Cold deformation effect on the microstructures and mechanical properties

of AISI 301LN and 316L stainless steels

Paulo Maria de O. Silva

a,b, Hamilton Ferreira G. de Abreu

c, Victor Hugo C. de Albuquerque

d,

Pedro de Lima Neto

c, João Manuel R.S. Tavares

e,⇑aPetróleo Brasileiro SA, Rodovia CE 422, km 0, Complexo Portuário do Pecém, Salgadinho, 61600-000 Caucaia – CE, Brazil

bUniversidade Federal do Ceará (UFC), Departamento de Engenharia de Teleinformática (DETI), Laboratório de Telecomunicações e Ciências e Engenharia de Materiais (LOCEM),

CEP 60455-760, Fortaleza, Ceará, Brazil

cUniversidade Federal do Ceará (UFC), Centro de Tecnologia, Departamento de Engenharia Metalúrgica e de Materiais, Campus do Pici Bloco, 714, Pici, 60455-760,

Fortaleza – CE, Brazil

dUniversidade de Fortaleza (UNIFOR), Centro de Ciências Tecnológicas (CCT), Núcleo de Pesquisas Tecnológicas (NPT), Av. Washington Soares, 1321, Sala NPT/CCT, CEP 60.811-905,

Edson Queiroz, Fortaleza, Ceará, Brazil

eFaculdade de Engenharia da Universidade do Porto (FEUP), Departamento de Engenharia Mecânica (DEMec) and Instituto de Engenharia Mecânica e Gestão Industrial (INEGI),

Rua Dr. Roberto Frias, S/N – 4200-465 Porto, Portugal

a r t i c l e

i n f o

Article history:

Received 9 May 2010 Accepted 8 August 2010 Available online 12 August 2010

Keywords:

A. Ferrous metals and alloys G. Image analysis G. Metallography

a b s t r a c t

As austenitic stainless steels have an adequate combination of mechanical resistance, conformability and resistance to corrosion they are used in a wide variety of industries, such as the food, transport, nuclear and petrochemical industries. Among these austenitic steels, the AISI 301LN and 316L steels have attracted prominent attention due to their excellent mechanical resistance. In this paper a microstruc-tural characterization of AISI 301LN and 316L steels was made using various techniques such as metal-lography, optical microscopy, scanning electronic microscopy and atomic force microscopy, in order to analyze the cold deformation effect. Also, the microstructural changes were correlated with the altera-tions of mechanical properties of the materials under study. One of the numerous uses of AISI 301LN and 316L steels is in the structure of wagons for metropolitan surface trains. For this type of application it is imperative to know their microstructural behavior when subjected to cold deformation and correlate it with their mechanical properties and resistance to corrosion. Microstructural analysis showed that cold deformation causes significant microstructural modifications in these steels, mainly hardening. This modification increases the mechanical resistance of the materials appropriately for their foreseen appli-cation. Nonetheless, the materials become susceptible to pitting corrosion.

Ó2010 Elsevier Ltd. All rights reserved.

1. Introduction

Stainless steels first appeared when scientists were trying to de-velop a state of passivity for ferrous alloys; a state that would not visibly show any oxidization, as was initially produced by Faraday [1]. Harry Bearley’s experiment in 1912, which was the addition of 12.5% Cr (chromium) to Fe (iron), initiated commercial production of stainless steels[2]. This material had a martensitic microstruc-tural matrix. Later, following the works of Guillet (France) and Gie-sen (Germany), Monnartz developed the Fe–Cr–Ni (iron– chromium–nickel) steels in Essen (Germany), giving origin to

stainless steels of the austenitic matrix, universally known as 18% Cr–8% Ni[3].

There are five major classes of stainless steels[3]: ferritic, mar-tensitic, duplex, hardened by precipitation, and austenitic, the lat-ter being the focus of this work.

The application of austenitic stainless steels in the food, petro-chemical and nuclear industries is due to their combination of good conformability, mechanical resistance and resistance to cor-rosion. Specifically, steel 301, according to the American Iron and Steel classification (AISI), is widely employed in the making of kitchen sinks and train wagon structures for underground or sur-face metropolitan trains. The highest level of mechanical resistance of this 301 steel is in the AISI3xx steel family; however, it does not show such a satisfactory level in terms of corrosion[4].

As steel 301 is mechanically unstable, deformation induces extensive martensitic transformation, whose crystalline structure may be compact hexagonal (CH), usually known as martensite

e

0261-3069/$ - see front matterÓ2010 Elsevier Ltd. All rights reserved. doi:10.1016/j.matdes.2010.08.012

⇑ Corresponding author. Tel.: +351 22 5081487; fax: +351 22 5081445.

E-mail addresses:paulomsilva2003@yahoo.com.br(P.M. de O. Silva),hamilton@ ufc.br (H.F.G. de Abreu), victor.albuquerque@fe.up.pt (V.H.C. de Albuquerque), pln@ufc.br(P. de Lima Neto),tavares@fe.up.pt(J.M.R.S. Tavares).

Contents lists available atScienceDirect

Materials and Design

or body centered cubic (BCC) designated as martensite

a

0[4,5]. It isknown that martensitic transformation, like other changes, derived from shear stress, which cause microscopic wave propagations on the surface of the material[6]and an increase in volume resulting in residual tensions[7,8].

Stainless steels owe their corrosion resistance to passive oxide films that are formed on their surfaces. However, their level of resistance is especially compromised in settings where there are Cl (chlorine) ions or halogens [1,4]. In the case of steels of the 3xx series, notably AISI 301 and 304, the martensitic transforma-tion may cause the rupture of the passive film due to higher den-sity of flaws and generate residual stress or a galvanic effect caused by the presence of two distinct phases[9]. Corrosion resis-tance in more mechanically stable steels may be reduced by defor-mation, and the introduction of flaws[10]. Also the shrinkage of microstructures makes austenitic steels even more vulnerable to corrosion[11].

Many research studies concerning austenitic steels have been carried out. For instance, the effects of thermo-mechanical param-eters were investigated by Eskandari et al.[12]in order to achieve a nanocrystalline structure in the as-cast AISI 301 stainless steel. Silva et al.[13], evaluated the effect of welding heat cycles on AISI 316L austenitic stainless steel corrosion resistance in a medium containing heavy petroleum. Korkut et al.[14], analyzed the opti-mum cutting speed when turning AISI 304 austenitic stainless steel with cemented carbide cutting tools. Finally, Wasnik et al. [15], studied the precipitation in a AISI steel using a combination of dif-ferential scanning calorimetry, electrical resistivity measurements and transmission electron microscopy, and identified the coherent precipitation, its coarsening, the initiation of the grain boundary precipitation,

r

phase and lastly the M23C6 precipitation.Different studies on the effect of cold deformation on stainless steels have been made, for example: to correlate processing parameters and strain-induced martensitic transformation in AISI 301 stainless steel [16]; to evaluate magnetic properties and

a

0martensite in AISI 301LN stainless steel[17]; to analyze the effect of process parameters on the properties of spot welded cold de-formed AISI 304 grade austenitic stainless steel[18]; and to study the evolution of the microstructure and texture of a AISI 316L austenitic stainless steel[19].

A metropolitan train project is under way in a costal city with a saline environment including chlorides and AISI 301LN and 316L steels have been selected to build the wagon structures. The aim of this work was to corroborate the excellent mechanical proper-ties usually pointed out for these steels and analyze, at the micro-structural level, the influence of cold deformation imposed by lamination with these environmental conditions. A microstructural analysis was carried out using the different techniques of optic microcopy (OM), scanning electronic microscopy (SEM) and atomic force microscopy (AFM), and the resulting microstructures found were correlated with the mechanical properties of the materials to confirm their adequacy for their projected use. Even though the mechanical properties of these steels are relatively well known, the study of the microstructural variations by imposing cold defor-mations using the techniques of analysis above mentioned is still incipient. Also the correlation of the microstructural variations found with the alterations of mechanical properties of the same steels has not yet been fully validated. This work is, therefore, con-tributing to further the knowledge of AISI 301LN and 316L steels, particularly concerning their behavior when subjected to cold deformations.

This paper is organized as follows: The materials used are de-tailed in the following section, which also describes the steps taken for their microstructural evaluation. In Section3, the results are presented and discussed. Finally, in Section4, the conclusions of the work are pointed out.

2. Materials and methods

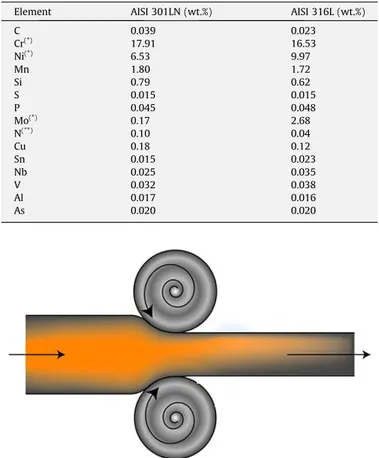

Two laminated steel sheets measuring 50251.9 mm3, one of AISI 316L steel and the other of AISI 301LN steel with a superfi-cial reduction of 4%, were analyzed in their as-received states. Ta-ble 1shows the chemical composition of the AISI 301LN and 316L sheets. To obtain the accurate composition of the steels, the Cr, Ni and Mo (molybdenum) elements were measured using an energy dispersive X-ray detector (EDS – (*)), and the N (nitrogen) was

determined via coulometric measurement (**). Mass spectrometry

was used for all the other elements.

The cold deformation was carried out with a pilot laminator, a bench and duo type, without reversion, and with 43.5 mm diame-ter cylinders that were 106 mm long,Fig. 1. This laminator was at-tached to a reducer system connected to an 250 W electric motor with 1750 rpm. After lamination, the test bodies, 10 for each type of steel were prepared with dimensions of 502.51.9 mm3. The

thickness reduction was carried out at room temperature with common lubricating oil and adopting a reduction of 0.1 mm per each consecutive pass for approximately 3 s, until two levels of thickness: 1.4 mm (26% or true deformation of 0.31) and 1.0 mm (47% or true deformation of 0.64) were obtained; for a detail expla-nation on the lamiexpla-nation, see[20].Table 2gives the deformation levels and average deformation rates in each pass to reduce the thickness.

For the microstructural characterization, an Olympus optic microscope, model BX51M (Japan) with a digital video camera at-tached to a computer was used to acquire the images. A Philips scanning electron microscope, model XL-30 (USA), was used to

de-Table 1

Nominal chemical composition of AISI 301LN and 316L sheets ((*) EDS and (**) coulometry).

Element AISI 301LN (wt.%) AISI 316L (wt.%)

C 0.039 0.023

Cr(*) 17.91 16.53

Ni(*) 6.53 9.97

Mn 1.80 1.72

Si 0.79 0.62

S 0.015 0.015

P 0.045 0.048

Mo(*) 0.17 2.68

N(**) 0.10 0.04

Cu 0.18 0.12

Sn 0.015 0.023

Nb 0.025 0.035

V 0.032 0.038

Al 0.017 0.016

As 0.020 0.020

tect the secondary electrons (SE), backscattering electrons (BSE), as well as a detector of energy-dispersive X-ray spectroscopy EDS (USA). For high resolution images, a Digital Instruments atomic power microscope, model Nanoscope (USA), with a digital camera was used to acquire images of the samples exhibited on the mon-itor. The camera visor was also used to position the microscope probe over the sample.

The metallographic preparation was carried out conventionally for all samples. First they were immersed in Bakelite type resin and then were sandpapered until half of their original thickness. After which, the reagents of Villela (1 g of picric acid, 5 ml of HCl (hydrogen chloride) and 100 ml of ethanol), with etching time be-tween 10 and 13 min for AISI 301LN and bebe-tween 15 and 17 min for AISI 316L, and Behara (0.3–0.6 g of metabisulfite of potash, 20 ml of HCl and 100 ml of distilled water), with etching time from 15 s to 1 min for both steels, and a reagent for electrolytic etching (30% of HNO3(nitric acid) in de-ionized water), with current

be-tween 0.12 and 0.5 A and tension bebe-tween 1.5 and 6.0 V, were used. The etching time, after stabilization of the corrosive reaction, was from 2 to 3 min for the AISI 301LN steel samples and 3.5–5 min for the AISI 316L steel samples.

A commercial image analysis system was used to obtain the stereological information of the samples in the as the received and laminated conditions. All images had a resolution of 640512 pixels and included the whole field of the optic micro-scope. The grain size of the sheets as received was also measured with the optic microscope using the intercepts technique, see [21], magnification of 1000and counting 400 intercepts.

The volumetric fraction of the second phase was evaluated using OM captured images with 200magnification and a thresh-old applied in the grey contrast scale. Some 10–40 regions were examined for each sample. The exposed surfaces of the samples were also analyzed by the same technique with images of SEM in secondary electrons (SE) and back scattering electrons (BSE) with magnification from 2500 to 10,000. The inspection in AFM was carried out using the deflection, attrition and height modes either with normal sweep or lateral force microscopy (LFM) in areas of analysis with 10

l

m of maximum size.3. Results and discussion

The volumetric fraction (VF) measurements of the AISI 316L and 301LN austenitic stainless steel samples were made using X-ray

diffractogram curves, adjusting them with the pattern decomposi-tion program – PROFIT (Philips, Eindhoven, The Netherlands) and calculating the associated areas.

The VF values obtained point to the growth of the second phase fraction with an increment of deformation, which is the expected behavior for the formation of martensite

a

0in AISI steels[22].Ta-ble 3shows the deformations that the steels went through during lamination, their final thickness after lamination, and the percent-ages for all the detected phases with their respective standard deviations.

In the case of AISI 316L, notably the austenitic matrix, the sec-ond phase fraction hardly varied with the deformation. Normally the appearance of the martensite

a

0 at room temperature at thelevels of deformation employed in AISI 316 steel is not observed [23]. However, it is observed when subjected to cyclical deforma-tions [24,25]. This observation sustains the conclusion that the only phase that meets the requirements, within the experimented conditions used here, is the ferrite d that is formed during the solidification of the ingot [3]. This was also described by Nebel and Eifler with a AISI 321 steel dowel in a fatigue study[25]. The small variation encountered may be attributed to heterogeneity of the original sheet. Therefore, our findings are in line with previ-ous works: Llewellyn, in a review of the influence of composition on the work hardening behavior of commercial grades of austenitic stainless steels, concluded that in unstable grades, the formation of strain induced martensite during fatigue testing reduces the crack propagation rate due to perturbation of the stress field around the advancing crack tip[23]. Also the composition design for the devel-opment of the optimum work hardening rate was discussed, par-ticularly for end applications. Maeng and Kim studied the characteristics of the cyclic plastic strain zone of AISI 316L and 316LN stainless steels at the crack tip by using micro hardness tests, X-ray diffraction and transmission electron microscopy [24]. Thus, these authors discussed the improvement of the fatigue crack growth resistance of the AISI 316LN stainless steel in relation to the degree of crack closure, strain induced martensite transfor-mation and the dislocation structure in the cyclic plastic stain zone at the fatigue crack tip. On the other hand, Nebel and Eifler pre-sented an investigation to characterize the cyclic deformation behavior and the plasticity-induced martensite formation of meta-stable austenitic stainless steels at ambient and high temperatures, taking into account the influence of the alloying elements titanium and niobium[25]. The experiments conducted yielded characteris-tic cyclic deformation curves and corresponding magnecharacteris-tic signals

Table 2

Roll conditions, thicknesses, deformation, and deformation rate.

Roll passes Roll condition Initial thickness (mm) Final thickness (mm) Deformation Deformation rate (10 2/s)

1 1/2 1.90 1.80 0.05 1.80

2 1/2 1.80 1.70 0.06 1.90

3 1/2 1.70 1.60 0.06 2.02

4 1/2 1.60 1.50 0.06 2.15

5 1/2 1.50 1.40 0.07 2.30

6 2 1.40 1.30 0.07 2.47

7 2 1.30 1.20 0.08 2.67

8 2 1.20 1.10 0.09 2.90

9 2 1.10 1.00 0.10 3.12

Table 3

Thickness, volumetric fraction, standard deviation and crystalline domain (D) for AISI 301LN and 316L steels.

Material AISI State Thickness [mm] Volumetric fraction (%) (phase) Standard deviation (%) D (nm) (phase)

301LN Initial 1.9 80.1 (a0) 8.78 0.19 (a0)

26% thickness reduction (0.31 of deformation) 1.4 81.2 (a0) 6.15 0.17 (a0)

47% thickness reduction (0.64 of deformation) 1.0 94.9 (a0) 1.78 0.17 (a0)

316L Initial 1.9 3.34 (d) 0.74

26% thickness reduction (0.31 of deformation) 1.4 4.15 (d) 1.05 0.32 (d)

according to the actual fatigue state and the amount of martensite. The fatigue behavior of the steel studied was characterized by cyc-lic hardening and softening effects that are strongly influenced by specific loading conditions. Additionally, martensite formation var-ied with the composition, loading conditions, temperature and number of cycles. Therefore, these works aimed to evaluate aus-tenite steels, mainly, by mechanical test and, in[24], to establish a simple correlation between mechanical properties and transmis-sion electron microscopy. Hence, besides the aforementioned cor-roboration, this paper complements the findings of these previous works by studying the cold deformation of the AISI 316L and 316LN stainless steels in detail.

The presence of the

a

0phase in AISI 301LN steel is because theinitial condition was obtained by hot lamination, which predis-poses both phases in the residual deformation. The increment of deformation to 0.31 provokes a relaxation of compression on

a

0and a relief of deformation (traction) treated on the

c

phase. The increment of deformation to 0.64 alters only very slightly the deformation state of the phases, which suggests that the material has reached its shrinkage saturation capacity.In the case of AISI 316L steel, there is also residual stress in the initial condition in the

c

phase. Upon imposing deformation a com-pression of thedphase and increase of thee

0inc

take place. It isvery likely that this is due to the hardening of both phases. The increment of deformation provokes a relaxation of compression on the d phase accompanied by a discreet relief in

c

that does not correspond to the magnitude of relaxation. This is evidence of deformation microstructure recovery, the phenomenon associ-ated to the change in the arrangement of discrepancies with a con-sequent change in the deformation regime[26,27].In both steels, it was impossible to unequivocally determine the parameterDof the phases. The fact of introducing deformation in the

c

phase contributed to hardening it, which would allow the formation of discrepancy cells and even sub-grains [28]. This may be a justification for such lowDvalues.The values inTable 3indicate that the increase of deformation to 0.31 did not cause a considerable change in the VF of the

a

0phase in AISI 301LN steel, despite a distribution change of

a

0 to amore regular mode. Upon increasing the level of deformation to

0.64, the VF presented a discreet increase. These results suggest that the 0.64 deformation level could perhaps be close to the satu-ration level of the

a

0fraction.With the AISI 316LN steel, the variation in the VF of thedphase is not significant with the increase of deformation, as was ex-pected. This proves the mechanical stability of AISI 316LN steel, which was also observed by Dewidar et al.[29]with compression tests and by Le et al.[30]through electromechanical techniques. Also, OM revealed that the VF is kept at a low level and is practi-cally unaltered with a deformation increase.

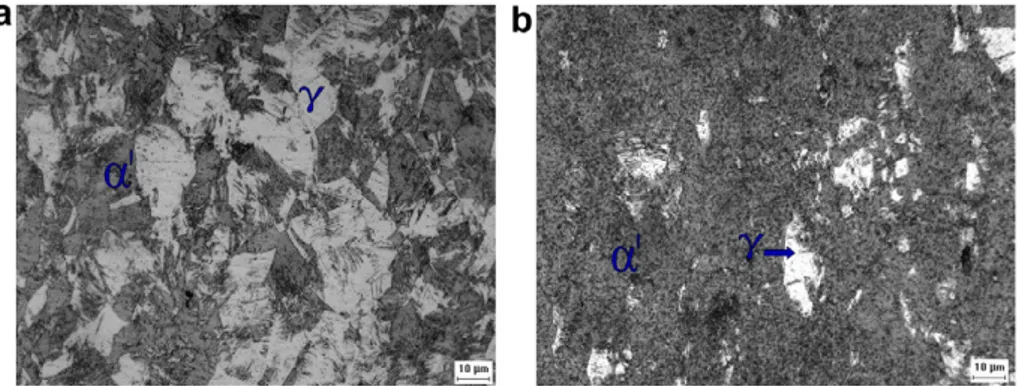

Figs. 2a and 2bshow the appearance of the austenitic grains, under the studied conditions, for the AISI 301L and AISI 316LN steels, respectively, considering that the initially equiaxial grain sizes (GS) for these materials were 14.75 ± 0.74

l

m (ASTM grain nr. 8.7) for AISI 301L steel, and 24.75 ± 1.24l

m (ASTM grain nr. 7.3) for AISI 316LN steel. The grains of these samples were normal-ized in an electrical furnace at 950°C for 2 h as can be seen in themicrographs. InFig. 2c, corresponding to the initial condition of AISI 301L steel, in which the

c

anda

0phases were observed, andthe OM analysis indicated that the distribution of the

c

phase was irregular. Superior magnification confirmed that the phases are really intertwined. Thea

0phase is in the form of plaques andappears in higher proportions than the

c

phase.Deformation caused grain hardening of the steel studied (Fig. 3), affecting its mechanical properties by increasing its resistance, flow stress, hardness and fragility; and by reducing its malleability, ductility and resistance to corrosion[31].

Upon imposing a deformation of 0.31 to AISI 301L steel, the pla-ques of the

a

0phase are seen to be less aggregated than initially,and the retained

c

regions are more distinct, indicating some deformation,Fig. 4a. On the other hand, thec

phase is better dis-tributed and morphologies similar to the needles of martensite are clearly seen.Fig. 4b shows a 0.64 deformation and a small is-land ofc

regularly distributed in the martensite could be distin-guished, which indicates there was an increase in deformation.A metallographic analysis of the AISI 316L steel for the deforma-tion of 0.31 inFig. 5a shows that the VF of thedphase is practically unaltered in comparison to steel under the as-received state ( Ta-ble 3); additional, the austenitic grains appeared deformed. This

steel presents a higher ferritedfragmentation level after undergo-ing a deformation of 0.64 compared with the deformation of 0.31,

as shown in Fig. 5b. Additionally, the d phase is aligned with the lamination direction and the austenitic grains are more deformed.

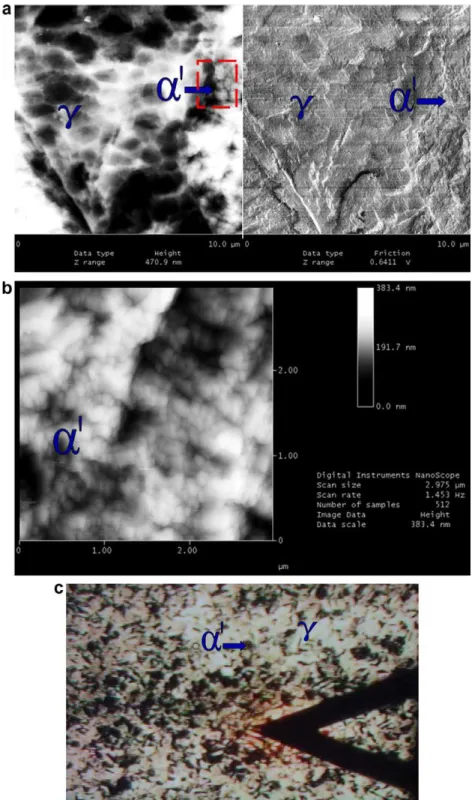

An illustration of the microstructural aspects of AISI 301LN steel, deformed at 0.64, using a SEM can be seen inFig. 6a. Also, Fig. 6b shows the morphology of the

a

0phase of the AISI 316L steelsample. This figure indicates that this phase has plaques and inter-connected needles that are intertwined with the

c

phase. Thea

0phase is higher than the

c

phase, which is usually associated to the martensite phase. This transformation results in shearing that causes superficial relief[6]. Additionally, thec

phase is more un-evenly distributed in the lower proportions than thea

0 phase, aswas revealed by OM. The crystallographic texture induced in the AISI 301LN steel samples was notable only for martensite

a

0 thatunderwent fiber reinforcementh1 1 1i//DN due to the deformation. Evidence was found that martensite

a

0was formed at theexpendi-ture of fiberbof the

c

phase following the Kurdjumov-Sachs orien-tation relationship.Fig. 3.Optic micrography of AISI 316L with deformation of 0.64 (magnification of 500).

Fig. 4.Micrography of sample of AISI 301LN with deformation of (a) 0.31, and (b) 0.64 (magnification of 1000).

Fig. 5.Micrography of sample of AISI 316L with deformation of (a) 0.31, and (b) 0.64 (magnification of 1000).

Fig. 7.Micrography of sample (a) AISI 301LN deformed with 0.31, and (b) 0.64, obtained by SEM on BSE and SE modes.

Fig. 8.Micrography of sample (a) AISI 316L in the as received condition, and deformation (b) 0.31, obtained by SEM with BSE and SE modes, respectively.

Fig. 7a shows the fragmentation of the lattice work of intercon-nected plaques clearly and here the

c

regions are visible and well distributed. The porous aspect of thec

phase suggests an incre-ment of deformation that increases the concentration of discrepan-cies and causes corrosion by pits due to a more effective chemical etching.Fig. 7b shows the AISI 301LN steel sample with a 0.64 deformation where thec

phase is difficult to distinguish and only a few plaques ofa

0, which are more fragmented, still stand out atthe very bottom that is full of pits. These pits may cause an in-crease of corrosion vulnerability[32,33]. This type of corrosion is

localized and consists of the formation of small cavities with con-siderable depth.

Fig. 8a presents AISI 316L steel in the as receive state, in which is observed a normalized structure for the austenitic grains. Thed

phase is dispersed and oriented according to the direction of the sheet’s original lamination. By imposing a 0.31 deformation, Fig. 8b, the proportion of the d phase does not seem to alter, although it fragments it and deforms the

c

phase. A further in-crease of deformation to 0.64 has the same effect with the differ-ence that the regions of the d phase were more easilydistinguishable than for the AISI 316L steel sample with deforma-tions of 0.31.

An image representing the microstructural aspects by atomic force microscopy (AFM) is presented inFig. 9a. The image is related to two sweeps using lateral force microscopy (LMF), height,

attri-tion and deflecattri-tion modes, showing the existence of two distinct regions in terms of interaction. One of these regions is apparently formed by small nanometric subunits (

a

0phase), while the secondone presents irregularities in the likeness of wrinkles that indicate that the phase is more sensitive to chemical flare (

c

phase). The morphology looks like needles,Fig. 9a, or laths, as can be seen in Fig. 9b, with much greater heights than thec

phase, thus confirm-ing unequivocally to be martensitic regions.Fig. 10a, obtained by LFM, illustrates a region of the AISI 301LN steel sample with deformation of 0.31 containing

a

0andc

phasesthrough deflection, height and attrition modes. In addition, Fig. 10b corresponds to a specific sweep over a

a

0phase showingits nanometric subunits. These subunits correspond to ellipses of axis 16070 nm2. Lee and Lin[34]evaluated this same structure

based on its morphology/geometry in a AISI 304L steel using TEM. Fig. 10c presents a digitalized image from the AFM probe, of a trian-gle over a region similar to the one that was swept for the image cap-ture inFig. 10b. This indicates that the regions that are darkened due to the Behara reagent are directly associated with the martensite re-gions, validating the VF measurement of the OM.Fig. 11a shows a re-gion of the AISI 301 LN sample with a deformation of 0.64, presenting the

c

anda

0phases and the subunits that composea

0and again wecan distinguish the standards of the two phases in AFM observed for other samples. For the AISI 316L steel sample, it was difficult to identify the ferritedregions clearly.Fig. 11b confirms once more that the austenitic grains were re-crystallized.Fig. 11c confirms that in the interior of the austenitic grain, there is another phase that is attributed tod.Fig. 11d corresponds to the sample AISI 316L steel with a 0.31 deformation and clearly shows the effect of deformation on the austenite that is starting to present irregular contours due to local changes of orientation[28].

Fig. 12a, which presents an AFM image, shows the effect of the increment of deformation on the austenite of the AISI 316L steel sample with a 0.64 deformation. The attrition image shows regions with different responses to attrition and in bands, which suggests that these regions may correspond to slide bands. Lee and Lin[34] obtained images from TEM with shearing bands similar in level to the next deformation; however, with a higher deformation rate. Fig. 12b presents an elliptic region of ferritedthat has major and minor axis of sizes of around 6

l

m and 3l

m, respectively, which are responsible for the embrittlement effect in stainless steels. The aspect is totally distinct from what is seen for the martensitea

0thatis also associated to embrittlement in this type of material, which in-creases its mechanical resistance and dein-creases its ductility. Also Fig. 12c shows the presence of ferritedand

c

phases by using a probe during a sweep through LFM over the same region asFig. 12b.4. Conclusions

A microstructural evaluation of AISI 301LN and 316LN steels was carried out using the different techniques of optic microscopy, scanning electronic microscopy and atomic force microscopy. Also, the microstructures of these steels were correlated with their mechanical properties. This study is of particular importance due to the integrated transportation project that will use AISI 301LN and 316L steels in the construction of the train wagons. Thus, the reliable and detailed knowledge of these materials, achieved in this work, is fundamental for the success of the above mentioned project.

The main important results of this experimental work can be summarized as follows:

1. Plastic deformation caused the formation of martensite

a

0in theAISI 301LN steel samples and shrinkage of the

c

phase in the AISI 316L steel samples. The more the thickness was reduced,the greater the amount of

a

0, and the superior the hardening ofc

. This hardening is responsible for modifying its mechanical properties, increasing its resistance, flow stress, hardness and fragility, reducing the malleability, ductility, as well as making the material very vulnerable to corrosion due to the formation of pit particles.2. For the AISI 301LN steel, the typical morphology of the

a

0phase acquired by a scanning electronic microscope was of rips that are made up of big plaques. Optic microscope and scanning electronic microscope reveled that these plaques change their arrangement according to the deforma-tion level.

3. For the AISI 316LA steel, the higher the level of deformation, the more easily the deformed structure of the

c

phase could be seen.Acknowledgements

To the Brazilian companies METROFOR and PETROBRAS for sup-plying the steel for this study.

The authors would also like to thank the Brazilian research agencies: CNPq – Conselho Nacional de Desenvolvimento Científi-co e TecnológiCientífi-co (National Counsel of Technological and Scientific

Development), FINEP – Financiadora de Estudos e Projetos (Re-search and Projects Financing) and CAPES – Coordenação de Aper-feiçoamento de Pessoal de Nível Superior (Coordination for the Improvement of People with Higher Education) for their financial support.

References

[1] Fontana MG. Corrosion Engineering. 3rd ed. Singapore: McGraw-Hill; 1986. [2] Streicher MA. Austenitic and ferritic stainless steels Uhlig’s Corrosion

Handbook. 2nd ed. John Wiley & Sons: Nova York; 2000. p. 601–50. [3] Davis JR. ASM specialty handbook: stainless steels. ASM

International: Materials Park; 1996.

[4] Sedriks JA. Corrosion of stainless steels. 2nd ed. Nova York: John Wiley & Sons; 1996.

[5] Falkland MLE. Duplex stainless steels Uhlig’s corrosion handbook. John Wiley & Sons: Nova York; 2000. p. 651–66.

[6] Swallow E, Bhadeshia HKDH. High resolution observations of displacements caused by bainitic transformation. Mater Sci Technol 1996;12:121–5. [7] Wang YD, Peng RL, Wang XL, McGreevya RL. Grain-orientation-dependent

residual stresses and the effect of annealing in cold-rolled stainless steel. Acta Mater 2002;50:1717–34.

[8] Bahadur A, Kumar BR, Chowdhury SG. Evaluation of changes in X-ray constants and residual stress as a function of cold rolling of austenitic steels. Mater Sci Technol 2004;20:387–92.

[9] Coutinho CB. Materiais metálicos para engenharia (Metallic materials for engineering). Belo Horizonte: Fundação Cristiano Ottoni; 1992 [in Portuguese]. [10] Mudali UK, Shankar P, Ningshen S, Dayal RK, Khatak HS, Raj B. On the pitting corrosion of nitrogen alloyed cold worked austenitic stainless steels. Corros Sci 2002;44:2183–98.

[11] Couvant T, Legras L, Vaillant F, Boursier JM, Rouillon Y. Effect of strain-hardening on stress corrosion cracking of AISI 304L stainless steel in PWR primary environment at 360°C. In: Proceedings of the 12th international conference on environmental degradation of materials in nuclear power system – water reactors, TMS (The minerals, metals & materials society) 2005; August 14–18, Salt Lake City, Utah, USA.

[12] Eskandari M, Najafizadeh A, Kermanpur A, Karimi M. Potential application of nanocrystalline 301 austenitic stainless steel in lightweight vehicle structures. Mater Des 2009;30:3869–72.

[13] Silva CC, Farias JP, Sant’Ana HB. Evaluation of AISI 316L stainless steel welded plates in heavy petroleum environment. Mater Des 2009;30:1581–7. [14] Korkut I, Kasap M, Ciftci I, Seker U. Determination of optimum cutting

parameters during machining of AISI 304 austenitic stainless steel. Mater Des 2004;25:303–5.

[15] Wasnik DN, Dey GK, Kain V, Samajdar I. Precipitation stages in a 316L austenitic stainless steel. Scripta Mater 2003;49:135–41.

[16] Mirzadeh H, Najafizadeh A. Correlation between processing parameters and strain-induced martensitic transformation in cold worked AISI 301 stainless steel. Mater Charact 2008;59:1650–4.

[17] Tavares SSM, Neto JM, Silva MR, Vasconcelos IF, Abreu HFG. Magnetic properties anda0martensite quantification in an AISI 301LN stainless steel deformed by cold rolling. Mater Charact 2008;59:901–4.

[18] Karcı F, Kaçar R, Gündüz S. The effect of process parameter on the properties of spot welded cold deformed AISI304 grade austenitic stainless steel. J Mater Process Technol 2009;209:4011–9.

[19] Chowdhury SG, Das S, De PK. Cold rolling behaviour and textural evolution in AISI 316L austenitic stainless steel. Acta Mater 2005;53:3951–9.

[20] Abreu HFG, Carvalho SS, Lima Neto PL, Santos RP, Freire VN, Silva PMO, et al. Deformation induced martensite in an AISI 301LN stainless steel: characterization and influence on pitting corrosion resistance. Mater Res 2007;10:359–66.

[21] Underwood EE. Application of quantitative metallography. New York: Addison-Wesley; 1973.

[22] Olson GB, Cohen M. Kinetics of strain-induced martensitic nucleation. Metall Trans A 1975;6A:791–5.

[23] Llewellyn DT. Work hardening of austenitic stainless steels. Mater Sci Technol 1997;13:389–400.

[24] Maeng WY, Kim MH. Comparative study on the fatigue crack growth behavior of 316L and 316LN stainless steels: effect of microstructure of cyclic plastic strain zone at crack tip. J Nucl Mater 2000;282:32–9.

[25] Nebel TH, Eifler D. Cyclic deformation behaviour of austenitic steels at ambient and elevated temperatures. Sa¯dhana¯ 2003;28:187–208.

[26] Karaman I, Sehitoglu H, Maier HJ, Chumlyakov YI. Competing mechanisms and modelling of deformation in austenitic stainless steel single crystal with and without nitrogen. Acta Mater 2001;49:3919–33.

[27] Byun TS, Lee EH, Hunn JD. Plastic deformation in 316LN stainless steel – characterization of deformation microstructures. J Nucl Mater 2003;321:29–39.

[28] Hughes DA, Hansen N. High angle boundaries formed by grains subdivision mechanisms. Acta Mater 1997;45:3871–86.

[29] Dewidar MM, Khalil KA, Lim JK. Processing and mechanical properties of porous 316L stainless steel for biomedical applications. Trans Nonferr Metals Soc China 2007;17:468–73.

[30] Le DP, Yoo YH, Kim JG, Cho SM, Son YK. Corrosion characteristics of polyaniline-coated 316L stainless steel in sulphuric acid containing fluoride. Corros Sci 2009;51:330–8.

[31] Callister Jr WD, Rethwisch DG. Materials Science and engineering: an introduction. 8th ed. New York: John Wiley and Sons; 2010.

[32] Muthukumaran V, Selladurai V, Nandhakumar S, Senthilkumar M. Experimental investigation on corrosion and hardness of ion implanted AISI 316L stainless steel. Mater Des 2010;31:2813–7.

[33] Cui Y, Lundin CD. Austenite-preferential corrosion attack in 316 austenitic stainless steel weld metals. Mater Des 2007;28:324–8.