LIST OF SYMBOLS H: Total enthalpy

S: Scalar measure of the deformation tensor T: Temperature

T2: Temperature at exit of stage d: Distance from the wall

fv1, fv2, fw: Empirical functions in the turbulence model k &RHI¿FLHQWRIWKHUPDOFRQGXFWLYLW\

K: Constant in the turbulence model p: Pressure

s 6SHFL¿FHQWURS\ t: Time

u: Velocity component in a Cartesian system x: Cartesian coordinate

g,r,S˜ ,QWHUPHGLDWHYDULDEOHV

ȗ (QHUJ\ORVVFRHI¿FLHQWLQWKHHQWURS\IRUP Ș 7RWDOHI¿FLHQF\

ȝ '\QDPLFYLVFRVLW\

Ȟ .LQHPDWLFPROHFXODUYLVFRVLW\

ȡ: Density

IJĀij: Shear stress tensor Ȥ ,QWHUPHGLDWHYDULDEOH

ĭĀ 5H\QROGVDYHUDJHRIDJHQHULFYDULDEOH ĭѺ )DYUHDYHUDJHRIDJHQHULFYDULDEOH ĭ 7LPHDYHUDJHRIYDULDEOHĭĀ ĭ 7LPHDYHUDJHRIYDULDEOH ĭѺ

i, j, k 8QLWYHFWRULQD&DUWHVLDQFRRUGLQDWHV\VWHP in, out : Inlet and exit conditions

0 6WDJQDWLRQYDOXH

INTRODUCTION

In the past, the experimental method was the single tool DGRSWHG WR XQGHUVWDQG ZLWK GHWDLOV DQG WR YLVXDOL]H VRPH VRXUFHORVVWKDWRFFXUDORQJWKHÀXLGÀRZ:LWKWKHDSSHDU-ance of computational techniques in the last 40 years, another DOWHUQDWLYHHPHUJHGWRDQDO\]HWKHÀXLGÀRZWKHQXPHULFDO VLPXODWLRQ7KHDFFXUDF\RIWKH&RPSXWDWLRQDO)OXLG'\QDP-LFV&)'SUHGLFWLRQVRIWXUERPDFKLQHU\FRPSRQHQWHI¿FLHQF\ at the design point is around ±2%, if one takes into account uncertainty in the numerical methods, models, geometry,

Numerical Simulation of Performance of an Axial Turbine First

Stage

Vinícius Guimarães Monteiro1,*, Edson Luiz Zaparoli1, Cláudia Regina de Andrade1, Rosiane Cristina de Lima2

1,QVWLWXWR7HFQROyJLFRGH$HURQiXWLFD±6mR-RVpGRV&DPSRV63±%UD]LO 29DOH6ROXo}HVHP(QHUJLD±6mR-RVpGRV&DPSRV63±%UD]LO

Abstract: TKis work KDs prHsHntHd tKH ¿rst stDgH pHrforPDnFH Dt dHsign Dnd offdHsign opHrDting points of Dn DxiDO turEinH, witK two stDgHs using D nuPHriFDO siPuODtion (xpHriPHntDO PHtKods of prHdiFting tKH pHrforPDnFH of DxiDO turEinH is FostO\ Dnd tiPH FonsuPing FoPpDrHd to tKH FoPputDtionDO Àuid d\nDPiFs DpproDFK TKHrHforH, FoPputDtionDO tHFKniTuHs wHrH DdoptHd to dHtHrPinH tKH stDgH pHrforPDnFH TKis stud\ DnDO\]Hd tKH ¿rst stDgH pHrforPDnFH of Dn DxiDO Àow turEinH, using D FoPputDtionDO tooO for siPuODting tKH stHDd\ stDtH twotKrHHdiPHnsionDO visFous Àow $ FoPputDtionDO Àuid d\nDPiFs softwDrH wDs usHd to soOvH tKH rDns HTuDtions witK tKH spDODrtDOOPDrDs turEuOHnFH PodHO TKH FoPputDtionDO Àuid d\nDPiFs rHsuOts wHrH FoPpDrHd witK tKosH oEtDinHd froP tKH PHDn OinH Ooss PodHO FodH TKH FoPpDrisons KDvH EHHn FonduFtHd to providH D prHtHst pHrforPDnFH for tKH turEinH ¿rst stDgH

Keywords: $xiDO TurEinHs, *Ds TurEinHs, &oPputDtionDO )Ouid '\nDPiFs, 1uPHriFDO SiPuODtion, 3HrforPDnFH

5HFHLYHG$FFHSWHG

DQGERXQGDU\FRQGLWLRQV'HQWRQDQG;X&RPPRQO\ GHVLJQHUVDGRSWWKLVDSSURDFKWRLQYHVWLJDWHWKHÀXLGÀRZ DQGWRFKRRVHH[SHULPHQWVWREHSHUIRUPHG)RUWXQD Computational techniques are less costly and time-consuming if compared to the experimental approach to predict the SHUIRUPDQFHRIWKHD[LDOWXUELQH)OHWFKHU

Dorney (2003) conducted a pretest performance for a WZRVWDJH VXSHUVRQLF WXUELQH 7KH REMHFWLYH RI WKH ZRUN was to quantify the performance of the turbine at off- design ÀRZFRQGLWLRQVDVZHOODVWRFKDUDFWHUL]HFKDQJHVLQWKH XQVWHDGLQHVVDVDIXQFWLRQRIÀRZFRQGLWLRQ7KHVLPXOD-tions were performed using a three-dimensional unsteady 1DYLHU6WRNHV HTXDWLRQ 7KH SUHGLFWHG UHVXOWV ZHUH FRPSDUHGZLWKVROXWLRQVIURPDPHDQOLQHFRGH7KLVFRGH uses a combination of the one-dimensional equations of PRWLRQDQGHPSLULFDOORVVPRGHOVWRSUHGLFWWKHÀRZDQG SHUIRUPDQFHTXDQWLWLHVLQWKHWXUELQH7KHUHVXOWVVKRZHG UHDVRQDEOHDJUHHPHQWRYHUDZLGHUDQJHRIÀRZFRQGLWLRQV and they were used to help determining the locations of the WUDQVGXFHUVLQWKHH[SHULPHQWV

:HOFK GHYHORSHG WKH WKUHHGLPHQVLRQDO ' DHURGHVLJQDQGDQDO\]HGWKHUHOHYDQWVWDJHRIDQDHURQDXWL-FDOWXUELQHFRPSRQHQWDWDOHYHOVXI¿FLHQWWRYHULI\WKDWWKH design and off-design performances of the 3D computational results are consistent with the mean line analysis used in the FRQFHSWXDOGHVLJQRIWKHWXUELQH7KHDXWKRUUHSRUWVWKDW' ÀRZIHDWXUHVDVVRFLDWHGZLWKWUDQVSRUWGXHWRUDGLDODFFHOHUD-WLRQ¿HOGVDQGFURVVSDVVDJHJUDGLHQWVZRXOGOHDGWRKLJKHU losses than predicted by the mean line loss correlations and WZRGLPHQVLRQDO'&)'DQDO\VHV,WZDVFRQFOXGHGWKDW the 3D computational results yield good agreement with the SUHGLFWHGRQHVE\WKHPHDQOLQHDQDO\VHVVKRZHGIURPHI¿-FLHQF\YHUVXVVSHHGWUHQGVVXSSRUWLQJWKHGHVLJQFKRLFHWR H[HFXWHWKHWXUELQHGHVLJQDWWKHFUXLVHRSHUDWLQJVSHHG 6DUDYDQDPXWWRLQDZRUNSXEOLVKHGDW$*$5' /6UHSRUWH[SODLQHGWKDWWKHVWHDG\VWDWHSUHGLFWLRQRI performance must be done at the beginning of an engine GHYHORSPHQWSURJUDPLQRUGHUWRHQVXUHWKDWWKHHQJLQHFDQ satisfy all the operation requirements (design and off-design SRLQWV7KXVWKHFRPSRQHQWFKDUDFWHULVWLFVPXVWEHHVWLPDWHG DQGWKHQXSGDWHGDVWKHSURJUDPXQIROGV 7KLVVWXG\GHDOVZLWKVWHDG\VWDWH'YLVFRXVÀRZWR REWDLQLQIRUPDWLRQDERXWWKHSHUIRUPDQFHRID¿UVWVWDJH D[LDOWXUELQHE\VLPXODWLQJWKHÀRZWKURXJKWKHEODGHV$ FRPPHUFLDOVRIWZDUHSDFNDJHZDVXVHGWRVROYHWKH5$16 HTXDWLRQV ZLWK WKH 6SDODUW$OOPDUDV WXUEXOHQFH PRGHO Despite of 2D CFD approach limitations, it is important to

HYDOXDWHGLIIHUHQFHVEHWZHHQ'DQG'DSSURDFKUHVXOWV 7KH NH\ REMHFWLYH RI WKH SUHVHQW HIIRUW ZDV WR FRQGXFW D SUHWHVW SHUIRUPDQFH IRU D ¿UVWVWDJH WXUELQH DW D OHYHO VXI¿FLHQWWRYHULI\LIWKH&)'UHVXOWVDUHFRQVLVWHQWZLWK WKHFODVVLFDOORVVPRGHODQGPHDQOLQHDQDO\VLV7RDFKLHYH WKHREMHFWLYHLWZDVFRQVWUXFWHGDSHUIRUPDQFHPDSIRUWKH ZKROHUDQJHRIRSHUDWLRQRIWXUELQH7KH&)'UHVXOWVZHUH compared with the mean line loss model code ones, which DFFRXQWWKHORVVHVE\'HQWRQORVVPRGHO)XUWKHUPRUHLW ZLOOEHSUHVHQWHGWKH0DFKQXPEHUDQGWRWDOSUHVVXUHIURP hub to tip of stator blade and rotor blade in the region near WKH OHDGLQJ DQG WUDLOLQJ HGJHV 7KH FRPSDULVRQ RI WKHVH parameters calculated by the 3D CFD simulations was made against mean line loss model code results generated by the PDQXIDFWXUHU 7KH FRPSDULVRQV KDYH EHHQ FRQGXFWHG WR YHULI\LIWKH'&)'UHVXOWVDUHFRQVLVWHQWZLWKWKHPHDQ OLQHDQDO\VLVXVHGLQWKHFRQFHSWXDOGHVLJQRIWKHWXUELQH

COMPUTATIONAL METHODOLOGY

Conservation equations

7KHÀRZ¿HOGZDVPRGHOHGXVLQJWKH5H\QROGV$YHUDJHG 1DYLHU6WRNHV(TXDWLRQV7DQQHKLOOHt DODVFDQEH VHHQLQ(TWR

&RQWLQXLW\HTXDWLRQ

+ = 0

xj uj

0RPHQWXPHTXDWLRQ

(2)

ȋ Ȍ Ϊ

α Ϋ Ϊ Ϋ

Ϋ Ϋ

Ϋ ̶ ̶

ui

t xj

xj ij xi

u

p

iuj

uiuj

(QHUJ\HTXDWLRQ

Ϊ Ϊ ̶ ̶Ϋ

α Ϊ Ϊ ̶

H

t xj u

p H

j

ui ui i j i j t

u Hj

TURBULENCE MODEL

7KHFKRLFHRIWXUEXOHQFHPRGHOLVDIDFWRUWKDWLQÀXHQFHV WKHQXPHULFDOVLPXODWLRQDFFXUDF\RIWKHÀRZWKURXJKWXUELQH blades (Pecnik Ht DO7KH6SDODUW$OOPDUDVWXUEXOHQFH

PRGHOZDVDGRSWHGLQWKLVVWXG\EHFDXVHLWZDVGHYHORSHG SULPDULO\IRUDHURG\QDPLFÀRZ-DYDKHUFKLDQGLWSUHV-HQWVJRRGSHUIRUPDQFHLQDGYHUVHSUHVVXUHJUDGLHQWUHJLRQV 0HQWHU7KHPRGHOUHTXLUHVPRGHUDWHFRPSXWDWLRQDO FRVWWRVROYHWKHYLVFRXVVXEOD\HU(XOLW]DQG(QJHO 6SDODUW DQG $OOPDUDV SURSRVHG WR FORVH WKH V\VWHPRIHTXDWLRQVLQWURGXFLQJHLJKWFORVXUHFRHI¿FLHQWV DQGWKUHHFORVXUHIXQFWLRQV7KHPRGHOLVZULWWHQLQWHUPVRI

PRGL¿HGHGG\YLVFRVLW\ȞѺ:LOFR[7KHHTXDWLRQV

of the Spalart-Allmaras turbulence model are expressed by (TWR

.LQHPDWLF(GG\YLVFRVLW\

t= v

t,

v

t= v f

v1ȡ

˜

(GG\YLVFRVLW\HTXDWLRQ

v+U

j = cb16 v - cw1 fw W˜ [j

2 ˜ ˜ ˜ ˜ ˜ ˜ ˜ v v [˜k

d v

+ [ (v + v) + k

ı1 ı [k[k

cb2 v v

&ORVXUHFRHI¿FLHQWV

Fb1 Fb2 Fv1 ı =

2

3

k² ı

cw1 =cb1

+ (1 + cb2),

cw2 = 0,3, cw3 = 2, k = 0,41

$X[LOLDU\UHODWLRQV

fv1 = fv2 = 1 - fw = g X3

X3+ c3

v1

1 + c6

w3

g6 + c6w3

X

1+ Xf v1

1 6

X = g = r + cw2 (r6 - r),

Sk2 d2 r = v˜ v˜ ˜ , v

S = S + S = 2ȍijȍij k2d2 fv2 ,

v

˜ ˜ (10)

The tensor

ȍ

ij=

1

8i2

8j

[j [i is the rotation tensor and

d

is the distance from tKHFORVHVWVXUIDFH

BOUNDARY CONDITIONS 7KH'VLPXODWLRQZDVPDGHDWPHDQOLQHRIWKH¿UVWVWDJH FKDQQHO7KHWRWDOFRQGLWLRQVRISUHVVXUHDQGWHPSHUDWXUHDW LQOHWZHUHFRQVLGHUHG$WWKHRXWOHWWKHVWDWLFSUHVVXUHZDV ¿[HG3HULRGLFLW\UHJLRQVZHUHFRQVLGHUHGDWWKHLQWHUEODGH SRVLWLRQV$WWKHVSDFHVEHWZHHQFRQVHFXWLYHURZVIUR]HQ URWRUDSSURDFKZDVDGRSWHG7KHSHULRGLFLW\RIVWDWRUURWRU EODGHVLVVROYHGE\DGRPDLQVFDOHDVGLVFXVVHGE\0XUDUL Ht DODQG7RXVVDLQWHt DOZKLFKUHVXOWVLQ¿YH

VWDWRUEODGHURZVDQGHLJKWURWRUEODGHURZV7KHVWDWLRQDU\ conditions to the absolute reference frame were applied to the VWDWRUEODGHV7KHURWRUEODGHVKDYHWUDQVODWLRQDOYHORFLW\RI PVRQWKHGHVLJQSRLQW 7KH'VLPXODWLRQZDVPDGHDWRQO\RQHEODGHSDVVDJH 7KLVZDVSRVVLEOHEHFDXVHWKHPL[LQJSODQHDYHUDJHVZHUH DGRSWHGDWWKHVSDFHEHWZHHQFRQVHFXWLYHURZV8VLQJWKH IUR]HQURWRUDSSURDFKIRU'PRGHOH[FHVVLYHO\LQFUHDVHVWKH computational cost, due to the numbers of blade rows neces-VDU\WRVDWLVI\WKHSHULRGLFLW\RIVWDWRUURWRUEODGHV)RUWKLV reason, it was chosen the mixing plane approach in the stage LQWHUIDFHVIRU'PRGHO7RWDOSUHVVXUHDQGWRWDOWHPSHUDWXUH DWLQOHWZHUHFRQVLGHUHG$WRXWOHWWKHVWDWLFSUHVVXUHZDV ¿[HG3HULRGLFLW\UHJLRQVZHUHFRQVLGHUHGDWWKHLQWHUEODGH SRVLWLRQV7KHVWDWLRQDU\FRQGLWLRQWRWKHDEVROXWHUHIHUHQFH IUDPHZDVDSSOLHGWRWKHVWDWRUEODGH7KHURWRUEODGHKDV URWDWLRQDOYHORFLW\RIUSPRQGHVLJQSRLQW7LSOHDNDJH ZDVQRWFRQVLGHUHG

The boundary conditions used in the inlet and outlet of 2D DQG'PRGHOVLQWKHGHVLJQSRLQWDUHSUHVHQWHGLQ7DEOH

7DEOH,QOHWDQGRXWOHWERXQGDU\FRQGLWLRQV

Total pressure inlet 3D

Total temperature inlet 1,100 K

Static pressure outlet 3D

Turbulent intensity inlet

The walls for 2D and 3D approaches are adiabatic and QRQVOLS FRQGLWLRQV ZHUH DGRSWHG 7R VROYH WKH ÀRZ QHDU WKHZDOOWKHVROYHUDSSOLHVWKHODZRIWKHZDOOGHYHORSHGE\ /DXQGHUH6SDOGLQJ$16<6DE7KLVPHWKRGLVQRW XWLOL]HGZKHQWKHYDOXHVRI\+ are smaller than six for the 6SDODUW$OOPDUDVWXUEXOHQFHPRGHO$16<6D7KHODZ of the wall is applied appropriately to the turbulent boundary

layer, when \YDOXHVDUHEHWZHHQDQG0HQWHU

NUMERICAL METHODS

The 2D approach was simulated by ANSYS Fluent VRIWZDUH YHUVLRQ ZKLFK XVHV WKH ILQLWHYROXPH GLVFUHWL]DWLRQPHWKRG$16<6D7KHVROYHUDGRSWHG is coupled, implicit, with a time marching to reach the steady state condition, and taking into account the turbulence effects E\6SDODUW$OOPDUDVRQHHTXDWLRQWXUEXOHQFHPRGHO

The 3D approach was simulated by ANSYS CFX soft-ZDUHYHUVLRQZKLFKHPSOR\VWKH¿QLWHHOHPHQWEDVHG YROXPHPHWKRG$16<6E,WZDVDGRSWHGWKH$16<6 CFX software for the 3D simulation, because the software SURYLGHVDJRRGSUHSURFHVVLQJIRUVROYLQJ'ÀRZLQD[LDO WXUERPDFKLQHU\7KHVROYHUDGRSWHGLVFRXSOHGLPSOLFLWXVHV WLPHPDUFKLQJWRUHDFKWKHVWHDG\VWDWHFRQGLWLRQDQGVROYHV the turbulence effects by Spalart-Allmaras one-equation WXUEXOHQFHPRGHO

7KHVLPXODWLRQRIFRPSUHVVLEOHÀRZZDVVPRRWKO\VWDUWHG WRDYRLGQXPHULFDOLQVWDELOLW\GXHWRDJJUHVVLYHEHKDYLRURI WKLVNLQGRIÀRZLQVLGHWKHWXUERPDFKLQHU\7KHUHIRUHLWZDV XVHGDGLVVLSDWLYHPHWKRGE\¿UVWRUGHUXSZLQGGLVFUHWL]DWLRQ IRU WKH FRQYHFWLRQV WHUPV 7KLV PHWKRG DYRLGV QXPHULFDO LQVWDELOLW\GXHWRVKRFNZDYHV

7KHÀRZLVQRWDOLJQHGZLWKWKHPHVKLHZKHQLWFURVVHV WKH PHVK OLQHV REOLTXHO\ KRZHYHU ¿UVWRUGHU FRQYHFWLYH GLVFUHWL]DWLRQ LQFUHDVHV WKH QXPHULFDO GLVFUHWL]DWLRQ HUURU QXPHULFDOGLIIXVLRQ7KHUHIRUHLWZDVXVHGWKHVHFRQGRUGHU GLVFUHWL]DWLRQWRREWDLQPRUHDFFXUDWHUHVXOWV

The algebraic multigrid was employed to accelerate the FRQYHUJHQFH

MESH GENERATION

The mesh was constructed for two sub-domains, one for VWDWRUEODGHSDUWDQGRWKHUIRUURWRUEODGHGRPDLQ

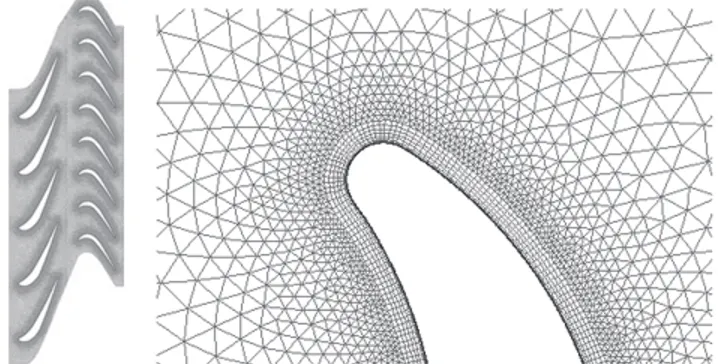

In the 2D model, the mesh is composed by quadrilaterals elements near to the blade region, in order to capture high JUDGLHQWVQRUPDOWRWKHZDOO7ULDQJXODUHOHPHQWVZHUHJHQHU -DWHGLQWKHUHVWRIWKHGRPDLQ7KHPHVKFRQWDLQV HOHPHQWV7KH'PRGHODOORZVDGRSWLQJDKLJKHUGHJUHHRI UH¿QHPHQWEHFDXVHLWGRHVQRWLQFUHDVHWKHFRPSXWDWLRQDO FRVWZKHQFRPSDULVRQLVPDGHZLWKWKH'PRGHOV7KHVRIW -ZDUHDGRSWHGWRFRQVWUXFWWKHPHVKGHPRQVWUDWHGE\)LJLV FDOOHG*DPELWYHUVLRQ

Figure 1 represents the mesh of all computational domains OHIWVLGHDQGWKHURWRUOHDGLQJHGJHULJKWVLGH

)LJXUH 7ZRGLPHQVLRQDOPHVKFRPSRVHGE\TXDGULODWHUDODQG WULDQJXODUHOHPHQWV

The mesh constructed in the 3D model is composed by WHWUDKHGUDOLQDOOFRPSXWDWLRQDOGRPDLQV7KHPHVKFRQWDLQV HOHPHQWV,QWKH'PRGHOWKHUH¿QHPHQWRIWKHPHVK LQFUHDVHVWKHFRPSXWDWLRQDOFRVW7KHUHIRUHWKHUH¿QHPHQWZDV made in regions where there are high gradients normal to the ZDOOVXFKDVQHDUWKHEODGHZDOOV)LJXUHVKRZVWKH'PHVK FRQVWUXFWHGXVLQJ$16<6,&(0VRIWZDUHYHUVLRQ

)LJXUH 7KUHHGLPHQVLRQDO PHVK FRPSRVHG E\ WHWUDKHGUDO HOHPHQWV

MEAN LINE LOSS MODEL CODE

WKHWXUELQH7KHSHUIRUPDQFHTXDQWLWLHVVXFKDVWKH¿UVWVWDJH HI¿FLHQF\RIWKHWXUELQHZHUHSUHGLFWHGRQO\RQGHVLJQSRLQW E\WKHPDQXIDFWXUHUXVLQJWKH.DFNHU2NDSXXORVVPRGHO 7KHVHUHVXOWVZLOOEHPHQWLRQHGLQWKLVZRUNDVGHVLJQGDWD

The performance maps constructed by CFD simulation

ZHUHYHUL¿HGDJDLQVWUHVXOWVJHQHUDWHGE\WKHPHDQOLQHORVV PRGHOFRGHZKLFKZDVGHYHORSHGE\+HVVDQGWKDW DGRSWHG'HQWRQORVVPRGHO7KLVPRGHOLVEDVHGRQUHVXOWVRI DODUJHQXPEHURIFDVFDGHWHVWVZLWKVSHFL¿HGYDOXHVRILQOHW DQGRXWOHWEODGHDQJOHVIRUDJLYHQSLWFKFKRUGUDWLRZKLFK UHVXOWVLQFXUYHVRIHQHUJ\ORVVFRHI¿FLHQWV 'HQWRQFRQVLGHUHGWKDWWKHSK\VLFDORULJLQRIWKH ORVVHVLVGH¿QHGLQWHUPVRIHQWURS\LQFUHDVHGXHWRYLVFRXV HIIHFWVLQERXQGDU\OD\HUVKRFNZDYHVKHDWWUDQVIHUDFURVV WHPSHUDWXUHGLIIHUHQFHVDQGYLVFRXVHIIHFWVLQPL[LQJSURFHVV

The loss model is established by means of applying boundary layer theories, basic thermodynamic equations, and

VLPSOL¿HGHTXDWLRQRIFRQVHUYDWLRQRIPDVVPRPHQWXPDQG HQHUJ\RQHDFKVSHFL¿FORVVFRQGLWLRQ6RPHHPSLULFDOSDUDP

-HWHUVDUHDOVRQHHGHGIRUWKHSUHGLFWLRQV,QVRPHFDVHVIRU

instance, attached blade boundary layers, the loss mechanisms

DUHXQGHUVWRRGEXWHYHQVRWKHORVVFDQVHOGRPEHSUHGLFWHG ZLWKJUHDWDFFXUDF\,QPDQ\RWKHUFDVHVHJHQGZDOOORVV

the loss mechanisms are still not clearly understood and

SUHGLFWLRQPHWKRGVUHPDLQYHU\GHSHQGHQWRQFRUUHODWLRQV 'HQWRQFODVVL¿HVWKHORVVLQYDULRXVIRUPVVXFKDVWUDLOLQJ

edge loss (ȗTe), tip leakage loss (ȗTip), end-wall boundary layer loss (ȗ(b), shock loss (ȗsKoFkDQGSUR¿OHORVVȗp7KHVXPVRIDOO

LQGLYLGXDOORVVHVDUHDFFRXQWHGDVWRWDOORVVJLYHQE\(T

ȗ

ȗ

ȗ

ȗ

ȗ

ȗ

ȗ

;

ȗ

p Te Tip Eb

i shock 7KHFUHDWLRQRIHQWURS\E\LUUHYHUVLEOHHIIHFWVZLOODOZD\V UHGXFHWKHHI¿FLHQF\RIDWXUELQH+HQFHWKHORVVRIHI¿FLHQF\ FDQEHUHODWHGWRWKHHQWURS\FUHDWHGYLDHT H

H T2

Ș

ǻ

ǻ

ǻV

PERFORMANCE MAP

7R HYDOXDWH WKH SHUIRUPDQFH RI WKH ¿UVWVWDJH WXUELQH

performance maps were constructed, which are the most

DFFXUDWHZD\IRUSUHGLFWLQJRIIGHVLJQSHUIRUPDQFH+DJOLQG DQG(OPHUJDDUG

+RZHYHUWKHRIIGHVLJQSHUIRUPDQFHRIDQD[LDOWXUELQHLV HYDOXDWHGE\SHUIRUPDQFHPDSV6DUDYDQDPXWWRRet DO ZKLFKDUHSUHVHQWHGE\UHODWLRQVEHWZHHQWRWDOHI¿FLHQF\Șt),

pressure ratio (rpFRUUHFWHGPDVVÀRZPForr), and corrected

speed (1ForrJLYHQE\(TVWR

(13) H Ș in in out out t H H H

p0in p rp

0out

(14)

mcorr

m T0in

T0in

T

N

0N

corr in 'LVFXVVLRQVDERXWWKHSHUIRUPDQFHPDSGHYHORSHGLQWKLV VWXG\ZLOOEHSUHVHQWHGLQWKHQH[WVHFWLRQRESULTS AND DISCUSSION

The \YDOXHVUHDFKWKHPD[LPXPYDOXHVRIIRXUIRUVWDWRU and rotor blades in the 2D simulation, which imply that the law of

WKHZDOOLVQRWEHLQJDSSOLHGWRVROYHWKHYLVFRXVVXEOD\HU,QWKH 'VLPXODWLRQWKHPHDQYDOXHVRI\UHDFKIRUVWDWRUEODGH DQGIRUWKHURWRUEODGHZKLFKLPSOLHVWKDWWKHODZRIWKHZDOO LVEHLQJDSSURSULDWHO\DSSOLHGWRWKHWXUEXOHQFHERXQGDU\OD\HU

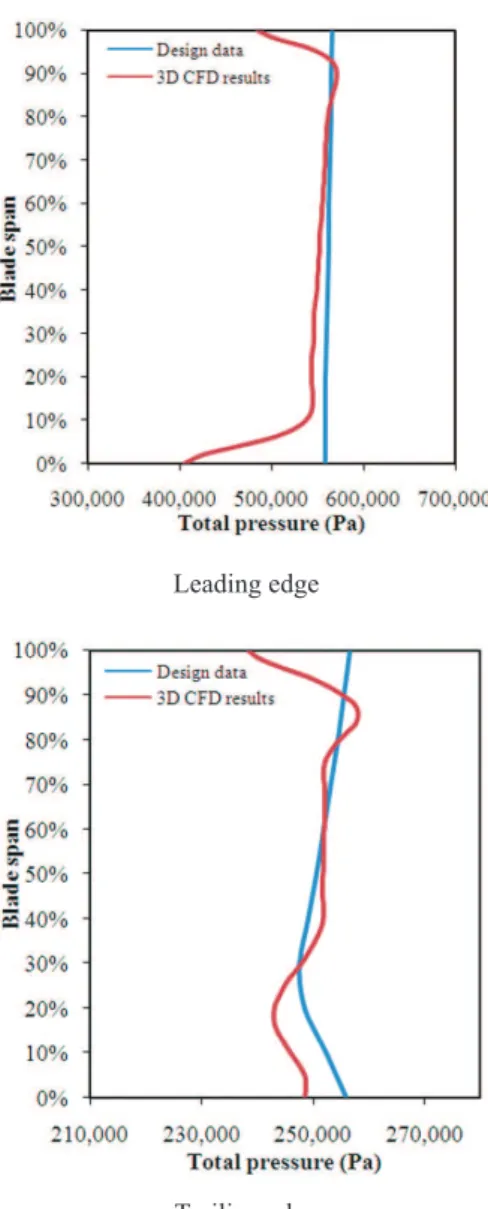

It will be presented, at the design point operation, the

0DFKQXPEHUDQGWRWDOSUHVVXUHGLVWULEXWLRQ7KHFRPSDULVRQ

of these parameters calculated by 3D CFD approach was

PDGHDJDLQVWGHVLJQGDWD

The mean line analysis represents a good comparison tool

WRYHULI\WKH&)'UHVXOWVDVGLVFXVVHGE\'RUQH\DQG :HOFK,WFDQEHQRWHGWKDWDOOFXUYHV)LJVWR SUHVHQWWKHVDPHJHQHUDOWHQGHQF\ 7KHPDMRUGLIIHUHQFHVEHWZHHQGHVLJQGDWDDQG'&)' UHVXOWVFDQEHQRWHGE\WKHEHKDYLRURIWKHSDUDPHWHUVDORQJWKH EODGHVSDQ'&)'UHVXOWVSUHVHQWHGVKDUSFXUYHVZKLOHWKH GHVLJQGDWDKDYHDOPRVWOLQHDUGLVWULEXWLRQ7KHVHGLIIHUHQFHV

can be attributed to the fact that the design data do not take

distribution along the blade span, as mentioned by Tomita and

%DUERVD7KHVHYDULDWLRQVFDQEHYLHZHGE\'&)' UHVXOWVVKRZHGE\)LJVDQG

The boundary layer effects, in the hub and tip of the blade, are

VKRZQE\WKH'&)'UHVXOWVFXUYHV7KLVEHKDYLRUFDQEHQRWHG E\VKDUSFXUYHVEHORZDQGDERYHRIWKHEODGHVSDQ

Table 2 presents a comparison of design data against 2D

DQG'&)'UHVXOWVIRUGHVLJQSRLQWRSHUDWLRQ

7DEOH&RPSDULVRQEHWZHHQPDVVÀRZSUHVVXUHUDWLRDQGHI¿FLHQF\

Descriptions Design data

2D CFD results

Difference (%)

3D CFD results

Difference (%)

0DVVÀRZNJV - -

Pressure ratio

(I¿FLHQF\

7KH PDVVÀRZ ZDV QRW SUHVHQWHG WR ' &)' UHVXOWV EHFDXVHWKHVLPXODWLRQZDVPDGHLQWKH'SODQHRQWKH RIWKHEODGHVSDQ

The difference between CFD results and design data is mainly due to one-dimensional characteristic of the mean

OLQHDQDO\VLVZKLFKLVQRWDEOHWRFDSWXUHDOOÀRZ¿HOGGHWDLOV

Similar conclusion can be obtained when comparing 2D and 3D

&)'UHVXOWV7KH'PRGHOQHJOHFWV'VRXUFHORVVHVGXHWR LQWULQVLFOLPLWDWLRQVRIWKHPRGHO6RPH'VRXUFHORVVHVFDQEH H[SODLQHGE\WKHGHYHORSPHQWRIERXQGDU\OD\HULQWKHHQGZDOO DQGVHFRQGDU\ÀRZLQWKHKXEDQGWLSRIWKHEODGH7KHOLPLWD

-WLRQVGHVFULEHGMXVWLI\WKHRYHUHVWLPDWHGHI¿FLHQF\REWDLQHGE\ WKH'&)'UHVXOWV7KHGHVLJQGDWDDFFRXQW'VRXUFHORVVHV

by empirical correlations (Kacker-Okapuu loss model), which

MXVWL¿HVWKHJRRGDJUHHPHQWZLWKWKH'&)'UHVXOWV Leading edge

Trailing edge

)LJXUH 7RWDOSUHVVXUHGLVWULEXWLRQDWVWDWRUEODGH

Leading edge

Trailing edge

7KHPDVVÀRZUDWHRIGHVLJQGDWDLVJUHDWHUWKDQWKDW SUHGLFWHGE\WKH'&)'UHVXOWV7KLVUHVXOWLVFRQVLVWHQW DVVXJJHVWHGE\'RUQH\7KHIDFWRUWKDWLQÀXHQFHG WKHPDVVÀRZLQWKHGHVLJQGDWDLVWKHPRGHOOLPLWDWLRQWKDW XVHVRQHGLPHQVLRQDOHTXDWLRQVRIPRWLRQWRSUHGLFWWKHÀRZ TXDQWLWLHVLQWKHWXUELQH:KLOHWKHIDFWRUWKDWLQÀXHQFHGWKH PDVVÀRZLQWKH'&)'UHVXOWVLVDWWULEXWHGWRWKH¿OOHWV FRQVLGHUDWLRQWKDWUHGXFHVWKHÀRZSDVVDJHDUHD

$VFDQEHVKRZQE\)LJWKHUHLVÀRZVHSDUDWLRQLQWKH

suction side of the rotor blade, which reduces the pressure

UDWLR DFURVV WKH WXUELQH 7RPLWD DQG %DUERVD 7KLV EHKDYLRUFDQMXVWLI\WKHGLIIHUHQFHEHWZHHQSUHVVXUHUDWLRVRI WKH'&)'UHVXOWVDQGWKHGHVLJQGDWDLQ7DEOH

The present study also focused on the performance maps

RIWKH¿UVWVWDJHD[LDOWXUELQH7KHVHPDSVZHUHFRQVWUXFWHGDW GHVLJQURWDWLRQDOVSHHGUSP

7KHFXUYHVVKRZQLQ)LJSUHVHQWVLPLODURYHUDOOWHQGHQF\

but 3D CFD results are in better agreement with Denton loss

PRGHOZKHQFRPSDUHGZLWK'&)'RQHV,WFDQEHREVHUYHGWKDW WKHWXUELQHHI¿FLHQF\LVSORWWHGDJDLQVWGLIIHUHQWRSHUDWLQJSRLQWV DQGWKHFXUYHVDUHVKLIWHGGXHWRWKHOLPLWDWLRQVRIHDFKPHWKRG

,WLVDOVRQRWHGWKDWWXUELQHHI¿FLHQF\LVQHDUO\FRQVWDQWRYHUD ZLGHUDQJHRISUHVVXUHUDWLRXSWRIRU'HQWRQORVVPRGHOHJ 7KLVKDSSHQVEHFDXVHWKHDFFHOHUDWLQJQDWXUHRIWKHÀRZDOORZVWKH EODGHWRRSHUDWHRYHUDODUJHUDQJHRILQFLGHQFHÀRZDQJOHVZLWKRXW LQFUHDVLQJWKHORVVDVGLVFXVVHGE\6DUDYDQDPXWWRRet DO

Leading edge

Trailing edge

)LJXUH $EVROXWH0DFKQXPEHUGLVWULEXWLRQDWVWDWRUEODGH

Leading edge

Trailing edge

)LJXUH 6WUHDPOLQHVRIWKHVHFRQGDU\ÀRZ

)LJXUH )LUVWVWDJHWXUELQHSHUIRUPDQFHPDSRIHI¿FLHQF\DVD IXQFWLRQRIWKHSUHVVXUHUDWLR

)LJXUHSUHVHQWVYDOXHVIRUWKHFRUUHFWHGPDVVÀRZDW HDFKRSHUDWLRQFRQGLWLRQ7KH'&)'FRUUHFWHGPDVVÀRZ ZDVQRWSUHVHQWHGEHFDXVHWKHVLPXODWLRQZDVHYDOXDWHGDW VWDJHPLGGOHVXUIDFH

%HVLGHV)LJVKRZVWKDWWKHFRUUHFWHGVSHHGOLQHVWHQGWR KRUL]RQWDORQHV7KLVFRQGLWLRQLVUHDFKHGDWKLJKHUSUHVVXUH

ratios, which produce chocking conditions at some point in

WKHWXUELQHVWDJH'HSHQGLQJRQWKHGHVLJQFKRFNLQJPD\ RFFXULQWKHQR]]OHWKURDWVRULQWKHDQQXOXVRXWOHWIURPWKH WXUELQH)LJXUHVKRZVFKRFNHGUHJLRQVLQWKHVWDWRUEODGHV LQGLFDWHGE\\HOORZLVRVXUIDFHV

Chocking conditions happen when the pressure ratio is

LQFUHDVHGDWDJLYHQURWDWLRQDOVSHHG7KHÀRZ¿HOGGHYHORSV VXSHUVRQLFYHORFLWLHVZKLFKXVXDOO\IRUPVKRFNZDYHVLQWKH QR]]OHWKURDWVUHVXOWLQJLQVKRFNZDYHORVVHV

)LJXUH )LUVWVWDJHWXUELQHSHUIRUPDQFHPDSRIFRUUHFWHGPDVV ÀRZDVDIXQFWLRQRIWKHSUHVVXUHUDWLR

)LJXUH <HOORZLVRVXUIDFHVRIPDFKDWVWDWRUEODGHV

CONCLUSIONS

$VHULHVRIFRPSXWDWLRQDOVLPXODWLRQVKDYHEHHQFRQGXFWHG WRSURYLGHSUHWHVWSHUIRUPDQFHIRUWKH¿UVWVWDJHD[LDOWXUELQH 7KHÀRZDQGSHUIRUPDQFHTXDQWLWLHVSUHGLFWHGXVLQJWKHPHDQ OLQHORVVPRGHOFRGHDQG'1DYLHU6WRNHVHTXDWLRQVDGRSWHG LQWKHQXPHULFDOVLPXODWLRQVKRZHGUHDVRQDEOHDJUHHPHQW

7KHUHVXOWVSURYLGHGE\WKHFRPSDULVRQRIWKHÀRZSDUDP

-HWHUVVXFKDV0DFKQXPEHUDQGWRWDOSUHVVXUHVKRZHGJRRG DJUHHPHQWREVHUYHGE\WKHJHQHUDOWHQGHQF\RIWKHFXUYHV7KLV

concludes that the 3D CFD results are consistent with mean line

DQDO\VLVXVHGLQWKHFRQFHSWXDOGHVLJQRIWKHWXUELQHLQVWXG\ 7KHDJUHHPHQWEHWZHHQSHUIRUPDQFHPDSVFXUYHVJHQHUDWHG

by the CFD simulation and mean line loss model using Denton

ORVVPRGHOVKRZHGWKDWWKHQXPHULFDOVLPXODWLRQZKLFKVROYHV WKHFRQVHUYDWLRQVHTXDWLRQVDQGWXUEXOHQFHPRGHOLVFRQVLVWHQW ZLWKORVVPRGHODGRSWHG7KHGLVSRVLWLRQRIFXUYHVJHQHUDWHGE\ 'DQG'VLPXODWLRQVVKRZHGWKHGHJUHHRI¿GHOLW\WKDWHDFK PRGHOGHSLFWVWKHORVVHV$VZRXOGEHH[SHFWHGWKH'&)'

FRPSDUHGZLWK'&)'RQHV7KLVKDSSHQVEHFDXVHWKH'&)' UHVXOWVDQG'HQWRQORVVPRGHODFFRXQW'ÀRZSDWWHUQVLQSHUIRU

-PDQFHTXDQWLWLHVZKLFKDUHQRWDFFRXQWHGLQWKH'VLPXODWLRQ 7KHDGYDQWDJHRIXVLQJWKH&)'VLPXODWLRQZKHQFRPSDU -ison is made against mean line loss model code, is the large

QXPEHURIDQDO\VLVWKDWWKH&)'WRROLVFDSDEOHRISURYLGLQJ VXFKDVÀRZYLVXDOL]DWLRQVKRZHGE\)LJVDQG

ACKNOWLEDGMENTS

The authors thank 9DOe SoOuo}es eP(nergiD(VSE) for the

VXSSRUWWRWKLVUHVHDUFK

REFERENCES

$16<6D³)OXHQWWKHRU\JXLGH´&DQRQVEXUJK 3$&DS

$16<6E³$QV\V&);VROYHUWKHRU\JXLGHUHOHDVH ´&DQRQVEXUJK3$&DS

'HQWRQ -' ³7KH ,*7, VFKRODU OHFWXUH ORVV PHFKDQLVPVLQWXUERPDFKLQHV´-RXUQDORI7XUERPDFKLQHU\ 9ROSS

'HQWRQ -' ;X / ³&)' IRU WXUERPDFKLQHU\ DHURG\QDPLF GHVLJQ´ /RQGRQ >VQ@ ,0(&+( *UDQG UHYLHZRI&)'

'RUQH\'-et DO³2IIGHVLJQSHUIRUPDQFHRIDPXOWL VWDJHVXSHUVRQLFWXUELQH´,Q$HURVSDFH6FLHQFHV0HHWLQJ DQG ([KLELW WK$HURVSDFH 6FLHQFHV 0HHWLQJ ([KLELW 5HQR3URFHHGLQJV:DVKLQJWRQ'&$,$$

(XOLW])(QJHO.³1XPHULFDOLQYHVWLJDWLRQRIZDNH LQWHUDFWLRQLQDORZSUHVVXUHWXUELQH´,QUG$,$$$60( 6$($6((-RLQW3URSXOVLRQ&RQIHUHQFH$QG([KLELW6HDWWOH :$3URFHHGLQJV:DVKLQJWRQ'&$,$$

)OHWFKHU&$-³&RPSXWDWLRQDOWHFKQLTXHVIRUÀXLG G\QDPLFV´HG%HUOLQ6SULQJHU9HUODJ9RO&DS

)RUWXQD$2³7pFQLFDVFRPSXWDFLRQDLVSDUDGLQkPLFD GRVÀXLGRVFRQFHLWRVEiVLFRVHDSOLFDo}HV´6mR3DXOR(GXVS

+DJOLQG ) (OPHUJDDUG % ³0HWKRGRORJLHV IRU SUHGLFWLQJWKHSDUWORDGSHUIRUPDQFHRIDHURGHULYDWLYHJDV WXUELQHV´(QHUJ\9ROSS

+HVV5³(VWXGRFRPSDUDWLYRGHPpWRGRGHDQiOLVHGH GHVHPSHQKRGHWXUELQDVD[LDLV´3K'7KHVLV,QVWLWXWR7HFQROyJL

-FRGH$HURQDXWLFD6mR-RVpGRV&DPSRV63%UD]LOS

-DYDKHUFKL7³5HYLHZRIVSDODUWDOOPDUDVWXUEXOHQFH PRGHODQGLWVPRGL¿FDWLRQV´+DUWIRUG&75HQVVODHU3RO\

-WHFKQLF,QVWLWXWH

0HQWHU)5³7XUEXOHQFHPRGHOOLQJIRUWXUERPD

-FKLQHU\´41(7&)'1HWZRUN1HZVOHWWHU9RO1R SS

0XUDUL6et DO³&)'DHURGXQDPLF&)'YDOLGDWLRQ RI D WZRVWDJH KLJK SUHVVXUH WXUELQH´ ,Q$60(785%2 (;32 9DQFRXYHU %ULWLVK &ROXPELD 3URFHHGLQJV 1HZ<RUN$60(

3HFQLN5et DO³1XPHULFDO,QYHVWLJDWLRQRIWKH

Secondary Flow of a Transonic Turbine Stage Using

9DULRXV7XUEXOHQFHF&ORVXUHV´,Q$60(7XUER([SR 3RZHUIRU/DQG6HDDQG$LU5HQR7DKRH$60( 3DSHU*7

6DUDYDQDPXWWRR+,+³2YHUYLHZRQEDVLVDQGXVH RI SHUIRUPDQFH SUHGLFWLRQ PHWKRGV´ &DUOHWRQ 8QLYHUVLW\ 2WWDZD$*$5'$GYLVRU\5HSRUW/6

6DUDYDQDPXWWRR+,+et DO³*DVWXUELQHWKHRU\´ HG+DUORZ3UHQWLFH+DOO&DS

6SDODUW35$OOPDUDV65$³2QHHTXDWLRQWXUEX

-OHQFHPRGHOIRUDHURG\QDPLFÀRZ´:DVKLQJWRQ'&$,$$ $,$$3DSHU

7RPLWD-7%DUERVD-5³,QÀXHQFHRILQÀRZWXUEX

-OHQFHLQWHQVLW\YDULDWLRQVLQDQD[LDOWXUELQHXVLQJ'5$16

FRPSXWDWLRQV´,Q,QWHUQDWLRQDO&RQJUHVVRI0HFKDQLFDO(QJL

-QHHULQJ1DWDO3URFHHGLQJV«5LRGH-DQHLUR$%&0

7RXVVDLQW &et DO ³&RPSDULVRQ RI VWHDG\ DQG

XQVWHDG\'YLVFRXVÀRZFRPSXWDWLRQVWKURXJKDWUDQVRQLF WXUELQHVWDJH´&KDWLOORQ)52I¿FH1DWLRQDOG(WXGHVHWGH 5HFKHUFKHV$HURVSDWLDOHV21(5$21(5$7$3

:HOFK *( ³&RPSXWDWLRQDO DVVHVVPHQW RI WKH DHURG\QDPLF SHUIRUPDQFH RI D YDULDEOHVSHHG SRZHU WXUELQHIRUODUJHFLYLOWLOWURWRUDSSOLFDWLRQ´&OHYHODQG 2KLR 1$6$ -RKQ + *OHQQ 5HVHDUFK &HQWHU DW /HZLV )LHOG