Experimental Investigation of Effect of Process Parameters on Mrr and Surface Roughness In Turning Operation on Conventional Lathe Machine For Aluminum 6082 Grade Material Using Taguchi Method

Texto

Imagem

Documentos relacionados

This paper reports the experimental investigation carried out on EDM to study the effects of machining parameters such as pulsed current on material removal rate, depth of cut,

The surface quality depends on process parameters (lead angle, tilt angle, feed per tooth, cut- ting speed, radial depth of cut, cutting depth) and the choice of the

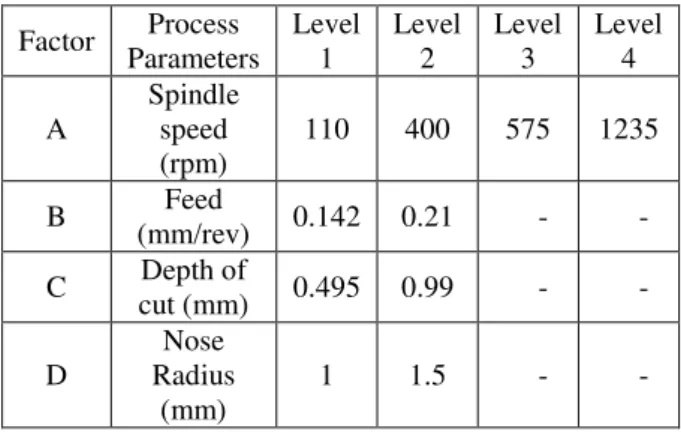

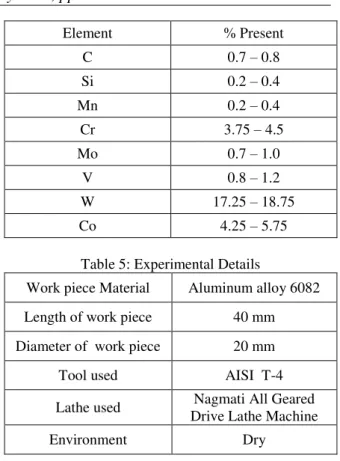

In the present paper an attempt has been made to study the effect of input parameters such as cutting speed, feed rate and depth of cut on Surface roughness, Tool wear,

The aspects subjected to evaluation included: the grain areas, shape and elongation coefficients of grains on a non-planar surface of the blade airfoil, using measurements taken

This article examines the effect of prolonged time of holding at the temperature of 620 0 C on the processes of secondary phase precipitation and mechanical properties of

Performed tests have shown that application of phosphorus in form of CuP10 and AlSr10 master alloy as an inoculant gives positive results in form of refinement of primary crystals

The parameters analyzed in the tests are: surface roughness (using bosses on the bonded phase of diferent thicknesses), compressive strength with monotonic and cyclic loadings.

The inluence of cutting speed, feed rate and radial depth of cut on various machinability characteristics such as maximum temperature ( T max ), surface roughness ( R a ) and