OPTIMAL DESIGN OF SINGLE PHASE

TRANSFORMER USING BACTERIAL

FORAGING ALGORITHM

S.SUBRAMANIAN * S.PADMA

Professor Assistant Professor

Department of Electrical Engineering Faculty of Engineering and Technology

Annamalai University, India.

Abstract:

The aim of the transformer design is to obtain the dimensions of all the parts of the transformer based on the given specification, using available materials economically in order to achieve lower cost, reduced size and better operating performance. In this paper, the task of finding optimal design of single phase transformer has been formulated as nonlinear programming problem, so as to meet the specification with the minimum cost and improve the efficiency. Four independent variables and two constraints are taken to meet the requirement of the design. The method utilizes Bacterial Foraging Algorithm (BFA) to provide optimum design of single phase transformer. The validity of the proposed method has been tested on a sample transformer and the simulation results obtained are compared with conventional method and Particle Swarm Optimization (PSO) technique. The simulation results reveal that the proposed scheme determines the optimal variables of transformer along with the performance parameters efficiently.

Keywords: Single phase transformer, design optimization, cost, efficiency, bacterial foraging algorithm.

Nomenclature

C (i) - Step size

i - Bacterium number

j - Counter for chemotactic step J (i, j, k, l) - Cost at the location of ith bacterium

Jcc - Swarm attractant cost

J ihealth - Health of bacterium i k - Counter for reproduction step l - Counter for elimination-dispersal step m - Counter for swimming locomotion Nc - Maximum number of chemotactic steps Ned - Number of elimination-dispersal events Nre - Maximum number of reproduction steps

Ns - Maximum number of swims

P - Dimension of the optimization problem Ped - Probability of occurrence of elimination-

dispersal events

s - Population of the E. coli bacteria i

(j, k, l) - Location of the ith bacterium at jth

chemotactic step, kth reproduction step, and l the elimination-dispersal step

attract - Width of attractant

repellant - Width of repellent

hrepellent - Height of repellent dattract - Depth of attract

1. Introduction

materials, reduction of size and overall material costs and development of design methods that decrease the manufacturing time. In the past, several design optimization techniques have appeared in the literature. The transformer design with the cost analysis has been reported in the literature. The authors developed a step by step procedure for the transformer design involved the material cost and labour cost [1]. The cost analysis involves with the material costs in detail and a labour analysis that sets forth a detailed list of labour operations necessary to construct the transformer being analyzed. To achieve accurate design with less time an economical manner using digital computers was discussed [2]. A unified method has been developed for the design of electrical machines including power transformers [3].The circulating and rotational fluxes make large contribution to the total power loss in the transformer and it requires the optimal design of joint [4]. The joint design based on the knowledge about the localized flux distribution, both in the corners and in the limbs. Simulated Annealing (SA) technique [5] has been applied to solve the transformer design problems. The minimization of material cost is taken as an objective. A combined genetic algorithm-neural network approach applied to distribution transformers for iron loss reduction was presented [6]. Optimum transformer design based on the given specification, using available materials economically to achieve lower cost, reduced size and better operating performance was discussed [7]. Application of finite element method to compute flux density and hence loss distribution in transformer cores was discussed [8]. Evolutionary algorithm based optimum design of induction motor was discussed [9]. The performance of two optimal design methods, Hooke Jeeves and, respectively, genetic algorithms, are compared in terms of performance and computation time effort in an exercise design of induction machine was reported [10]. A Novel approach, called Bacterial foraging algorithm has been developed based on modeling of bacteria E.coli behaviour present in human intestines and it has been proven that is efficient [11-16] for various optimization problems. In this article, BFA has been applied to obtain optimum design of single phase transformer. The effectiveness of the proposed BFA approach has been tested with the sample transformer.

2. Single phase transformer design optimization–problem formulation:

Theoptimization ofsingle phase transformer is carried out by considering the design parameters and the variables as a common nonlinear programming problem. The problem can be stated is mathematical terms as follows.

Find:

]

X

…

X

,

X

,

[X

=

X

1 2 3 n Such that F=f(X) is minimum subject toimax i

imin

<

X

<

X

X

, i=1, 2….nAndgi(X) < 0, i=1, 2, .m

Where X1, X2,……Xn are the set of independent design variables with their lower and upper bounds as Ximin

and Ximax. F=f(X) is the objective function to be optimized and gi(X) are the constraints imposed on the design.

2.1Design variables

The transformer design involves a large number of variables. In order to avoid undue complexities in the formulation and execution of the optimization problem, the following design quantities are chosen as the independent variables of optimization.

1. Maximum flux density (x1) Wb/m 2

2. Current density in HV winding (x2) A/mm2

3. Current density in LV winding (x3) A/mm2

4. EMF per turn(x4) volts

2.2 Constraints

gj(X) is the set of m explicit constraints imposed on a design to make it feasible and practically

acceptable, the constraints that have been used in this study are 1. Temperature rise

2. Regulation

The objective function optimization problem is to optimize the efficiency and cost. Total cost is sum of iron and copper cost. In the computation of F(X) and gj (X) as well as in calculating the performance of the

machine, the standard mathematical formulation is used. [17].

3. Bacterial foraging optimization

coli bacterium has a control system that enables it to search for food and try to avoid noxious substances. The bacteria distributed motion can model as the following four stages:

3.1 Swarming and Tumbling via flagella (Ns)

The flagellum is a left-handed helix configured so that as the base of the flagellum (i.e. where it is connected to the cell) rotate counter clockwise, from the free end of the flagellum looking towards the cell, it produces a force against the bacterium pushing the cell. This mode of motion is called swimming. A bacterium swims either for maximum number of steps Ns or less depending on the nutrition concentration and environment condition.

During clockwise rotation each flagellum pulls on the cell shown in Figure 1. So that the net effect is that each flagellum operates relatively independently of the others and so the bacterium “tumbles”.

Figure1. Swarming and Tumbling behaviour 3.2 Chemotaxis (Nc)

A chemotaxis step is a set of consequence swim steps following by a tumble. A maximum of swim steps with a chemotactic step is predefined by Ns. The actual number of swim steps is determined by the

environment. If the environment shows good nutrients concentration in the direction of the swim, the bacteria swim more steps. When the swim steps is stopped a tumble action takes place.

3.4 Reproduction (Nre)

After Nc chemotactic steps, a reproduction step is taken. Let Nre be the number of reproduction steps to

be taken. It is assumed that half of the population members have sufficient nutrients so that they will reproduce with no mutations. For reproduction, the population is sorted in order of ascending accumulated cost accumulated cost represents that it did not get as many nutrients during its lifetime of foraging and hence, is not as “healthy” and thus unlikely to reproduce). Least healthy group of bacteria dies out and the other healthiest splits into two.

3.5 Elimination and Dispersal (Ned)

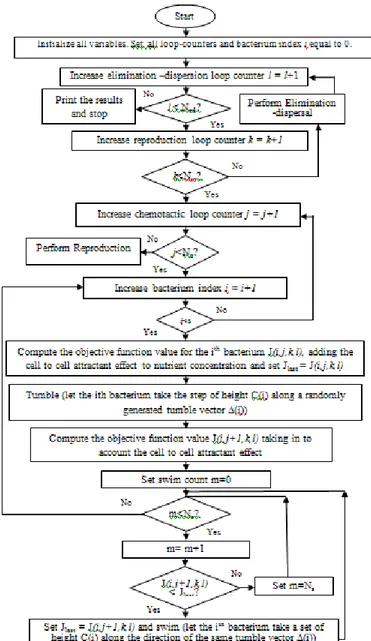

Figure 2 .Flowchart for bacterial foraging algorithm

The algorithmic steps of BFA are as follows.

Step-1 Initialize parameters P, s, Nre, Ned, Ped, C (i) (i=1, 2,……s), and Xi. Also initialize all the counter

values to zero.

Step-2 Elimination-dispersal loop: l=l+1 Step-3 Reproduction loop: k=k+1

Step-4 Chemotaxis loop: j=j+1

(a) For i=1, 2,…, s, calculate cost function value and efficiency- for each bacterium i as follows. 1. Nis signal samples are passed through the model.

2. The output is then compared with the corresponding desired signal to calculate the error.

3. The same of the squared error averaged over Nis is finally stored in J (i, j, k, l). The cost function is

calculated for number of input samples. 4. End of for loop.

(a) For i=1,2,…s take the tumbling/swimming decision

Move: Let

(i)Δ(i)

T Δ Δ(i) C(i) l) k, (j, i θ l) k, l, (j i

θ

Fixed step size in the direction of tumble for bacterium i is considered. Compute J(i, j+1, k, l) and then

Let

l))

k,

1,

P(j

l),

k,

1,

(j

i

(

θ

cc

J

l)

k,

1,

j

J(i,

l)

k,

1,

j

Jsw(i,

Swim:(i) Let m=0; (counter for swim length)

(ii) While m<Ns (have not climbed down too long)

Let m=m+1

If Jsw(i, j+1, k, l) < Jlast (if doing better), let

Jlast= Jsw(i, j+1, k, l) and Let

(i) (i)Δ T Δ Δ(i) C(i) l) k, (j, i θ l) k, l, (j i

θ And use this i( j +1, k,l) to compute the new J (i, j+1,l)

Else, let m=Ns. This is the end of the while statement.

(b) Go to next bacterium (i+1) if i ≠ s (i.e. go to b) to process the next bacterium.

Step-5 If j < Nc, go to step 4. In this case, continue Chemotaxis since the life of the bacteria is not over.

Step-6 Reproduction:

(a) For the given k and l, and for each i=1, 2,..s,

Let Jihealth=min Jsw(,i, j, k, l) be the health of the bacterium i (a measure of how many nutrients it got

over its life time and how successful it was at avoiding noxious substance). Sort bacteria in order of ascending cost Jhealth (higher cost means lower health).

(b) The Sr=s/2 bacteria with highest Jhealth values die and other Sr bacteria with the best value split (and the

copies that are made are placed at the same location as their parent)

Step-7 If k < Nre go to 3. In this case, the number of specified reproduction steps has not been reached, so the

next generation of the chemotactic loop is started.

Step-8 Elimination-dispersal: For i=1, 2, s, with probability Ped, eliminates and disperses each bacterium (this

keeps the number of bacteria in the population constant). To do this, if a bacterium is eliminated, simply disperse another one to a random location on the optimization domain. If l < Ned, then go to step 2; otherwise, print the results and stop.

4. Bacterial foraging algorithm based design optimization of single phase transformer

The proposed scheme is employed to search the optimal values of transformer independent variables, thereby minimizing the cost and improve the efficiency. Each bacterium X contains four variables x1, x2, x3and

x4 .The i th

bacterium is represented as follows: xi=(x1, x2, x3, x4).If there are s number of bacteria in a

population, then the dimension of a population is s x 4.

The following steps were followed in the optimization procedure.

Step 1. Input the bacterial foraging parameters and independent variables, and also specify lower and upper limits of the variables.

Step 2. Generate the positions of the independent variable randomly for a population of bacteria. Step 3. Evaluate the objective value of each bacterium.

Step 4. Modify the position of the variables for all the bacteria using the tumbling/swimming process Step 5. Perform reproduction and elimination operation.

Step 6. If the maximum number of chemotatic, reproduction and elimination-dispersal steps is reached, then go to step 7; otherwise, go to step4.

5. Results and discussion

To verify the effectiveness of proposed approach for solving the optimization problem has been tested on sample transformer. The specification of sample transformer was presented in table 1. The design optimization procedure starts with the design variables, four independent variables are chosen, such as flux density, current density in LV and HV winding, and Emf per turn changed during the iteration.

Table 1

Sample Transformer Specifications

Capacity 500 KVA Phase Single phase Primary voltage 6600 V

Secondary voltage 400 V

Type Core Frequency 50 Hz

In the present work the chosen objectives are cost and efficiency of the transformer. To demonstrate the superiority of the proposed method, the results obtained from the BFA are compared with conventional method and PSO technique. The comparison of the results for sample transformer is given in table 2.

Table 2: Comparison of BFA results with conventional method and PSO (Efficiency as objective function)

Variables Conventional method

PSO based results BFA based results

Maximum flux density (Wb/m2) 1.5 1.47 1.45 Current density in high voltage

winding (A/mm2) 2.75 2.32 2.21 Current density in low voltage

winding (A/mm2) 2.75 2.58 2.07 EMF per turn (V) 17.9 17.4 16.8

Temperature rise (0C) 80 77 75 Regulation (%) 19.7 18.7 18.2

Efficiency (%) 98.93 98.97 99

Cost (Rs) 145030 144255 143356

Table 3: Comparison of BFA results with conventional method and PSO (Cost as objective function)

Variables Conventional

method

PSO based results

BFA based results

Maximum flux density (Wb/m2) 1.5 1.48 1.44 Current density in high voltage winding

(A/mm2) 2.75 2.59 2.08 Current density in low voltage winding

(A/mm2) 2.75 2.68 2.28 EMF per turn (V) 17.9 17.5 16.4

Temperature rise (0C) 80 76 71 Regulation (%) 19.7 19 18.4

Cost (Rs) 1,45030 143576 1,41210

Efficiency(%) 98.93 98.94 98.96

summarized in table 4. Figure 3 shows the variations of efficiency with iteration for sample transformer. Figure 4 shows the variations of cost with iteration for sample transformer

Table4.Parameter selected for BFA

Parameter Value

Number of bacterium (s) 20

Number of chemotatic steps (Nc) 10

Swimming length (ns) 4

Number of reproduction steps (Nre) 4

Number of elimination and dispersal events (Ned) 5

Depth of attractant (dattract) 0.1

Width of attractant (attract) 0.2

Height of repellent (hrepellant) 0.1

Width of repellent (repellant) 10

Probability of elimination-dispersal events (Ped) 0.02

Figure 3: Variations of efficiency with iterations

Figure 4: Variations of cost with iterations

6. Conclusion

compared to conventional method and PSO based results. From that, it clearly shows the proposed provide good solution quality and convergence behaviour. The bacterial foraging algorithm having the merits such as less mathematical burden and high quality solution. This implies that the proposed method possesses a great potential of application to a wide class of electrical machine design problems.

Acknowledgements

The authors are grateful to the authorities of Annamalai University for providing all facilities to carry out this work

References

[1] P.H. Odessey, “Transformer Design by Computer”, IEEE Transactions on Magnetics, Vol. 3, No.1, June 1974, pp.1-17.

[2] S.BWilliams ,P.A Abetti and E.F Magnusson, “Application of digital computers to transformer Design, In Proceedings of AIEE Winter General Meeting, New York, August, 1956,pp. 728- 735.

[3] O.W. Andersen, “Optimum Design of Electrical Machines”, IEEE Transactions on Power Apparatus and Systems, No6, 1967, pp 707-11.

[4] Anthony J. Moses and Bleddyn Thomas, “Problems in the Design of Power Transformers”, IEEE Transactions on Magnetics, Vol. 10, No .2 June 1974, pp 148-150.

[5] S. Padma, R. Bhuvaneswari and S. Subramanian, “Optimal Design Power Transformer using Simulated Annealing Technique”, IEEE conference, International Conference on Industrial Technology ( ICIT), December 15-17, pp. 1015-1019, Mumbai, India 2006. [6] P.S Georgilakis, N.D.Doulamis,A.D Doulamis,N.D Hatziargyriou and S.D Kollais, “ A Novel Iron Loss Reduction Technique for

Distribution Transformer based on a Combined Genetic Algorithm-Neural Network Approach”,IEEE Transaction on system, man, cybernetics, Vol .31,No.1, February 2001,pp 16-34.

[7] Pavlos S. Georgilakis , Marina A. Tsili `and Athanassios T. Souflaris , “A Heuristic Solution to the Transformer Manufacturing Cost Optimization Problem,” Journal of Materials Processing Technology, Vol.181 , No. 1-3, January 2007,pp 260–266.

[8] Amitava Basak, Chi-Hang Yu and Graeme Lloyd, “Efficient Transformer Design by Computing Core Loss Using a Novel Approach "IEEE Transactions on Magnetics, Vol. 30, No. 5. September 1994, pp3725-3728.

[9] Jan Pawel Wieczorek, ozdemir Gol and Zbigniew Michalewicz, “An Evolutionary Algorithm for the Optimal Design of Induction Motors”, IEEE Transactions on Magnetics, Vol 34,No.6 November 1998.

[10] Lucian Tutelea and Ion Boldea, “Induction Motor Electromagnetic Design Optimization: Hooke Jeeves Method ersus Genetic Algorithms,” 12th International Conference on Optimization of Electrical and Electronic Equipment, OPTIM 20-22 May2010,pp 485-492,Basova.

[11] B.K. Panigrahi, V. Ravikumar Pandi, “ Bacterial Foraging Optimisation:Nelder–Mead Hybrid Algorithm for Economic Load Dispatch”, IET Generation, Transmission and Distribution , vol. 2, no. 4, 2008, pp. 556-565.

[12] M. Tripathy and S. Mishra, “Bacteria Foraging Based Solution to Optimize Both Real Power Loss and Voltage Stability Limit”, IEEE Transaction on Power Systems, vol. 22, no.1, February 2007, pp. 240-248.

[13] W.J Tang, Q.H. Wu and J.R. Saunders, “ Bacterial Foraging Algorithm for Dynamic Environments”, IEEE Congress on EVOLUTIONARY COMPUTATION, pp. 1324-1330, Canada, 16-21 July 2006.

[14] D.P. Acharya, G. Panda, S. Mishra and Y.V.S. Lakshmi, “Bacteria Foraging Based Independent Component Analysis”, International Conference on Computational Intelligence and Multimedia Applications , pp. 527-531,2007.

[15] V.P. Sakthivel and S. Subramanian, “Determination of Induction Motor Double Cage – Model Parameters Based on Bacterial Foraging Algorithm”, International Review of Electrical Engineering , vol. 5, no. 4, July-August 2010, pp. 1529-1537.

[16] Noriega, G. Restrepo, J. Guzman, V. Gimenez, M. Aller and Simón Bolívar, “On Line Parameter Estimation of Electric Systems Using the Bacterial Foraging Algorithm”, 13th European Conference on Power Electronics and Applications, pp. 8-10, September 2009.