Research & Development May 2008

95

Effect of ferrovanadium inoculation on

microstructure and properties of high

speed steel

*Zhang Xipeng1, Kou Guojun1, Wu Chunjing1, Gan Zhaiping2, Zhao Wanzi2, Chuan Xiangzhao2

, Ma Ye2

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China; 2. Wuhan Iron and Steel Group Co., Wuhan 430083, China)

Abstract: The effect of ferrovanadium inoculation on the microstructure and properties of high speed steel (HSS) used for rolls was studied. The results showed that the as-cast eutectic carbide network tends to be broken after ferrovanadium inoculation, and the carbides are changed to rod-like or nodular shape. After heat treatment, the carbides in the inoculated HSS are spheroidized and distributed more uniformly in the matrix. The impact toughness of high speed steel with ferrovanadium inoculation is obviously improved. The action mechanism of ferrovanadium inoculation on the microstructure of the alloy is also discussed.

Key words: high speed steel; carbides; inoculation

CLC Number: TG142.1 Document Code: A Article ID: 1672-6421(2008)02-0095-04

I

n recent years, roll materials have been developed to improve the quality and productivity of rolled products to meet industrial demands. High speed steel (HSS) has been used for rolls since it has several inherent advantages over conventional roll materials, such as excellent hardness, strength, fracture toughness, wear resistance, and thermal-fatigue life. The properties of HSS rolls are critically dependent upon the type, distribution and shape of carbides. It has been reported that most of the primary carbides are distributed mainly along intercellular boundaries formed during solidification and are retained even in the finished products, which may result in low fracture toughness and thermal-fatigue life [3,4]. In order to improve mechanicalproperties, modifi cation by specifi c minor additions has been

used for HSS [5-7]. Vanadium is a strong carbide forming element. It is reported that vanadium, as a modification agent, has significant effect on the properties of white cast iron and cast steel [8-9]. In HSS, vanadium is the most important element and its composition usually keeps to more than 4%. What will happen if a part of vanadium in HSS is

used as modifi cation agent? There is no report about this in

the literature; such a replacement was studied in the present research.

1 Experimental procedure

The charge materials for melting the HSS included scrap H S S , o t h e r s c r a p s t e e l , p i g i r o n , f e r r o m o l y b d e n u m , ferrochromium and ferrovanadium. Charge materials were melted in a 50 kg medium frequency air melting induction furnace. Two heats of HSS were prepared. One heat of HSS was melted as normal without ferrovanadium inoculation; the other heat of HSS used less ferrovanadium in charge and the liquid steel later was inoculated with 1% of ferrovanadium (containing 52% vanadium) of 2–3 mm in size. Ladle inoculation was used. The tap temperature was about 1,600℃ for both of the two heats. Melts with or without inoculation were both poured into a sand mould to

obtain ingots of 200 mm × 30 mm × 150 mm in size. The fi nal

chemical compositions of HSS samples are given in Table 1.

Male, born in 1977, doctor. Research interest: HSS roll materials and casting process.

E-mail: zhang_xipeng@126.com

Received: 2006-09-26, Accepted: 2007-12-20 *Zhang Xipeng

Table 1 HSS fi nal composition, wt.%

C Si Mn Cr Mo V Ni S P Addition of

Ferrovanadium Un-inoculated 1.79 0.50 0.50 5.10 4.22 5.10 0.50

≤0.05 ≤0.05 0

Inoculated 1.80 0.48 0.50 5.12 4.20 5.13 0.50 1.0

The cast samples were heat treated. The heat treatment

process is shown in Fig.1. As seen in Fig. 1, fi rstly the samples

were annealed at 900℃ for 3 hours, then cooled in the furnace to 550℃ and held for 2 hours, and fi nally air cooled to room

CHINA FOUNDRY

Vol.5 No.2

96

for 1 hour, then air cooled; thirdly the samples were tempered at 550℃ for 1 hour for three times.

T h e s p e c i m e n s t a k e n f r o m t h e H S S s a m p l e s w e r e polished and etched with 4% nital, and the microstructure

w a s i n v e s t i g a t e d u s i n g a n o p t i c a l m i c r o s c o p e a n d a scanning electron microscope (SEM). Compositions of carbides were analyzed by energy dispersive spectroscopy (EDS).

2 Results and discussion

The optical micrographs of as-cast HSS samples are shown in Figs. 2 (a) and (b). It can be seen from Fig. 2 (a) that the coarse eutectic carbides are mostly located along cell boundaries forming continuous networks, and the cell sizes are 50 to 100 µm. With ferrovanadium inoculation, see Fig. 2 (b), the network carbides are broken and refined, and the rod-like or nodular carbides increased, and the carbides are relatively uniformly distributed in the matrix, and the cell sizes are relatively small.

(a) Uninoulated

(a) Uninoulated

the uninoculated HSS after quenching although the carbides become thinner, the strip-like carbides formed during solidification are still around cell boundaries, the carbide continuous network still exists, see Fig. 3 (a); whereas in the inoculated HSS by ferrovanadium, the lath-shaped coarse carbides disappear and are replaced by short rod-like and spherical carbides less than 10 um in size. Generally the carbides become separated from each other and relatively uniformly distributed. This is because inoculation makes the network carbides break and isolate from each other. When austenitized at a high temperature it is much easier for carbides to decompose and spheroidize[10], this is beneficial for the mechanical properties of HSS.

The hardness and impact toughness of the HSS are given in Table 2. It is noted that the ferrovanadium inoculation increases Fig.1 The treatment process of HSS

Figure 3 shows the micrographs of the samples after quenching. In this study, the HSS samples were austenitized at a high temperature of 1,060℃, this makes the carbides decompose and dissolve in the matrix relatively easy. For

(b) Inoculated by 1.0% ferrovanadium

Fig.2 Microstructure of as-cast HSS

Research & Development May 2008

97 the impact toughness of HSS obviously, but has little effect on

the hardness. Studies in references [3,11] had found that fracture of HSS rolls occurred along coarse and hard carbides, the microcracks were initiated at the carbide/matrix interfaces or by the fracture of carbides themselves which formed along the cell boundaries. Therefore the shape, size, distribution and volume fraction of coarse carbides distributed along cell boundaries

have signifi cant effect on the fracture properties such as impact

toughness. In this study, the carbides in the uninoculated HSS are coarse and form a network along cell boundaries, and have a destructive effect on the matrix; the microcracks are easily formed and propagated in these brittle carbides, hence the uninoculated HSS has a lower impact toughness. On the contrary, in the inoculated HSS by ferrovanadium, carbides are refined and more uniformly distributed; the spherical carbides are separated from one another. In this case, impact toughness is improved because a higher stress intensity factor is required and cracks are not easy to propagate. The overall hardness of HSS are mainly dependent on the volume fraction of carbides and the hardness of the matrix [12] and inoculation has little effect on the volume fraction of carbides and the hardness of the matrix [12], so the overall hardness of the HSS has little change after inoculation.

and L→c+M7C3. Therefore, the eutectic carbides are mainly distributed around the primary cell boundaries.

When certain amount of ferrovanadium is added into liquid steel, the concentration of vanadium is increased at local micro-areas of the liquid phase because the percentage o f v a n a d i u m i s h i g h i n f e r r o v a n a d i u m ( a b o u t 5 2 % ) . According to the Fe-5Cr-5W-5Mo-V-C diagram, when the vanadium content is high enough at local micro-areas during solidification, primary MC carbide is formed before c from the liquid and these primary MC carbides could supply more nuclei for c and MC during eutectic reaction, therefore the

crystal grains are refi ned. It can be said that the ferrovanadium

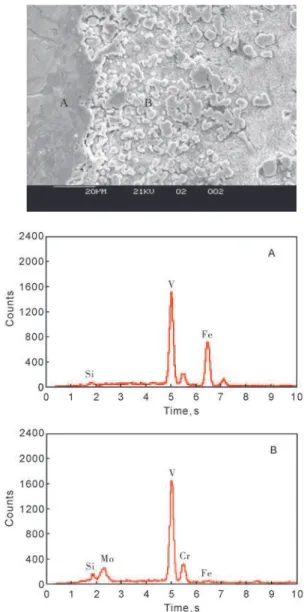

plays a role of nucleating agent in solidification. Figure 5 shows the undissolved ferrovanadium particles in the HSS sample. EDX analysis indicated that the large white area (A)

is ferrovanadium, a lot of fi ne particles around this area are

primary MC carbides. This is in agreement with the previous analysis.

3 Conclusions

( 1 ) I n t h e m i c r o s t r u c t u r e o f H S S a l l o y w i t h o u t Fig. 4 Liquidus surface diagram of Fe-5Cr-5W-5Mo-V-C

alloy system

Investigation on the microstructure and properties of HSS reveals that inoculation of HSS by ferrovanadium can break up the coarse continuous carbide network, and the carbides are refined and more uniformly distributed in the matrix.

This is because the addition of ferrovanadium infl uences the solidifi cation process of the HSS.

In order to analyze the effects of vanadium added to the HSS, the liquidus surface diagram of Fe-5Cr-5W-5Mo-V-C showing

the solidifi cation process, as in Fig.4, can be applied roughly to

the alloy compositions of the HSS used in the present study[14]. In the case of HSS without ferrovanadium inoculation, eutectic reaction L→c+MC occurs after the crystallization of primary c from liquid is ended; after the eutectic reaction L→c+MC

is fi nished, alloy content is increased in the residual liquid metal,

M2C or M7C3 carbides are crystallized from the residual liquid by the peritectic and eutectic reactions of L+MC→c+M2C

Fig. 5 Microstructure and EDX analysis of undissolved ferrovanadium particles in the HSS

Table 2 Properties of high speed steel Hardness

HRC

Impact toughness J/cm2

Un-inoculated 62.0 3.3

CHINA FOUNDRY

Vol.5 No.2

98

ferrovanadium inoculation, coarse eutectic carbides are connected to each other forming continuous network along grain boundaries. After ferrovanadium inoculation, the morphology, size and distribution of carbides are changed greatly. The carbide network is broken and the carbides are changed to rod-like or nodular shape. After heat treatment, the carbides are spheroidal and more uniformly distributed in the metal matrix.

( 2 ) T h e i m p a c t t o u g h n e s s o f H S S i n o c u l a t e d w i t h ferrovanadium is increased obviously because inoculation improves the shape and distribution of carbides.

References

[1] Kerr E, Webber R and Mccaw D. Roll performance – technical overview and future outlook. Ironmaking and Steelmaking, 2004, 31(4): 295 – 299.

[2] Andersson M, Finnstrom R and Nylen T. Introduction of enhanced indefinite chill and high speed steel rolls in European hot strip mills. Ironmaking and Steelmaking, 2004, 31(5): 383 – 388.

[3] Hwang Keun Chul, Lee Sunghak, Lee Hui Choon. Effects of alloying elements on microstructure and fracture properties of cast high speed steel rolls: Part II. Fracture Behavior. Materials Science & Engineering, 1998, A254: 296 – 304. [4] L e e S u n g h a k , L e e C h a n g G i l , S o h n K e e - S u n , e t a l .

Correlation of microstructure and fracture toughness in three high-speed steel Rolls. Metallurgical and Materials Transactions A, 1997, 28A: 123 – 134.

[5] Boccalini Jr M, Correa A V O, Goldenstein H. Rare earth

metal induced modification of c-M2C, c-M6C, and c-MC

eutectics in as-cast M2 high speed steel. Materials Science and Technology, 1999, 15: 621– 626.

[6] Kheirandish Sh, Kharrazi Y H K, and Mirdamadi Sh. Cast M7 high speed steel modified with titanium. Materials Science and Technology, 1998, 14: 683– 688.

[7] Pan Fuzhen, Yang Hua, Jiao Jinling, et al. Effect of K/Na-RE multiple modification on structure and mechanical property of high speed steel used for roll collar. Foundry, 2006, 55(2): 164 – 168. (in Chinese)

[8] Liu Bing. Effect of modifi cation on structure and properties of

white cast iron with low chromium. Hot Working Technology, 2004(7):18– 19. (in Chinese)

[9] S u n B e n m a o , Wa n g Z h i f u , X i n g G u i x i a n g . E ff e c t o f metamorphism on properties of high Cr and Ni cast steel. Journal of Shangdong University of Technology, 1997, 27(1): 45 – 49. (in Chinese)

[10] Di Hongshuang, Zhang Xiaoming, Wang Guodong, et al. Spheroidizing kinetics of eutectic carbide in the twin roll-casting of M2 high-speed steel. Journal of Materials Processing Technology, 2005, 166: 359 – 363.

[11] Byun Gwihwan, Oh Seungchan, Lee Chang Gil, et al. Correlation of microstructure and micro fracture mechanism

of fi ve work rolls. Metallurgical and Materials Transactions A, 1999, 30A: 234 – 243.

[12] Fu Hanguang, Song Jinchun, Liu Jinhai, et al. Study on modifying high speed steel guide roller. Foundry, 2003, 52(5) : 324 – 327. (in Chinese)