.SC1r

American SocietyiiFII

..

of Civil Engineers180 I ALEXANDER BELL DRIVE

RESTON, VIRGINIA 20191-4400

EDITED BY

Atorod Azizinamini

David Darwin

Catherine French

July 13-18

,

1997

Kona, Hawaii

SPONSOREDBY

United Engineering Foundation, Inc.

PROCEEDINGS

First

International Conference

Copyright @ 1999 by the American Society of Civil Engineers, All Rights Reserved. Library of Congress Catalog Card No: 99-17899 ISBN 0-7844-0419-4 Manufactured in the United States of America.

Any statements expressed in these materials are those of the individual authors and do not necessarily represent the views of ASCE, which takes no responsibility for any statement made herein. No reference made in this publication to any specific method, product, process or service constitutes or implies an endorsement, recommendation, or warranty thereof by ASCE. The materials are for general information only and do not represent a standard of ASCE, nor are they intended as a reference in purchase specifications, contracts, regulations, statutes, or any other legal document. ASCE makes no representation or warranty of any kind, whether express or implied, concerning the accuracy, completeness, suitability, or utility of any information, apparatus, product, or process discussed in this publication, and assumes no liability therefore. This information should not be used without first securing competent advice with respect to its suitability for any general or specific application. Anyone utilizing this information assumes all liability arising from such use, including but not limited to infringement of any patent or patents.

Photocopies:

Authorization to photocopy material for internal or personal use under circumstances not falling within the fair use provisions of the Copyright Act is granted by ASCE to libraries and other users registered with the Copyright Clearance Center (CCC) Transactional

Reporting Service, provided that the base fee of $8.00 per article plus $.50 per page is paid directly to CCC, 222 Rosewood Drive, Danvers, MA 01923. The identification for ASCE Books is 0-7844-0419-4/99/ $8.00

+

$.50 per page. Requests for special permission or bulk copying should be addressed to Permissions & Copyright Dept., ASCE.Engineering Foundation Conference on High Strength Concrete (1S!: 1997: Kona, Hawaii) High strength concrete: first international conference: proceedings, July 13-18, 1997, Kona, Hawaii /sponsored by United Engineering Foundation, Inc.; edited by Atorod Azizinamini, David Darwin, Catherine French.

p. cm.

Includes bibliographical references. ISBN 0-7844-0419-4

1. High strength concrete-Congresses. 2. Concrete construction-Congresses. I. Azizinamini, Atorod. II. Darwin, David. III. French, Catherine (Catherine E.) IV. United Engineering Foundation (U.S.) V. Title.

TA439.E474 1997

624.1'834-dc21 99-17899

CIP Library of Congress Cataloging-in-Publication Data

Abstract: This proceedings,

High Strength Concrete,

consists of papers presented at the first Engineering Foundation Conference on High Strength Concrete, held July 13-18, 1997, in Kona, Hawaii. The conference brought together a group of individuals known for their contributions to high strength concrete (HSC); from material aspects to applications in the field. Since the 1980s, intense research activities have been conducted to resolve design issues related to the use of HSC. These papers explore such issues as the behavior of interior beam-and column subassemblages in a reinforced concrete frame, ductility and strength of HSC columns, shear strength of HSC beams, seismic behavior of prestressed concrete beam-column joints, crack growth and cyclic loads, and thermal performance of HSC.High Strength Concrete: Design Issues in the Canadian Code 582

Dents

MitchellCo

d

es

On Extending ACI318 to High Strength Concrete 5S4

Mohamed A.At. and Richard N.White

Provisions in U.S. Codes Related to nigh Strength Concrete 568

S.

K

.

GhoshVII

Use of CFRP Composites with High Strength Concrete in Bridges ...•... 391 Nabil F Grace. GCO'1lCAbdel-Sayed, and Michael S. Ledesma

Cracking in HighStrength Concrete at Early Ages...•...•.••... 401 Tor Arne Hammer. Erik J. Sellevold, and 0yvind Bjontegaard

Studying Initiation and Growth of Shear Cracks inReinforced Concrete

Bea

m

s

lsing Full-Field Digital Imaging.. _ .41

2

Daniel C Jansen. Sokhwan Choi, and Surendra P.ShahPenetration Resistance Tests on High Strength Concrete ...•...•....•...•....•.. ·U5

Sergio \.1 R

L

o

pes

and Miguel C.S. NcpomuccnoHigh Strength Concrete from Low Water Demand Cemenl. ....•...•... .434 J Moreno. Sh

r

Babaev, N.F Bashlykov, C. Eberhardt. B.E. Yudovich. andV.

R

Fali

k

rnan

Crack Gro» tb in Four Concretes under Monotonic or Cyclic Splitting Load .444

Kal

Duan and Jan G.M.van MierFundamental Aspects of Mechanical Behavior of

H

S/

HP

C

:

The EuropeanApproach 457

Jan G.M van Mier

Comparative 'tudy of High Strength Concrete Fracture Uniaxial and

Triaxial Loading _ 470

K

a

mran M

Nemati and Paulo J.M. MonteiroFiber Reinforced Higb Strength Concrete Beams in Shear .480 Kelvan xoghabai, Thomas 010fs50n, and Jonas Gustafsson

High Performance :\Ju!timodal Fiber Reinforced

C

e

m

e

nt

Composites(HP;\fFRCC) 494

P

ROSSI~1aterial Aspects of High Performance Concrete

50..

Surendra P

ShahThe L e of High Reactiv it) Mctakaolin in Higb Performance Concrete .517

\1D.A Thomas. K.A Gruber. and R.D. Hooton

Thermal Performance of Concretes Including High Strength Concrete S31 J.A. Tinker

Higb Strengtb Phosphate Cement Using Industrial By-Product Ashes S42

·us

As

a way of estimating the "in situ" strength for high strength concrete, some techniques, previously used in normal strength concrete, have been adapted and The interest of high strength concrete has increased considerably in the last lew years. Several research works on this subject have contributed to a better understanding of the material properties and mechanical behavior in structural elements ofhigh strength concrete.One subject, which needs some investigation as far as the use of high strength concrete In building construction is concerned, is the prediction of "in situ' concrete strength. It is known that the strength measured on standard specimens, at 28 days and cured in standard conditions, only gives the potential value of the concrete strength, which is useful for quality control purposes and for checking the acceptability of the concrete as it is produced (1.

2).

However, this reference strength is normally achieved by the real structure at ages much higher than 28 days, depending on various parameters, mostly associated with curing conditions. On the other hand it is often necessary to know the strength of concrete before 28 days to determine when the forms can be disassembled or to know the structure peliormance at certain age.INTRODUCTION

The aim of the investigation described here is to verify the applicability of penetration resistance tests on high strength concrete as a way of estimating its compressive strength "in situ". A relationship between compressive strength of a given concrete and its resistance to penetration by a steel probe fired into the concrete surface is presented to a compressive strength range varying from 50 MPa to 90 MPa using an alternative firing apparatus to the standard apparatus Windsor Probe Test System.

ABSTRACT

Miguel C. S. Nepomuceno Lecturer

University of Beira Interior Dep. of Civil Eng.

6200 Covilha - Portugal Sergio M. R.Lopes

Assistant Professor University of Coimbra Dep. of Civil Eng. - FCTUC 3049 Coimbra Codex - Portugal

PENETRATION RESISTANCE TESTS ON

HIGH STRENGTH CONCRETE

The way of delivering the energy to the probe by

t

he A

l

temative Firing Appa

r

atus

has littl

e

difference from the

W

PT System previously mentioned

.

Bo

t

h sys

t

ems use

a po

w

der cartridge and probes, but

w

hile in the first apparatus I;NPT System)

d

e

tonation resu

l

tant energy of the powd

e

r cartridge is transmitted d

i

rectl

y

to

t

he

probe

,

which Is accele

r

a

t

ed and projected into the concrete surface, In the

Altemative FIring Apparatus this energy Is transmitted to a pis

t

on,

w

hich is projected

i

n high velo

ci

ty againstlhe probe

,

li

k

e a hammer

,

thrus

t

In the probe by the Impact.

A

l

t

e

rn

a

t

i

ve Fir

i

ng Apparatu

s

A test apparatus

,

designed for penetrat

i

on resistance measu

r

ements,

u

sing a

specia

l

probe and standardized po

w

de

r

charge,

w

as deve

l

oped In t

h

e US

A d

uring

the 1960s' and is kno

w

n as

W

indsor Probe Test System a

n

d covered by

t

he

A

ST

M

Standards (AST

M

-C803-90)

<a)

.

In Europe, similar s

t

andards are the British

Standards (BS 1881

:

Part 207

:

1992) (i). This system allo

w

s

t

he use of t

w

o

kin

ds of

probes:

t

he silver colored probe

,

t

o use

I

n co

n

cre

t

e

w

llh na

t

ural aggregate; and the

gold colored probe, to use with lightwe

i

ght co

n

crete. Two dif

f

e

r

en

t

power leve

l

s a

r

e

also posslole

,

using the same power

l

oad, by an adjustme

n

t

In

the instrumen

t

:

t

he

standard power and

l

ow power

.

For the purpose of this s

t

udy

,

I

t w

as decided

t

o use

the silver colored probe (of hardened steel alloy wi

t

h 6

.

35 mm diameter, 79

.

5 mm

leng

t

h, a b

l

unt conical end and a plastic guide) associated

w

ith the standard po

w

er.

Probes were fired into concrete, using

t

he driver unit, and t

h

e exposed le

n

g

t

h

w

as

measured Individually, by using a rectangu

l

ar p

l

a

t

e

,

placed over p

r

obe and

pressured agains

t

the concrete by a knurted spring-nut, and a measuring cap

threaded on top of probe

.

The distance

w

as measured

f

rom

t

op of cap to plate

w

i

t

h

the micrometer depth gauge

.

W

i

ndsor Pr

o

be T

es

t System

TEST EQUIPMENT

In an attempt to use

W

indsor Probe Test S

y

stem in

hi

gh strength conc

r

e

t

e,

pertormed by the authors

,

it

w

as foun

d

tha

t

the available

pr

ob

e

s and/or t

h

e

p

o

w

er

level are unsuitable; probes didn't pene

t

rate the co

n

crete surtace. I

t

means tha

t

probab

l

y a new probe and/or a ne

w

po

w

er leve

l

has

t

o be pro

v

ided by manufacturer

in order to be possible i

t

s use in high stre

n

gth conc

r

ete.

On the present i

n

vestigation

t

he possibility of us

i

ng a

n

a

l

temati

v

e firing a

p

para

tu

s

t

o

the traditiona

l W

indsor P

r

obe Test System

w

as e

v

aluated fo

r th

e ra

n

ge o

f

concrete

compressive strengt

h

varyi

n

g

f

rom 50

M

Pa to 90

M

Pa

.

A

p

r

e

v

ious study, comparing

the reliability of bo

t

h appara

t

us, Is a

l

so presented for

th

e

r

ange of co

n

c

r

ete

compressive strength up to 50

M

Pa.

used. One of those tech

n

iques cons

i

s

t

s on

ca

l

ibratin

g a

rel

ations

hi

p be

twe

e

n th

e

compressive strength

of a

gi

ven

conc

ret

e

and

its r

e

sis

ta

nce

to pene

tration b

y a s

t

e

el

probe

f

i

r

ed in

t

o the co

n

crete surtace. T

hi

s test, genera

ll

y

kn

o

wn

as

W

indso

r P

robe

Test System

,

has o

n

ly s

h

own its applicabil

i

ty in conc

r

e

t

es i

n wh

ich strengths are

n

o

more than 50

M

Pa (measuredIn cubes o

f

150 mm).

HIGH STRENGTHCONCRETE

The specimens

w

ere cured together at approximately 1~C and relative humidity of

65%.

A

ll the tests were performed at 28 days age lor each group of specimens and,

at the time o

f

testing

,

the specimencondition was dry.

Five differen

t

mix propo

rt

ions, cor

r

espondingto five different c

l

asses of compression

st

r

ength,

w

e

r

e produced in order

t

o obtain five sets of specimens, each one

comprising a 750x550x

1

70 mm slab and 4 cubes o

f

150 mm, all obtained by using

metallic

m

oulds

.

Each slab

w

as co

n

struc

t

ed to

w

i

t

hstand S tests of

W

PT System

and, at least, 12 tests by the

Alt

emative Firing Appara

t

us

.

The dimensions were

determined in order

t

o obtain

,

l

or standard power, the recommended edge

distances

,

member thickness and minimum dista

n

ces bet

w

een tests, given by

AST

M

standards

(a),to preven

t

splitting of

t

he member under tes

t

, structural

crackinga

n

d a

l

so to avoid overlapping 01 zones 01 inlluence

.

The mix proportions were estab

l

ished In order to fix the maximum number of

parameters.

Th

erefore,

t

he Faury modules of fineness remained exact

l

y the same

and the workability of fresh concrete

,

measured by slump test

,

was fixed between

80 mm and 120 mm.

Al

so the operations of mixing and compacting (type and

frequency)were kept cons

t

an

t

In all

t

he cast specimens.

The coarse aggregates were crushed rock from granite with

t

he max

i

mum

dimension of 25.4 mm and a Mohs

'

hardness scale level 7

.

The fine aggregate was

a natu

r

a

l

sa

n

d

f

rom the river

.

In a pre

v

ious study o

n

normal st

r

ength concrete, performed b

y t

he au

t

hors ~),

t

he

possibili

t

y of using a

n

a

lt

emative

f

iring apparatus to the traditional

W

indsor Probe

Tes

t

System

w

as evaluated

.

Prev

i

ous Studies on Normal Strength Concrete

PROCEDURE

In bo

t

h cases

t

he exposed lengt

h w

as direct

l

y measured, by using a depth gauge,

relatively

t

o the original surface of the concrete.

For high streng

t

h conc

r

ete,

t

he probe

w

as made of steel alloy with 4.5 mm diameter

a

nd

42.0 mm length, a conical end an

d

a plastic guide

.

The powder charge

w

as

l

evel 7

.

T

he probe used for normal st

r

e

n

gth co

n

crete

w

as made of s

t

eel alloy

w

iltl 4.5 mm

dia

m

e

t

er and 52

.

0 mm

l

e

n

gth, a conical end and a plastic guide

.

The po

w

der charge

w

as

l

evelS.

The

A

ltemat

iv

e

F

iring

A

p

p

aratusenables the control

o

f the energy leve

l

, delivered to

the probe by

t

he driver, as well as dif

f

erent dime

n

sions and geometries

f

or the

p

r

obe.

4

27

I

g

h

i

i

Sand (ko)

802

755

660

549

422

Coarse agg.l (kg)

241

306

399

401

503

Coarse aoo.2(ko)

730

708

670

732

716

Cement (kg)

400

425

485

535

600

Admixture

(I)10

.

0

10

.

6

12.1

13.4

15

.

0

Water!l)

142

140

1

4

5

145

157

WIC

0

.

36

0

.

33

0

.

30

0

.

27

0

.

26

T

a

b

le

1

- Basic m

i

x proportions per cubic meier

For concrete mix proportions a water

/

cement relationship based on we

i

ght varying

from 0.36 to 0.26 was considered in order to obtain the compresstve strength

between 50 MPa and 90 MPa. The cement quantity varied from 400 kg to 600 kg

per cubic meter and the workability

,

measured by slump lest

,

remained between 60

and 100 mm

.

The live basic mix proport

i

ons are presented on Table 1.

The fine aggregate is nalural sand from

t

he river

w

ith a fineness modulus about 3.5

and the coarse aggregates is a crushed rock from granite supplied with

two

gradations, classified as coarse aggregate 1 and coarse aggregate 2, with a

maximum dimension of 25.4 mm and a Mohs

'

hardness scale level 7

.

As for normal strength concrete, mix proportions were determined

i

n order to keep

constant the maximum number of parameters, such as, Faury modules of

f

ineness,

workability and the operations of mixing and compacting.

Among the types of cement available in Portugal

,

a normal portland cement

,

type I,

class 42.5R

,

class

i

fied accordingto the Portuguese Norms NP2064, was chosen.

Considering the desirable level of strength and concre

t

e producing conditions, a

superplasticizer was selected which was highly concentrated and based on

synthetic resins without air-enlraining agents. This superplastiCizerenabled a water

reduction of about 22%, keeping the same workabili

t

y.

Five different mix proportions were produced with constituent materials of the same

characteristics, which allows five different classes of compression strength between

50 MPa and 90 MPa

.

From each batch 3 standard cubes of 150 mm were produced

as well as one prismatic slab with dimensions 550x50Ox170mm

.

Studies

o

n H

ig

h Stre

n

gth Con

cr

ete

The Altemative Firing Apparatus

was

studied in order to find out its suitability and

reliability for normal strength concretes and good results were obtained. Therefore

the same study was applied to high strength concrete

w

hich is explained in this

paper.

HIGHSTRENGTH CONCRETE

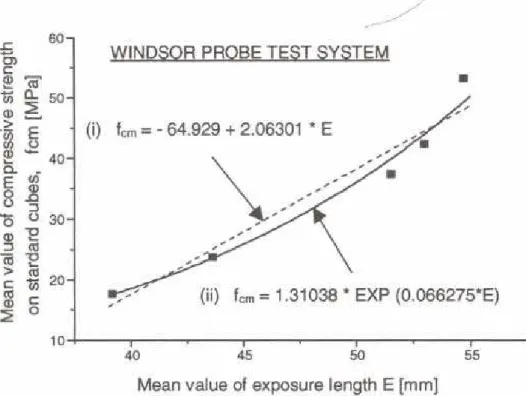

The results presented on the above Table 2 were analyzed and plotted individually for both apparatus used, as shown in Fig. 1 and Fig.2.

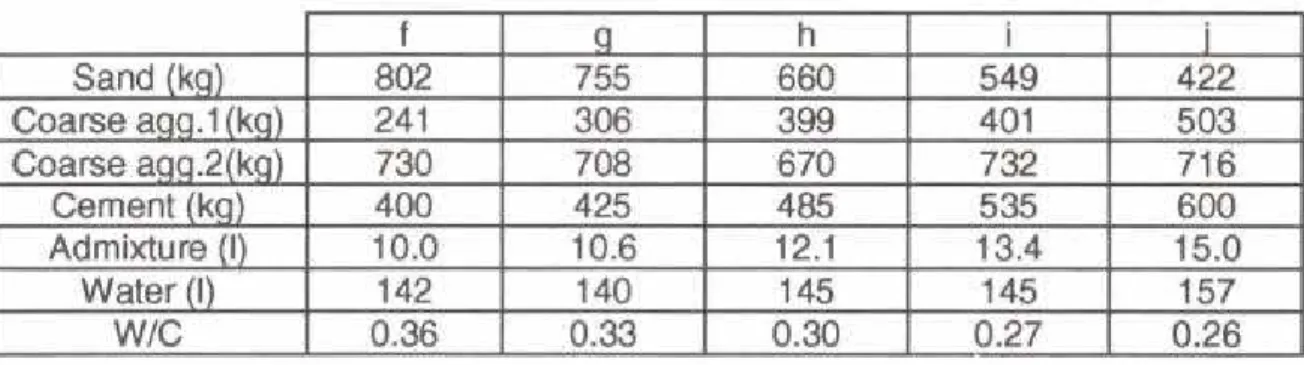

a b c

d

eCubes of 150 mm fem[MPa] 17.70 23.80 37.43 42.33 53.18

cured at 1211C, (4) (3) (4) (4) (4)

R.H. 65%, tested SOX [MPa) 0.47 2.62 0.87 1.74 1.94 drv, at 28 days CVI%] 2.66 11.00 2.32 4.11 3.65 Penetration Test E (mm] 39.14 43.59 51.52 52.97 54.70 Resistance by (6) (6) (6) (6) (5) WPT System SOX [mmJ 3.34 1.54 1.65 1.64 2.34 CV 1%1 8.53 3.53 3.20 3.10 4.27 Penetration Test E [mm] 16.40 19.82 24.53 25.08 26.92 Resistance by (17) (13) (12) (13) (17) the Altemative SOX [mmJ 1.40 0.85 1.65 0.80 1.13 Firina Apparatus CVI%l 8.54 4.29 6.73 3.19 4.20

Table 2 -Results obtained for normal strength concrete (Number in parenthesis shows the number of measurements).

Ets the mean value ofthe exposure length.

femis the mean value of compressive strength on standard cubes.

Both apparatus were simultaneously used on the same concrete and the obtained experimental results are shown In Table 2.

Previous Studies on Normal Strength Concrete ANALYSIS OF RESULTS

All specimens (slab and cubes) were cured in water at controlled temperature of 2()!!C±2!!C and ali the tests were performed at 28 days. For each batch, 3 cubes were tested for compression strength and penetration resistance tests applied on concrete slab surface by using the "Altematlve Firing Apparatus". All specimens were wet at the time oftesting.

4

29

HIGH STRENGTH CONCRETEFig. 2 - Results obtained from theAltemative Firing Apparatus lor normal strength concrete.

60

~L TERN~ TIVE FIRINQ AEP~BAI!.!S

:;

0)c

(Il....

~ 50-

VIa.as

~~.

2j

E

(iii) tem=·37.5+

3.2101 • E!!!

0.co

,a. -

_

\

,/

<;

E VI8~

- a

0 30 (Il"e,

,

'

.:2~ """as c

>

as

20(Iv)

fem= 3.1772 • EXP(0.1 02926 • E)c-as

VI (Il C ~ 010

16 18 20 22 24 26 28Mean value of exposure length E [mm)

Fig. 1-Results obtained from the Windsor Probe Test for normal strength concrete. Mean value of exposure length E[mm)

45 50 55 40

104----.----~---r----~--,_--~----,_--~

(if)

f

e

m

= 1.31038 • EXP (0.06627S·E)(i)

tern

= - 64.929+

2.06301 • E\_

,,///

~

/'•

WINDSOR PROBE TEST SYSTEM

HIGH STRENGTH CONCRETE

Fi

g

.

3 - Results obtained

I

rom the

A

ltemati

v

e F

i

ring

A

pparatus fo

r

high streng

th

Concre

t

e

.

21

17 18 19 20

M

ean value 01 e

x

posure length E [mm)

16 £;

OJ

a5

ALTER

NA

TIVE FIRING APPAR

A

TUS

.:::(i 80

"'a.

~~.

_

~'"

~ 5

a. - 70E

<Ii8~

00

Q)'O .2 (ij 60 CIl '0(

v

)

'

em::

-

81

.

5344

+8

.

02508

•

E

> c:: ~~ Q)c

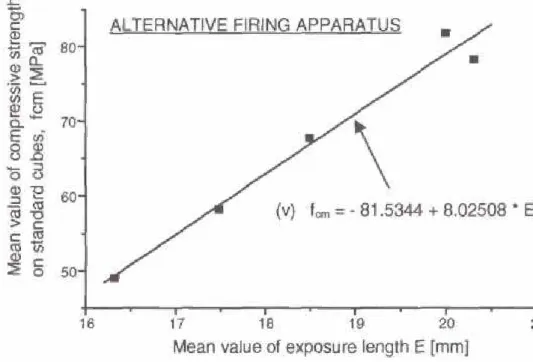

~ 0 50The obtained results (Table 3)

w

ere analyzed and p

l

otted as shown

i

n Fig

.

3

.

f

gh

I

I

Cubes o

f

150 rnm

'0m[

M

Pa)

4

9.12

58

.

27

67

.

77

7

8.35

8

1

.9

4

cured in

wat

er

(3)

(3)

(3)

(3)

(3)

at 20 !lC. tested

SOX [

M

Pal

1.02

0

.

82

1.56

2

.

17

1

.

12

w

et at 28 days

CV(

%

)

2.08

1.

4

1

2

.

30

2

.

77

1

.

37

Pene

t

ration Test

E [mm)

16

.

32

17

.

48

18.49

20.31

20.00

Resis

t

ance by

(10)

(9)

(

1

0)

(7)

(8)

t

h

e Alt

emati

v

e

SO

X (

mm}

0.92

0.97

1.64

0.56

0.8

7

Flri

nq A

pparatus

CV

(

%

1

5.64

5

.

50

8

.

87

2.7

6

4

.

35

T

able 3

- Resulls obtained for high strenglh concre

t

e

.

(Number In parenthesis shows the number of measurements)

.

E is the mean value 01the exposure length

.

l

em

Is the mean value of compressive s

t

rength on standard cubes

.

The

e

xperimental study on high strength concrete lead

t

o the

t

olowing results

presented on Table 3

.

S

t

udies

o

n

H

igh S

t

r

eng

t

h C

o

n

c

rete

411

(

1)

-

Yuan

,

Robert L

.

;

Ragab

,

Mostala

;

H

ill,

Robert E.

;

Cook

,

James E. - Evaluat

i

on

of Core Strength

i

n H

i

gh

-

Strength Concrete

,

Concrete Internati

o

nal

,

Vol. 13

.

pp 30

to

3

4

,

May 1991

.

(2) - Price

,

W. F

.

;

Hynes. J

.

P

.

-

I

n-s

i

tu Strength Test

i

ng of H

i

gh Strength Concrete.

Magazine of Concrete Research,48

,

N!l176

,

pp 189 to 197, Sept

1996

.

REFERENCES

E

- is the mean value of

the exposure length

.

f

em - I

s the mean value of compress

i

vestrength on standard cubes

.

SDX -

is the Standard deviation

.

CV

-

is

the Coeffic

i

ent of variation

.

R

.

H.

-

is the relative hum

i

dity

.

NOTATION

The authors

would like to thank the Univers

i

ty of Be

i

ra Interior for providing the

laboratory conditions and to

Mr. Armando

M

.

C

.

Trindade for h

i

s precious

collaboration

in the laboratory

works

.

They would like

to extend the

i

r thanks to the Univers

i

ty of Co

i

mbra and JNICT

research project ref.

PBIC/C/CEG/2384/95.ACKNOWLEDGMENTS

Other aspect that cannot be ignored

i

s the h

i

gher cost of WPT System equ

i

pment

and probes

in Europe when compared

w

i

th the Altemative Firing Apparatus

.

It is clear and mentioned by different authors (Q.

n

that. as most other

non-destructive

tests. aggregate characteristics and other factors may have a

considerable influence on the results and, therefore

,

the valid

i

ty of calibration tables

has to be carefully analyzed for each Situation.So

.

the results presented

on

Fig

.

1

.

Fig.

2 and

Fig

.

3 are valid for

the

established condit

i

ons of th

i

s

i

nvestigation

.

The main

physical limitation of penetration resistance

tests is

the surface damage

and the danger of splitting of members,which limits

the zones of testing. However. it

was found that the Altemative F

i

ring Apparatus causes less damage than

WPT

System

.

Consequently

,

m

i

nor distances between probes are possible

.

Penetration resistance tests applied to high strength concrete, using the

Altemative

Firing

Apparatus has shown

a linear correlation, Fig.

3.

which probably can be

impute to more closeness between cement paste and aggregate strength.

The results obta

i

ned for the range

o

f norma

l

strengt

h

concrete, Fig. 1 and Fig. 2,

showed that the A

lt

emat

i

ve Fi

rin

g Apparatus

co

uld be

a

suitable mean for the

assessment of "in-situ

·

strength, and gives a good agreement when compared to

Windsor Probe Test System

@

.

When testing high strength concrete (Fig. 3), the

Altemative Firing

Apparatus appears

to be

particularly useful since the results

obtained so far are very consistent.

CONCLUSIONS

HIGH STRENGTHCONCRETE 432

(3)

-

A

ST

M

Ca03-90

.

Standard

T

est

M

ethod for Pe

n

etration Res

i

s

t

a

n

ce of Harde

n

ed

Con

c

rete

.

American So

ci

ety for Testing and

M

ateria

l

s

.

(4) - BS 1881

:

Part 207

:

1992 - Recommendat

i

onsfor

t

he assess

m

en

t

of concrete

strength by near

-

to

-

surface

t

ests

.

British Standards Institutio

n

,

L

ondon

.

(

5

)

- Lopes

,

Serg

io;

Nepomuceno,

M

iguel

-

A Compa

r

a

t

i

v

e S

tu

d

y

of Penetration

Resistance Apparatus on Concrete

,

ICCEJ

4

,Ha

w

aii

,

Ju

1

1997

.

(

6

) -

Bungey

,

J. H. - Testing by Pene

t

ra

ti

on Resis

t

ance - Concre

t

e,

V

ol. 15,

N

il

1

,

Jan

.

1981

,

pp 30 to 32.

(7)

-

Bungey

,

J. H

.;

M

illard

,

S. G

.

-

Testing of Co

n

crete in

St

ructures

,

3 ed

.,

Chapman

&Hall

,

London - UK.

,

1996.

433