ISSN 0976-2612, Online ISSN 2278–599X, Vol-7, Special Issue-Number4-July, 2016, pp767-775

http://www.bipublication.com

Research Article

Analysis of the Turbulent Flow of Nanofluid Containing Ethylene Glycol and

Water Base Fluid by using the Fluent Model

Ata Salari1 and Mohsen Irandoust*2

1MSc in Water Structure, Department of water engineering ,

kerman branch, Islamic Azad University, kerman, Iran 2Assistant professor, Department of Water Engineering,

Kerman branch, Islamic Azad University, Kerman, Iran

Irandostmo@gmail.com*

ABSTRACT:

Given that the use of nano-fluids has increased in heat exchangers and since the flow regime in heat exchangers is often turbulent, justifying the effectiveness of using nano-fluids requires studying the nano-fluids turbulent flow. Analysis of nano-fluids steady flow, containing water-based fluid and aluminum oxide nanoparticles AR, AF and AK, has performed in developing and fully developed turbulent flow, in the pipe with a diameter of 150 mm and a length of 30 m by Gambit and Fluent software. After examining the independence of numerical results from the network, the results of numerical modeling were compared with the experimental results and given the consistency of numerical results with existing relationships; created model was used to study the nano-fluids flow. In this study, the impact of the type of nanoparticles on the parameters of nano-fluids flow in turbulent flow regime has been thoroughly investigated. in case of using ethylene glycol in the nano-fluid suspension, it might be because it has the pressure drop of 1437 Newton per meter squared, the shear stress of 0.74428 Pascal, the friction coefficient of 0.0415804 and the viscous drag force of the pipe wall of 24.884367 Newton due to having higher viscosity. Therefore, out of the two reviewed base fluids, water is economically preferred in the nanofluid suspension.

Key words: nano-fluid, pipe, turbulent flow, simulation

1- INTRODUCTION:

With the development of modern technology in various industries, increasing heat transfer, reducing the time of heat transfer, downsizing the heat exchangers and increasing energy and fuel efficiency are the serious needs. Cooling has raised as one of the most important challenges in energy savings and increased productivity of many industries [1]. The first serious obstacle in compressing the heat transfer devices and making them efficient is the common weak heat transfer properties of fluids.Cooling systems are one of the main concerns of factories and industries such as

cooling systems are required. Given that justifying the effectiveness of using nano-fluids requires studying the nano-fluids turbulent flow in the pipe (as a common geometry), the parameters of nano-fluids in pipe has been studied numerically and the impact of different parameters such as volume fraction of nanoparticles, type of nanoparticle, type of base fluid, Reynolds number of flow and volumetric flow rate on the flow of nano-fluids has been investigated fully. If the nano-fluid is used in cooling systems, the capability of these systems will be increased in terms of reducing energy consumption and increasing their efficiency due to the better heat transfer properties of nano-fluids, such as thermal conductivity and convection heat transfer coefficient, than common fluids of heat transfer such as water or ethylene glycol. So, the use of nano-fluids reduces the costs due to reduced energy consumption and will lead to a more efficient implementation of a cooling project [9].

Mirmasoomi, et al., in the year 2008, studied the movement of water-alumina combined Nanofluid's movement in the fully developed area numerically. Their analysis, which included considering a two-phase mixture model, had the results that the convection heat transfer coefficient increased considerably by reducing the average diameter of the nanoparticles [5].

Convection heat transfer of nanofluids includes alumina nanoparticles in the laminar flow in the internal thermal regime which were reviewed by Kim, et al. in 2013.

In their experimental study, which was confirmed for water fluid, they found out that by reducing the thermal conductivity of nanofluids and by reducing the thermo-physical properties, the heat transfer coefficient is reduced. They also expressed that the heat transfer coefficient of the nanofluids is always lower than the water base fluid or it is equal to it [7].

1-2- Thermo-physical properties of nanofluids Given that suspension nanofluid is composed of nanoparticle and base fluid, its thermo-physical properties are the combination of nanoparticle

properties and base fluid’s properties. In this study, following equations were used to calculate thermo-physical properties of nanofluid [8]. 1-2-1- The density of nanofluids

indicates the density of nanofluid which

estimated by eq.(1-1) [6]:

(1-1)

and are the density of base fluid and the

density of nanoparticles, respectively and is the volume fraction.

1-2-2- The viscosity of nanofluids

is the viscosity of nanofluid which estimated

by eq.(1-2) [11]:

(1-2)

is the viscosity of base fluid and is constant.

Einstein considered a equal to 2.5 in his proposed equation to calculate the viscosity of nanofluids. For nanofluids, it is greater than 2.5 because nanoparticles have more volume in suspension than the microparticles.

Using the experimental results by Chan et al. [10], for three aluminum oxide nanoparticles AR, AK and AF, a has been estimated equal to 4.9407, 3.5573 and 15.4150, respectively.

1-3- Calculation of thermo-physical properties of nanofluids

In this study, three aluminum oxide nanoparticles (AR, AF and AK) were used that are different in terms of surface, size and shape [12].

The reasons of choosing aluminum oxide can be summarized as follows:

Metal oxides such as aluminum oxide, are chemically more stable than metals in suspension.

Aluminum oxide nanoparticles show good stability in different PH in suspension.

Nanoparticles, containing aluminum oxide, have high heat transfer.

Nanofluids containing aluminum oxide nanoparticles have excellent stability without

any additive.

Table 1-1 shows the properties of various base fluids:

Table 1-1: physical properties of the base fluids

Fluid

density Viscosity

Liquid water 998.2 0.001003

Ethylene glycol 1111.4 0.0157

Table 1-2 shows the physical properties of aluminum oxide nanoparticles. Table1-2. Physical properties of aluminum oxide nanoparticles [15]

Aluminum oxide AK AR AF

Company Degussa N&A Materials

Size(mm) 43 27-43 7

Shape Spherical Spherical bar

Surface Hydrophobic hydrophilic hydrophilic

Density

3970 3970 3970

1-3-1- The density of nanofluids Eq. (1-1) was used to calculate the density of nanofluids. Figure 1-1 shows the density of nanofluids in terms of different volume fractions:

Figure1-1. The density of nanofluids containing various base fluids

Given figure 1-1, it is observed that the density of nanofluids is more than base fluid and it increases by increasing volume fraction of nanoparticle, because all of the nanoparticle used in this study are of aluminum oxide, so, figure 1-1 represents

the density of all nanofluids containing various base fluids [13].

1-3-2- The viscosity of nanofluids

nanofluids consisting of water-based fluid and nanoparticles of AR, AF and AK.

Figure 1-2: viscosity of water- aluminum oxide nanofluids (AK, AR, and AF)

In figure 1-3, the nanofluids viscosity composed of ethylene glycol base fluid and AF, AR and AF nanoparticles have been shown:

Figure 1-3: viscosity of aluminum oxide-ethylene glycol nanofluids (AK, AR, and AF)

As it has been shown in figures 1-2 and 1-3, the viscosity of the nanofluids is more than the base fluids and it is increased as the volume fraction of the nanoparticle increases. As shown in figure 1-2, the nanoparticle of AF increases the viscosity more than two other nanoparticles and the nanoparticle of AK has higher viscosity than the nanoparticle of AR in suspension. Given the eq. (1-2), the value of a is maximum for aluminum oxide nanoparticle of AF and minimum for the aluminum oxide nanoparticle of AR and given this equation, there is a direct relationship between a and the viscosity of nanofluids, so, the nanofluid

containing aluminum oxide nanoparticle of AF has the highest viscosity and the nanosluid containing the aluminum oxide nanoparticle of AR has the lowest one [14].

2- MATERIAL AND METHODS

geometry, meshing the solution field was performed by the use of tetrahedral elements. A non-uniform network with the non-uniformity coefficient of 1.1 was used to chop the network near the wall, because, severe gradients occur quickly in the wall of pipe. Applied boundary conditions were the boundary conditions of

velocity inlet, pressure outlet and upper wall. In addition to axial asymmetry in a proposed geometry, the boundary of axis is assigned to the lower boundary of pipe because of reducing the computing costs, so, only half of the problem was analyzed in software. Figure 2-1 shows the created network in Gambit software:

Figure 2-1. Network created in Gambit software

2-1- Confirmation of numerical work

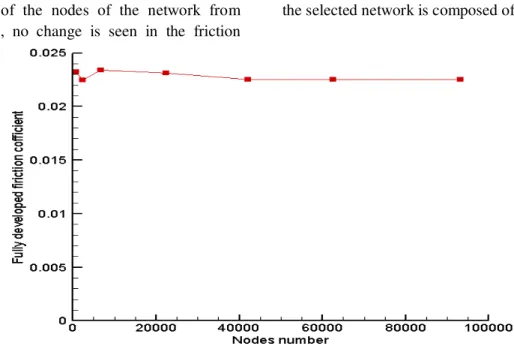

2-1-1- Reviewing the independency of the results of created network As it has been shown in figure 2-2, by increasing

the number of the nodes of the network from 42084 nodes, no change is seen in the friction

coefficient in the fully developed area; therefore, the selected network is composed of 42084 nodes.

Figure 2-2: reviewing the independency of the results of the friction coefficient of the created network

2-1-2- Comparing the friction coefficient In order to confirm the results obtained from numerical simulation, the results of the friction coefficient of modeling have been compared with the results of the Petukhov friction equation [16]. The experimental Petukhov relation, which is used in a wide spectrum of the Reynolds numbers

for calculating the friction coefficient in the fully developed area in the Turbulent flow regime, is calculated from the equation below:

Figure 2-3 shows the comparison between the results of numerical simulation of the friction coefficient in the fully developed area and the

experimental Petukhov relation for various Reynolds numbers in the turbulent flow:

Figure 2-3: comparing the results of the friction coefficient of the present work with the results of Petukhov relation

As it is seen in figure 2-3, there is a very good compliance between the numerical results and the results of the experimental Petukhov relation with a difference percentage of approximately one percent.

2-2- Reviewing the impacts of base fluids In the reviewed modes, the fluid pressure exiting the pipe is 1 atmosphere. In order to review the impact of the base fluid on the parameters of nanofluids flow, the aluminum oxide-water nanofluid AR with a volume fraction of 2 percent has been used. The speed of the entrance of the

nanofluid to the pipe has been considered to be equal to 0.5358976m/s.

2-2-1- Reviewing the impact of the base fluid on the friction coefficient in the fully developed area

In order to review the impact of the base fluid on the friction coefficient in the fully developed area two base fluids with completely different physical properties have been used which are: water and ethylene glycol. The nanoparticle used here is AR aluminum oxide with the volume fraction of 2 percent. In table 2-1, the impact of the base fluid on the friction coefficient in the fully developed area has been reviewed.

Table 2-1: reviewing the impact of base fluid on the friction coefficient in the fully developed area

Base Fluid Water Ethylene glycol

The friction coefficient in

the fully developed area 0.0190154 0.0415804

As it is seen in table 2-1, the nanofluid containing ethylene glycol base fluid has the highest friction coefficient, equal to 0.0415804, in the fully developed area due to having a higher viscosity and the nanofluid containing water base fluid has the lowest one with the coefficient of 0.0190154. 2-2-2- Reviewing the impact of base fluid on the shear stress of the wall of the pipe in the fully developed area

Table 2-2: reviewing the impact of the shear stress of the wall of the pipe in the fully developed area

Base Fluid Water Ethylene glycol

The shear stress of the wall of the pipe in the fully developed area (Pascal)

0.721939 1.74428

The nanofluid containing ethylene glycol base fluid has the highest shear stress in the fully developed area, equal to 1.74428 Newton per meter squared, due to having the highest shear stress and the nanofluid containing water base fluid has the lowest one with the shear stress of 0.721939.

Since the nanofluid containing ethylene glycol base fluid has higher viscosity, thus it has the maximum shear stress.

2-2-3- Reviewing the impact of base fluid on the pressure drop created between the inlet and outlet pipes

In order to review the impact of the base fluid on the pressure drop created between the inlet and outlet pipes, two different base fluids have been used: water and ethylene glycol. The nanoparticle used here is AR aluminum oxide with the volume fraction of 2 percent. In table 2-3, the impact of the base fluid on the pressure drop has been reviewed.

Table 2-3: reviewing the impact of the base fluid on the pressure drop

Base Fluid Water Ethylene glycol

Pressure drop (Pascal) 592 1437

As it is seen, the nanofluid containing ethylene glycol base fluid creates the highest pressure drop with the rate of 1437 and the nanofluid containing water base fluid imposes the lowest drop pressure on the system for the rate of 592 Pascal. The cause of such matter is the viscosity of the nanofluid containing ethylene glycol base fluid. 2-2-4- Reviewing the impact of base fluid on the viscous drag force of the pipe wall

In order to review the impact of the base fluid on the viscous drag force of the pipe wall, two different base fluids have been used: water and ethylene glycol. The nanoparticle used here is AR aluminum oxide with the volume fraction of 2 percent. In table 2-4, the impact of the base fluid on the viscous drag force of the pipe wall in case of using nanofluids containing different base fluids has been reviewed.

Table 2-4: reviewing the impact of the base fluid on the viscous drag force of the pipe wall

Base Fluid Water Ethylene glycol

The viscous drag force of the pipe

wall (Newton) 10.313886 24.884367

As it is seen, the nanofluid containing ethylene glycol base fluid creates the highest viscous drag force of the pipe wall with the rate of 24.884367 Newton and the nanofluid containing water base fluid has the lowest rate with the rate of 10.313886 Newton. The cause of such matter is the viscosity of the nanofluid containing ethylene glycol base fluid. Since the nanofluid containing ethylene glycol base fluid has higher viscosity than the nanofluid containing water base fluid,

thus it has the maximum viscous drag force of the pipe wall.

3- CONCLUSION

numerical results from the network, the numerical results of friction coefficient were compared with the experimental results of Petukhov’s equation and the comparison showed the consistency of numerical results with it. In this study, the impact of different parameters such as type of nanoparticle and type of base fluid on the friction coefficient, shear stress of pipe wall, viscous drag force of wall and pressure drop have been investigated fully. Among the two reviewed base fluids, water has the friction coefficient of 0.0190154 and the shear stress of 0.721939 Newton per meter squared in the fully developed area and also imposes the pressure drop of 592 Newton per meter squared on the system and has the viscous drag force of the pipe wall of 10.313886 Newton. And in case of using ethylene glycol in the nanofluid suspension, it might be because it has the pressure drop of 1437 Newton per meter squared, the shear stress of 0.74428 Pascal, the friction coefficient of 0.0415804 and the viscous drag force of the pipe wall of 24.884367 Newton due to having higher viscosity. Therefore, out of the two reviewed base fluids, water is economically preferred in the nanofluid suspension

REFERENCES:

1. Maxwell J.C.,A, 1881. Treatise on Electricity and Magnetism, second ed., ClarendonPress, Oxford, UK.

2. Jang,S.P., Choi, S.U.S., 2004. Role of brownian motion in the enhanced thermal conductivity of nanofluids, Applied Physics

Letters, Vol. 84, No.21, pp.4316-4318.

3. D.Wen, Y.Ding, Experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions, International Journal of Heat and

Mass Transfer,47,(2004),pp.5181-5188.

4. S.Zeinali Heris, S.G.Etemad, M.Nasr Esfahany, Experimental investigation of oxide nanofluids laminar flow convective heat transfer, International Communications in Heat and Mass Transfer 33 (2006) 529-535.

5. D.Kim, Y.Kwon, Y.Cho, C.Li, S.Cheong, Y.Hwang, J.Lee, D.Hong, and S.Moon, Convective heat transfer characteristics of nanofluids under laminar and turbulent flow conditions, Current Applied Physics, 9 (2009) 119-123.

6. P.Kumar, R.Ganesan, A CFD Study of Turbulent Convective Heat Transfer Enhancement in Circular Pipe flow, International Journal of Civil and Environmental Engineering 6 (2012) 385-392. 7. M.T.Naik, E.Vojkani, G.Ravi, Numerical

Investigation of Turbulent Flow and Heat Transfer Characteristics of PGW-CuO Nanofluids, International Journal of Mining, Metallurgy & Mechanical Engineering (IJMMME) Volume 1, Issue 2 (2013) ISSN 2320–4060 (Online) 141-145.

8. L. Syam Sundar, K.V. Sharma, Turbulent heat transfer and friction factor of Al2O3 Nanofluid in circular tube with twisted tape inserts, International Journal of Heat and Mass Transfer 53 (2010) 1409–1416.

9. A.Merilainen, A.Seppala, K.Saari, J.Seitsonen, J. Ruokolainen, S.Puisto, N.Rostedt, T.Ala-Nissila,Influence of particle size and shape on turbulent heat transfer characteristics and pressure losses in water-based nanofluids, International Journal of Heat and Mass Transfer 61 (2013) 439–448.

10.V.Bianco, O.Manca, S.Nardini, Numerical investigation on nanofluids turbulent convection heat transfer inside a circular tube, International Journal of Thermal Sciences 50 (2011) 341-349.

11.J.C. Maxwell, Electricity and Magnetism. Clarendon Press, Oxford, 1873.

12.J.C. Maxwell, A Treatise on Electricity and Magnetism. OxfordUniversity Press, Cambridge, 1881.

14.Hwang, K.S., Pil Jang, S., Choi, S.U.S, 2009. Flow and convective heat transfer characteristics of water-based

nanofluids in fully developed laminar flow regime, International Journal of Heat and

Mass Transfer ,vol.52, pp. 193–199.

15.. Bozorgan, N., Panahizadeh, F., Bozorgan, N. (2011) “Application of ethylene glycol- Aluminum oxide nanofluids as cooling fluid in twin-tube heat exchanger”, Journal of Modares Mechanical Engineering, Vol.11, No.3, pp. 75-84

16.Almohammadi, H., Nasiri Vatan, Sh. , Esmaeilzadeh, E., Motezaker, A., Nokhosteen, A., 2012. Experimental Investigation of Convective HeatTransfer and Pressure Drop of /Water Nanofluid in Laminar Flow

Regime inside a Circular Tube, World

Academy of Science, Engineering and