MODELING RELEASE OF CHEMICALS FROM MULTILAYER

MATERIALS INTO FOOD

by

Xiu-Ling HUANG a,b*, Xiao ZHANG a, Xian-Tao ZHANG a, and Kit L. YAM c

a School of Mechatronics En gi neer ing and Au to ma tion, Shang hai Uni ver sity, Shang hai, China b Jiangsu Key Lab o ra tory of Ad vanced Food Man u fac tur ing Equip ment & Tech nol ogy,

Jiangnan Uni ver sity, Jiangsu, China

c School of En vi ron ment and Bi o log i cal Sci ences, Rutgers, State Uni ver sity of New Jer sey,

N. J., USA

Orig i nal sci en tific pa per DOI: 10.2298/TSCI1603839H

The mi gra tion of chem i cals from ma te ri als into food is pre dict able by var i ous math e mat i cal mod els. In this ar ti cle, a gen eral math e mat i cal model is de vel oped to quan tify the re lease of chem i cals through multilayer pack ag ing films based on Fick's dif fu sion. The model is solved nu mer i cally to elu ci date the ef fects of dif fer ent diffusivity val ues of dif fer ent lay ers, dis tri bu tion of chem i cal be tween two ad ja cent lay ers and be tween ma te rial and food, mass trans fer at the in ter face of ma te rial and food on the mi gra tion pro cess.

Key words: model, controlled release, migration

In tro duc tion

Mi gra tion of chem i cals, such as plasticizers and other trim mer pro duced dur ing pack ag ing man u fac tur ing, has been a ma jor con cern for food pack ag ing in dus try and has been stud ied ex ten sively [19]. The abil ity to pre dict the mi gra tion is crit i cal to as sess the haz ards. How -ever, the cur rent pre dic tive mod els have many lim i ta tions, and the most ac cu rate pre dic tive val ues were ob tained from sim ple Crank's model [10, 11], which are valid only for uni form pack ag ing ma te ri als, and the pre dic tion be comes com pletely in valid for multi-layer cases, which has a com plex bound ary and ini tial con di tions, and each layer fol lows dif fer ent diffusivity of chem i cals [12, 13].

The ob jec tive of this pa per is to de velop a gen eral mi gra tion model for multi-layer film con sist ing of dif fer ent ma te ri als. In this model, one-di rec tion mi gra tion, dif fer ent diffusivities of mi grants in dif fer ent lay ers, par ti tion co ef fi cient be tween two lay ers, par ti tion co ef fi cient be tween ma te rial and food, and mass trans fer co ef fi cient be tween ma te rial and food are con sid -ered. A se ries of equa tions are de vel oped based on Fick's dif fu sion, and solved nu mer i cally by fi nite dif fer ence method [14-16].

Mod el ing As sump tions

The as sump tions of this model are:

– all the layers are in perfect contact. Migrant is from the outermost layer to food, fig. 1, – at the initial stage, the initial concentration of migrant is uniform in the outmost layer, – the migration is in one direction, i. e. from the outermost layer into food, there is no

migration from the packaging film into air, and there is a finite coefficient of mass transfer, hm, from innermost contact layer to food,

– the migration in each layer follows Fick's diffusion, and diffusivities of migrant in each layer are constant,

– the partition coefficients of a migrant are constant at the interface of adjacent packaging layers, and between packaging and food, and

– there is no migration of food into the package.

Model de vel op ment

The model is de vel oped based on Fick's dif fu -sion model:

¶

¶

¶

¶ C

t D

C

x l x l j N

j j

j

j j

= - < < £ £

2 , 1 , 1 (1)

where Cj is the con cen tra tion of mi grant in layer,

j, at po si tion, x, and time, t. Dj is the diffusivity in layer, j.

The ini tial con di tions are:

– t = 0

C1 =Cin 0< <x l1 (2)

Cj =0 l1< <x lN (3)

where Cin is the ini tial con cen tra tion of mi grant in the out er most layer.

The bound ary con di tions ex press the fact that there is no ex ter nal trans fer at x = 0; the flux of com pound is con stant whereas the con cen tra tion is not con stant at x = lj:

– t > 0

¶

¶ C

x x

1 =0, =0 (4)

D C

x D

C

x x l j N

j j

x l j

j

x l

j

j j

¶

¶

¶

¶

=

+ +

=

= 1 1 = £ £

-1 1

, (5)

Cj+1 =k Cj j, x=lj 1£ £j N -1 (6)

- = æ

-è

çç ö

ø

÷÷ =

=

D C

x h C

C

k x l

x l

m N

M

N N N F

N

¶

¶ , (7)

C

C V M

V

m j

j N

F in

F

=

- å

=1

where kj and kN are the con stant par ti tion co ef fi cient of com pound at the in ter face be tween ad ja -cent lay ers, and be tween pack ag ing film and food, re spec tively. The hm is the con stant mass trans fer co ef fi cient of mi grant at the in ter face be tween the in ner layer and food. The CF is the con cen tra tion of the mi grant in food, and VF is the vol ume of food.

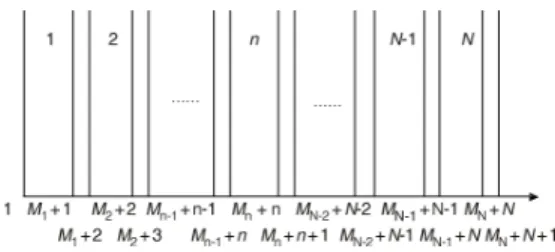

The pack ag ing film is di vided into a uni form mesh in the di rec tion along film thick ness, fig. 2, in which lN is di vided into M parts (h is mesh size, Mjrep re sents j layer ma te rial); re lease time,

T, is di vided into n parts (time step is t). The in -ter faces be tween ad ja cent lay ers are con sid ered to be sep a rated for the con ve nience of cal cu la -tion, wherein l, Mj + j, Mj–1 + j, MN + N + 1 in di -cate the in ter face of pack ag ing ma te rial and air, j

layer ma te rial right bound ary, j layer ma te rial left bound ary, and chem i cal lo ca tion in food, re spec

-tively. Ac tu ally, Mj + j and Mj + j + 1 are all rep re sented in the size x = lj. The fol low ing signs are in tro duced [14, 15]:

C C C C C C

i k

i k

i k

i k

i k

i k

t

- +

-

-= + = +

( / )

( / )

( ), ( ),

1 2 1

1 2 1

1 2

1 2

s C C C

C

h C C

i k

i k

i k

x ik ik ik

-

--

-=

-=

-( / )

( / )

( ),

( ),

1 2 1

1 2 1

1

1

t

s s s s

x2Cik h xCik 1 2 xCik 1 2

1

= ( + - - )

( / ) ( / )

Equa tions (1)-(8) can be con verted into:

1 2

1 2

1 2 1 2

1 2

1 2 2

s s s

t ji k

t ji k

j x ji

C --( / )( / ) + C +-( / )( / ) -D Ck-( / )1 2 =0

1£ £j N, Mj-1 + + £ £j 1 i Mj + -j 1 1, £k £TN (9)

C10i C i M

1

2 1

= in, £ £ + (10)

Cji0 j N M i M N

1

0 2 2

= , £ £ , + £ £ N + (11)

s s

tCk x k

D

h C k T

1

1 2 1 1

1 2

1 1 2 1 1 2

2

1

+ +

- = - £ £

( / ) ( / ) ( / ) ( / ),

N (12)

Left bound ary of j layer:

s s

t jM

k j

x jM

k i

C D

h C

D

j- + +j j- + +j

- = - -

-1 1 2 1 1

1 2 1 2

( / )

( / ) ( / ) 1

1 1 2

1 1 2 1

h xCj M j N k T

k

j j s

-- + -- £ £ £ £

( / )

, , N (13)

Right bound ary of j layer:

s s

t jM j

k j

x j M j

k i

C D

h C

D h

j+ - j

- +

+ + +

-=

-( / )

( / ) ( / )

1 2

1 2 1

1 1

1 2 s

x jM

k

C j N k T

j+ -j

- £ £ £ £

1

1 2 2 1

( / ), ,

N (14)

C k C j N k T

j M j

k

j jM j

k

j j

+ + +

-+

-= £ £ - £ £

1 1

1 2 1 2 1 1 1

( / ) ( / ), ,

N (15)

s

t NM M

k m

NM M

k FM N

k

C h

h C

C

N N

N +

-+

- + +

-+

-( / )

( / ) ( / )

(

1 2

1 2 1 2 1

1 2

1 1 2 0 1 / )

( / ) ,

k

D

h C k T

N

N

x NM N

k

N

N æ

è ç ç

ö

ø ÷

÷+ + - = £ £

-s (16)

C

C V h C C

FM N

k

in jM j

k jM j k N j j + + - + -+ -= - + -1 1 2 1 1 2 1 2 1 ( / )

( / ) (1 2 1 1 2 1 1 1 1 / ) ( / ) æ è çç ö ø ÷÷

å + å å

= -= + + + -= -j N i k

i M j

M j j N h C j j

VF k N

- £1 £ (17)

The cor re spond ing fi nite dif fer ence scheme is:

( ) ( ) ( )

( )

1 2 2 1

1 1 1 1 - + + + - = = + - +

-r C r C r C

r C

j kji j jik j kji

j jik +(2-2r Cj) kji-1 +(1+r Cj) kji+-11, 1£ £j N, 1£k£TN (18)

Ini tial con di tions:

C10i C i M

1

1 1

= £ £ +

in (19)

Cji0 j N M i MN N

1

0 2 2

= , £ £ , + £ £ + (20)

Bound ary con di tions:

(1 1) 11 (1 1) 12 (1 1) 111 (1 ) , 1

1 121

+r Ck + -r Ck = -r Ck- + +r Ck- £k T

N

£ (21)

Left bound ary of j layer:

- - - + - + - - + - + + +

- -

-rj C r C r C

j M j

k

j kj M j j jM

j j j

1 1 1 2 1 1 1 1 (1 ) k 1 j j kjM j

j j M j

k

j j

r C

r C r C

j j + - = = -+ -+ - -- + - -

-(1 )

1 1

1

1 11 2 1 k 1M j j jM j k

j jM j

k

j-+ - r C j- r C j

-+ -+ -+ -+ - + +

1 1 1 1

1 1 1 1 1 1 2 ( ) ( )

£ £j N, 1£k £TN (22)

Right bound ary of j layer:

(1 ) (1 )

1 1 1 1 1

-r Cj + - + +r C + +r+ C + + + -r+

jM j k

j jM j

k

j j M j

k

j

j j j

C

r C r C r

j M j

k

j jM j

k

j jM j

k j j j j + + + + -+ -+ = = + + - -1 2 1 1 1 1 1

( ) ( ) 1

1 1

1

1 1 2

1

1 1 1

C r C

j N k T

j M j

k

j j M j

k

N

j j

+- + + + + +- + +

£ £ - , £ £ (23)

Cjk M j k Cj kjM j j N k TN

j j + + + -+ -= £ £ - £ £ 1 1

1 2 1 2 1 1 1

( / ) ( / ), , (24)

1 1 2 1 1 2 1 -æ è ç ö ø

÷ +æ + +

è

ç ö

ø

÷

-+ - +

r C r h

h C

h

N NM N

k

N m NM N

k m

N N

t t

hK C

r C r h

h

N

FM N

k

N NMk N N m

N N + + + -=

=æ +

è

ç ö

ø

÷ +æ -

-1 1 1 1 1 2 1 1 2 t è ç ö ø ÷ + £ £ + -+ + -C h hK C k T NM N k m N

Mk N

N N N 1 1 1 1 t (25) 1 2 1 1 1 1 1

h C C h C

jM k

jM j k

ik

i M j

M j j j j j -+ + = + + + -+ æ è çç ö ø

÷÷ + å å + =

å = - -+ + = = + + -+ -V C

V C h C

F FM N

k

j N

j N

F FM N

k jM j N N j 1 1 1 1 1 1 2 1 k jM j k ik

i M j

M j

C h C C

j j j -+ - -= + + + -+ æ è çç ö ø

÷÷ - å +

-1 1 1

1 1

1

2 inV

k T m j N j N N = = å å £ £ 1 1 1 (26)

Con clu sion

The pa per re ports a gen eral math e mat i cal model aim ing to pre dict the mi gra tion of chem i cals from multilayer pack ag ing ma te rial into food. Many im por tant pa ram e ters are con -sid ered in the model, such as dif fer ent dif fu sion co ef fi cient, dif fer ent par ti tion co ef fi cient, and trans mit co ef fi cient at the in ter face of ma te rial and food. Nu mer i cal so lu tion is given by it er a -tive com pu ta tion from fi nite dif fer ence method.

Ac knowl edg ment

The work is sup ported by the Open ing Fund of Jiangsu Key Lab o ra tory of Ad vanced Food Man u fac tur ing Equip ment & Tech nol ogy at Jiangnan Uni ver sity (FM-201508).

Ref er ences

[1] Lin, Q. B., et al., Anal y sis of Isothiazolinone Biocides in Pa per for Food Pack ag ing by Ul traHighPer for -mance Liq uid Chro ma tog ra phy-Tan dem Mass Spec trom e try, Food Ad di tives and Con tam i nants, 27

(2010), 12, pp. 1775-1781

[2] Mai, H. T., et al., De ter mi na tion of 2,4,6Triiodoresorcinol and other Side Re ac tion Prod ucts and In ter me di ates in the Color Ad di tive FD&C Red No. 3 (Eryth ro sine) Us ing HighPer for mance Liq uid Chro ma tog -ra phy, Food Ad di tives and Con tam i nants, 23 (2006), 6, pp. 547-551

[3] Zhu, X., et al., Re lease Prop erty and An ti ox i dant Ef fec tive ness of Tocopherol-In cor po rated LDPE/PP Blend Films, Food Ad di tives and Con tam i nants, 29 (2012), 3, pp. 461-468

[4] Huang, X. L., et al., Fac tors Af fect ing Mi gra tion of Con tam i nants from Pa per through Poly mer Coat ing into Food Simu lants, Pack ag ing Tech nol ogy and Sci ence, 26 (2013), Suppl. 1, pp. 23-31

[5] Gemili, S., et al., De velop- Ment of Cel lu lose Ac e tate Based Antimicrobial Food Pack ag ing Ma te ri als for Con trolled Re lease of Lysozyme, Jour nal of Food En gi neer ing, 90 (2009), 4, pp. 453-462

[6] Pires, C., et al., Hake Pro teins Edibile Films In cor po rated with Es sen tial Oils: Phys i cal Me chan i cal, An ti -ox i dant and An ti bac te rial Prop er ties, Food Hy dro col loids, 30 (2013), 1, pp. 224-231

[7] Chen, X., et al., Re lease Ki net ics of Tocopherol and Quercetin from Bi nary An ti ox i dant Con trolledRe -lease Pack ag ing Films, Jour nal of Ag ri cul ture and Food Chem is try, 60 (2012), 13, pp. 3492-3497 [8] Bierhalz, A., et al., Natamycin Re lease from Alginate/Pec tin Films for Food Pack ag ing Ap pli ca tions,

Jour nal of Food En gi neer ing, 110 (2012), 1, pp. 118-125

[9] Wang, Z. W., et al., A Sys tem atic Study on the Sta bil ity of UV Ink Photoinitiators in Food Simu lants Us -ing GC, Pack ag ing Tech nol ogy and Sci ence, 22 (2009), 3, pp. 151-159

[10] Mastromatteo, M., et al., Con trolled Re lease of Thymol from Zein Based Film. In no va tive Food, Sci ence

and Emerg ing Tech nol o gies, 10 (2009), 2, pp. 222-227

[11] Balasubramanian, A., et al., Ef fect of Nisin's Con trolled Re lease on Mi cro bial Growth as Mod eled for Micrococcus Luteus, Probiotics & Antimicro, 3 (2011), 2, pp. 113-118

[12] Huang, X. L., et al., Re lease Math e mat i cal Model of Ac tive Agent from Pack ag ing Ma te rial into Food,

Math e mat i cal Prob lems in En gi neer ing, 2013 (2013), ID 607546

[13] Huang, X. L., et al., Mi gra tion Model of Chem i cal Sub stances from Pa per-Plas tic Pack ag ing Ma te rial Into Food, Jour nal of Ap plied Pack ag ing Re search, 6 (2012), 3, pp. 165-183

[14] Sun, Z. Z., A Sec ond-Or der Dif fer ence Scheme for a Model of Oil De pos its, Acta Mathematicae

Applicatae Sinica, 20 (1997), 4, pp. 551-558

[15] Sun, Z. Z., A Sec ond-Or der Ac cu rate Dif fer ence Scheme for the Hy per bolic Prob lem with Con cen trated Data, in: Nu mer i cal Anal y sis and Its Ap pli ca tions, Pro ceed ings (Eds. S. Margenov, L. Vulkov, J. Wasniewski), 4th In ter na tional Con fer ence, NAA 2008, Lozenetz, Bul garia, 2008 Springer, 2009, pp.

556-563

[16] Beibalaev, V. D., Shabanova, M. R., A Fi niteDif fer ence Scheme for So lu tion of a Frac tional Heat Dif fu -sion-Wave Equa tion with out Ini tial Con di tions, Ther mal Sci ence, 19 (2015), Suppl. 1, pp. S157-S162