List of Symbols Q Heat generation I Electrical current R Ohmic resistance t Time

IR Infrared

ITA Instituto Tecnológico de Aeronáutica LBW Laser Beam Welding

P Pressure

PEEK Poly-etheretherketone PES Poly-ethersulphone PPS Poly-phenylenesulphide PEI Poly-etherimide T Temperature

Tg Glass transition temperature Tm Melting temperature

UNESP Universidade Estadual Paulista Júlio de Mesquita Filho USP Universidade de São Paulo

INTRODUCTION

&RQWLQXRXV¿EHUUHLQIRUFHGWKHUPRSODVWLFPDWUL[FRPSRVLWH laminates have shown great promise as materials for current and IXWXUHDLUFUDIWFRPSRQHQWV:KHQFRPSDUHGWRWKHUPRVHW¿EHU reinforced composite laminates, thermoplastic laminates are HDVLHUWRSURFHVVDVWKH\GRQRWUHTXLUHFRPSOH[FKHPLFDOUHDF-tion nor lengthy curing process, they are easily recycled and do QRWQHHGUHIULJHUDWLRQIRUVWRUDJHGLVSOD\LQJSUDFWLFDOO\LQ¿QLWH VKHOIOLIH7KHUPRSODVWLFFRPSRVLWHVDOVRH[KLELWYHU\ORZOHYHORI moisture uptake, which means their mechanical properties are less degraded under hot/wet conditions, not to mention their higher GDPDJHWROHUDQFHFKDUDFWHULVWLFVDQGJUHDWHUUHSDUDELOLW\SRWHQWLDO DVFRPSDUHGWRWKHUPRVHWWLQJPDWUL[ODPLQDWHV1LQJet al., 2007; Sinmazçelik, 2006; Jayamol et al., 1998; Mallick, 1993).

A Review of Welding Technologies for Thermoplastic Composites

in Aerospace Applications

Anahi Pereira da Costa1, Edson Cocchieri Botelho1,*, Michelle Leali Costa2, Nilson Eiji Narita3, José

Ricardo Tarpani4

1 Universidade Estadual Paulista Júlio de Mesquita Filho– Guaratinguetá/SP – Brazil 2 Instituto de Aeronáutica e Espaço – São José dos Campos/SP, Brazil

3 EMBRAER– São José dos Campos/SP, Brazil 4 Universidade de São Paulo – São Carlos/SP, Brazil

Abstract: Reinforced thermoplastic structural detail parts and assemblies are being developed to be included in current aeronautic programs. Thermoplastic composite technology intends to achieve improved properties and low cost processes. Welding of detail parts permits to obtain assemblies with weight reduction and cost saving. Currently, joining composite materials is a matter of intense research because traditional joining technologies are not directly transfer-able to composite structures. Fusion bonding and the use of thermoplastic as hot melt adhesives offer an alternative to mechanical fastening and thermosetting adhesive bonding. Fusion bonding technology, which originated from the thermoplastic polymer industry, has gained a new interest with the introduction of thermoplastic matrix composites, which are currently regarded as candidate for primary aircraft structures. This paper reviewed the state of the art of the welding technologies devised to aerospace industry, including the ¿elds that Universidade Estadual Paulista -~lio de Mesquita Filho and Universidade de São Paulo are deeply involved.

Keywords: Aircraft structural joint, Thermoplastic composite, Welding technology.

Received: 05/07/12 Accepted: 03/08/12 DXWKRUIRUFRUUHVSRQGHQFHHERWHOKR#IHJXQHVSEU

'HSDUWDPHQWR GH 0DWHULDLV H 7HFQRORJLD)(* $Y $ULEHUWR

8QOLNH WKHUPRVHWWLQJ UHVLQV WKHUPRSODVWLFV PD\ EH UHPHOWHG DIWHU WKH\ DUH IRUPHG 7KH\ PD\ DOVR EH MRLQHG XVLQJVHYHUDOGLIIHUHQWDVVHPEOLQJSURFHVVHV-RLQLQJSOD\V an important role in manufacturing of composite structures in marine, automotive and aerospace industry. Mechanical IDVWHQLQJDQGDGKHVLYHERQGLQJDUHZLGHO\XVHGWRDVVHPEOH metals or composite components. However, there are disadvantages associated with these methods such as stress FRQFHQWUDWLRQLQGXFHGE\GULOOLQJKROHVLQPHFKDQLFDOIDVWHQ-LQJRUH[WHQVLYHVXUIDFHSUHSDUDWLRQGXULQJDGKHVLYHERQGLQJ 1RZDGD\VMRLQLQJFDQEHDFKLHYHGXVLQJYDULRXVZHOGLQJ PHWKRGVVXFKDVHOHFWULFUHVLVWDQFHXOWUDVRQLFYLEUDWLRQKRW plate, electromagnetic induction, dielectric/microwave and IR ZHOGLQJ0RX]DNLVet al., 2008; Botelho and Rezende, 2007; Wang and Hahn, 2007; Jones, 1994; Loos et al., 1981).

Researches involving welding in composites in Brazil were LQLWLDWHGLQE\)DFXOGDGHGH(QJHQKDULDGH*XDUDWLQJXHWi RI81(63,7$DQG(VFRODGH(QJHQKDULDGH6mR&DUORVRI USP. The work started in these universities with cooperation RI(PSUHVD%UDVLOHLUDGH$HURQiXWLFD(0%5$(5DFURP\Q in Portuguese) focused on the mechanical and thermal FKDUDFWHUL]DWLRQRIZHOGHGODPLQDWHVRI336VHPLFU\VWDOOLQH PPS thermoplastic polymer) reinforced with continuous KLJKSHUIRUPDQFH¿EHUV1RZDGD\V81(63LVGHYHORSLQJ resistance welding technology whereas USP is advancing in IR lamp welding methodology.

7KLVSDSHUDLPHGWRH[DPLQHGLIIHUHQWZHOGLQJWHFK-niques for thermoplastic composite laminates devised to structural aerospace applications, focusing on recent developments in this area.

HIGH PERFORMANCE THERMOPLASTIC COMPOSITES FOR AEROSPACE APPLICATIONS

The automotive industry has traditionally produced a wide range of thermoplastic parts with the advantage of shorter SURFHVVLQJWLPHVDQGIXOO\DXWRPDWHGHTXLSPHQWV5D\ Botelho et al., 2005; Botelho et al., 2002; Botelho et al., 2001; Todo et al., 2000).

,QWKHODWHVJODVVDQGFDUERQUHLQIRUFHGWKHUPRSODVWLF 3(,ODPLQDWHVZHUH¿UVWXVHGLQ)RNNHUMHWSODQH*XOIVWUHDP * DQG * EXVLQHVV MHWV DQG$LUEXV %HOXJD WUDQVSRUW DLUFUDIWDVWKHUPRIRUPHGÀRRULQJSDQHOV&RVWDet al., 2010; Vieille et al., 2009; Young and Ye, 2005; Botelho et al., 2003).

More recently, thermoplastic composites have found utiliza-WLRQLQODQGLQJJHDUGRRUVZLQJOHWVHOHYDWRUVDLOHURQVÀDSV

VSRLOHUVVSHHGEUDNHVVODWVWRFLWHDIHZDSSOLFDWLRQV'H)DULD et al., 2011; Rezende et al., 2011; Chevali et al., 2010; Bates et al., 2009; Arici, 2007; Espert et al., 2004; Lee et al., 1993).

A wide range of high performance thermoplastic matrices LVDYDLODEOHQRZDGD\VZLWK3((.DQG336WKHPRVWZLGHO\ studied and reported. Both of them are semi-crystalline poly-mers, and crystallinity in high-performance polymers is quite LPSRUWDQWDVLWKDVDVWURQJLQÀXHQFHRQWKHLUFKHPLFDODQG mechanical properties. Crystallinity tends to increase stiffness and tensile strength while amorphous areas are more effective LQDEVRUELQJLPSDFWHQHUJ\7KHGHJUHHRIFU\VWDOOLQLW\LVGHWHU-PLQHGE\PDQ\IDFWRUVLQFOXGLQJWKHW\SHRISRO\PHUDQGWKH SURFHVVLQJFRQGLWLRQV1LQRet al., 2009; Mazur et al. 2008). Today, joining thermoplastic composite structures LV EHFRPLQJ LQFUHDVLQJO\ LPSRUWDQW VLQFH WKHUPRSODVWLF composite usage is rapidly replacing metallic and thermoset FRPSRVLWHFRXQWHUSDUWVWREHWWHUZLWKVWDQGW\SLFDOVWDWLFDQG fatigue loads applied to aerospace vehicles. Many welding WHFKQLTXHV KDYH EHHQ GHYHORSHG WR MRLQW XQUHLQIRUFHG DQG UHLQIRUFHGWKHUPRSODVWLFSRO\PHUVEXWHDFKWHFKQLTXHKDVLWV own advantages and pitfalls.

WELDING PROCESSES

In choosing a structural engineered material for aerospace application, an important consideration is how easy is to manu-facture, join, inspect, repair and replace it in service. One of the many advantages of thermoplastic over thermoset composites LQWKHVHFDVHVLVWKDWWKHUPRSODVWLFPDWULFHVFDQEHPHOWHGDQG reformed. In theory, using adequate temperature and P levels, a FRPSRVLWHODPLQDWHFDQEHUHVKDSHGLQGH¿QLWHO\

0DQ\ QRYHO MRLQLQJ WHFKQLTXHV KDYH EHHQ SURSRVHG developed and evaluated for thermoplastic applications in the ODVW\HDUV,QUHJDUGWRIXVLRQERQGLQJPHWKRGRORJLHVWKH\ FDQEHVXPPDUL]HGDVIROORZVLQ)LJ

Fusion bonding

FƌiĐƟonĂůŚĞĂƟng ůĞĐƚƌoŵĂgnĞƟĐŚĞĂƟng uůŬŚĞĂƟng dŚĞƌŵĂůƚĞĐŚniƋuĞs

^Ɖin ǁĞůding

sibƌĂƟon ǁĞůding

hůƚƌĂsoniĐǁĞůding

/nduĐƟon ǁĞůding

DiĐƌoǁĂǀĞǁĞůding

iĞůĞĐƚƌiĐǁĞůding

ZĞsisƚĂnĐĞǁĞůding

,oƚŵĞůƚĂdŚĞsiǀĞs

uĂůƌĞsin bonding

,oƚƉůĂƚĞǁĞůding

,oƚ gĂs ǁĞůding

ZĂdiĂnƚǁĞůding

/nĨƌĂƌĞd ǁĞůding

>ĂsĞƌǁĞůding

6HYHQPDLQZHOGLQJWHFKQLTXHVDUHGHVFULEHGEHORZDFFRUG-ing the order they appear in the schematic provided in Fig. 1.

Ultrasonic welding

Ultrasonic welding is a process in which high frequen-FLHVDUHXVHGW\SLFDOIUHTXHQFLHVUDQJHIURPWRN+] in order to induce molecular motion, thus creating friction, ZKLFKLVFRQYHUWHGWRKHDW7KHDELOLW\WRZHOGWZRRUPRUH components using ultrasonic welding depends on material physical properties, frequency and amplitude of ultrasonic ZDYHDQGMRLQWGHVLJQ7KLVMRLQLQJSURFHVVFDQEHDSSOLHG LQGLVWLQFWO\WRDPRUSKRXVZHOGLQJWHPSHUDWXUHEHWZHHQWKH Tg and TmDQGVHPLFU\VWDOOLQHSRO\PHUVZHOGLQJRFFXUVDW WKHPHOWLQJSRLQW/HY\et al., 2008; Siddiq and Ghassemieh, .UJHUet al. 2004; Ageorges and Ye, 2002).

Figure 2 presents a schematic of an ultrasonic welding PDFKLQHXVLQJDSLH]RHOHFWULFWUDQVGXFHUE\ZKLFKWKHRVFLO-ODWLRQVDUHJHQHUDWHGE\DSSO\LQJHOHFWULFDOSRZHUDWKLJK frequency. All ultrasonic welding systems are composed of WKHVDPHEDVLFHOHPHQWVLDSUHVVWRSXWWKHWZRRUPRUH SDUWVWREHDVVHPEOHGXQGHUPLLDQHVWRUDQYLOLQZKLFK WKHSDUWVDUHSODFHGDQGDOORZLQJWKHKLJKIUHTXHQF\YLEUD-WLRQWREHDSSOLHGLLLDQXOWUDVRQLFVWDFNFRPSRVHGRID WUDQVGXFHULYDFRQYHUWHUWRFRQYHUWWKHHOHFWULFDOVLJQDO LQWRDPHFKDQLFDOYLEUDWLRQYERRVWHUWRPRGLI\WKHDPSOL-WXGHRIWKHXOWUDVRQLFYLEUDWLRQYLDVRQRWURGHWRDSSO\ WKHPHFKDQLFDOYLEUDWLRQWRWKHSDUWVWREHZHOGHGYLLDQ ultrasonic generator to provide and control the ultrasonic HQHUJ\$JHRUJHVet al..UJHUet al., 2004; Yousef-pour et al., 2004; Siddiq and Ghassemieh, 2008; Levy et al., 2008; Ageorges and Ye, 2002).

7KHDSSOLFDWLRQRIXOWUDVRQLFZHOGLQJLVTXLWHH[WHQVLYH LQPDQ\LQGXVWULDOEUDQFKHVLQFOXGLQJHOHFWULFDOFRPSXWHU

automotive, aerospace, energy, medical and packaging. In particular, aerospace industry employs this methodology to MRLQWOLJKWZHLJKWWKHUPRSODVWLFPDWUL[FRPSRVLWHPDWHULDOV DQGDQXPEHURIVWXGLHVKDYHEHHQFRQGXFWHGWR¿QGRSWLPXP parameters and process windows to produce high quality ZHOGV6LGGLTDQG*KDVVHPLHK.UJHUet al., 2004). /DSMRLQWVKHDUVWUHQJWKVRIRUGHURI03DKDYHEHHQ LQIRUPHG IRU 336FDUERQ ¿EHU ODPLQDWHV ERQGHG XOWUDVRQL-FDOO\.DJDQDQG1LFKROV7KLVPHWKRGZDVDOVRXVHGE\ Lockheed-Georgia to weld together thermoplastic/graphite tape PDWHULDOIRUWKH&+HUFXOHVDLUFUDIW/HY\et al., 2008).

Induction welding

Induction welding utilizes inductive heating for melting GRZQSRO\PHUPDWUL[LQWKHMRLQLQJ]RQH7KHFRPSRQHQWV WR EH ZHOGHG DUH VXEPLWWHG WR DQ DOWHUQDWLQJ HOHFWURPDJ-QHWLF¿HOG:KHQWKHUHDUHHOHFWULFDOO\FRQGXFWLYHORRSVLQ WKHFRPSRQHQWHJGXHWRFDUERQ¿EHUUHLQIRUFHPHQWHGG\ FXUUHQWVDUHLQGXFHGUHVXOWLQJLQHI¿FLHQWORFDOL]HGKHDWLQJ RIWKHODPLQDWH*ODVV¿EHUUHLQIRUFHPHQWVDUHHOHFWULFDOO\ QRQFRQGXFWLYHVRWKDWH[WULQVLFHOHFWURPRJQHWLFVXVFHSWRUV HJPHWDOJULGVKDYHWREHLQFRUSRUDWHGWRWKHFRPSRVLWHDUUD\ to convert the magnetic energy into thermal energy. In the FDVHRIIHUURPDJQHWLFPDWHULDOVK\VWHUHVLVHIIHFWVFRQWULEXWH IXUWKHUWRKHDWLQJ7KHKHDWLQJLVEDVHGRQWZRPHFKDQLVPV namely, the energy dissipation due to Joule heating and energy dissipation due to magnetic hysteresis. The heat generation is GHVFULEHGE\(T.DJDQDQG1LFKROV

, 2005)

:Q = I2ǜ R ǜ t

7KHDERYHHTXDWLRQHVWDEOLVKHVWKDWKHDWLQJGHSHQGVRQ WLPHtRKPLFUHVLVWDQFHR), and the square of the induced HOHFWULFDOFXUUHQWI7KHFXUUHQWLVLQGXFHGE\DQDOWHUQDW-LQJPDJQHWLF¿HOGVRLWWKHUHIRUHGHSHQGVRQWKHLQGXFWRU JHRPHWU\WKHFRLOFXUUHQWDQGWKHGLVWDQFHWRWKHPDWHULDOLQ WKHFDVHRIWKHPDWHULDOWREHZHOGHGLVQRWLQVLGHWKHFRLO DVGHSLFWHGLQ)LJ0RVHUet al..DJDQDQG1LFKROV 2005

;

Yousefpour et al., 2004; Stokes, 2003; Velthuis and Mitschang, 2003; Hou et al., 1999)..DJDQ DQG 1LFKROV UHIHU WR WKUHH FDWHJRULHV RI KHDWLQJVRXUFHVGXULQJLQGXFWLRQZHOGLQJRI¿EHUUHLQIRUFHG thermoplastic composites:

¿EHUKHDWLQJKHDWLQJLVWKHUHVXOWRI-RXOHORVVHVGXHWRWKH LQKHUHQWUHVLVWDQFHKHDWLQJRI¿EHUV0RVHUet al., 2008); )LJXUH6FKHPDWLFRIDQXOWUDVRQLFZHOGLQJPDFKLQH<RXVHISRXU

GLHOHFWULFK\VWHUHVLVKHDWLQJWKLQOD\HURIPDWUL[PDWHULDO DWWKHERQGLQJOLQHVHSDUDWHV¿EHUVIURPWKHFRQVROLGDWHG laminates. A capacitor is then created and dielectric heat-ing occurs due to the movement of charge and rotation of WKHPROHFXOHVEHWZHHQWKH¿EHUV6WRNHV

FRQWDFW UHVLVWDQFH KHDWLQJ KHDWLQJ RFFXUV RQ ORFDWLRQV ZKHUH WKH ¿EHU¿EHU FRQWDFW LV KLJK FURVVRYHU SRLQWV LQWKHFDVHRIZRYHQIDEULFV7KLVWKHRU\H[SODLQVZK\ VHYHUDOIDEULFW\SHVKDYHDGLIIHUHQWKHDWLQJJHQHUDWLRQ 9HOWKXLVDQG0LWVFKDQJ

)LJXUH6FKHPDWLF LOOXVWUDWLRQ RI D PDJQHWLF ¿HOG DQG HGG\ FXUUHQWJHQHUDWHGE\DHOHFWURPDJQHWLFFRLO.DJDQDQG 1LFKROV

A special type of induction welding is the so-called (PDZHOGERQGLQJ +HUH WKHUPRSODVWLF SDVWHV ZLWK PHWDO SDUWLFOHV DUH H[WUXGHG LQ YDULRXV VKDSHV GHSHQGLQJ RQ WKH ZHOGLQJ]RQHJHRPHWU\DVWKH\IRUPWKHERQGLQJEHWZHHQ the joining parts. The Emaweld-process is fast compared to conventional induction welding. However, due to the metal SDUWLFOHVLQWKHZHOGLQJ¿OOHUHYHQVPDOOFUDFNVOHDGWRQRWFKHV in the welding zone thus reducing the mechanical properties RIWKHMRLQW+RXet al. 1999).

$VIRUYLEUDWLRQZHOGLQJVLQJOHODSMRLQWVKHDUVWUHQJWKVRI RUGHURI03DKDYHDOVREHHQUHSRUWHGIRULQGXFWLRQZHOGHG 336FDUERQ¿EHUODPLQDWHV$GGUHVVHGLQYHVWLJDWLRQVFRPSDU-ing resistance and induction weld336FDUERQ¿EHUODPLQDWHV$GGUHVVHGLQYHVWLJDWLRQVFRPSDU-ing showed that, under equivalent heating conditions, induction welded specimens GLVSOD\HGKLJKHUVKHDUVWUHQJWKV.DJDQDQG1LFKROV *UXPPDQ$LUFUDIW/DERUDWRULHV.DJDQDQG1LFKROV UHSRUWLQGXFWLRQKHDWLQJDVKLJKO\VXLWDEOHIRUERWKWKHFRQVWUXF-WLRQDQGUHSDLURIFDUERQ¿EHUUHLQIRUFHGWKHUPRSODVWLFSDUWVRIWKH )$DLUFUDIWKRUL]RQWDOVWDELOL]HUOHDGLQJHGJHGHPRQVWUDWLRQ

FRPSRQHQWXVLQJWKHJUDSKLWH¿EHUVDVWKHFRQGXFWLQJHOHPHQW 6WUXFWXUDOHOHPHQWVSURGXFHGE\WKLVPHWKRGFRPSDUHGIDYRU-DEO\WRWKRVHPDQXIDFWXUHVE\DXWRFODYHFRFRQVROLGDWLRQ 7KHH[DPSOHVDERYHVKRZWKDWLQGXFWLRQKHDWLQJFDQEH XVHGIRUZHOGLQJRIWKHUPRSODVWLF¿EHUUHLQIRUFHGFRPSRVLWHV DQGDFFHSWDEOHERQGLQJSURSHUWLHVDUHREWDLQHG

Microwave welding

7KH SRVVLELOLW\ RI XVLQJ PLFURZDYH WR ZHOG SDUWV KDV H[LVWHGVLQFHWKHGHYHORSPHQWRIWKHPDJQHWURQLQWKHV ,WVXVDJHLQWKHIUHTXHQF\UDQJHIURPWR*+]KDVEHHQ reported in the literature to weld thermoplastic composites .Xet al., 2003; Wise and Froment, 2001; Chung-Yuan et al., 1999; Vodicka, 1996).

0RVWWKHUPRSODVWLFGRQRWH[SHULHQFHDWHPSHUDWXUHULVH ZKHQLUUDGLDWHGE\PLFURZDYHV+RZHYHUWKHLQVHUWLRQRID PLFURZDYHVXVFHSWLEOHLPSODQWDWWKHMRLQWOLQHDOORZVORFDO KHDWLQJWRWDNHSODFH,IWKHMRLQWLVVXEMHFWHGVLPXOWDQHRXVO\ to microwaves and an applied P melting of the surrounding SODVWLFUHVXOWVDQGDZHOGLVIRUPHG6XLWDEOHLPSODQWVLQFOXGH PHWDOVFDUERQRURQHRIDUDQJHRIFRQGXFWLQJSRO\PHUVEXW ZKLFKHYHULVVHOHFWHGEHFRPHVDFRQVXPDEOHLQWKHZHOGLQJ SURFHVV<RXVHISRXUet al..Xet al., 2003; Wise and Froment, 2001; Chung-Yuan et al., 1999; Vodicka, 1996).

The particular advantage of microwave welding over other IRUPVRIZHOGLQJLVLWVFDSDELOLW\WRLUUDGLDWHWKHHQWLUHFRPSR-QHQWDQGFRQVHTXHQWO\SURGXFHFRPSOH[WKUHHGLPHQVLRQDO MRLQWV:HOGVDUHW\SLFDOO\FUHDWHGLQOHVVWKDQPLQXWH:LVH and Froment, 2001).

2QHGUDZEDFNRIPLFURZDYHHQHUJ\LVWKDWKRPRJHQHRXV PDWHULDOKHDWLQJLVRQO\SRVVLEOHZLWKVLPSOHJHRPHWULHVRU WKURXJKWKHHODERUDWHDGDSWDWLRQRIWKHUDGLDWLRQHTXLSPHQWWR WDVNDWKDQG7KLVWHFKQLTXHKRZHYHULVSHUIHFWO\VXLWDEOHIRU what are normally straight-line heating tasks in the welding of ¿OPVDQGVKHHWLQJ.Xet al., 2003; Wise and Froment, 2001; Chung-Yuan et al., 1999; Vodicka, 1996).

dielectric loss factors using focused microwave energy :LVHDQG)URPHQW$W\SLFDOVFKHPDWLFRIWKHVHW up is shown in Fig. 4. Joint elements with low-to-medium GLHOHFWULFORVVIDFWRUVUHTXLUHQRHOHFWURPDJQHWLFDEVRUEHQW PDWHULDOLQWKHERQGOLQH7KHWHPSHUDWXUHRIWKHERQGOLQH increases and reaches the polymer TmDVWKHERQGOLQHSDVVHV underneath the focused microwave energy. Meanwhile, localized fusion occurs in the presence of P, resulting in a weld. Joint elements with high dielectric loss factor UHTXLUHHOHFWURPDJQHWLFDEVRUEHQWPDWHULDOVDWWKHLQWHUIDFH 8QGHUPLFURZDYHUDGLDWLRQWKHHOHFWURPDJQHWLFDEVRUEHQW PDWHULDOVDEVRUEPLFURZDYHHQHUJ\PRUHUDSLGO\WKDQMRLQW elements, and then evaporate, leaving a localized melting ]RQH DW WKH ERQGOLQH 7KH IXVLRQ ERQGLQJ RFFXUV LQ WKH ERQGOLQHLQWKHSUHVHQFHRIP, producing a weld. Materials DQGVROYHQWVZLWK2+&212DQG1+ERQGVDUHW\SLFDO HOHFWURPDJQHWLF DEVRUEHQW PDWHULDOV 'XULQJ WKH ZHOGLQJ process, some of these materials evaporate and some remain LQWKHZHOGDUHD.Xet al., 2003; Wise and Froment, 2001; Chung-Yuan et al., 1999; Vodicka, 1996).

)LJXUH6FKHPDWLF VHWXS IRU PLFURZDYH KHDWLQJ <RXVHISRXU et al., 2004).

The technique is still in the development stages and, as such, there are currently no reported industrial applications. However, it is anticipated that microwave welding may prove WREHVXLWDEOHIRUMRLQLQJDXWRPRWLYHXQGHUERG\FRPSRQHQWV and aerospace parts.

Resistance welding

5HVLVWDQFHZHOGLQJKDVEHHQFRQVLGHUHGDYHU\SURPLVLQJ joining technique for aerospace application. This process is UHODWLYHO\IDVWZHOGLQJWLPHVIURPWRPLQXWHVUHTXLUHV

OLWWOHDPRXQWRIPDWHULDODQGFDQEHDSSOLHGWRODUJHVWUXF-tures. Good thermal insulation and a correct amount of input energy can reduce the welding time and enhance weld qual-LW\$JHRUJHVDQG<H&RVWD<RXVHISRXUet al., 2004; Yang and Pitchumani, 2002a, Yang and Pitchumani, E$JHRUJHVDQG<H;LDRet al., 1992). In this SURFHVVDFRQGXFWLYHHOHPHQWJHQHUDOO\DVWHHOPHVKRUD FDUERQVWULSLVSODFHGDWWKHLQWHUIDFHEHWZHHQWKHODPLQDWHV WR EH MRLQHG 7KLV FRQGXFWLYH HOHPHQW LV FRQQHFWHG WR D SRZHUVXSSO\DQGWKHQDVXI¿FLHQWI is applied so that Joule ORVVJHQHUDWHVKHDWHQRXJKWRFUHDWHDERQGOLQH6WDYURY Bersee, 2005; Stavrov et al., 2003; Yang and Pitchumani, 2002A, Yang and Pitchumani, 2002B; Don et al.;LDR et al., 1992). Figure 5 shows a schematic of the resistance welding process.

)LJXUH6FKHPDWLFVHWXSIRUUHVLVWDQFHZHOGLQJSURFHVV$JHRUJHV

and Ye, 2002).

7KHHOHFWULFDOFRQQHFWLRQEHWZHHQWKHKHDWLQJHOHPHQW and the power circuit is critical to the resistance welding process. In order to introduce adequate current into the KHDWLQJHOHPHQWVHYHUDOZD\VKDYHEHHQXVHGLQFOXGLQJ GLUHFWFODPSLQJRQWKHSUHSUHJFODPSLQJRQWKHEDUH¿EHUV SUHSUHJ GLSSHG LQWR OLTXLG PHWDO EDWK FODPSLQJ RQ WKH EDUH ¿EHUV SDLQWHG ZLWK D VLOYHU ¿OOHG HSR[\ FRPSRXQG among others. Instead of using continuous power during the SURFHVVWKHSRZHUFDQEHDSSOLHGLQWKHIRUPRILQWHQVH pulses. This process is called impulsive resistance welding DQGUHTXLUHVOHVVHQHUJ\WRPHOWWKHPDWUL[GXHWRORZHUKHDW ORVVHV%DOOHet al., 2009

).

Hot plate welding

7KHUPDOZHOGLQJLVDIXVLRQERQGLQJPHWKRGRORJ\WKDWEDVL-FDOO\FRQVLVWVLQKHDWLQJSRO\PHUPDWUL[FRPSRVLWHVSLHFHVDWWKHLU interface causing a decrease of viscosity thus allowing polymer chains to interdifuse as the surfaces are held tightly together, with IXUWKHUVORZFRROLQJIRUMRLQWFRQVROLGDWLRQ<RXVHISRXUet al., 2004; Ageorges et al., 2001; Ageorges et al., 2000).

Inside of this concept, hot plate or hot-tool welding is one of WKHPRVWSRSXODUPHWKRGVIRUMRLQLQJWKHUPRSODVWLFVEHFDXVHLW LVDVLPSOHUHOLDEOHDQGHFRQRPLFDOZD\RISURGXFLQJVWURQJ ZHOGV7KLVZHOGLQJSURFHVVFDQEHGLYLGHGLQWRKHDWLQJMRLQLQJ DQGFRROLQJVWHSV7KHODPLQDWHVXUIDFHVWREHZHOGHGPXVW¿UVW EHEURXJKWLQWRLQWLPDWHFRQWDFWRUVRPHWLPHVLQTXDVLFRQWDFW ZLWK DQ H[WHUQDO KHDWLQJ HOHPHQW JHQHUDOO\ LV XVHG D SRO\ WHWUDÀXRURHWK\OHQHFRDWHGKRWPHWDOSODWHLQRUGHUWKHLQWHUIDFH WREHZHOGHGWRPHOW:KHQQHFHVVDU\DGHTXDWHPPXVWEH DSSOLHGWRHQIRUFHWKHKRWWRRODJDLQVWWKHODPLQDWHV)LJ,Q FDVHRIH[FHVVLYHPWKHPHOWZLOOEHSUHVVHGLQWRWKHÀDVKDQG LQVXI¿FLHQWDPRXQWRIPHOWHGPDWHULDOZLOOUHPDLQRQVXUIDFHV Often mechanical stops are employed to prevent squeezing the HQWLUHPHOWRXWRIWKHERQGOLQHZKLFKFRXOGUHVXOWLQDµFROG weld’. In case of too little pressure, full contact and thus good KHDWFRQGXFWLRQEHWZHHQKRWSODWHDQGMRLQLQJSDUWVPLJKWQRW EHHQVXUHG7KHDSSOLHGSUHVVXUHVKRXOGEHPDLQWDLQHGXQWLOWKH WKHUPRSODVWLFPDWUL[EHJLQVWRVRIWHQDQGÀRZ$IWHUWKLVWKH hot element is removed and melted surfaces are pressed against each other until consolidation occurs. Small parts demand EHWZHHQWRVHFRQGVWREHZHOGHGZKHUHDVODUJHSDUWVWDNH at least 30 minutes to guarantee a good connection. Risks of VXUIDFHFRQWDPLQDWLRQDUHDPRQJVWWKHPDLQGUDZEDFNVRIWKLV WHFKQLTXH$JHRUJHVet al., 2001; Ageorges et al., 2000).

IR welding

,5ZHOGLQJLVDQRWKHUVRPHZKDWQHZFRPHUWRWKH¿HOG RI QRQFRQWDFW WHFKQLTXHV IRU MRLQLQJ ILEHU UHLQIRUFHG

WKHUPRSODVWLFSRO\PHUPDWUL[FRPSRVLWHV<RXVHISRXUet al., 2004; Ageorges et al., 2001).

0DLQDGYDQWDJHVRI,5VRXUFHVDUHWKHLUDELOLW\WRIDVWKHDW-LQJW\SLFDOO\VHFRQGVFDSDFLW\WRDWWHQXDWHFRQWDPLQDWLRQ ULVNVWKXVDOORZLQJKLJKSURGXFWLYLW\UDWHVRIUHSURGXFLEOH strong joints in automated systems. For instance, retention RIRISRO\PHUEXONVWUHQJWKKDVEHHQUHSRUWHGIRU LQYROXPHRIVKRUWJODVV¿EHULQ3(6PDWUL[&KHQ Besides high consistent, low scattered mechanical properties of IR welded joints, which is translated in high structural UHOLDELOLW\DVFUXFLDOO\UHTXLUHGLQKLJKGHPDQGLQJFRPSR-nent devised to aeronautical industry, huge potential of this PDQXIDFWXULQJWHFKQLTXHFDQEHIRUHFDVWLQWKHDHURQDXWLFDO HQYLURQPHQWE\YLUWXHRILWVJUHDWÀH[LELOLW\DQGFDSDELOLW\ WRMRLQODUJHÀDWDQGFXUYHGDUHDV3RWHQWHet al., 1993; Chen, 2000; Miller, 2006). In the other hand, a main shortcoming of IR welding is the detrimental effect of colorants and pigments LQ FKDQJLQJ SRO\PHU DEVRUSWLRQ SURSHUWLHV WKXV UHGXFLQJ the quality of the end product. Darker polymers are espe-cially prone to display overheating surface degradation due to low IR energy transfer rates down through melting zone, QHYHUWKHOHVVGHHSKHDWSHQHWUDWLRQPD\EHDFRQFHUQGXHWR SRVVLEOHODPLQDWHGHFRQVROLGDWLRQDQGZDUSLQJGXULQJKHDWLQJ stage, as well as thermal residual stresses development along FRROLQJVWDJH6ZDUW] 6ZDUW]3RWHQWHet al., 1993; Chen, 2000; Ageorges et al., 2001;

.DJDQ

Bray, 2003;

Grewell et al.*UHZHOO %HQDWDU

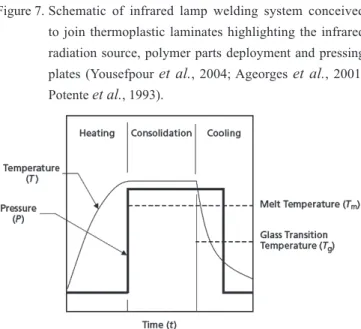

%DVLFDOO\ WKH WHFKQLTXH FRPSULVHV WKUHH VXEVHTXHQW SKDVHV6LOYHUPDQDQG*ULHVH6FKZDUW]&KHQ and Benatar, 1995). Figures 7 to 9 feature some important aspects related to IR radiation welding, particularly in regard to the welding system operation, applied thermomechanical F\FOHDQGFRQWDFWLQWHUIDFHEHKDYLRURIWKHUPRSODVWLFMRLQW

Laser welding

In order to produce integral composite structures and thus PDNHWKH¿QDOFRPSRVLWHFRPSRQHQWPRUHFRVWHIIHFWLYHWKH H[SORUDWLRQRIWKH/%:DOUHDG\DSSOLHGWRPHWDOOLFSDUWVFDQ EHXVHIXOLQWKHFDVHRIMRLQLQJHLWKHUWKHUPRSODVWLFSRO\PHUV or thermoplastic composite components. Thermoplastic poly-PHUVKDYHORQJPROHFXODUFKDLQVKHOGWRJHWKHUE\VHFRQGDU\ FKHPLFDOERQGVZKLFKDOORZVWKHPWREHKHDWHGDQGUHPHOWHG Through the activation of this physicochemical mechanism, WKHUPRSODVWLFVFDQEHMRLQHGXVLQJDZLGHYDULHW\RIIXVLRQ DQGLQWHUOD\HUERQGLQJSURFHVVHV/DEHDVet al., 2010

;

3UDE-hakaranet al.

,

2006; Grewell et al., 2004).

/%: KDV EHHQ HQYLVLRQHG DV D VXLWDEOH WHFKQLTXH IRU joining thin, as well as medium to thick thermoplastic components used in the aeronautic sector. Moreover, size, JHRPHWULFDO UHTXLUHPHQWV DQG VSHFL¿FDWLRQV RI DHURQDXWL-FDOSDUWVDUHFODLPHGWREHPRUHHDVLO\IXO¿OOHGE\DSSO\LQJ

/%:WHFKQLTXHUDWKHUWKDQDOWHUQDWLYHWHFKQRORJLHV/DEHDV et al., 2010

).

LBW allows joining thermoplastics, provided WKDWRQHRIWKHPDWHULDOVWRSPDWHULDOLVWUDQVSDUHQWWRODVHU UDGLDWLRQDQGWKHRWKHUERWWRPPDWHULDOLVDEVRUEHQWHQRXJK IRUWKHZHOGLQJWRWDNHSODFHRWKHUZLVHRQO\EXWWMRLQWVZLOOEH DOORZHGZKLFKLVQRWDQDWWUDFWLYHSRVVLELOLW\IRUFRQWLQXRXV ¿EHUUHLQIRUFHGVWUXFWXUHV,QWKH¿UVWDSSURDFKSDUWVWREHMRLQHGDUHEURXJKWLQWR GLUHFWFRQWDFWSULRUWRZHOGLQJ7KHODVHUEHDPLVWUDQVPLWWHG WKURXJKWKH¿UVWPDWHULDODQGLVWRWDOO\DEVRUEHGZLWKLQWKH VXUIDFHRIWKHDEVRUELQJPDWHULDO'LUHFWFRQWDFWEHWZHHQ ERWKSDUWVHQVXUHVKHDWLQJRIWKHWUDQVSDUHQWSDUWE\KHDW FRQGXFWLRQIURPWKHDEVRUELQJSDUW)LJ:HOGLQJRFFXUV XSRQPHOWLQJDQGIXVLRQRIERWKWKHUPRSODVWLFPDWHULDOVDW WKHLQWHUIDFH7KH/%:WHFKQRORJ\RIIHUVWKHSRVVLELOLW\RI joining separate parts ensuring full continuity of the resin system without the addition of an adhesive system and avoid-LQJDOVRULYHWLQVWDOODWLRQOHDGLQJWRDQXPEHURIVXEVWDQWLDO advantages, such as cost savings, weight reduction, and PDQXIDFWXULQJF\FOHWLPHUHGXFWLRQDVZHOODVDFFHSWDEOH ERQGVWUHQJWK/DEHDVet al., 2010

).

Only few studies of the application of LBW process for the joining of structural thermoplastic composites such as FDUERQ3((.RUFDUERQ336DUHDYDLODEOHLQWKHOLWHUDWXUH VRWKDWUHOLDEOHDSSOLFDWLRQRI/%:WHFKQRORJ\IRUMRLQLQJ primary aeronautic parts made of thermoplastic composites VWLOO UHTXLUHV VLJQL¿FDQW GHYHORSPHQW DQG LQYHVWLJDWLRQ /DEHDVet al., 2010

)

.REMARKABLE CONCLUSIONS

)URPWKLVPDQXVFULSWLWFDQEHFRQFOXGHGWKDWQRWRQO\RQH MRLQLQJWHFKQRORJ\FDQEHDSSOLFDEOHWRDOOVLWXDWLRQV$OOMRLQ-ing methodologies showed in this work present advantages and GUDZEDFNVDQGWKH\PD\EHPRUHRUOHVVVXLWDEOHWRDSDUWLFXODU

Figure 7. Schematic of infrared lamp welding system conceived to join thermoplastic laminates highlighting the infrared radiation source, polymer parts deployment and pressing

SODWHV<RXVHISRXUet al., 2004; Ageorges et al., 2001; Potente et al., 1993).

Figure 8. Typical thermomechanical cycle of the infrared welding

V\VWHP GHSLFWHG LQ )LJ <RXVHISRXUet al., 2004; Ageorges et al., 2001; Potente et al., 1993).

Figure 9. Macromolecular interdiffusion mechanism occurring in

EHWZHHQWZRFRQWDFWLQJSDUWVGXULQJWKHLQIUDUHGZHOGLQJ SURFHVVSRUWUD\HGLQ)LJVDQG<RXVHISRXUet al., 2004;

DSSOLFDWLRQ GHSHQGLQJ RQ LWV VSHFL¿F UHTXLUHPHQWV )XVLRQ ERQGLQJPHWKRGVSUHVHQWDKXJHSRWHQWLDOIRUYROXPHLQWHQVLYH applications in which short processing cycles are necessary. 7KHVHERQGLQJSURFHVVHVRIIHUDGGLWLRQDODGYDQWDJHVLQFOXGLQJ reduced surface preparation requirements, reprocessing, recy-FODELOLW\DQGLPSURYHGLQWHJULW\GXUDELOLW\$PRQJWKHYDULRXV WHFKQLTXHVRIWKLVFDWHJRU\WKHPRVWPDWXUHRQHVDUHXQGRXEW-edly the ultrasonic, induction and the resistance welding.

Process integration is a critical aspect of joining technol-ogy. Particular requirements of each joining techniques should EHFROODWHGLQGHVLJQVFRGHVLQRUGHUWRLQWHJUDWHWKHVHUHTXLUH-ments at the very early stage of the design process.

,QVLGHRIWKLVFRQWH[WVLQFH81(63DQG863KDYHJHW involved in development and/or application of welding technolo-JLHVLQDHURVSDFH¿HOG(PSKDVLVRIWKHZRUNLQ81(63LVLQ the development of the resistance welding technology associated ZLWKWKHHQYLURQPHQWDOLQÀXHQFHRQWKHWKHUPDODQGPHFKDQL-cal properties of thermoplastic laminates, whereas USP is in the forefront of IR lamp welding methodology and advanced destructive and nondestructive characterization of the joints. 0RVW RI WKH GDWD LQ WKLV SDSHU ZHUH REWDLQHG IURP WKH literature, since this manuscript is a state-of-the-art review. Therefore, such data do not provide information for deals of UHSHDWDELOLW\RUUHSURGXFLELOLW\DQGWKH\DUHXVHIXORQO\IRU an initial mapping of potential techniques over a wide range RIZHOGSURFHVVLQJFRQGLWLRQVDQGSDUDPHWHUVWREHXVHGLQ DHURVSDFH¿HOG

Acknowledgements

7KHDXWKRUVWKDQNIXOO\DFNQRZOHGJHWKH¿QDQFLDOVXSSRUW from Fundação de Amparo à Pesquisa do Estado de São Paulo )$3(63&RQVHOKR1DFLRQDOGH'HVHQYROYLPHQWR&LHQWt¿FR H7HFQROyJLFR&13TDQG&RRUGHQDomRGH$SHUIHLoRDPHQWR GH3HVVRDOGH1tYHO6XSHULRU&$3(6

REFERENCES

Ageorges, C., Ye, L., 2001, “Simulation of impulse resistance ZHOGLQJ IRU WKHUPRSODVWLF PDWUL[ FRPSRVLWHV´ $SSOLHG &RPSRVLWH0DWHULDOV9RO1RSS

$JHRUJHV & <H / ³)XVLRQ ERQGLQJ RI SRO\PHU FRPSRVLWHVIURPEDVLFPHFKDQLVPVWRSURFHVVRSWLPLVDWLRQ´ Springer, London.

Ageorges, C. et al. ³$GYDQFHV LQ IXVLRQ ERQGLQJ WHFKQLTXHV IRU MRLQLQJ WKHUPRSODVWLF PDWUL[ FRPSRVLWHV D UHYLHZ´&RPSRVLWHV3DUW$9RO1RSS

Ageorges, C. et al.³([SHULPHQWDOLQYHVWLJDWLRQRIWKH UHVLVWDQFHZHOGLQJIRUWKHUPRSODVWLFPDWUL[FRPSRVLWHV3DUW ,KHDWLQJHOHPHQWDQGKHDWWUDQVIHU´&RPSRVLWHV6FLHQFHDQG 7HFKQRORJ\9RO1RSS±

Arici, A.A., 2007, “Effect of hygrothermal aging on poly-HWKHULPLGHFRPSRVLWHV´-RXUQDORI5HLQIRUFHG3ODVWLFVDQG &RPSRVLWHV9RO1RSS

Balle, F. et al., 2009, “Ultrasonic metal welding of aluminium VKHHWVWRFDUERQ¿EUHUHLQIRUFHGWKHUPRSODVWLFFRPSRVLWHV´ $GYDQFHG(QJLQHHULQJ0DWHULDO9RO1RSS

Bates, P.J. et al.³6KHDUVWUHQJWKDQGPHOWGRZQEHKDY-LRU RI UHLQIRUFHG SRO\SURS\OHQH DVVHPEOLHV´ &RPSRVLWHV 3DUW$9RO1RSS

Botelho, E.C. et al., 2005 “Processing and hygrothermal effects RQ YLVFRHODVWLF EHKDYLRU RI JODVV ¿EHUHSR[\ FRPSRVLWHV´ -RXUQDORI0DWHULDO6FLHQFH9RO1RSS

Botelho, E.C. et al.³0HFKDQLFDOEHKDYLRURIFDUERQ ¿EHUUHLQIRUFHGSRO\DPLGHFRPSRVLWHV´&RPSRVLWHV6FLHQFH DQG7HFKQRORJ\9RO1RSS

%RWHOKR (& DQG 5H]HQGH 0& ³'DPSLQJ EHKDY-LRU RI K\JURWKHUPDOO\ FRQGLWLRQHG FDUERQ ILEHUHSR[\ ODPLQDWHV´ -RXUQDO RI$SSOLHG 3RO\PHU 6FLHQFH9RO 1RSS±

Botelho, E.C. et al., 2002, “Study of polyamide 6/6 synthesis FDUULHGRXWE\LQWHUIDFLDOSRO\PHUL]DWLRQRQFDUERQ¿EHU´ 3RO\PHU,QWHUQDWLRQDO9RO1RSS

Botelho, E.C. et al.³6\QWKHVLVRISRO\DPLGHE\ interfacial polycondensation with the simultaneous impregna-WLRQRIFDUERQ¿EHUV´0DFURPROHFXOHV9RO1RSS 3367-3375.

Chen, Y.S. and Benatar, A., 1995, “Infrared welding of poly-SURS\OHQH´$QQXDO7HFKQLFDO&RQIHUHQFH6RFLHW\RI3ODVWLFV Engineers, Vol.1, pp.1235-1238.

Chevali, V.S. et al., 2010, “Effect of environmental weathering RQÀH[XUDOFUHHSEHKDYLRURIORQJ¿EHUUHLQIRUFHGWKHUPR-SODVWLFFRPSRVLWHV´3RO\PHU'HJUDGDWLRQDQG6WDELOLW\9RO 1RSS

Chung-Yuan, W. et al.,1999, “Microwave welding of HDPE XVLQJLPSHGDQFHPDWFKLQJV\VWHP´-RXUQDORI5HLQIRUFHG 3ODVWLFVDQG&RPSRVLWHV9RO1RSS

&RVWD$3³(IHLWRGRFRQGLFLRQDPHQWRDPELHQWDOHP FRPSyVLWRVVROGDGRVGH336¿EUDVFRQWtQXDV´GLVVHUWDomR GH PHVWUDGR 8QLYHUVLGDGH (VWDGXDO 3DXOLVWD 81(63 Guaratinguetá, SP.

Costa, A.P. et al.³,QÀXHQFHRIHQYLURQPHQWDOFRQGL-WLRQLQJRQWKHVKHDUEHKDYLRURISRO\SKHQ\OHQHVXO¿GHJODVV ¿EHUFRPSRVLWHV´-RXUQDORI$SSOLHG3RO\PHU6FLHQFH9RO 1RSS

De Faria, M.C.M. et al.,, 2011, “The effect of the ocean water immersion and UV ageing on the dynamic mechanical proper-WLHVRIWKH336JODVV¿EHUFRPSRVLWHV´-RXUQDORI5HLQIRUFHG 3ODVWLFVDQG&RPSRVLWHV9RO1RSS

Don, R.C. et al. ³([SHULPHQWDO FKDUDFWHUL]DWLRQ RI processing-performance relationships of resistance welded JUDSKLWHSRO\HWKHUHWKHUNHWRQH FRPSRVLWH MRLQWV´ 3RO\PHU (QJLQHHULQJ6FLHQFH9RO1RSS

Espert, A. et al.³&RPSDULVRQRIZDWHUDEVRUSWLRQLQ QDWXUDO FHOOXORVLF ¿EUHV IURP ZRRG DQG RQH\HDU FURSV LQ SRO\SURS\OHQHFRPSRVLWHVDQGLWVLQÀXHQFHRQWKHLUPHFKDQLFDO SURSHUWLHV´&RPSRVLWHV3DUW$9RO1RSS

Grewell, D. and Benatar, A., 2007, “Welding of plastics: IXQGDPHQWDOVDQGQHZGHYHORSPHQWV´,QWHUQDWLRQDO3RO\PHU 3URFHVVLQJ9RO1RSS

Grewell, D.A. et al., 2003, “Plastic and composite welding KDQGERRN´9RO+DQVHU3XEOLVKHUV0XQLFKS

Grewell, D. et al. ³5HODWLRQVKLS EHWZHHQ RSWL-cal properties and optimized processing parameters for WKURXJKWUDQVPLVVLRQ ODVHU ZHOGLQJ RI WKHUPRSODVWLFV´ Journal of Reinforced Plastics and Composites, Vol. 23, 1RSS

Hou, M. et al.³$QH[SHULPHQWDOVWXG\RIUHVLVWDQFH ZHOGLQJRIFDUERQ¿EUHIDEULFUHLQIRUFHGSRO\HWKHULPLGH&) IDEULF3(,FRPSRVLWHPDWHULDO´$SSOLHG&RPSRVLWH0DWHUL-DOV9RO1RSS

Jayamol, G. et al., 1998, “Effects of environment on the prop-erties of Low-density polyethylene composites reinforced ZLWKSLQHDSSOHOHDI¿EUH´&RPSRVLWHV6FLHQFHDQG7HFKQRO-RJ\9RO1RSS

-RQHV)5³0RLVWXUHDEVRUSWLRQDQRPDORXVHIIHFWV´ ,Q+DQGERRNRISRO\PHU¿EUHFRPSRVLWHV/RQJPDQ6FLHQ-WL¿FDQG7HFKQLFDO8.SS

.DJDQ9DQG%UD\5³)RUZDUGWREHWWHUXQGHUVWDQG-ing of optical characterization and development of colored SRO\DPLGHVIRUWKHLQIUDUHGODVHUZHOGLQJSDUW,HI¿FLHQF\ RISRO\DPLGHVIRULQIUDUHGZHOGLQJ´-RXUQDORI5HLQIRUFHG 3ODVWLFVDQG&RPSRVLWHV9RO1RSS

.DJDQ9 DQG 1LFKROV 5- ³%HQH¿WV RI LQGXFWLRQ welding of reinforced thermoplastics in high performance DSSOLFDWLRQV´-RXUQDORI5HLQIRUFHG3ODVWLFVDQG&RPSRVLWHV 9RO1RSS

.UJHU6et al., 2004, “Ultrasonic welding of metal/compos-LWHMRLQWV´$GYDQFHG(QJLQHHULQJ0DWHULDOV9RO1RSS 157-159.

.X+6et al.³9DULDEOHIUHTXHQF\PLFURZDYH9)0 processing facilities and application in processing thermo-SODVWLFPDWUL[FRPSRVLWHV´-RXUQDORI0DWHULDOV3URFHVVLQJ 7HFKQRORJ\9RO1RSS

/HH.+et al.³&U\VWDOOL]DWLRQEHKDYLRURISRO\SKHQ-\OHQHVXO¿GH336DQG336FDUERQ¿EHUFRPSRVLWHV(IIHFW RIFXUH´3RO\PHU%XOOHWLQ9RO1RSS

Levy, A. et al., 2008, “Ultrasonic welding of thermoplastic FRPSRVLWHVPRGHOLQJRIWKHSURFHVV´,QWHUQDWLRQDO-RXUQDORI 0DWHULDO)RUPLQJ9RO1RSS

Loos, A.C. et al.³0RLVWXUHDEVRUSWLRQRISRO\HVWHU( JODVVFRPSRVLWHV´LQ6SULQJHU*6HGLWRU(QYLURQPHQWDO HIIHFWV RQ FRPSRVLWH PDWHULDOV 7HFKQRPLF 3XEOLVKLQJ &RPSDQ\1HZ<RUN

0DOOLFN3.³)LEHUUHLQIRUFHGFRPSRVLWHVPDWHULDOV PDQXIDFWXULQJDQGGHVLJQ´0DUFHO'HNNHU1HZ<RUNS

Mazur, R.L. et al., 2008, “Avaliações térmica e reológica da PDWUL]WHUPRSOiVWLFD3(..XWLOL]DGDHPFRPSyVLWRVDHURQiX-WLFRV´ 3ROtPHURV &LrQFLD H 7HFQRORJLD 9RO 1R pp. 237-243.

Miller, R., 2006, “Method and apparatus for infrared ZHOGLQJ RI WKHUPRSODVWLF SDUWV´ 8QLWHG 6WDWHV 3DWHQW 1XPEHU IURP KWWSZZZIUHHSDWHQWVRQOLQH com/7006763.html

Moser, L. et al., 2008, “Induction welding of thermoplastic SRO\PHUFRPSRVLWHVXVLQJURERWLFWHFKQLTXHV´6$03(-RXU-QDO9RO1RSS

Mouzakis, D.E. et al., 2008, “Accelerated environmental DJHLQJVWXG\RISRO\HVWHUJODVV¿EHUUHLQIRUFHGFRPSRVLWHV *)53&V´&RPSRVLWHV3DUW%9RO1RSS

1LQJ+et al.,, 2007, “Design, manufacture and analysis of DWKHUPRSODVWLFFRPSRVLWHIUDPHVWUXFWXUHIRUPDVVWUDQVLW´ &RPSRVLWH6WUXFWXUHV9RO1RSS

1LQR*)et al.³7KHUPDO1',RIUHVLVWDQFHZHOGHG FRPSRVLWHVWUXFWXUHV´&RPSRVLWHV3DUW%9RO1R pp. 237-248.

Potente, H. et al., 1993, “Comparative investigation into the ZHOGLQJRIJODVV¿EUHUHLQIRUFHG3(6´-RXUQDORI7KHUPR-SODVWLF&RPSRVLWH0DWHULDOV9RO1RSS

3UDEKDNDUDQ5et al., 2006, “Contour laser - laser-transmission ZHOGLQJRIJODVVUHLQIRUFHGQ\ORQ´-RXUQDORI7KHUPRSODVWLF &RPSRVLWH0DWHULDOV9RO1RSS

Ray, B.C., 2006, “Temperature effect during humid ageing RQ LQWHUIDFHV RI JODVV DQG FDUERQ ¿EHUV UHLQIRUFHG HSR[\ FRPSRVLWHV´-RXUQDORI&ROORLGDQG,QWHUIDFH6FLHQFH9RO 1RSS

Rezende, M.C. et al., 2011, “Compósitos estruturais – tecno-ORJLDHSUiWLFD´(GLWRUD$UW/LEHU6mR3DXOR%UDVLO

6FKZDUW]00³-RLQLQJRIFRPSRVLWHPDWUL[PDWHUL-DOV´$60+DQGERRN$60,QWHUQDWLRQDO2KLRS

Siddiq, A. and Ghassemieh, E., 2008, “Thermomechanical analyses of ultrasonic welding process using thermal and DFRXVWLFVRIWHQLQJHIIHFWV´0HFKDQLFVRI0DWHULDOV9RO 1RSS

Silverman, E.M. and Griese, R.A., 1989, “Joining methods for JUDSKLWH3((.WKHUPRSODVWLFFRPSRVLWHV´6$03(-RXUQDO 9RO1RSS

6LQPD]oHOLN7 ³1DWXUDO ZHDWKHULQJ HIIHFWV RQ WKH mechanical and surface properties of polyphenylene sulphide 336 FRPSRVLWHV´ 0DWHULDOV DQG 'HVLJQ9RO 1R pp. 270-277.

6WDYURY'DQG%HUVHH+(1³5HVLVWDQFHZHOGLQJRI WKHUPRSODVWLFFRPSRVLWHVDQRYHUYLHZ´&RPSRVLWHV3DUW$ $SSOLHG6FLHQFHDQG0DQXIDFWXULQJ9RO1RSS

Stavrov, D. et al. ³([SHULPHQWDO LQYHVWLJDWLRQ RI ODUJHVFDOHZHOGLQJRIFDUERQ¿EHUWKHUPRSODVWLFFRPSRVLWH PDWHULDOV´,Q3URFHHGLQJVRI,&&0&RQIHUHQFH San Diego.

6WRNHV9.³([SHULPHQWVRQWKHLQGXFWLRQZHOGLQJRI WKHUPRSODVWLFV´3RO\PHU(QJLQHHULQJDQG6FLHQFH9RO 1RSS

Todo, M. et al., 2000, “Strain-rate dependence of the tensile IUDFWXUH EHKDYLRXU RI ZRYHQFORWK UHLQIRUFHG SRO\DPLGH FRPSRVLWHV´&RPSRVLWHV6FLHQFHDQG7HFKQRORJ\9RO 1RSS

Velthuis, R. and Mitschang, P., 2003, “Induction welding WHFKQRORJ\MRLQLQJ¿EUHUHLQIRUFHGWKHUPRSODVWLFSRO\PHUV FRPSRVLWHVIRUDHURVSDFHDSSOLFDWLRQV´0HFKDQLFDO(QJL-QHHULQJ3DSHUV9RO1RSS

Vieille, B. et al. ³,QÀXHQFH RI WHPSHUDWXUH RQ WKH EHKDYLRURIFDUERQ¿EHUIDEULFVUHLQIRUFHG336ODPLQDWHV´ 0DWHULDOV 6FLHQFH DQG (QJLQHHULQJ$ 9RO 1R pp. 51-60.

Vodicka, R., 1996, “Thermoplastics for airframe Applications, a review of the properties and repair methods for thermoplas-WLFFRPSRVLWHV´$XVWUDOLDQ'HSDUWPHQWRI'HIHQFH'672 $HURQDXWLFDODQG0DULWLPH5HVHDUFK/DERUDWRU\$XVWUDOLD

Wang, Y. and Hahn, T.H., 2007, “AFM characterization of WKHLQWHUIDFLDOSURSHUWLHVRIFDUERQ¿EHUUHLQIRUFHGSRO\PHU FRPSRVLWHVVXEMHFWHGWRK\JURWKHUPDOWUHDWPHQWV´&RPSRV-LWHV6FLHQFHDQG7HFKQRORJ\9RO1RSS

:DQJ;et al., 2006, “FEM investigation of the temperature ¿HOGRIHQHUJ\GLUHFWRUGXULQJXOWUDVRQLFZHOGLQJRI3((. FRPSRVLWHV´-RXUQDORI7KHUPRSODVWLF&RPSRVLWH0DWHULDOV 9RO1RSS

Wise, R.J. and Froment, I.D., 2001, “Microwave welding of WKHUPRSODVWLFV´-RXUQDORI0DWHULDOV6FLHQFH9RO1R pp. 5935-5954.

;LDR;5et al.,1992, “Processing and modelling of resis-WDQFHZHOGLQJRI$3&FRPSRVLWH´-RXUQDORI&RPSRVLWH 0DWHULDOV9RO1RSS

Yang, F.and Pitchumani, R., 2002a, “Healing of thermoplastic SRO\PHUV DW DQ LQWHUIDFH XQGHU QRQLVRWKHUPDO FRQGLWLRQV´ 0DFURPROHFXOHV9RO1RSS

<DQJ)DQG3LWFKXPDQL5E³,QWHUODPLQDUFRQWDFW GHYHORSPHQWGXULQJWKHUPRSODVWLFIXVLRQERQGLQJ´3RO\PHU (QJLQHHULQJ 6FLHQFH9RO1RSS

<RXQJ.DQG<H/³,QÀXHQFHRIPDWUL[DQGLQWHUIDFH on transverse mechanical properties of CF-PEI thermoplastic FRPSRVLWHVDWHOHYDWHGWHPSHUDWXUHV´-RXUQDORI5HLQIRUFHG 3ODVWLFV&RPSRVLWHV9RO1RSS

![Figure 2 presents a schematic of an ultrasonic welding PDFKLQHXVLQJDSLH]RHOHFWULFWUDQVGXFHUE\ZKLFKWKHRVFLO-ODWLRQVDUHJHQHUDWHGE\DSSO\LQJHOHFWULFDOSRZHUDWKLJK frequency](https://thumb-eu.123doks.com/thumbv2/123dok_br/18888956.424525/3.918.105.457.850.1047/schematic-ultrasonic-pdfklqhxvlqjdslh-rhohfwulfwudqvgxfhue-zklfkwkhrvflo-odwlrqvduhjhqhudwhge-lqjhohfwulfdosrzhudwkljk-frequency.webp)