A R C H I V E S

o f

F O U N D R Y E N G I N E E R I N G

Published quarterly as the organ of the Foundry Commission of the Polish Academy of Sciences

ISSN (1897-3310)

Volume 9

Issue 1/2009

113-116

25/1

Eutectic solidification as explained by the

thermodynamics of irreversible processes

W. Wo

á

czy

Ĕ

ski

a,*, E. Guzik

ba

Institute of Metallurgy and Materials Science, Polish Academy of Sciences, Reymonta 25, 30-059 Kraków, Poland

b

Faculty of Foundry Engineering, University of Science and Technology, Reymonta 23, 30-059 Kraków, Poland

*e-mail: nmwolczy@imim-pan.krakow.pl

Received

26.02.2009; accepted in revised form: 30.03.2009Abstract

The grain size diameter is the main parameter characterizing a given metallic alloy. In the case of Al-Si or Fe-C eutectic alloy the average inter-lamellar spacing is a good parameter which seems to be adequate to describe this irregular structure. To define the average inter-lamellar spacing the regular areas within generally irregular structure has been distinguished.

It has been postulated that the formation of regular structure could be related to the minimum entropy production criterion. From the other side the maximum destabilization of the non-faceted phase interface could be referred to marginal stability.

The criterion of minimum entropy production allows to formulate the growth law for regular lamellar structure solidifying under stationary state. It defines the regular eutectic spacing versus growth rate. The marginal stability concept allows to define the maximum wavelength which can be developed at the solid / liquid interface of non-faceted (Al) phase. It defines the maximum spacing within irregular structure taking into account the wavelength of instability (marginal stability) created at the non-faceted phase interface.

An average inter-lamellar spacing results from the relationship formulated on the basis of both spacings. It should be

emphasized that both conditions (criteria) are deduced from the thermodynamics of irreversible processes

.The simplified scheme of irregular structure incorporates, additionally the intermediate lamella of faceted phase that is also taken into account in the definition of average inter-lamellar spacing, O . The intermediate morphology existing between two distinguished distances is treated as being under oscillation between stationary state and marginal stability. The state of marginal stability is defined by a vanishing excess entropy production. Therefore, It is suggested that the structural oscillation takes place between an attractor and point of bifurcation in the system.

Key words: fundamentals of eutectic solidification, in situ composites structure, marginal stability, minimum entropy production, excess entropy production, structural oscillation

1. Introduction

The well known models of irregular eutectic growth are based on diffusion in the liquid and thermodynamics of the solid / liquid interface taking into account undercooling, GT,[1-13].

Some of the equations for average lamellar spacing O , which are presented in mentioned papers do not consider the temperature gradient.

The current model makes attempt to consider not only the thermodynamics of the s/l interface but the thermodynamics of the whole considered solidification process.

Therefore, the undercooling is to be envisaged while considering the behavior of the s / l interface and entropy production while considering the whole solidification process, [14]. Two typical interlamellar spacings are distinguish within the irregular eutectic morphology.

The first distance is named as and is the smallest spacing which can be revealed within a morphology. The second

distance is the largest spacing named and is the largest

spacing revealed.

i O

i s O

It is evident that interlamellar spacing oscillates between both typical distances: between the smallest and maximum distance. Thus two thermodynamic criteria should be applied to description of irregular structure formation: criterion of minimum entropy production and marginal stability concept.

It will allow to take into account not only an influence of the solidification rate, v on the interlamellar average spacing, O , but an influence of the temperature gradient, G as well. It requires, however, to consider both transport phenomena in the system, that are mass and heat transfer.

The growth rate is taken into account due to analysis of the micro-field of solute concentration ahead of the solid / liquid

interface, while -component of temperature gradient due

to a model of heat balance worked out for a given Bridgman’s system used during experiment of directional solidification.

x T w

w /

Moreover, thermodynamic equilibrium attributed to the separation plane situated within the liquid is introduced, [15].

The separation plane makes a lengthening of the D/E

boundary between solid phases.

Also, a mechanical equilibrium at the triple point of the solid / liquid interface is taken into account, [16].

3. An eutectic solidification model

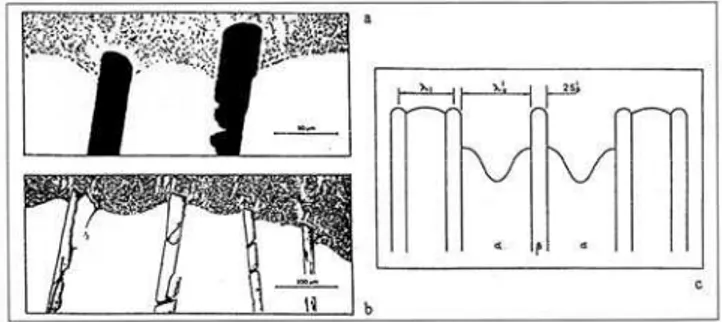

Some difficulties of theoretical nature arise from the cause of simultaneous and coupled growth of non-faceted and faceted phases. Furthermore, the solid / liquid interface is non-isothermal during irregular eutectic structure formation. The phase protrusion is related to a kinetic undercooling of the interface, GTK, Fig. 1c.

Fig. 1. Irregular Al-Si eutectic morphology: a/ interface for the regular Al-Si eutectic formation, b/ development of non-faceted interface instability, c/ current model of the s / l interface.

The local stability of the solid / liquid interface corresponds to the regular structure formation, Fig. 1a within the generally irregular structure. Other parts of the structure are not stable against perturbation, Fig. 1b. The marginal wavelength is applied for one of the extreme cases of the perturbation development.

There are some parts of the s / l interface of non-faceted phase lamellae where instability develops or vanishes and branching of faceted phase lamellae is observed. This phenomenon decides on the existence of a whole spectrum of interlamellar spacings, O. From the thermodynamic viewpoint some regions of the system are in stationary state while others in state of rotation around it. Stationary state changes continually its localization. Thus, some respective regions oscillate from rotation (marginal stability for which excess entropy production vanishes) to stationary state. This is the fundamental assumption in the current analysis.

3.1. Regular / irregular structure formation

The simplified scheme of irregular eutectic structure, based on the observation for the Al-Si or Fe-C eutectic alloy is applied to current analysis, Fig. 1c. The presented scheme of the irregular morphology allows to formulate some definitions of parameters:

D E D ED O V O V V V S i is

i

2 4 /

2 (1)

E E D EE O V O V V V

S i

i s i

2 4

/

(2)

The definition (2) is connected with the intermediate lamella of the faceted phase shown in Fig. 1c.

Combining both the definitions (1) and (2) together with the scheme in Fig. 1c the definition for the average spacing is:

i s i

i S O

O

O 0.5 E 0.5 (3)

Equation (3) is a new growth law determined for irregular structure formation using criteria known in the thermodynamics of irreversible processes, [14].

The parameter is given by means of the growth law worked

out for regular structure formation: i

O

4 5 27 6 3 1 2 2

3 2

3W Oi v W Oi vW W Oi v W W (4)

where, , Wn 1,...7 material coefficients, (with G Gx,Gz).

The Ois is the marginal wavelength of perturbation.

Particularly, Oi spacing depends on G wT/wx,wT/wz but

depends on the .

i s O z

T Gz w /w

The applied scheme of the irregular eutectic structure, Fig. 1c, includes stationary region (Oi

v,Gx,Gz marginal stability region zi sv,G

O and intermediate lamella ,Si .

E

2 z c

i

s S D G mDG

O * (5)

Ec v D k N

G / 1 D (6)

D - diffusion coefficient in the liquid,

D

k - partition ratio for non-faceted phase formation,

D

m - slope of the liquidusline,

E

N - eutectic concentration of the solute,

D

* - capillarity parameter.

3.2. Oscillatory mode of the eutectic growth

The width of non-faceted phase oscillates between minimum

lamella width, and maximum one, as it was proved by

some observations. At a given temperature gradient, oscillations depend on growth rate,

i SD

2 Ois

v, only, Eq. (5), Fig. 2. The system oscillates between stationary state and marginal stability towards which is driven by perturbation occurring at the interface of non-faceted phase, Fig. 3.

Since the width of non-faceted phase follows the zig-zag mode, Fig. 2, other and other parts of the structure become stable while others are in rotation.

According to the oscillation mode the s/l interface of non-faceted phase changes its velocity as it is sketched schematically in Fig. 2.

Fig. 2. A simplified scheme of the oscillation of non-faceted phase, (dotted line shows previous extreme position of the non-faceted interface displaced due to assumed zig-zag mode).

When instability is vanishing the non-faceted phase lamella becomes narrower but at the same time accelerates its growth and eventually achieves stationary state. It means that previously

unstable interface of the non-faceted phase, Ois , evens

geometrically its position with existing s/l interface of the stationary structure, Si

D

2 .

In this case kinetic protrusion vanishes, , Fig. 1c, and the width of the non-faceted phase fulfills the following condition:

0

k

d

i i

s SD

O 2 (7)

As it results from an analysis of atoms’ attachment the

vanishing of the - protrusion causes the decay of kinetic

undercooling, , defined as:

k d

K T G

g E bK w D R T S v

T E

G / /' (8)

Fig. 3. Virtual oscillation on an arc of parabola created at an intersection of the paraboloid of entropy production by the plane drawn for a given temperature gradient, G

4. Concluding remarks

A growth law for irregular eutectic growth, is formulated, Equation (3). It is based simultaneously on two thermodynamic criteria

a/ criterion of minimum entropy production defining stationary state created locally within the system,

b/ concept of marginal stability for which excess entropy production vanishes.

It allows to deliver a physical justification for the operating range of structure formation, existence of which, was suggested by Magnin and Kurz, [8], but operating points known in the MK theory are replaced by A – attractor and B – bifurcation point.

Both, Magnin and Kurz theory as well as the current model make attempt to justify an existence of a critical temperature gradient for which full transition from irregular to regular structure could be observed.

However, MK theory considers that the critical temperature gradient corresponds to maximum undercooling while the critical temperature gradient, is responsible for the annihilation of the solid / liquid interface instability (according to the current model assumptions).

The A – attractor is associated with the appearance of the parameter within the irregular structure while B – bifurcation point with the wavelength of perturbation, Fig. 4.

i O

i s O

Fig. 4. Oscillation (on the parabola of entropy production) between an attractor (A) and bifurcation point (B) for a given temperature gradient, G.

The zig-zag mode of propagation of the instability, Fig. 2, is responsible for branching phenomenon and as a response of the system the mechanical equilibrium turns the interface of non-faceted phase towards the stationary state when perturbation wavelength becomes equal to marginal wavelength in the system.

The intermediate lamella of the faceted phase (E), Fig. 1c, is responsible for the interaction between the stationary part of morphology and structure being in rotation around it (marginal stability).

5. Symbols used in the text

g

R thermodynamic constant,

S

S half the width of the S – phase lamella in regular

structure, S D,E,

i S

S half the width of the S – phase lamella in regular region

within irregular structure, S D,E,

s

v growth rate of an interface of the non-faceted phase D

S

V volume fractions of a given solid solution, S D,E,

thermodynamic force associated with mass transfer, C

X

T

X thermodynamic force associated with heat transfer.

Acknowledgements

The financial support from the Polish Ministry of Science

and Higher Education (MNiSW) under the contract N R15

006004 is gratefully acknowledged.

Literature

[1] T. Sato, Y. Sayama, Completely and Partially Co-operative Growth of Eutectics, Journal of Crystal Growth, vol. 22 (1974) 259-271.

[2] B. Toloui, A. Hellawell, Phase Separation and Undercooling in Al-Si Eutectic Alloy – The Influence of Freezing Rate and Temperature Gradient, Acta Metallurgica, vol. 24 (1976) 563-573.

[3] D.J. Fisher, W. Kurz, A Theory of Branching Limited Growth of Irregular Eutectics, Acta Metallurgica, vol. 28 (1980) 777-794.

[4] H. Jones, W. Kurz, Relation of Interphase Spacing and Growth Temperature to Growth Velocity in Fe-C and Fe-Fe3C

Eutectic Alloys, Zeitschrift fur Metallkunde, vol. 72 (1981) 792-797.

[5] R. Elliott, S.M.D. Glenister, The Growth Temperature and Inter-flake Spacing in Aluminium Silicon Eutectic Alloys, Acta Metallurgica, vol. 28 (1980) 1489-1494.

[6] E. FraĞ, Theoretical Basis of the Grain Growth of Irregular Eutectics, Archiwum Hutnictwa, vol. 29 (1984) 80-93.\ [7] L. M. Hogan, H. Song, Inter-particle Spacings and

Undercoolings in Al-Si Eutectic Microstructures, Metallurgical Transactions, vol. 18A (1987) 707-713.

[8] P. Magnin, W. Kurz, An Analytical Model of Irregular Eutectic Growth and its Application to Fe-C, Acta Metallurgica, vol. 35 (1987) 1119-1128.

[9] J. Liu, Y. Zhou, B. Shang, Lamellar Eutectic Stable Growth – I. Modeling, Acta Metallurgica and Materialia, vol. 38 (1990) 1625-1630.

[10] P. Magnin, R. Trivedi, Eutectic Growth: A Modification

of the Jackson and Hunt Theory, Acta Metallurgica and Materialia, vol. 39 (1991) 453-467.

[11] P. Magnin, J.T. Mason, R. Trivedi, Growth of Irregular

Eutectics and the Al-Si System, Acta Metallurgica and Materiallia, vol. 39 (1991) 469-480.

[12] H.A.H. Steen, A. Hellawell, The Growth of Eutectic

Silicon – Contributions to Undercooling, Acta Metallurgica, vol. 23 (1975) 529-535.

[13] E. Guzik, D. KopyciĔski, Modeling Structure

Parameters of Irregular Eutectic Growth: Modification of Magnin – Kurz Theory, Metallurgical and Materials Transactions, vol. 37A (2006) 3057-3067.

[14] P. Glansdorff, I. Prigogine, Thermodynamic Theory of

Structure, Stability and Fluctuations, Ed. John Wiley & Sons, London- New York - Sydney - Toronto, 1971, 306 pages. [15] W. WoáczyĔski, Concentration Micro-field for Lamellar

Eutectic Growth, Defects and Diffusion in Semiconductors, vol. 272, (2007), 123-138.

[16] D.I. Popov, L.L. Regel, W.R. Wilcox, Application of

the theorem of minimum entropy production to growth of lamellar eutectics with an oscillating freezing rate, Journal of Crystal Growth, vol. 209 (2000) 181-197.