J. Braz. Chem. Soc., Vol. 17, No. 5, 1045-1047, 2006.

Printed in Brazil - ©2006 Sociedade Brasileira de Química 0103 - 5053 $6.00+0.00

Short Report

*e-mail: mmh1331@yahoo.com

Copper(II) Sulfate Pentahydrate (CuSO

4.5H

2O). A Green Catalyst for Solventless Acetylation

of Alcohols and Phenols with Acetic Anhydride

Majid M. Heravi,* Farahnaz K. Behbahani, Vahideh Zadsirjan and Hossien A. Oskooie

Department of Chemistry, School of Sciences, Azzahra University, Vanak, Tehran, Iran

Álcoois e fenóis foram acetilados eficientemente com anidrido acético na presença de sulfato de cobre (II) em temperatura ambiente, com altos rendimentos.

Alcohols and phenols were efficiently acetylated with acetic anhydride in the presence of copper (II) sulfate at room temperature in high yields.

Keywords: copper (II) sulfate, solventless acetylation, alcohols, phenols, acetic anhydride

Introduction

Acetylation of hydroxyl groups is a frequently used transformation method in organic synthesis. Among the various protecting groups used for the hydroxyl function, acetyl is the most convenient group in view of its easy introduction, being stable to the acidic reaction conditions, and also easily removable by mild alkaline hydrolysis.1

Commonly used reagent for this reaction uses acetic anhydride in the presence of an acid or base catalyst.2 Various

metal salts such as CoCl2,3 TiCl

4-AgClO4,4 Me3SiCl,5

LiClO4,6 Mg(CLO

4)2,7 and some metaltriflates such as

Se(OTf)3,8 MeSiOTf,9 In(OTf)

3,10 Cu(OTf)2,11 and Bi(OTf)3,12

have been investigated to meet the demands for more efficient and selective methods. In spite of these waves of interest, due to the importance of acetylation, it is necessary to develop inexpensive, eco-friendly and reusable catalyst.

Recently, CuSO4.5H2O has been used as a Lewis acid catalyst for various organic transformations.13-15 It is an

inexpensive, available and extremely safe reagent to be used in chemical reactions. We are interested in catalytic reactions16 and acetylation reactions17 in eco-friendly and

solventless conditions.18 We describe herein an efficient

and convenient procedure for acetylation of alcohols and phenols under solvent-free conditions in the presence of a catalytic amount of Copper (II) sulfate pentahydrate with acetic anhydride at room temperature.

Initially a systematic study was carried out for the catalytic evaluation of CuSO4 for acetylation of benzyl alcohol. The reaction could not be carried out in acetic acid

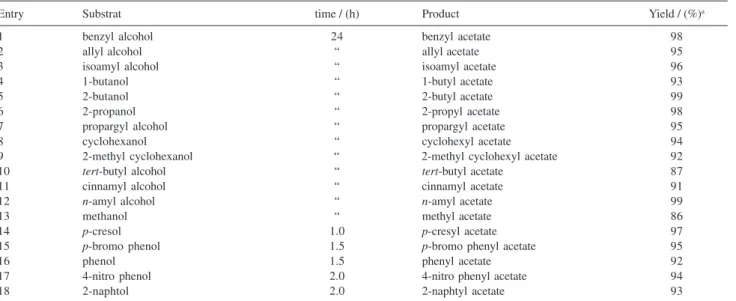

with catalytic amount of catalyst (5 mol %) and in acetic anhydride in the absence of catalyst. The efficiency of this reaction is evident from the variety of hydroxy compounds including primary, secondary, tertiary, benzylic and allylic alcohols and phenols, to give the products in mild conditions and excellent yields. This method works well with a 1:1.5 molar ratio of alcohol or phenol to acetic anhydride in the presence of a catalytic amount of copper(II) sulfate (0.02 mmol) without solvent (Scheme 1, Table 1). We examined equimolar amounts of 1-BuOH and 2-BuOH (1 mmol, 1 mmol), catalyst (2 mol %) in acetic anhydride (1.5 mmol) and found after 24 h 1-butyl acetate is formed as a product and no 2-buthyl acetate in the reaction mixture was detected (monitored by TLC). However 2-butyl acetate was obtained in high yield when 2-buthanol was used independently in the same reaction conditions. It means although sec-alcohols can be acetylated with this method, in the presence of primary hydroxyl group, the chemoselective reaction takes place and only primary hydroxyl group can be selectivity acetylated.

In conclusion we have developed a catalytic and solventless system for acetylation of alcohols and phenols using available, inexpensive and extremely safe reagent such as copper (ll) sulfate for the mild and high yielding

1046 Heravi et al. J. Braz. Chem. Soc.

acetylation of alcohols and phenols. The salient features of these reactions are, use of 1-1.5 equivalent of acetic anhydride to substrate and catalytic amounts of copper (ll) sulfate which are concomitant with solventless and catalytic nature of the reaction. Neither use of solvent nor elevation of reaction temperature makes operations more convenient. The catalyst can be recycled at least five times without significant lose of catalytic activity. We believe copper (ll) sulfate is the greenest catalyst which has ever been used for acetylation of alcohols and phenols and this hetero-geneous catalytic and solventless acetylation will find many applications in organic synthesis and industry.

Experimental

All products were known and their physical and spectroscopic data were compared with those of authentic samples. IR spectra were recorded on Brucker 4000-400 cm-1. Yields of conversion are based on GC/ MS analysis

using Agilent 6890 GC system HP-5 capilary 30m × 530 µm × 1.5 µm nominal. All chemicals were purchased from commercial suppliers and were used as received.

Acetylation of alcohols and phenols catalyzed by copper (ll) sulfate. Typical procedure

Benzyl alcohol (5 mmol, 0.504 mL) and acetic anhydride (7.5 mmol, 0.7 mL) were added to CuSO4.5H2O (0.1 mmol, 0.025g). The mixture was stirred at room temperature for 24 hours (Table 1). Upon completion of the reaction (monitored by TLC) the mixture was diluted with sodium bicarbonate 10% (15 mL) and extracted with

CH2Cl2 (3×20). Combined organic layers were dried over Na2SO4, filtered and evaporated to dryness to afford the acetylated products in high yields.

Recycling of the catalyst

At the end of the reaction, the catalyst was filtered, washed with dichloromethane, dried at 110 °C for 1 hour, and reused in another reaction.

References

1. Green, T. W.; Wuts, P. G. M.; Protective Groups in Organic Chemistry, John Wiley &Sons: New York, 1991, pp. 150-160;

Pearson, A. L.; Roush, W. J.; Handbook of Reagents for Organic Synthesis: Activating Agents and Protecting Groups, John

Wiley & Sons: UK, 1999, pp. 9-16; Kocienski, P. J.; Protecting Groups, Georg Thieme Verlag Stuttgart: New York, USA, ed.

1994, p. 23.

2. Larock, R. C.; Comprehensive Organic Transformations, VCH:

NewYork, 1989, p. 980.

3. Iqbal, J.; Srivastava, R. R.; J. Org. Chem. 1992, 57, 2001.

4. Miyashita, M.; Shiina, I.; Miyoshi, S., Mukaiyama, J. T.; Bull. Chem. Soc. Jpn. 1993, 66,1516.

5. Kumareswaran, R.; Gupta, A.; Vankar, Y. D.; Synth. Commun.

1997, 27, 277.

6. Nakae, Y.; Kusaki, I.; Sato, T.; Synlett 2001, 1584.

7. Bartoli, G.; Bosco, M.; Dalpozzo, R.; Marcantoni, E.; Massaccesi, M.; Rinaldi, S.; Sambri, L.; Synlett 2003, 39.

8. Ishihara, K.; Kubota, M.; Kurihara, H.; Yamamoto, H.; J. Org. Chem. 1996, 61, 4560.

9. Procopiou, P. A.; Baugh, S. P. D.; Flack, S. S.; Inglis, G. G. A.;

J. Org. Chem. 1998, 63, 2342.

Table 1. Acetylation of various alcohols and phenols catalyzed by CuSO4.5H2O

Entry Substrat time / (h) Product Yield / (%)a

1 benzyl alcohol 24 benzyl acetate 98

2 allyl alcohol “ allyl acetate 95

3 isoamyl alcohol “ isoamyl acetate 96

4 1-butanol “ 1-butyl acetate 93

5 2-butanol “ 2-butyl acetate 99

6 2-propanol “ 2-propyl acetate 98

7 propargyl alcohol “ propargyl acetate 95

8 cyclohexanol “ cyclohexyl acetate 94

9 2-methyl cyclohexanol “ 2-methyl cyclohexyl acetate 92

10 tert-butyl alcohol “ tert-butyl acetate 87

11 cinnamyl alcohol “ cinnamyl acetate 91

12 n-amyl alcohol “ n-amyl acetate 99

13 methanol “ methyl acetate 86

14 p-cresol 1.0 p-cresyl acetate 97

15 p-bromo phenol 1.5 p-bromo phenyl acetate 95

16 phenol 1.5 phenyl acetate 92

17 4-nitro phenol 2.0 4-nitro phenyl acetate 94

18 2-naphtol 2.0 2-naphtyl acetate 93

1047 Copper(II) Sulfate Pentahydrate (CuSO4.5H2O)

Vol. 17, No. 5, 2006

10. Chauhan, K. K.; Frost, C. G.; Love, I.; Waite, D.; Synlett 1999,

1743.

11. Chandra, D.; Saravanan, P.; Singh, R. K.; Singh, V. K.;

Tetrahedron 2002, 58, 1369.

12. Orita, A.; Tanahashi, G.; Kakuda, A.; Orera, J.; Angew. Chem., Int. Ed. 2000, 39, 2877; Orira, A.; Tanahashi, C.; Kakuda, A.;

Otera, J.; J. Org. Chem. 2001, 66, 8926.

13. Khan, A. T.; Lokman, H.; Choudhury, Ghosh, S.; Tetrahedron Lett. 2004, 45, 7891.

14. Akhlaghinia, B.; Tavakoli, S.; Synthesis 2005, 11.

15. Gohain, M.; Prajapati, D.; Sandhu, J. S.; Synlett 2004, 235.

16. Heravi, M. M.; Behbahani, F. K.; Oskooie, H. A.; Hekmat Shoar, R.; Tetrahedron Lett. 2005, 46, 2543; Heravi, M. M.; Bigdeli,

M. A.; Nahid, N.; Ajami, D.; Indian J. Chem. Sect B-Org. Chem. Incl. Med. Chem. 1999, 38, 1285; Heravi, M. M.; Behbahani,

F. K.; Hekmat Shoar, R.; Oskooie, H. A.; J. Mol. Catal. A:Chem.

2006, 244, 8; Heravi, M. M.; Behbahani, F. K.; Hekmat Shoar,

R.; Oskooie, H. A.; Catal. Commun. 2006, 7, 136; Heravi, M.

M.; Derikvand F.; Bamoharram F. F.; J.Mol. Catal. A: Chem.

2005, 242, 173; Heravi, M. M.; Bakhtiari, K.; Bamoharram, F.

F.; Catal. Commun., 2006, 7, 373.

17. Tajbakhsh, M.; Mohajerani, B.; Ghassemzadeh, M.; Indian J. Chem. Sect B-Org. Chem. Incl. Med. Chem.1999, 37, 859;

Bigdeli, M. A. N.; Nahid, N.; Heravi, M. M.; Iran J. Chem. Chem. Eng.-Int. Engl. Ed., 2000, 19, 37; Asadolah, K.; Heravi,

M. M.; Phosphorus Sulfur Silicon Relat. Elem., 2004, 179,

2335.

18. Oskooie, H. A.; Amiri, S. S.; Heravi, M. M.; Ghassemzadeh, M.; Phosphorus Sulfur Silicon Relat. Elem. 2005, 180, 2047;

Heravi, M. M.; Nami, N.; Oskooie, HA.; Hekmatshoar, R.;

Phosphorus Sulfur Silicon Relat. Elem.2005, 180, 1873;

Heravi, M. M.; Nami, N.; Oskooie, H. A.; Hekmatshoar, R.;

Phosphorus Sulfur Silicon Relat. Elem., 2005, 180, 1605;

Heravi, M. M.; Shoar, R. H.; Pedram, L.; J. Mol. Catal. A:

Chem. 2005, 231, 89; Heravi, M. M.; Ghassemzadeh, M.;

Phosphorus Sulfur Silicon Relat. Elem. 2005, 180, 347; Heravi,

M. M.; Motamedi, R.; Heterocyclic Commun.2005, 11, 19;

Heravi, M. M.; Derikvand, F.; Oskooie, H. A.; Ghassemzadeh, M.; Heterocyclic Commun. 2005, 11, 75.

Received: January 4, 2006