SIMULATION AS A DECISION SUPPORT TOOL IN MAINTENANCE FLOAT

SYSTEMS – The Automatic Generation of Simulation Programs

Francisco Peito Guilherme Pereira Armando Leitão Luís Dias

Polytechnic Institute of Bragança Higher School of Technology and

Management

University of Minho School of Engineering

Polytechnic Institute of Bragança Higher School of Technology

and Management

University of Minho School of Engineering Industrial Management Dpt. Production and Systems Dpt. Industrial Management Dpt. Production and Systems Dpt.

Campus de Santa Apolónia Campus de Gualtar Campus de Santa Apolónia Campus de Gualtar 5301-857 Bragança

Portugal pires@ipb.pt

4710 057 Braga Portugal gui@dps.uminho.pt

5301-857 Bragança Portugal afleitao@ipb.pt

4710 057 Braga Portugal lsd@dps.uminho.pt

KEYWORDS

Simulation, Discrete Event Simulation, Maintenance, Preventive Maintenance, Queueing Theory, Float Systems.

ABSTRACT

This paper is concerned with the use of simulation as a decision support tool in maintenance systems, specifically in MFS(Maintenance Float Systems). For this purpose and due to its high complexity, in this paper the authors propose a flexible way to develop typical MFS models, for any number of machines in the workstation, spare machines and maintenance crews. Arena® simulation language is used to understand a specific MFS, create the corresponding MFS model and analyze most common performance measures.

INTRODUCTION

According to (Pegden et al. 1990), simulation can be understood as the process of construction of a real system representative model, as well as an experimental process aiming to a better understanding of their behavior and to assess the impact of alternative operations strategies. Thus, simulation may also be considered as a decision support tool that allows to predict and to analyze the performance of complex systems and processes as they are in many real systems. In addition, with the use of simulation we acquired a capacity to forecast and to achieve quickly the importance of taking some decisions about the system under analysis. In some real systems like production areas, services such as transport companies, health service systems and factories, the main goal is to achieve high levels of competitiveness and operational availability. In this environment the need for equipment to work continuously is very likely in order to maintain high levels of productivity. This is why MFS has an important role on equipment breakdown and production stoppage has a high and direct impact on production process efficiency and, as a consequence, on their operational results. Therefore, maintenance control and optimization of equipment utilization become not only an important aspect for the mentioned reasons, but also for personnel security matters and to prevent negative environmental impact.

In general, preventive maintenance implementation increases equipment control and avoids unexpected stoppages. However, these maintenance actions could

make maintenance costs too high for a required availability.

In production systems involving identical equipments such as Float Systems it is an advantage to integrate maintenance management with materials and human resources. The existence of spare equipment to replace machines that fail or need overhaul is an example of this type of situation. Then, direct and indirect costs due to equipment stoppage are minimized and the level of production or service requirements fulfilled. Although the existence of spare equipment is important to maintain the production process working keeping the number of spare equipment at an optimum level is recommended.

Mainly due to the non-existence of a specific simulator for the maintenance field, we had a great difficulty in choosing an appropriate simulation tool. However, (Dias et al. 2005) had a definite contribution as far as the simulation tool decision is concerned.

In fact, the choice of Arena® as a simulation language was based on the fact that its hierarchical structure offers different levels of flexibility, thus allowing the construction of extremely complex models, allied to a strong visual component (Kelton 2004; Pidd 1989; Dias 2006 and Pidd 1993).

Having referred the importance of studying MFS, the next section of this paper will focus on the literature review on analytical models, but also on some type of simulation metamodels for this type of maintenance systems.

The following section describes new developments on a previous simulation model towards flexibility. In fact, the model presented in (Peito et al. 2011) will gain the capacity to automatically generate a specific simulation program for each specific MFS desired. The program will then be adapted for specific situations with no need of further coding effort. In fact the new proposed tool is intended exclusively to give a response to a type-standard configuration of MFS. Nevertheless, within this type-standard configuration, the user could easily evaluate different strategies under different number of resources available (active machines, maintenance crews and spare machines). This way, the resulting MFS model aims to fill a gap in terms of computer solutions currently existing for this specific type of maintenance systems. Conclusions and Future Developments are the closing sections for this paper.

To conclude this introduction, once more, we must refer that the proposed tool is intended exclusively to give a response to a type-standard configuration of MFS. Nevertheless, within this type-standard configuration, the user could easily evaluate different strategies under different values for the number of active machines, the number of maintenance crews and the number of spare machines This way, the resulting MFS model aims to fill a gap in terms of computer solutions currently existing for this specific type of maintenance systems.

RESEARCH BACKGROUND

As far as float systems maintenance models is concerned, (Lopes 2007) refers some studies where simulation has been used to produce results based on specified parameters. Due to the fact that these simulation models were only concerned with the input/output process, without dealing with what is happening during the simulation data process, some metamodels have emerged (Madu and Kuei 1992a; Madu and Kuei 1992b; Madu and Lyeu. 1994; Kuei and Madu 1994; Madu 1999; Alam et al. 2003). The metamodels express the input/output relationship through a regression equation. These metamodels can also be based on taguchi methods (Madu and Kuei 1992a; Kuei and Madu 1994) or neural networks (Chen and Tseng 2003). These maintenance system models were also recently treated on an analytical basis by (Gupta and Rao 1996; Gupta 1997; Zeng and Zhang 1997; Shankar and Sahani 2003; Lopes 2007). However, the model proposed by (Lopes 2007) is the only one that deals, simultaneously, with three variables: number of maintenance crews, number of spare equipments and time between overhauls, aiming the optimization of a system composed by M active and identical equipments. Although this proposed model already involves a certain amount of complexity it may become even more complex by adding new variables and factors such as: a) time spent on spare equipment transportation, b) time spent on spare equipment installation; c) the introduction of more or different ways of estimating efficient measures; d) allowing the system to work discontinuously; e) speed or efficiency of the repair and revision actions; f) taking into account restrictions on workers timetable to perform the repair and revision actions; g) taking into account the workers scheduling to perform the repair and revision actions; h) taking into account the possibility of spare equipment failure; etc. Anyway these mentioned approaches would aim at ending up with MFS models very close to real system configurations. In fact, the literature review showed that most of the works published, involving either analytical or simulation models, concentrate on a single maintenance crew, or on a single machine on the workstation or even considering an unlimited maintenance capacity – thus overcoming the real system complexity and therefore not quite responding to the real problem as it exists.

As far as the model presented by (Lopes et al. 2005; Lopes et al. 2006; Lopes 2007) is concerned it is assumed that systems work continuously, its availability is not calculated and the system optimization is only based on the total maintenance cost per time unit. Moreover, it

considers that the total system maintenance cost is the same without taking into account the number of machines unavailable, which in many real situations is not the best option. Finally the referred analytical model only allows that its failures occur under a Homogeneous Poisson process (HPP).

Another important aspect on the companies management strategic definition is to have their tasks correctly planned. To help this planning procedure it is important to know different indicators such as: machine availability, equipment performance and maintenance costs, among others. Therefore one should consider new factors that affect these float systems indicators: possibility of some machine failure, efficiency, repair time.

Moreover, when preventive maintenance policy is used, the time for individual replacement is smaller than time for group replacement. It means that the latter situation requires more machines on the process to be stopped, and also implies an increase on the number of maintenance crews for certain time periods.

In general, companies policy lies on using economic models to define their best strategies. Profits maximization or costs minimization are the most frequent goals used. However, strictly from the maintenance point of view, availability is frequently used as an efficient measure of the system performance, and sometimes more important than the cost based process.

DESCRIPTION OF THE MFS

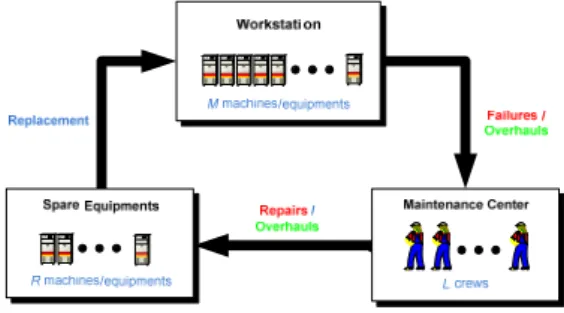

Our model represents a typical Maintenance Float System and it is composed of a workstation, a maintenance centre with a set of maintenance crews to perform overhauls and repair actions and a set of spare machines (Fig.1). The workstation consists of a set of identical machines and the repair centre of a limited number of maintenance crews and a limited number of spare machines. However, the model we have adopted, being a typical MFS, presents certain specificities both as far as the philosophy of the maintenance waiting queues are concerned, and related to the management of the maintenance crews.

Fig. 1 –Typical Maintenance Float System

t a t e a f o a F n r b c o w r b a i h o m a r a D H s b o c e t u

to the mainten assisted accor their optimal end of a perio also kept on a failed machin overhaul is lo available, mac FIFO (First In

number of ma replaced (whil be sent to th complete a du operation with workstation, w replaced when be submitted assured by the n the immedi happens to fa overhaul, then machine is ava In this ve active machin rate while the Time betw and identical Distribution f

Homogeneous

simulation run between over overhauls imp As far as concerned, we even though c than the repair For our M

1. Numb 2. Numb 3. Numb 4. Mach 5. Mach 6. Crew 7. Crew 8. Failu 9. Repa 10. Overh 11. Repla 12. Cost 13. Holdi 14. Labo 15. Time (TConv

(*) This vari

The devel us to estimate a) Avera

nance park wa rding to arriv overhaul tim od T without a virtual queue nes plus the n ower than the chines are rep

n First Out) ru aintenance cre

le there are sp he maintenan uration period hout failures where they wa n they are rem to a prevent e machine tha iately previou ail it awaits f n it will be im

ailable or as so ersion of our m

es of the work model runs. tween failures lly distribute for all mach

s Poisson P

n, this value c rhauls. Obvio plies greater tim

s time to ov e have assum considering ov

r time. MFS, the varia

ber of active m ber of mainten ber of spare m hine- Overhau hine-Initial Fa ws-Repair rate ws-Overhaul ra ure cost (Cf);

air cost (Crep);

haul cost (Crev

acement cost ( due to loss pr ing cost per ti ur cost per tim e to convey

vInst).

iable can be adju

loped simulat the following age system av

aiting queue, w val time. Ma me are kept in failures. How e to overhaul number of m

number of m laced and rep ule. Otherwis ews, the mach pare machines ce queue. Th

T or time betw are maintain ait to be assis moved from th tive action. I

t leaves the m us instant. If a for the accom mmediately re

oon it is avail model it is as kstation have s are assume ed following hines (failure

Process). How could be adjus ously a small me between fa erhaul and ti med the Erla

verhaul time s ables used are machines (M)

nance crews ( machines (R); uls rate (λrev)*;

ailures rate (λf)

(µrep)*;

ate (µrev)*;

v);

(Cs);

roduction (Clp)

ime unit (h); me unit (k);

and install

usted during the s

tion model for g global efficie vailability (Avg

where they wi chines that r n service until wever they wi

. If the numbe machines requ

maintenance cr aired accordin e if it exceed ines will eithe s available) or

he machines ween overhau ned active in sted, and they he workstatio

ts replacemen maintenance ce an active mac mplishment o eplaced, if a s

able.

ssumed that th a constant fa d as indepen an Expone

s occur und wever, durin sted based on ler time betw ailures. ime to repair

ang-2 distribu significantly lo the following ; L); ; )*; );

l spare mac

imulation run.

r our MFS al ency measures gSAv); ill be reach l the ill be er of uiring crews ng to s the er be r will that uls in n the y are on, to

nt is entre chine of an

spare he M

ailure ndent ential der a ng a time ween r are ution, ower g: chine llows s: es an or IN SI in 20 th au sp nu m (R pr in m

b) Total m However, stimated, such c) Avera works d) Avera waitin e) Avera queue f) Avera g) Probab (Probi h) Probab (Probs

nd still, some r maintenance i) Utiliza j) Utiliza k) Numb perfor l) Avera NCREASING IMULATION The Arena n the previous 011), has been he previous m utomatically g pecific charac umber of a maintenance cr

R). However, revious simula n figure 2, fo model develope

Fig. 2 -St

maintenance c some other p h as:

ge number o tation (AvgMe

ge number of ng queue (AvgL

ge waiting tim (Avg Wt); ge operating c bility of exist

im);

bility of the

s);

individual eff e crew, i.e.,

ation rate per ation rate per ber of over med per main ge availability

G FLEX N MODEL

a® simulation s developmen n now revisite model. The u generate a sim cteristics of th active machi rews (L) and t the steps tow ation model w r a better un ed.

teps for simula

cost per time u performance m of missing m

Meq),

f machines in

gLq); me in the mai

cycle time (Av

ting 1 or mor system bein ficiency meas machine; maintenance rhauls and ntenance crew

y per machine

XIBILITY

n language en nt (see details ed, aiming to g user, now, w mulation progr the MFS, nam

ines (M), t the number o wards the dev were all kept a nderstanding o

ation model d

unit (AvgTCu)

measures are a machines at the maintena intenance wait

vgD); re idle Machi ng fully ac

ures per mach

crew; repair acti w;

e.

OF T

nvironment, u s on Peito et. give flexibility would be able

ram according mely varying the number

f spare machi velopment of and are presen of the simulat

m d

i c a l m A d p c ( a n

Figures 3 model before different devel

1. Activ 2. Statis 3. Main 4. Mach

crew

5. Spare 6. Main

Statio

7. Relea 8. Statis 9. Spare

Fig. 3 - Arena

Fig. 4 - Aren This logi dentical for t clear global vi a great simplic ogical model, more simplifi Arena resourc data arrays an previous Are contributed to The comp (Fig. 6) includ all repair and not the case in

and 4 explic and after gai loped compon ve machines (

stics 1 (Recor

ntenance queu hines’ transp

ws);

e machine req ntenance ce

ons);

ase machines stics 2 (Recor

e machines (in

a® Logic Mod

na® Logic Mo ical model c the MFS (Fig isualization of city to make c , after increasi ed – see figu e sets, the inc nd also a set

ena internal a simplified m ponents 1 an de now a gen overhaul requ n the previous

cit the global ining flexibilit nents:

(workstation);

rding Machine

ue;

portation (by

quest; enter (set

to the set of s

rding Machine

n the start of t

del before incr

odel after incre configuration g. 3 and 4), p

f the undergoi changes in the ing flexibility ure 4. The im clusion of inde

of control va variables, model.

d 9 after inc neration and c

uests of all m model (Fig. 5

logical simula ty, underlinin

es Tup);

the mainten

of mainten

spare machine

es Tup and Tdow

the system).

reasing flexibi

easing flexibil choice was providing aga ing operations model. In fac y, will appear

mplementatio exed variables ariables, repla have defin reasing flexib control system machines, this 5). For this con

ation ng its

ance

ance

es;

wn);

ility

lity kept ain a s and ct the even on of

s and acing nitely bility m for was ntrol

sy gu fo at m m re an fa

M

ar si m of m

sy In m th in m cr w is fo re of re re

ystem to be uarantee abso or every mac ttribute iden mechanism, it i machine and t equest (failure nd color (see f In Fig. 6 ( act, some Are

Modules. This re now easy t imple table for Finally, fig modules, allow f the failure in machine.

Fig. 5 - Gen over

A

A

Fig. 6 - Gen ove

The maint ynchronization n the compon mechanism", w

here is a free nclude the u maintenance c rew that has th

The rules were all kept u

the rule for t or the case equests (overh f maintenance equiring repa equiring overh

effective, it olute independ chine. For thi ntification w is now possib the occurrenc e or overhaul), figure 6, zone (Zone B), a s ena Blocks h way, planned to implement rmat.

gure 6, Zone C wing the regist nstants and th

neration and co rhaul requests

neration and co erhaul request

enance waitin n of events be nent 4 (figures which only al maintenance use of an A

rews, selectin he least numbe for the mai unchanged. In the maintenan when the to hauls plus repa e crews avail air action ha hauls.

would also dence of each is purpose, a was develop ble to identify

ce of every t , at any instan A).

small change have been rep d changes to t once Arena C shows four R

tration, in an he number of

ontrol system s before increa

B

ontrol system ts after increas

ng queue is d etween the com

s 7 and 8) th llows a reque

crew. Compo Arena Resour

ng the availa er of services intenance que fact, FIFO (F nce queue man otal number air actions) ex lable – in thi

ave priority

be necessary h type of requ a mechanism ed. With

the state of e type of mach nt – entity num has occurred placed by Ar some parame shows data i

ReadWrite Ar excel worksh failures for e

for repair and asing flexibilit

C

for repair and sing flexibility

defined throug mponent 3 an here is a "con est to proceed onent 4 will n

rce Set for able maintena

allocated. eue managem First In First O nagement, exc of maintena xceed the num s case, machi over machi

y to uest

for this each hine mber d. In

rena eters in a rena heet, each

d ty

d y

gh a d 4. ntrol d if now

a t t e u

r c w m m s

Fig. 7 - Ma

Fig. 8 - Ma

Compone and now inclu the identificati transport state even a mach updates the nu

Fig. 9 - Requ

Fig. 10 - Req

In compo request of a s crew, there is o with the dema model include machine.

In comp structure of th

aintenance wai flex

aintenance wa flex ent 4 (figures udes an Assig

ion of the mai e (for a spare m hine needing umber of main

uest and activa increasin

quest and activ increasin onent 5 (figur spare machine only a small c and with one f

es a Search B

onent 6 (Fig he component

iting queue be xibility

M

aiting queue a xibility

7 and 8) has a

gn Module in intenance crew machine or a

overhaul), t ntenance crew

ation of spare ng flexibility

E

vation of spar ng flexibility res 9 and 10) e, performed change in Zon free available m

Block that se g. 11), the c t. In fact, the

efore increasin

Maint enance Waiting Queue Nº Machines in Ouverhauls Fails Overhauls Virtual-Marks

aint enance Waiting Queue

0

0 0 0

after increasing

also been chan Zone D. Bes w and the mac failed machin this Module s that are free

machines bef

re machines af

that performs by a mainten ne E, that is rel

machine. Now earches for a change is in

discrete varia ng

D

g

nged sides chine ne or also e.

fore

fter

s the nance lated w the free n the

ables ar po in

un w

M

th va ea

to ef

re now index ossible to in ndicators for b

Fig. 11 – Iden

In compon nder maintena work, either rep

Modules have his was possib ariable is capa ach machine.

Componen o record funda

fficiency meas

Fig. 13 – D

Fig. 14 – D

xed discrete ndividually s both types of m

ntification and mainten nent 7, respo ance crew acti pairing or perf

been replaced ble once now

able of saving

Statistics 1

Statistics 2

Fig. 12 – Re nts 2 and 8 (F amental statist

sures, do not s

Data input area increasing

Data input are increasing

variables – save a set maintenance o

d statistics of t nance crew onsible for rel

ions whenever rforming overh

d by a single only a single g all the infor

ecord statistics Fig. 12) which tical data to c suffered any c

a sample scree g flexibility

ea sample scre g flexibility

this way, it of performa operations.

the states of th

leasing machi r they finish th hauls, all Rele

Release Bloc

indexed disc rmation related

s

h are respons alculate adequ change.

enshot before

F

eenshot after t is ance

he

ines heir

ease ck – crete d to

f a n c t w a m C o This work flexibility, allo any Maintena

number of ac crews and the these three va will instantly automatically Fig. Fig. 16 The prese model animati CONCLUSIO This new our Maintenan

More T prese of sim main of ac crews user w

k, making prev ows the user

ance Float Sy

ctive machine numbers of s alues (Zone F y get the a

generated.

15 - Variable

6 – Animation

entation of ou ion (Fig. 16) h

ONS AND FU

w developmen

nce Float Syst

e flexibility This was the

nted in this p mulation mo maintenance ctive machine s; R, number o would just hav

vious simulati to get a sim

ystem desired s, the numbe spare machine F, figures 13 appropriate s

s and graphic

n area sample utput statistics had no change

UTURE DEV

nt of our simu

tem presents:

main challen aper. The aut odels, depend system varia es; L, numbe of reserve mac ve to introduc

ion model gai mulation mode d – regardless er of mainten es. After inpu and 14), the simulation m

s control

screenshot (Fig. 15) and es.

VELOPMENT

ulation model

nge for the w tomatic genera

ing on the t bles – M, num r of mainten chines. In fact ce M, L and R

ining el for s the nance utting user model d the TS l for work ation three mber nance t, the and, an co tr as co de in re ou m w P fu ca m si R A Tr a Sy Sh C de M D G M D C R pp D J. ‘P Sy H A instant model More N with th run. I param analys behavi Better Th mainte visual clarifie allows interac results The simul nalysis of usu oncern toward ends for the a s far as a oncerned. Nev evelopment ncorporating s eached by dev ur simulation maintenance sy while the mod

oisson Proce

uture developm apability of s managers and

imulation expe

REFERENCE

Alam, Fasihul revor J. (2003

Maintenance ystems Dep hrivenham, Sw hen, M. C. a esign of m Manufacturing Dias, Luis M. Guilherme A. Modelling La Different Parad onference On Riga, Letónia. p. 452-461 Dias, Luis S; P

M. Guimar Popular’ Discr ymposium on House. Ed. M Alemanha. pp.

tly, he will to run and ex interactivity

ow the user he simulation In fact the u eters of the sis and can, ior under diffe

information his model enance inform

aspect offer es the actual p s a better un ctions in the s.

lation model ual performan ds new effici analysis and d specific Ma

vertheless the of an ad still more flex veloping and i n tool, in ystems where del runs, i.e.,

ess (NHPP) ments also in imulation to decision ma erts. ES M.; McNau 3), “Developin e Float Syst

artment, Cr windon SN6 8 and Tseng, H maintenance

Systems, vol. S; Rodrigues, B. (2005), A anguage with

digms, Proce n Modelling A

Ed. Yury Me Pereira, Guilhe

rães (2006), rete Simulatio n Simulation M. Becker an

159-163.

get the adeq xperiment.

has the possi model during user can now e maintenanc

therefore, ferent mainten

now offers rmation. Inde red by the d process inside nderstanding

model and o

here presente nce measures iency measure discussion of t

aintenance F

authors are n dvanced sim xibility. This incorporating

order to a e failure rates where a No

is present. T ntend to poten efficiently co akers, even

ught, Ken R ng Simulation tem”, AMOR ranfield Uni 8LA, UK

. Y. (2003), float system . 14, pp. 458-4 , A. J. M. Gu An Activity h Automatic eedings of the And Simulatio

ercuryev et al erme A. B. an

“A Shortlis on Tools”, A

Technique. nd H. Szczer

quate simulat

ibility to inte g each simulat

w modify so e system un evaluate sys ance strategie

s much be eed, the str developed mo e the system. T of the differ of the simulat

ed, incorporat s, also drives

es, enabling n the best decisi

Float System

now aiming to mulation mo target would g new module also incorpo would also v

on Homogene

These mentio ntiate the kno ommunicate w if they are

R. and Ringro n Metamodels RG, Engineer iversity, RM "An approach ms," Integra 467. uimarães; Pere Oriented Vis Translation e 19th Europ on (ECMS 200

. Junho de 20 nd Rodrigues st of the M SIM 2006 - 1 SCS Publish rbicka. Hano tion ract tion ome nder tem es. etter rong odel This rent tion ting s its new ions

Dias, Luis S.; Pereira, Guilherme A. B. and Rodrigues, A. J. M. Guimarães (2006), “Activity based modeling with automatic prototype generation of process based arena models”, EMSS 2006 - 2nd European Modeling and Simulation Symposium. Barcelona, Espanha. pp. 287-296 Gupta, V. and Rao, T. (1996), "On the M/G/1 machine interference model with spares," European Journal of Operational Research, vol. 89, pp. 164-171.

Gupta, S. M. (1997), "Machine interference problem with warm spares, server vacations and exhaustive service," Performance Evaluation, vol. 29, pp. 195-211.

Ingalls, Ricki G. (2001), "Introduction to Simulation", in Proceedings of 2001 Winter Simulation Conference, B.A. Peters, J.S. Smith, D.J. Medeiros, and M. W. Rohrer, eds. Kelton, W. David; Sadowski, Randall P. and Strurrok, David T. (2004), "Simulation With Arena", (3rd edition), McGraw-Hill, (1998-2004).

Kuei, C. H. and Madu, C. N. (1994), "Polynomial metamodelling and Taguchi designs in simulation with application to the maintenance float system," European Journal of Operational, Reseach, vol. 72, pp. 364-375. Lopes, Isabel S. (2007), "Técnicas Quantitativas no Apoio à Decisão em Sistemas de Manutenção", Tese de Doutoramento, Universidade do Minho.

Lopes, Isabel S.; Leitão, Armando L. F. and Pereira, Guilherme A. B. (2005), "Modelo de Custos de Manutenção para um Sistema com M Unidades Idênticas", in C. G.Soares, A. P. Teixeira e P. Antão (eds), Análise e Gestão de Riscos, Segurança e Fiabilidade 2: p 603-620, Lisboa: Edições Salamandra (ISBN 972-689-230-9). Lopes, Isabel S.; Leitão, Armando L. F. and Pereira, Guilherme A. B. (2006), "A Maintenance Float System with Periodic Overhauls", in Guedes Soares & Zio (eds), Safety and Reliability for Managing Risk 1: p 613-618, London: Taylor & Francis Group (ISBN 0-415-41620-5). Madu, C. N. and Kuei, C. H. (1992a), "Group screening and Taguchi design in the optimization of multi-echelon maintenance float simulation metamodels," Computers and Operations Research vol. 19, pp. 95-105.

Madu, C. N. and Kuei, C. H. (1992b), "Simulation metamodels of system availability and optimum spare and repair units," IIE Transactions, vol. 24, pp. 99-104.

Madu, C. N. and Lyeu, P. (1994), "On the use of simulation metamodeling in solving system availability problems," Microelectronics Reliability, vol. 34, pp. 1147-1160.

Madu, I. E. (1999), "Robust regression metamodel for a maintenance float policy," International Journal of Quality & Reliability Management, vol. 16, pp. 433-456.

Mamede, Nuno (1984), "Simulação Digital de Processos", Tese de Mestrado em Engenharia Electrotécnica e de Computadores (Telecomunicações e Computadores), Instituto Superior Técnico.

Pegden, C.D.; Shannon, R. E.and Sadowski, R. P. (1990) "Introduction to Simulation Using SIMAN, McGraw-Hill", New York, USA. v. 2. 1990.

Peito, Francisco; Pereira, Guilherme; Leitão, Armando; Dias, Luís (2011), “Simulation as a Decision Support Tool in Maintenance Float Systems” ,17th European Concurrent Engineering Conference (ECEC´2011). London, England. pp.68-74.

Pidd, Michael (1989), "Computer Modelling for Discrete Simulation", (Editor), Wiley.

Pidd, Michael (1993), "Computer Simulation in Management Science", Third Edition, Wiley.

Rodrigues, Guimarães and Carvalho, Valério (1984), "CAPS - ECSL, Experiência de modelagem e simulação aplicada a um sistema de elevadores", Relatório Técnico, Universidade do Minho.

Rubinstein, Reuven Y. and Melamed, Benjamin (1998), "Modern Simulation and Modeling", Wiley Series in Probability and Statistics, Applied Probability and Statistics Section, A Wiley-Interscience Publication, John Wiley & Sons, INC., ISBN 0- 471-17077-1.

Shannon, Robert E. (1998), "Introduction to the Art and Science of Simulation", in Proceedings of 1998 Winter Simulation Conference, D.J.Medeiros, E.F. Watson, J.S. Carson and M.S. Manivannan, eds.

Shankar, G. and Sahani, V. (2003), "Reliability analysis of a maintenance network with repair and preventive maintenance," International Journal of Quality & Reliability Management, vol. 20, pp. 268-280.

Vik, P.; Pereira, G. and Dias, L. (2009), “Software Tools Integration for the Design of Manufacturing Systems”, Proceedings of the Industrial Simulation Conference, Loughborough, eds. Diganta Bhusan Das, Vahid Nassehi and Lipika Deka, pp 127-131

Vik, P.; Dias, L. and Pereira, G. (2010), “Automatic Generation of Computer Models Through the Integration of Production Systems Design Software Tools”. ASMDO2010 - Third International Conference on Multidisciplinary Design Optimization and Applications. Paris (France)

Vik, P.; Dias, L.; Pereira, G. and Oliveira, J. (2010), “Improving Production and Internal Logistics Systems – An Integrated Approach Using CAD and Simulation”. ILS2010 - 3rd International Conference on Information Systems, Logistics and Supply Chain - Creating value through green supply chains. Casablanca (Morocco), April 14-16.

A

a

U i

m M

U a M

AUTHOR BI

and Maintenan

University of nterests are O

main researc Maintenance.

University of M are Simulation Modeling.

IOGRAPHY FRANCI

1966 in Portugal. Engineer in Polyte holds a Maintena main res nce.

GUILHE

born in graduated Managem Minho, degree in PhD de Mechani f Birmingham Operational Re

ARMAN

1958 in in Me Universit an MS Engineer Productio Universit ch interests

LUÍS M

Vila No graduate Systems of Minh degree in a PhD Systems Minho, Portu n, Operationa

ISCO PEIT

n Macedo . He graduate ring-Managem echnic Institu an MSc d ance in Unive search interes

ERME A B

1961 in Por d in Industria ment at the

Portugal. He n Operational egree in Ma cal Enginee m, UK. His esearch and Si

NDO LEITÃ

Porto, Portug echanical E ty of Porto, P Sc degree

ring and a on Enginee ty of Birmin

are Reliabil

M S DIAS wa ova de Foz C ed in Compu Engineering ho, Portugal. H

n Informatics degree in

Engineeri gal. His main l Research an

TO was born de Cavale ed in Mechan ment of Produc ute of Porto. degree Indus rsity of Porto ts are Simula

PEREIRA

rto, Portugal. l Engineering e University e holds an l Research an anufacturing ering from

s main rese imulation.

ÃO was born gal. He gradu

Engineering Portugal. He h

in Produc PhD degree ring from ngham, UK. lity and Qu

as born in 197 Côa, Portugal

uter Science at the Unive He holds an s Engineering Production ng from n research inte

nd Systems V n in eiros,

nical ction . He strial . His ation

was . He g and y of

MSc nd a

and the earch

n in uated

at holds ction e in

the His uality

70 in . He and ersity MSc g and