Abst ract

Submitted: May 16, 2016 0RGL¿FDWLRQ)HEUXDU\ Accepted: March 10, 2017

Effect s of porcelain t hickness on

WKHÀH[XUDOVWUHQJWKDQGFUDFN

propagat ion in a bilayered zirconia

syst em

2EMHFWLYH 7KLV VWXG\ HYDOXDWHG WKH LQÀXHQFH RI SRUFHODLQ 90 9,7$ =DKQIDEULN*HUPDQ\WKLFNQHVVRQWKHÀH[XUDOVWUHQJWKDQGFUDFNSURSDJDWLRQ in bilayered zirconia syst em s ( YZ, VI TA Zahnfabrik, Germ any) . Mat erial and Met hods: Thir t y zir conia bar s ( 20.0x4.0x1.0 m m ) and six zir conia blocks ( 12.0x7.5x1.2 m m ) were prepared and veneered wit h porcelain wit h different t hickness: 1 m m , 2 m m , or 3 m m . The bars of each experim ent al group ( n= 10) ZHUHVXEMHFWHGWRIRXUSRLQWÀH[XUDOVWUHQJWKWHVWLQJ,QHDFKFHUDPLFEORFND Vickers indent at ion was creat ed under a load of 10 kgf for 10 seconds, for t he SURSDJDWLRQRIFUDFNV5HVXOWV7KHUHVXOWVRIÀH[XUDOVWUHQJWKZHUHHYDOXDWHG E\2QHZD\$129$DQG7XNH\¶VWHVWZLWKDVLJQL¿FDQFHOHYHORI7KH IDFWRU³WKLFNQHVVRIWKHSRUFHODLQ´ZDVVWDWLVWLFDOO\VLJQL¿FDQWS DQG WKHPPJURXSSUHVHQWHGWKHKLJKHVWYDOXHVRIÀH[XUDOVWUHQJWK7KHFUDFNV were predom inant am ong t he bending specim ens wit h 1 and 2 m m of porcelain, and cat ast rophic failures were found in 50% of 3- m m - t hick porcelain. Aft er t he indent at ion of blocks, t he m ost severe defect s were observed in blocks wit h 3- m m - t hick porcelain. Conclusion: The sm allest ( 1 m m ) t hickness of porcelain RQWKH]LUFRQLDLQIUDVWUXFWXUHSUHVHQWHGKLJKHUYDOXHVRIÀH[XUDOVWUHQJWK Bet t er resist ance t o defect propagat ion was observed near t he porcelain/ ]LUFRQLD LQWHUIDFH IRU DOO JURXSV +LJKHU ÀH[XUDO VWUHQJWK ZDV IRXQG IRU D t hinner porcelain layer in a bilayered zirconia syst em . The dam age caused by a Vickers indent at ion near and far t he int erface wit h t he zirconia shows t hat WKHVWUHVVSUR¿OHVDUHGLIIHUHQW

Ke yw or ds: Ceram ics. Porcelain. Mechanical st ress. Confocal m icroscopy. Viviane Maria Gonçalves de

FIGUEIREDO1

Sarina Maciel Braga PEREIRA1

Eduardo BRESSIANI2

Márcia Carneiro VALERA2

Marco Antônio BOTTINO1

Yu ZHANG3 5HQDWD0DUTXHVGH0(/21

1Univ. Estadual Paulista, Instituto de Ciência e Tecnologia de São José dos Campos, Departamento

de Materiais Odontológicos e Prótese, São Jose dos Campos, SP, Brasil.

2Univ. Estadual Paulista, Instituto de Ciência e Tecnologia de São José dos Campos, Departamento

de Odontologia Restauradora, São Jose dos Campos, SP, Brasil.

3New York University, College of Dentistry, Biomaterials and Biomimetics, New York, USA.

Corresponding address:

5HQDWD0DUTXHVGH0HOR

I nt roduct ion

Ceram ic m at erials are increasingly used in dent al

rest orat ions because of t he excellent com binat ion of

est het ic, biological, and m echanical propert ies, such as

wear resist ance and rigidit y20, m aking t hem a m at erial

of choice for oral rehabilit at ion11,12. Dent al ceram ics can

be used for fram ew ork, e.g., yt t rium - oxide part ially VWDELOL]HG ]LUFRQLD ZKLFK KDV KLJK ÀH[XUDO VWUHQJWK and fract ure t oughness, but lim it ed t ranslucency20,26.

Excellent est het ic propert ies are achieved by applying

a veneering ceram ic ( feldspat hic glass or porcelain) t o

t he fram ew ork23.

The m ost com m on clinical com plicat ions associat ed

w it h t he infrast r uct ur e of zir conia r est orat ions ar e

loss of ret ent ion, t he need for endodont ic t reat m ent ,

veneering ceram ic fract ures and bleeding on probing12.

Mechanical com plicat ions such as porcelain fract ure

t end t o be m ore prevalent in veneered zirconia crow ns

t han in t hose w it h m et al coping18,24.Clinical reasons

for t he failure of t hese ceram ic rest orat ions include

m echanical st ress for high occlusal loads, which causes

crack propagat ion and lat er result s in “ chipping”20,28

and locat ion in t he dent al arch21. From a biom echanical

m at erials perspect ive, residual st resses in com pression

and t ension generat ed along t he porcelain layer play a

crit ical role in t he failure of porcelain veneered zirconia

crow ns27.

5HVLGXDOVWUHVVHVLQÀXHQFHWKHVWUHQJWKDQGIUDFWXUH behavior of ceram ic crow ns and w hen com bined w it h

funct ional st resses m ay lead t o rest orat ion failure17.

Am ong t he fact ors t hat cont rol t he am ount of residual

st resses are t he geom et ry of t he infrast ruct ure6,8,16,19,

t he t hickness of t he ceram ic overlay and fram ew ork16,

and t he cooling rat e at t em perat ures above t he glass

t ransit ion t em perat ur e10, 15. The nat ur e of st r esses,

eit her com pressive or t ensile, also affect s ceram ics

st rengt h, t he form er increases st rengt h and t he lat t er

increases crack propagat ion under occlusal loadings.

From a clinical view point , t he t hickness of zirconia

fram ework m ay vary from 0.3 t o 1.0 m m , while t hat of

t he veneering ceram ic varies from 0.3 t o 3.0 m m22,29.

This variat ion in t hickness is due t o t he dent al crown

com plex shape, w hich has regions, such as cusps and

axial walls built up w it h varying porcelain t hicknesses,

prom ot ing different st ress m agnit udes27. Few st udies

KDYHVSHFL¿FDOO\DGGUHVVHGWKHPHFKDQLFDOEHKDYLRURI different t hicknesses of porcelain- zirconia25.Therefore,

it is necessary t o know t he effect s of m echanics and

crack propagat ion at different t hicknesses of

porcelain-zirconia infrast ruct ure perform ance.

The m et hodologies used t o analyze t he cracks in

ceram ics include m icrotom ography19, t ransillum inat ion3,

and Scanning Elect ron Microscopy ( SEM) . However, t he

lit erat ure does not report crack behavior of ceram ic

bilayer syst em w it h regard t o it s dept h, volum e, and

t he ext ent of dependence on porcelain t hickness. This VWXG\ DLPHG WR HYDOXDWH WKH LQÀXHQFH RI SRUFHODLQ ]LUFRQLDWKLFNQHVVRQWKHÀH[XUDOVWUHQJWKDQGFUDFN propagat ion of a bilayered syst em by m eans of confocal

m icroscopy analysis. The hypot heses t o be t est ed were + ± 7KH VPDOOHVW WKLFNQHVV RI YHQHHULQJ FHUDPLF LQFUHDVHV ÀH[XUDO VWUHQJWK DQG + ± 7KHUH ZLOO EH differences in t he propagat ion of defect s ( indicat ive

of residual st resses) , depending on veneering ceram ic

t hicknesses.

Mat erial and Met hods

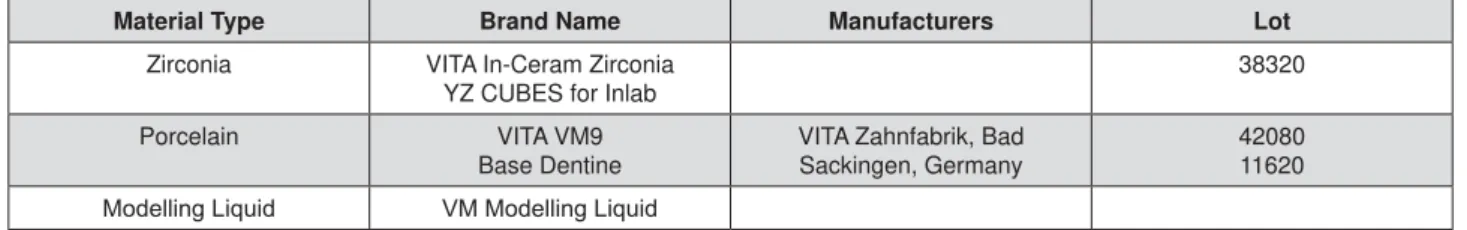

Th e m at er ials u sed in t h is st u dy ar e sh ow n in

Figure 1.

Sam ple preparat ion

I n t his st udy, zirconia blocks pre- synt hesized wit h

dim ensions 14x15x20 m m ( VI TA I n- Ceram® YZ Cubes,

Vit a Zahnfabrik, Bad Säckingen, Germ any) w ere used

t o m ake bar and block specim ens. Thirt y bar- shaped

zirconia specim ens, wit h dim ensions of 20.0 m m lengt h

x 4.0 m m w idt h x 1.0 m m t hickness, and six

block-shaped zirconia specim ens, w it h dim ensions of 12.0

m m lengt h x 7.50 w idt h x 1.2 m mt hickness, w ere

cut w it h t he aid of a cut t ing m achine ( 1000 I SOMET,

Buehler Lt d., Lake Bluff, I L, USA) . Specim en dim ensions

Material Type Brand Name Manufacturers Lot

Zirconia VITA In-Ceram Zirconia

YZ CUBES for Inlab

38320

Porcelain VITA VM9

Base Dentine

VITA Zahnfabrik, Bad Sackingen, Germany

42080 11620 0RGHOOLQJ/LTXLG 900RGHOOLQJ/LTXLG

w ere obt ained aft er a sint ering process in a Zyrcom at

furnace ( Vit a Zahnfabrik, Bad Sackingen, Germ any) .

Specim en s w er e clean ed in an u lt r ason ic bat h

( Vit asonic, Vit a Zahnfabrik, Bad Sackingen, Germ any)

for 5 m in in 10% isopropyl alcohol to rem ove any residue

from previous st eps and dried at room t em perat ure.

They w ere t hen random ized int o experim ent al groups,

w it h 10 bars and 2 blocks for each group. The groups

follow ed t he porcelain t hickness, accordingly:

Group 1: Bars and blocks w it h 1 m m of zirconia

and 1 m m of porcelain.

Group 2: Bars and blocks w it h 1 m m of zirconia

and 2 m m of porcelain.

Group 3: Bars and blocks w it h 1 m m of zirconia

and 3 m m of porcelain.

Applicat ion of veneering ceram ic

The applicat ion of porcelain ( VM9; Vit a Zahnfabrik,

Bad Sackingen, Germ any) was perform ed m anually.

The zirconia specim ens w ere insert ed int o a silicone

m old for t he applicat ion of porcelain layers. Thus, t he

ceram ic powder was m ixed w it h t he m odeling liquid,

applied, and condensed ont o zirconia bars. The powder

used was Base Dent in ( VM9; Vit a Zahnfabr ik , Bad

Sackingen, Germ any) , w hich was applied w it h a brush

under vibrat ion.

7KH¿ULQJSURFHVVZDVWKHEDVLFF\FOHIRU9,7$90 ( recom m ended by t he m anufact urer) . Base Dent in was ¿UVWDSSOLHGXQWLOFRPSOHWLRQRIWKHGHVLUHGWKLFNQHVV DQG ¿UHG LQ D 9DFXPDW 9LWD =DKQIDEULN %DG 6DFNLQJHQ*HUPDQ\IXUQDFHLQWZR¿ULQJF\FOHVIRU all groups ( Table 1) . Bar and block shaped specim ens ZHUH WKHQ ¿QLVKHG ZLWK VLOLFRQ FDUELGH VDQGSDSHU # 600, 800, 1000, and 1200 ( 3M, Sum aré, SP, Brazil) ,

under const ant wat er ir r igat ion ( Aut om et , Buehler,

Lake Bluff, I L, USA) .

)RXUSRLQWÀH[XUDOVWUHQJWKWHVW

The st rengt h of t he bilayer syst em was m easured

by t he four- point bending t est . Specim ens were placed LQDIRXUSRLQWEHQGLQJ¿[WXUHPPGLDPHWHUUROOHUV

support s spaced 16 m m apart , and rollers 8 m m apart ) ,

w here t he porcelain was t est ed under t ensile st ress. 7KHÀH[XUDOVWUHQJWKWHVWZDVSHUIRUPHGDWDVSHHGRI 0.5 m m / m in, w it h a 1000- kgf load cell, in a universal

t est ing m achine, EMI C DL 1000 ( São José dos Pinhais, 35%UD]LO0D[LPXPORDG3ZDVUHFRUGHGDWWKH¿UVW VLJQRIIUDFWXUHYHUL¿HGE\WKH¿UVWFUDFNLQJVRXQG DQGFKDQJHVLQWKHGHÀHFWLRQFXUYH6WUHQJWKYDOXHV ıZHUHFDOFXODWHGIRUÀH[XUDOVWUHQJWKRIWKHELOD\HU

according t o t he follow ing equat ion9:

w here P is t he applied load in New t ons ( N) , L is

t he dist ance bet ween t he support rollers in m illim et ers

( m m ) , Y’ is t he dist ance in m m from t he neut ral axis RIWKH¿EHUDQGRXWHUITOT is t he m om ent of inert ial cross- sect ion around t he cent ral axis.

The Y’ value was given by equat ion 2:

w here tc and tv, correspond t o t he t hickness ( T in m m ) of t he zirconia infrast ruct ure and porcelain,

respect ively, and Ec and Ev are t he elast ic m odulus ( E) of t he ceram ic layers of infrast ruct ure and porcelain,

respect ively.

Th e ITOT var iable w as det er m in ed accor din g t o equat ion 3:

and w is t he sam ple w idt h.

Mat er i al t h i ck n esses w er e m easu r ed w i t h a

digit al caliper, and t he elast ic m oduli obt ained from

t he lit erat ure w ere 209.3 GPa for YZ and 66.5 GPa

for VM97. The glaze layer was not used in t his st udy

and, t herefore, t he values for t his m at erial w ere not

considered.

Analysis by st ereom icroscopy

The failur es of t he bar - shaped specim ens w er e

observed w it h a st ereo m icroscope (Discovery z- 20,

Firing process

Starting T (°C) Pre-drying t (min) and closing t (min)

Heating t (min)

Heating rate (°C/min)

Firing T (°C) Holding t (min)

Vacuum holding t

(min)

Wash Firing 500 2 8.11 55 950 1 8.11

1st dentine

Firing

500 6 7.27 55 910 1 7.27

2nd dentine

Firing

500 6 7.16 55 900 1 7.16

Zeiss, Jena, Germ any)DW[DQG[PDJQL¿FDWLRQ

an d classif ied accor d in g t o Lim a, et al.1 5 ( 2 0 1 3 )

DV FUDFNLQJ D ¿VVXUHFUDFN LQ WKH SRUFHODLQ OD\HU delam inat ion/ chipping of veneer ing ceram ics; t ot al

rem oval of porcelain from t he zirconia layer, leaving

YZ free of veneering ceram ics; or cat ast rophic failure.

Vickers indent at ion

A defect in t he six block- shaped specim ens was

sim ulat ed by a Vickers indent at ion, perform ed w it h a

load of 10 kg for 10 s. Prior t o t hat , t he blocks w ere

em bedded in acrylic resin and w et - ground wit h SiC

sandpaper in t he sam e way t he bending specim ens

w ere.

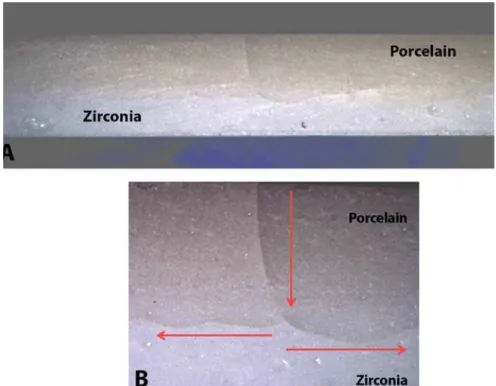

Each block received t w o indent at ions ( Figure 2) ,

eit her close t o ( 0.3 m m fr om t he int er face) or far

from ( 0.3 m m from t he upper surface of t he porcelain)

zirconia. Vickers indent at ion was perform ed using a

DHV- 1000 Micro Hardness Test er ( Durom et er MD- 1;

Micr ot est , Asker, Kyot o, Japan) . As a high loading

force w ould lead t o int eract ions bet w een t he cracks

and im pair t he evaluat ion, w e per for m ed only one

indent at ion on each sit e.

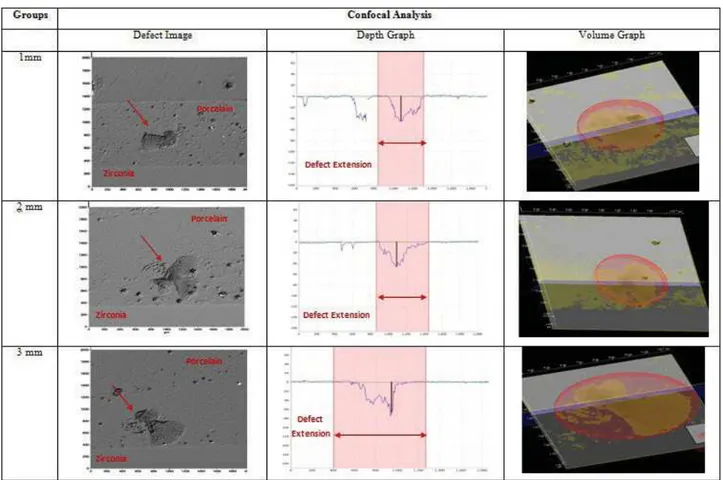

Confocal m icroscopy analysis

Dam age sust ained fr om t he Vicker s indent at ion

were exam ined in a 3D confocal m icroscope ( Mit ut oyo,

Suzano, SP, Brazil) , whereby t he dept h, ext ension, and

volum e of t he defect obt ained w ere m easured using

t he appropriat e soft ware ( Cyber CT Scan 8, I ngolst adt ,

Germ any) .

St at ist ical analysis

5HVXOWVRIÀH[XUDOVWUHQJWKZHUHDQDO\]HGE\2QH ZD\$129$DWDVLJQL¿FDQFHOHYHORI7XNH\¶VWHVW LGHQWL¿HGGLIIHUHQFHVDPRQJJURXSV5HVXOWVRIFUDFN propagat ion analysis w ere evaluat ed by m easures of

cent ral t endency and st andard deviat ions.

Result s

The effect of por celain t hick ness on t he bilayer ]LUFRQLDV\VWHPZDVVWDWLVWLFDOO\VLJQL¿FDQWp= 0.001) , acco r d i n g t o On e- w ay ANOVA. Th e cer am i c b ar ZLWK PP SRUFHODLQ KDG KLJKHU ÀH[XUDO VWUHQJWK 7XNH\¶VWHVWGLGQRWLGHQWLI\DVWDWLVWLFDOO\VLJQL¿FDQW difference bet w een t he bilayers ( Table 2) . Cracking

predom inat ed am ong groups w it h 1 m m and 2 m m

porcelain t hickness, cat ast rophic failures were found in

50% of specim ens wit h 3 m m veneering ceram ics, and

delam inat ion/ chipping was present in 20% of bars wit h

2 m m of porcelain. The origin of failures occurred at

t he porcelain surface w it h propagat ion at t he int erface

bet ween zirconia and porcelain in all groups. Failures

ran from t he cent er t o t he edges in all groups ( Figures

3 and 4) . The proport ion of porcelain det ached from

zirconia in cat ast rophic failures was larger in t he 3 m m

t han in t he 2 m m group ( Figure 4) .

Groups Flexural

strength means

Type of failure p-value Grouping**

(SD) Cracking Delamination/

chipping

Catastrophic

1 mm 51.5 (9.84) 10 (100%) 0 (0%) 0 (0%) 0.001 A

2 mm 35.5 (9.03) 7 (70%) 2 (20%) 1 (10%) B

3 mm 35.8 (6.01) 5 (50%) 0 (0%) 5 (50%) B

Table 2- Flexural strengths (MPa) and types of failures

*URXSVWKDWVKDUHDOHWWHUZHUHQRWVWDWLVWLFDOO\VLJQL¿FDQWO\GLIIHUHQW7XNH\¶VWHVWD IRUÀH[XUDOVWUHQJWKGDWD

Defect variables

Indented region Groups Depth

ȝP ExtensionȝP VolumeȝP3)

1 mm 37.3 465.5 2.35

Close 2 mm 39.2 425.5 3.01

3 mm 52.7 610.5 3.01

1 mm 38 288.5 0.88

Far 2 mm 33.3 324.5 1.22

3 mm 30.3 386 0.77

Table 3- Mean value of depth, extension, and volume close to and far from zirconia

Figure 3- 1-mm-thick porcelain bar. Porcelain cracking (A) (10x). Origin of the crack in the porcelain surface and propagation toward the interface, from center to ends (B) (40x)

Figure 4-PPWKLFN$%DQGPPWKLFN'&(SRUFHODLQEDU'HIHFWSURSDJDWLRQIURPSRUFHODLQVXUIDFHWRLQWHUIDFH[DQG

Figure 5-5HSUHVHQWDWLYHLPDJHVIURPFRQIRFDOPLFURVFRS\RIWKHH[SHULPHQWDOJURXSVWRSSUR¿OHGHSWKDQGYROXPHH[WHQVLRQRIGHIHFWV

generated in the block specimens close to the interface

Figure 6-5HSUHVHQWDWLYHLPDJHVIURPFRQIRFDOPLFURVFRS\RIWKHH[SHULPHQWDOJURXSVWRSSUR¿OHGHSWKDQGYROXPHH[WHQVLRQRIGHIHFWV

Average dept h, ext ension, and volum e of near and

far indent at ions are show n in Table 3. Propagat ion of

defect s show ed higher dept h, ext ension, and volum e

close t o zirconia, while all t hese param et ers were lower

w hen far from zirconia, except for dept h in t he 1 m m

group. Figures 5 and 6 show defect s generat ed in t he

block specim ens.

Discussion

I nv est igat in g t h e f ailu r es in por celain - zir con ia

infrast ruct ures has becom e a m aj or focus of research

in t h e scien ce of d en t al m at er ials. I n p ar t icu lar,

underst anding t he role of residual st resses in t hese

failures rem ains a challenge for researchers. I n t he

present st udy, w e show ed t hat t hin porcelain layers PP SUHVHQWHG KLJKHU ÀH[XUDO VWUHQJWK DQG WKH indent at ion ( defect ) progression did not depend on

porcelain t hickness, but was m ore severe near t he

zirconia subst rat e t han on t he porcelain surface.

These result s agree w it h Lim a, et al.15 ( 2013)and

Whit e, et al.25 ( 2005) , in which a t hin veneer t hickness

SURYLGHGKLJKHUÀH[XUDOVWUHQJWKRIELOD\HUFHUDPLF specim ens. These st udies also present ed cracking as

t he principal failure m ode for low- t hick bilayers.

How ever, in clinics20,27, t he m ost frequent failure

is cusp fract ures of all- ceram ic rest orat ions because

t hey present great er t hicknesses of porcelain and are

affect ed by residual and m echanical st resses27. The

int erface bet w een porcelain and zirconia is sensit ive

t o t he poor heat t ransfer am ong m at erials29 and w hen

t hick layers of porcelain t hat have even low er t herm al

diffusivit y are used, t here is spalling of porcelain27.

Therefore, t hickness of porcelain increased from PP WR PP VLJQL¿FDQWO\ LQFUHDVHV WKH WKHUPDO t r an si en t st r ess g r ad i en t s b et w een t h e zi r co n i a

and veneer29, explaining t hus t he change in failure

p at t er n s b et w een 1 m m an d 2 m m g r ou p s, an d

j ust ifying t he occurrences of delam inat ion/ chipping.

Th e r esidu al st r ess scen ar io w as ev en w or se f or

t h e 3 m m sp ecim en s, also j u st if y in g t h e h ig h er

num ber of cat ast rophic ( delam inat ion) failures. The

p r ed om in an ce of cr ack s in t h e 1 m m g r ou p can

be ex plain ed by t h e com pr essiv e st r esses du e t o

t he t em per ing effect17 t hat favor ed t he m echanical

st rengt h of such bilayer syst em .

One can argue t hat bilayered disks are not t he

sam e as cr ow ns. Never t heless, t he layer ed m odel,

w hile sim plist ic in it s geom et ry, provides a physical

basis for invest igat ing t he role of m at erial propert ies

and t he effect of t hickness in t he idealizat ion of

all-ceram ic crow ns13, besides facilit at ing t he assessm ent

of t he origin and propagat ion of t he defect14. Wit h

r eg ar d t o r esid u al st r esses, t h e m ain d if f er en ce

bet w een crow ns and disks is a t endency of t he lat t er

for residual com pressive st resses t o increase w it h an

increase in t hickness from 1 t o 2 m m1. How ever, t he

m ore aggressive dam ages seen aft er t he indent at ion RIPPVSHFLPHQVGLGQRWFRQ¿UPVXFKREVHUYDWLRQ w hich is probably relat ed t o t he fact t hat w e used a

slow cooling prot ocol t hat led t o relaxat ion of st resses

w it hin t he layers.

I n t he present st udy, w e w ere not able t o quant ify

spat ially residual st resses in t he porcelain layers using

Vicker s indent at ions, alt hough t his has been done

before w it h t he sam e m et hod on curved surfaces1.

Th u s, w e on ly ob ser v ed t h e occu r r en ce of cr ack SURSDJDWLRQQHDUWKHLQWHUIDFHFRQ¿UPLQJWKHSUHVHQFH of t ensile st resses, as shown previously4,8,10,13- 17,27. Most

RIWKHFUDFNVH[WHQGHGODWHURLQZDUGO\FRQ¿UPLQJD t endency for porcelain chipping inst ead of porcelain

debonding from zirconia. Therefore, t ensile residual

st r esses occu r pr edom in an t ly par allel r at h er t h an

per pen dicu lar t o t h e por celain / zir con ia in t er face2.

Based on t he dam age ext ension, t he cracks ran m ore

rapidly in regions close t han far from zirconia. Alt hough

t he 1 m m group showed higher defect dept hs near t he

porcelain surface, crack lengt h and volum e rem ained

relat ively sm all. The higher dept h in t his group can

be explained by t he presence of a pore in t he vicinit y.

The presence of such irregularit y inside t he layers is

a lim it at ion of using t he indent at ion m et hod, because

t he crack can easily int eract w it h t he pore in t he bulk.

On t he ot her hand, com pressive st resses are prevalent

near t he porcelain surface5 regardless of t he veneer

t hickness17, as shown by sim ilar defect sizes and crack

lengt hs. How ever, t his t ype of residual st ress is m ore

int ense in fast cooled bilayers.

The use of Vick er s indent at ions for m easur ing

residual st ress has already been proved it self useful1,2.

Though it is not appropriat e t o com pare t he m echanical

propert ies m easured by t his m et hod, t he result s of

t he present st udy w ere consist ent in show ing t hat ,

depending on t he t hickness of t he porcelain, residual VWUHVV PD\ GLI¿FXOW FRPSUHVVLYH VWUHVV RU IDYRU ( t ensile st ress) crack propagat ion. I t is im port ant t o

as in t he Vickers indent at ion t est , is not analogous

t o t he m ast icat ory load, but it is a way t o prom ot e

t he occurrence of a severe defect and t o probe t he

fract ur e r esist ance of t he por celain. We ar e awar e

of t he residual st resses im part ed by t his indent at ion

m et hod but , in t he present st udy, it helped driving t he

crack along w it h t he residual t ensile st resses inside

t he porcelain.

Ot her t echniques for t he obser vat ion of crack s

and defect s are scanning elect ron m icroscopy ( SEM) , WUDQVLOOXPLQDWLRQ DQG PLFURWRPRJUDSK\ 7KH ¿UVW m et hod is im port ant for surface assessm ent but does

not allow in- dept h observat ions. The second m et hod

allow s us t o det ect int ernal defect s, precluding t hese

m easurem ent s. Finally, m icrot om ography facilit at es

t he obser vat ion of crack pr opagat ion but r equir es

considerable specim en preparat ion, w hich can dist ort

t h e or ien t at ion of cr ack s, lead in g t o d if f icu lt y in

dam age assessm ent1. The use of confocal m icroscopy

show ed sat isfact ory result s in t he analysis of defect s

found in t he ceram ic bilayer syst em . I t proved t o be a

quick and sim ple t echnique t hat does not require cost ly

sam ple preparat ion and t hat offers crucial inform at ion

on defect s in t he sur face and beneat h it , being a

viable m et hod for observing ceram ic defect s. Thus,

we believe t hat t he associat ion of confocal m icroscopy

and t he Vickers indent at ion is an effect ive resource for

observing defect s/ crack propagat ion and it highlight s

t he presence of residual st resses in ceram ic m at erials.

The ant icipat ed hy pot heses ( H1 and H2 ) w er e

a c c e p t e d . Li m i t a t i o n s o f t h i s s t u d y w e r e t h e

absence of r ealist ic scenar ios r esem bling t he oral HQYLURQPHQWVXFKDVWKHFRPSOHWLRQRIWKHÀH[XUDO t est or t herm alcycling in wat er, w hich w ere avoided t o

m inim ize t he occurrence of subcrit ical crack grow t h.

Furt her researches should be developed using confocal

m icr oscop y t o assess t h e p at h w ay of d ef ect s in

com plex geom et ries, such as crow ns and bridges. I n

addit ion, it is im port ant t o evaluat e t he behavior of

cracks or defect s generat ed under fat igue loading or

ot her t ypes of dam age28.

Conclusions

The t hinnest ( 1 m m ) porcelain/ zirconia specim ens SUHVHQWHGKLJKHUÀH[XUDOVWUHQJWK'HIHFWVLQFHUDPLFV close t o t he porcelain/ zirconia int erface grew fast er

t han defect s close t o t he por celain sur face for all

t hicknesses, suggest ing t hat t he occurrence of residual

t ensile st resses is higher at t his sit e.

Acknow ledgem ent s

YZ acknowledges t he US Nat ional I nst it ut e of Dent al

and Craniofacial Research Grant 2R01 DE017925.

References

$O$POHK%1HLO:DGGHOO-/\RQV.6ZDLQ09,QÀXHQFHRIYHQHHULQJ

porcelain t hickness and cooling rat e on residual st resses in zirconia

m olar crow ns. Dent Mat er. 2014; 30( 3) : 271- 80.

2- Baldassar r i M, St apper t CF, Wolff MS, Thom pson VP, Zhang Y.

Residual st r esses in por celain- veneer ed zir conia pr ost heses. Dent

Mat er. 2012; 28( 8) : 873- 79.

3- Beck N, Graef F,Gerst brein O, Karl M. Sensit ivit y of t ransillum inat ion

for det ect ing m icrocracks in feldspat hic and zirconia ceram ic m at erials.

J Prost het Dent . 2010; 104( 5) : 301- 5.

%HQHWWL3.HOO\-56DQFKH]0'HOOD%RQD$,QÀXHQFHRIWKHUPDO

gr adien t s on st r ess st at e of v en eer ed r est or at ion s. Den t Mat er.

2014; 30( 5) : 554- 63.

5- Bhow m ick S, Meléndez- Mar t ínez JJ, Her m ann I , Zhang Y, Law n

BR. Role of indent er m at erial and size in veneer failure of brit t le layer

st ruct ures. J Biom ed Mat er Res B Appl Biom at er. 2007; 82( 1) : 253- 9.

6- Bonfant e EA, Raffert y B, Zavanelli RA, Silva NR, Rekow ED, Thom pson

VP, et al. Therm al/ m echanical sim ulat ion and laborat ory fat igue t est ing

of an alt ernat ive yt t ria t et ragonal zirconiapolycryst al core- veneer

all-ceram ic layered crow n design. Eur J Oral Sci. 2010; 118( 2) : 202- 9.

7- Borba M, Araúj o MD, Lim a E, Yoshim ura HN, Cesar PF, Griggs JA, et

al. Flexural st rengt h and failure m odes of layered ceram ic st ruct ures.

Dent Mat er. 2011; 27( 12) : 1259- 66.

'H-DJHU13DOODY3)HLO]HU$-7KHLQÀXHQFHRIGHVLJQSDUDPHWHUV

on t he FEA- det erm ined st ress dist ribut ion in CAD- CAM produced

all-ceram ic dent al crow ns. Dent Mat er. 2005; 21( 3) : 242- 51.

'HOOD%RQD$$QXVDYLFH.-'H+RII3+:HLEXOODQDO\VLVDQGÀH[XUDO

st rengt h of hot - pressed core and veneered ceram ic st ruct ures. Dent

Mat er. 2003; 19( 7) : 662- 9.

1 0 - Jak ubow icz- Kohen BD, Sadoun MJ, Douillar d T , Mainj ot AK.

,QÀXHQFHRI¿ULQJWLPHDQGIUDPHZRUNWKLFNQHVVRQYHQHHUHG<7=3

discs curvat ure. Dent Mat er. 2014; 30( 2) : 242- 8.

11- Kohal RJ, Klaus G. A zirconia im plant - crown syst em : a case report .

I nt J Periodont ics Rest orat ive Dent . 2004; 24( 2) : 147- 53.

1 2 - Kohal RJ, Klaus G, St r ub JR. Zir conia- im plant - suppor t ed

all-ceram ic crow ns w it hst and long- t erm load: a pilot invest igat ion. Clin

Oral I m plant s Res. 2006; 17( 5) : 565- 71.

13- Law n BR, Bhow m ick S, Bush MB, Qasim T, Rekow ED, Zhang Y.

Failure m odes in ceram ic- based layer st ruct ures: a basis for m at erials

design of dent al crow ns. J Am Ceram Soc. 2007; 90( 6) : 1671- 83.

14- Law n BR, Deng Y, Thom pson VP. Use of cont act t est ing in t he

charact erizat ion and design of all- ceram ic crow n like layer st ruct ures:

a review. J Prost het Dent . 2001; 86( 5) : 495- 10.

15- Lim a JM, Souza AC, Anam i LC, Bot t ino MA, Melo RM, Souza RO.

Effect s of t hickness, processing t echnique, and cooling rat e prot ocol

RQ WKH ÀH[XUDO VWUHQJWK RI D ELOD\HU FHUDPLF V\VWHP 'HQW 0DWHU

2013; 29( 10) : 1063- 72.

0DLQMRW$.6FKDMHU*69DQKHXVGHQ$-6DGRXQ0-,QÀXHQFHRI ]LUFRQLDIUDPHZRUNWKLFNQHVVRQUHVLGXDOVWUHVVSUR¿OHLQYHQHHULQJ

ceram ic: m easurem ent by hole- drilling. Dent Mat er 2012; 28( 4) :

17- Mainj ot AK, Schaj er GS, Vanheusden AJ, Sadoun MJ. Residual

st ress m easurem ent in veneering ceram ic by hole- drilling. Dent Mat er.

2012; 27( 5) : 439- 44.

18- Pelaez J, Cogolludo PG, Serrano B, Serrano JF, Suarez MJ. A

four-year pr ospect ive clinical evaluat ion of zir conia and m et al- ceram ic

SRVWHULRU¿[HGGHQWDOSURVWKHVHV,QW-3URVWKRGRQW

19- Rekow ED, Zhang GM, Thom pson VP, Kim JW, Coelho P, Zhang Y.

Effect s of geom et ry on fract ure init iat ion and propagat ion in all- ceram ic

crow ns. J Biom ed Mat er Res B Appl Biom at er. 2009; 88( 2) : 436- 46.

20- Rueda AO, Seuba J, Anglada M, Jim énez- Piqué E. Tom ography of

indent at ion cracks in feldspat hic dent al porcelain on zirconia. Dent

Mat er. 2013; 29( 3) : 348- 56.

21- Schm it t er M, Mussot t er K, Ram m elsberg P, Gabbert O, Ohlm ann

% &OLQLFDO SHUIRUPDQFH RI ORQJVSDQ ]LUFRQLD IUDPHZRUNV IRU ¿[HG

dent al prost heses: 5- year result s. J Oral Rehabil. 2012; 39( 7) : 552- 7.

22- Swain MV. Unst able cracking ( chipping) of veneering porcelain on

DOOFHUDPLFGHQWDOFURZQVDQG¿[HGSDUWLDOGHQWXUHV$FWD%LRPDWHU

2009; 5( 5) : 1668- 77.

2 3 - Th o m p so n JY, St o n er BR, Pi asci k JR, Sm i t h R. Ad h esi o n /

cem ent at ion t o zirconia and ot her nonsilicat e ceram ics: w here are w e

now ? Dent Mat er. 2011; 27( 1) : 71- 82.

24- Vigolo P, Mut inelli S. Evaluat ion of zirconium - oxide- based ceram ic

VLQJOHXQLW SRVWHULRU ¿[HG GHQWDO SURVWKHVHV )'3V JHQHUDWHG ZLWK

t w o CAD/ CAM syst em s com pared t o porcelain- fused- t o- m et al

single-unit post erior FDPs: a 5- year clinical prospect ive st udy. J Prost hodont .

2012; 21( 4) : 265- 9.

25- Whit e SN, Miklus VG, McLaren EA, Lang LA, Caput o AA. Flexural

st rengt h of a layered zirconia and porcelain dent al all- ceram ic syst em .

J Prost het Dent . 2005; 94( 2) : 125- 31.

26- Zhang Y. Making yt t ria- st abilized t et ragonal zirconia t ranslucent .

Dent Mat er. 2014; 30( 10) : 1195- 203.

27- Zhang Y, Allahkaram i M, Hanan JC. Measuring residual st ress in

ceram ic zirconia- porcelain dent al crow ns by nanoindent at ion. J Mech

Behav Biom ed Mat er. 2012; 6: 120- 7.

28- Zhang Y, Sailer I , Law n BR. Fat igue of dent al ceram ics. J Dent .

2013; 41( 12) : 1135- 47.

29- Zhang Z, Zhou S, Li Q, Li W, Swain MV. Sensit ivit y analysis of