrainboundariesbyutting,isof0;4R

s ,6R

s

and8R

s

forthesampleswithsingle,two,threeandfour

grain-domainsrespetively. Then, inthis experiments,

thelevitationforeanbeformulatedas:

F

L =

2R

s

2R

s +L

F

1

(5)

Thelevitationfore of thesample withdierentL

in Fig.5. As weansee from Fig.5, the alulated

re-sult is in good agreementwith theexperimental data.

The insert in Fig.5 shows that the experimental data

forms astraight line between the levitation fore and

min =

total

. This onformsthat thelevitation fore is

reallyinverseproportionaltothetotalgrain-boundary

lengthofthesuperondutingsample.

IV Conlusion

A single-grain-domainYBCOsample(=30mm)has

beenpreparedbyatopseededmeltgrowthproessand

separated into two, three and four grain-domains

af-tereahlevitationforemeasurements. Themaximum

levitation fore of the single-domain sample is about

1.68, 2.05 and 2.4 times higher thanthat of the

sam-ples with two, three, and four grain-domains

respe-tively. It is foundthat thelevitation foreof a

single-domain YBCO bulk is muh higher than that of the

same sized samples with smaller gain-domains. The

levitationforeisinverseproportiontothetotallength

ofgrain-boundariesofthesample,and asimple

physi-al model hasbeensuggestedand wellinterpreted the

experimentresults.

This work is supported by the Ministry of

Si-eneand Tehnologyof China(NKBRSF-G19990646),

Projet\973".

Referenes

[1℄ J. R. Hull, E. F. Hilton, T. M. Mulahy, Z. J. Yang,

A.Lokwood, and M. Strasik, J. Appl. Phys.78, 6833

(1995).

[2℄ B. R. Weinberger, L. Lynds, J. R. Hull, and U.

Bal-ahandran,Appl.Phys.Lett.59,1132 (1991).

[3℄ J.R.Hull,Superond.Si.Tehnol.13,R1(2000).

[4℄ J. R.Hull, T.M. Mulahy,K. L. Uherka,R. A. Erk,

andR.G.Abboud,Appl.Superond.2,449(1994).

[5℄ H.Kameno,Y.Miyagawa,R.Takahata,andH.Ueyama,

IEEETrans.Appl.Superond.9,992(1999).

[6℄ H. J. Bornemann, T. Ritter, C. Urban, O. Zaitsev,

K. Weber, and H. Rietshel, Appl. Superond.2, 439

(1994).

[7℄ Q. Y. Chen, Z. Xia, K. B. Ma, C. K. MMihael, M.

Lamb,R.S.Cooley,P.C.Fwler,andW.K.Chu,Appl.

Superond.2,457(1994).

[8℄ T. A.Coombs,A. M. Campbell, I. Ganney, W.Lo, T

Twardowski,andB.DawSon,Matr.Si.Eng.B53,225

(1998).

[9℄ M. Tosa, A. K.Yosihara,Fourth Int. Symp. Magneti

[10℄ W. M. Yang, L. Zhou, Y. Feng, P. X. Zhang, J. R.

Wang, C. P. Zhang, Z. M. Yu,and X. D. Tang,

Pro-eedings of the Maglev'2000, 2000 in Rio de Janeiro,

Brazil.

[11℄ B.Oswald, M. Krone,M. Soll, T.Strsser,J.Oswald,

K.J.Best, and W.Gawalak,L. Kovalev,IEEETrans.

OnAppl.Superond.9(2),1201 (1999).

[12℄ H.Weh,ProeedingsofMT-15,15 th

international

on-fereneonmagnettehnology,P883(1998).

[13℄ M. Murakumi, MeltProessedHigh-Temperature

Su-perondutors(Singapore: WorldSienti,1992).

[14℄ M. Ullrih, H. Walter, A. Leenders, and H. C.

Frey-hardt,PhysiaC311,86(1999).

[15℄ D. L. Shi, D. Qu, Sagar, and K. Lahir, Appl. Phys.

Lett.70(26),3606 (1997).

[16℄ W. Henning, D. Parks,R. Weistein, R.P.Sawh, and

YRen,Superond.Si.Tehnol.13,1447(2000).

[17℄ C.J. Kim,H.J.Kim, J.H.Joo,G.W.Hong,S.C. Han,

Y.H. Han, T.H. Sung,and S.J. Kim, PhysiaC, 336,

223(2000).

[18℄ A.W. Kaiser,M. Adam,and H.J.Bornemann,

Super-ond.Si.Tehnol.11,26(1998).

[19℄ W. Gawwalek, T.Habisreuther, T. Strasser, M. Wu,

D.Littzkendorf,K.Fisher,P.Gornert,A.Glodum,P.

Stoye,P.Verges,K.V.Ilushin,andL.K.Kovalev,Appl.

Superond.2(7-8),465(1995).

[20℄ A.Endon,H.S.Chauhan,T.Egi,andY.Shiohara,J.

Mater.Res.11,795(1996).

[21℄ W. M. Yang, L. Zhou, Y. Feng, P. X. Zhang, z. M.

Wu,W.Gawalek, andP.Gornert, PhysiaC305,269

(1998).

[22℄ J.Unsworth,J.Du,B.J.Crosby,andJ.C.Mafarlane,

IEEETrans,Magn.29,108(1993).

[23℄ H.Teshima,M.Morita,andM.Hashimoto,PhysiaC

269,15(1996).

[24℄ W. M. Yang, L. Zhou, Y. Feng, P. X. Zhang, J. R.

Wang,C.P.Zhang, Z.M.Yu,andX.Z.Wu,Advanes

inCryogeniEngineering,46(A),663(1999).

[25℄ W. M. Yang, L. Zhou, Y. Feng, P. X. Zhang, J. R.

Wang,C.P.Zhang,Z.M.Yu,X.D.Tang,andW.Wei,

PhysiaC354,5(2001).

[26℄ B.A.Tent,D.Qu,D.Shi,W.J.Bresser,P.Boolhand,

andZ.X.Cai,Phys.Rev.B58(11),761(1998).

[27℄ W.M.Yang,L.Zhou,Y.Feng,P.X.Zhang,Z.M.Wu,

W.Gawalek,P.Gornert,J.R.Wang,C.P.Zhang, and

Z.M.Yu,PhysiaC307,271(1998).

[28℄ W.M.Yang,L.Zhou,Y.Feng,P.X.Zhang,Z.M.Wu,

W.Gawalek,P.Gornert,J.R.Wang,C.P.Zhang, and

Z.M.Yu,PhysiaC319,164(1999).

[29℄ M. Murakumi, Jpn. J. Appl. Appl. Phys. 29, L1991

(1990).

[30℄ Y. Iwasa, H. Lee, M. Tsusda, M. Murakami, and T.

Miyamoto,IEEETrans.onAppl.Superond.9(2),984

(1999).

[31℄ M.Yang,L.Zhou,Y.Feng,P.X.Zhang,C.P.Zhang,

andZ.M.Yu,RareMetalMaterialsandEngneering28

(4),231(1999).

[32℄ Wanmin Yang, Lian zhou, Minzhi Wu, C. Wende,

W.Gawalek, T.Strasser, Yong Feng, Pingxiang Zhang,