ABSTRACT

Ch ar act er isat ion an d m icr oleak ag e of a n ew

K\GURSKLOLF¿VVXUHVHDODQW8OWUD6HDO;7

®

hydro™

Zeynep A. GÜÇLÜ1, Nazmiye DÖNMEZ2$QGUHZ3+8573, Nichola J. COLEMAN3

(UFL\HVhQLYHUVLWHVL'Lú+HNLPOL÷L)DNOWHVL3HGRGRQWL.D\VHUL7XUNH\ %H]PLDOHP9DNÕIhQLYHUVLWHVL'Lú+DVWDOÕNODUÕYH7HGDYLVLøVWDQEXO7XUNH\ 3- University of Greenwich, Faculty of Engineering and Science, Kent, United Kingdom.

Corresponding address: Nichola J. Coleman - Faculty of Engineering and Science, University of Greenwich - Chatham Maritime - Kent - ME4 4TB - United Kingdom - Phone: +44 (0)7980 017088 - e-mail: nj_coleman@yahoo.co.uk

6XEPLWWHG-DQXDU\0RGL¿FDWLRQ0DUFK$FFHSWHG0D\

O

EMHFWLYHV 7KH DLP RI WKLV VWXG\ ZDV WR FKDUDFWHULVH WKH QHZ K\GURSKLOLF ¿VVXUHsealant , Ult raSeal XT® hydro™ ( Ult radent Product s, USA) , and t o invest igat e it s in vit ror esist ance t o m icr oleakage aft er placem ent on convent ionally acid et ched and sequent ially lased and acid et ched m olar s. Mat er ial and Met hods: The sealant was charact er ised by Four ier t ransfor m infra- r ed spect r oscopy ( FTI R) , scanning elect r on m icr oscopy ( SEM) , ener gy disper sive X- ray analysis ( EDX) , and Vicker s indent at ion t est . Occlusal sur faces of ext ract ed hum an m olar s w er e eit her convent ionally acid et ched ( n= 10) , or sequent ially acid et ched and laser ir radiat ed ( n= 10) . Ult raSeal XT® hydr o™ was applied t o bot h gr oups

of t eet h w hich w er e t hen subj ect ed t o 2,500 t her m ocycles bet w een 5 and 55°C pr ior t o m icr oleakage assessm ent by fuchsin dye penet rat ion. Result s: Ult raSeal XT® hydr o™ is an

acr ylat e- based sealant t hat achieved a degr ee of conver sion of 50.6± 2.2% and a Vicker s m icrohardness of 24.2± 1.5 under st andard light curing ( 1,000 m Wcm- 2 for 20 s) . Fluoride ion

release is negligible wit hin a 14- day period. SEM and EDX analyses indicat ed t hat t he sealant com pr ises ir r egular subm icr on and nano- sized silicon- , bar ium - , and alum inium - bear ing

¿OOHUSKDVHVHPEHGGHGLQDGXFWLOHPDWUL[/DVHUSUHFRQGLWLRQLQJZDVIRXQGWRVLJQL¿FDQWO\

reduce m icroleakage ( Mann-Whit ney U t est , p< 0.001) . The lased t eet h present ed enhanced

VXUIDFHURXJKQHVVRQDWRNjPVFDOHWKDWFDXVHGWKHVHJUHJDWLRQDQGFRQFHQWUDWLRQ RIWKH¿OOHUSDUWLFOHVDWWKHHQDPHOVHDODQWLQWHUIDFH&RQFOXVLRQ/DVHUSUHFRQGLWLRQLQJ VLJQL¿FDQWO\ GHFUHDVHG PLFUROHDNDJH DQG LQFUHDVHG HQDPHO VXUIDFH URXJKQHVV ZKLFK FDXVHG]RQLQJRIWKH¿OOHUSDUWLFOHVDWWKHHQDPHOVHDODQWLQWHUIDFH

Ke y w or ds: Hydr ophilic. Fissur e sealant s. Er : YAG laser s. Micr oleakage. Micr ohar dness.

I N TROD UCTI ON

Appr ox im at ely 90% of all dent al car ies ar ise i n t h e occl u sal p i t s an d f i ssu r es, si n ce t h ese r egion s ar e an at om ically def en ded again st t h e

UHPLQHUDOLVLQJÀRZRIVDOLYDDQGURXWLQHEUXVKLQJ8. Accor dingly, r esin- based or glass ionom er sealant s ar e placed over t he occlusal sur faces of pr em olar s and m olar s t o pr event car iogenic m icr oor ganism s and fer m ent able or ganic debr is fr om accum ulat ing

LQWKHSLWVDQG¿VVXUHV11.

The m aj or it y of com m er cially available r

esin-EDVHG SLW DQG ¿VVXUH VHDODQWV DUH K\GURSKRELF

m at er ials t h at bon d t o t h e en am el su r f ace v ia m icrom echanically int erlocking t ags13. The presence

of m oist ur e and saliva- cont am inat ion dur ing t he placem ent of t he sealant com pr om ise t he qualit y of adhesion at t he sealant - enam el int er face, w hich im pact s t he ongoing r esist ance t o m icr oleakage of m icr oor ganism s. Recent ly int r oduced hydr ophilic sealant s, w hich bond effect ively t o m oist enam el sur faces, pr esent a dist inct advant age in paediat r ic dent ist r y w her e pat ient - com pliance, isolat ion, and m oist ur e- cont r ol can be par t icular ly challenging10.

Ul t r a Sea l XT® h y d r o ™ i s a n ew m o i st u r e-t olerane-t , self- adhesive, lighe-t- cured, acrylae-t e- based, h y d r op h ilic p it , an d f issu r e sealan t w h ich h as been developed by Ult radent Pr oduct s, USA4. The sealant com pr ises a 53 w t % m ixt ur e of inor ganic

is r epor t ed t o “ chase” m oist ur e int o t he pit s and

¿VVXUHVWKXVHOLPLQDWLQJPRLVWXUHUHODWHGIDLOXUH

associat ed w it h hydr ophobic sealant s4.

Pr i o r t o t h e a p p l i ca t i o n o f a r e si n - b a se d

¿VVXUHVHDODQWWKHHQDPHOVXUIDFHLVHWFKHGZLWK

phosphor ic acid gel t o enhance sur face r oughness and wet t abilit y and t o increase porosit y and surface ar ea available for bonding1. Recent r esear ch has indicat ed t hat t he applicat ion of laser ablat ion as an adj unct t o phosphor ic acid et ching m ay im pr ove t h e ad h esion , m ar g in al ad ap t at ion , r et en t ion , an d r esist an ce t o m icr oleak age of r esin - based sealant s10 7KLV ¿QGLQJ LV QRW XQLYHUVDO DQG WKH

HI¿FDF\ RI ODVHU FRQGLWLRQLQJ DSSHDUV WR GHSHQG

upon t he rheological and physicochem ical propert ies of differ ent sealant s3,5,12. I t is suggest ed t hat less

YLVFRXV PRUH ³ÀRZDEOH´ PDWHULDOV PD\ DIIRUG

bet t er adapt at ion t o t he rougher surfaces present ed by lased enam el9.

The obj ect ives of t his st udy were t o charact erise t he new hydrophilic sealant , Ult raSeal XT® hydro™, and t o invest igat e it s r esist ance t o m icr oleakage

in vit r o. The chem ical com posit ion and degr ee of

cur ing of Ult raSeal XT® hydr o™ w er e invest igat ed by Fourier t ransform infra- red spect roscopy ( FTI R) . Scanning elect r on m icr oscopy ( SEM) was used t o ex am ine t he fract ur e sur face and t he elem ent al com posit ion was det er m ined by ener gy disper sive X- ray analysis ( EDX) . Microhardness was evaluat ed

XVLQJ WKH 9LFNHUV LQGHQWDWLRQ WHVW DQG ÀXRULGH

r e l e a se w a s m o n i t o r e d w i t h a n i o n - se l e ct i v e elect r ode.

M ATERI AL AN D M ETH OD S

Et hical appr oval for t his pr oj ect was obt ained on 1st Oct ober 2014 by t he Et hical Com m it t ee of Bezm iâlem Vak if Un iv er sit y ( r ef er en ce n u m ber 71306642/ 050- 01- 04/ 282) , w hich was per for m ed accor ding t o t he et hical st andar ds laid dow n in t h e 1 9 6 4 Declar at ion of Helsin k i an d it s lat er am endm ent s.

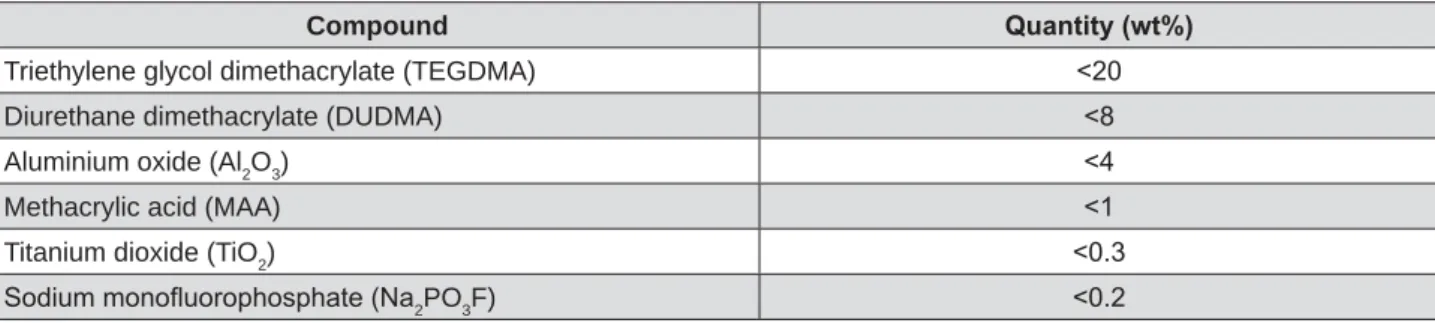

Ch a r a ct e r isa t ion of Ult r a Se a l X T® h y dr o™ The com posit ion of t he Ult raSeal XT® hydr oTM sealant ( Ult radent Pr oduct s, Sout h Jor dan, Ut ah, USA) used in t his st udy, as list ed in t he safet y dat a

sheet pr ovided by t he m anufact ur er14, is given in Figure 1. Cylindrical polypropylene m oulds of 7 m m

GLDPHWHUDQGPPGHSWKZHUH¿OOHGZLWK8OWUD6HDO

XT® hydr o™ m onom er solut ion t hat was light - cur ed for 20 s at 1000 m Wcm- 2 ( using a BA Opt im a 10 cur ing light , BA I nt er nat ional Lt d., Nor t ham pt on, No r t h a m p t o n sh i r e , UK) . Th e r e su l t i n g cu r e d Ult raSeal XT® hydro™ discs w ere t hen charact erised by FTI R, SEM, and EDX and t heir m icrohardness and

ÀXRULGHUHOHDVHEHKDYLRXUZHUHPHDVXUHG

Sca n n in g e le ct r on m icr oscopy a n d e n e r gy dispe r siv e X - r a y a n a ly sis

Fract ur e sur faces of Ult raSeal XT® hydr o™ for SEM and EDX analysis w er e pr oduced by cr ushing t he cur ed discs bet w een st eel plat es under a low-im pact for ce. Scanning elect r on m icr oscopy was car r ied out on t he fract ur e sur faces of uncoat ed sam ples at t ached t o car bon t abs on a JEOL JSM-5 4 1 0 LV el ect r o n m i cr o sco p e w i t h an Ox f o r d I nst r um ent s X- MaxN EDX det ect or in low vacuum m ode. All back- scat t er ed and secondar y elect r on im ages w er e obt ained w it h an accelerat ing volt age of 1.0 kV at a w or king dist ance of 8.4 m m .

Fou r ie r t r a n sfor m in fr a - r e d spe ct r oscopy

The FTI R spect ra of t he unset Ult raSeal XT® hydr o™ m onom er solut ion and of t he cur ed discs w er e obt ained in t r iplicat e using a Per k in Elm er Sp ect r u m Tw o sp ect r o m et er w i t h a Un i v er sal

'LDPRQGDWWHQXDWHGWRWDOUHÀHFWDQFHDWWDFKPHQW

( Per kin Elm er, London, UK) . Spect ra w er e r ecor ded w it h 16 accum ulat ed scans bet w een 4000 cm- 1 and 450 cm- 1 wavenum ber s at a r esolut ion of 4 cm- 1.

The degree of conversion ( DC) was est im at ed by com par ing t he rat ios of t he int ensit ies of t he FTI R peaks for t he r eact ive polym er ising C= C bond ( at 1637 cm- 1) and t he invar iant C= O bond ( at 1717 cm- 1) in t he cur ed polym er and m onom er using t he follow ing equat ion:

Flu or ide ion r e le a se

Thr ee cur ed Ult raSeal XT® hydr o™ discs w er e individually placed in t hree polypropylene cent rifuge t ubes cont aining 5 cm3 of deionized wat er and st ored

Compound 4XDQWLW\ZW

Triethylene glycol dimethacrylate (TEGDMA)

Diurethane dimethacrylate (DUDMA)

Aluminium oxide (Al2O3)

Methacrylic acid (MAA)

Titanium dioxide (TiO2)

6RGLXPPRQRÀXRURSKRVSKDWH1D2PO3F)

in t he absence of light at 37°C. The r elease of fr e e

ÀXRULGHLRQVIURPWKHFXUHGGLVFVZDVPRQLWRUHG

daily t hr oughout a 14- day per iod using an ion-select ive elect r ode ( Cole- Par m er, London, UK) and

2ULRQ6WDUPHWHU7KHUPR)LVKHU6FLHQWL¿F(DVW

Gr inst ead, UK) .

M icr oh a r dn e ss e v a lu a t ion

The Vicker s m icr oindent at ion t est was car r ied out on 3 Ult raSeal XT® hydro™ discs using a Buehler Micr om et Har d n ess Test er ( Bu eh ler, Cov en t r y, War w ickshir e, UK) w it h a load of 200 g and cont act t im e of 2.5 s. Thr ee m easur em ent s w er e t aken at random point s on bot h sides of each sam ple d isc. I n d en t at ion d iag on als w er e m easu r ed in m icrom et res wit h t he aid of a st ereom icroscope and convert ed t o Vickers hardness num bers ( VHN) using conver sion t ables pr ovided by Buehler, Covent r y, War w ickshir e, UK.

M icr ole a k a ge a sse ssm e n t

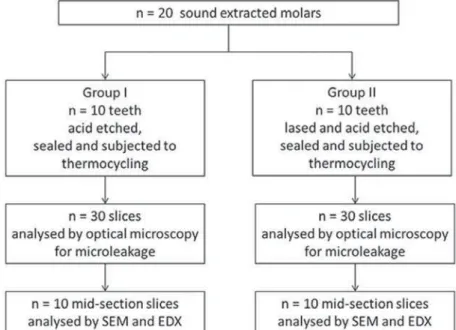

Tw en t y sou n d ex t r act ed h u m an m olar t eet h w er e obt ained fr om pat ient s w it h or t hodont ic or p er iod on t al p r ob lem s w h o h ad t en d er ed t h eir i n f o r m e d co n se n t . Th e t e e t h w e r e m a n u a l l y debr ided w it h scaling inst r um ent s, cleaned w it h p u m ice p ast e an d st or ed in d ist illed w at er f or up t o four w eeks. The t eet h w er e t hen random ly

GLYLGHG LQWR WZR JURXSV $ ÀRZ GLDJUDP IRU WKH

exper im ent al pr ocedur es is given in Figur e 2. The occlusal sur faces of Gr oup I t eet h ( n= 10) w er e acid et ched w it h 35% phosphor ic acid gel ( Ult raSeal XT® hydr o™, Ult radent Pr oduct s, Sout h Jor dan, Ut ah, USA) for 20 s, r insed and light ly air dr ied, as suggest ed by t he m anufact ur er. The Ult raSeal XT® hydr o™ sealant was t hen applied by t he sam e operat or, according t o t he m anufact urer ’s

inst r uct ions, and light cur ed for 20 s ( using a BA Op t im a 1 0 cu r in g lig h t , BA I n t er n at ion al Lt d ., Nor t ham pt on, Nor t ham pt onshir e, UK) .

Gr o u p I I t e e t h ( n = 1 0 ) w e r e se q u e n t i a l l y subj ect ed t o laser ablat ion and acid et ching. Laser condit ioning of t he occlusal sur faces of Gr oup I I t eet h was carried out using a 2940 nm Er: YAG laser syst em ( Light Walker®, Fot ona, Lj ublj ana, Slovenia) . The Er : YAG laser ener gy was applied at a densit y of 19 m J cm- 2, pow er out put of 1.2 W, and pulse

HQHUJ\RIP-XVLQJDNjPGLDPHWHUVDSSKLUH

t ip w it h a beam spot size of 0.63 m m2 at a w or king dist ance of 8 m m at an angle of 90° under wat er cooling at 50 cm3 m in- 1. The lased t eet h were rinsed w it h wat er, t hor oughly air dr ied, acid et ched ( as out lined above) , and t hen light ly air dr ied pr ior t o sealing w it h Ult raSeal XT® hydr o™.

I m m ed i at el y af t er seal i n g , t h e t eet h w er e placed in dist illed wat er at 37°C for 24 h and t hen t h er m ocy cled 2 5 0 0 t im es bet w een 5 an d 5 5 °C w it h a t ransfer t im e of 10 s and a dw ell t im e of 30 s. The t eet h w er e t hen coat ed w it h nail var nish, leaving a 2 m m w indow ar ound t he sealant , and t he root s were em bedded in an acrylic resin cylinder ( Melioden t , Bay er Co., Lev er k u sen , Ger m any ) . Each sam ple was placed in 0.5% basic fuchsin dye

VROXWLRQIRUKULQVHGXQGHUÀRZLQJWDSZDWHU

for 5 m in t o r em ove excess dye, and sect ioned in t he bucco- lingual dir ect ion using a wat er- cooled diam ond saw t o obt ain t hr ee slices. Each of t he t oot h sam ple slices was t hen exam ined t w ice under a st ereom icroscope ( SMZ 800, Nikon, Tokyo, Japan)

DW[PDJQL¿FDWLRQE\WZRLQYHVWLJDWRUVZKRZHUH

unawar e of t he pr e- t r eat m ent of each sam ple. The m icroleakage scoring crit eria are list ed in Figure 31,9.

The m icr oleakage dat a w er e analysed using t he st at ist ical package SPSS 14.0.0 for Windows ( SPSS,

Ch icag o, I llin ois, USA) . Sig n if ican t d if f er en ces w er e evaluat ed using t he Mann- Whit ney U t est ( p= 0.05) . I nt er- exam iner var iabilit y was analysed w it h t he kappa st at ist ic, w hich was found t o be 0.9, indicat ing high r epr oducibilit y.

SEM a n d ED X a n a ly se s of se a le d t e e t h

SEM and EDX analyses w er e car r ied out on t he m iddle slices of t he sect ioned t eet h using uncoat ed sam ples at t ached t o car bon t abs on a JEOL JSM-5 4 1 0 LV el ect r o n m i cr o sco p e w i t h an Ox f o r d I nst r um ent s X- MaxN EDX det ect or in low vacuum m ode. All back- scat t er ed elect r on im ages and EDX m aps w er e obt ained w it h an accelerat ing volt age of 20 kV at a w or king dist ance of 20 m m .

RESULTS

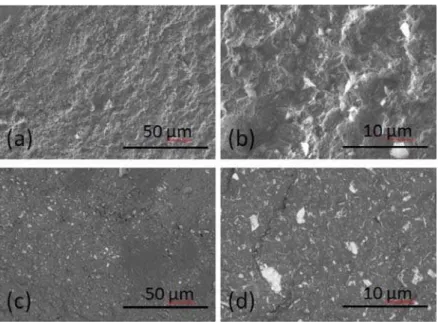

SEM a n d ED X a n a ly se s

S e c o n d a r y e l e c t r o n i m a g e s s h o w i n g t h e t opography of t he fract ur e sur faces of light cur ed Ult r aSeal XT® hy dr o™ ar e pr esen t ed in Figu r es

D DQG E $QJXODU ¿OOHU IUDJPHQWV RI XS WR a NjPLQGLDPHWHUDUHVHHQWREHHPEHGGHGLQWKH

polym erised m at rix. The t ext ured irregular surfaces observed arise from duct ile fract ure wit h associat ed plast ic defor m at ion.

Back- scat t er ed elect r on im ages of t he Ult raSeal XT® hydr o™ fract ur e sur faces ( Figur es 4c and d) pr ovide com posit ional infor m at ion, since elem ent s w it h higher at om ic num ber scat t er elect r ons m or e effect ively and appear as br ight er r egions. These im ages also show a dist r ibut ion of highly angular

DQG¿EURXVVXEPLFURQDQGQDQRVL]HG¿OOHUSDUWLFOHV

t hr oughout t he polym er ised m at r ix.

7KH ('; DQDO\VLV RI D NjP E\ NjP

w indow of a polished sect ion of t he light cur ed sealant indicat ed t hat t his m at er ial is pr incipally com p osed of car b on , ox y g en , b ar iu m , silicon , alum inium , calcium , and phosphor us ( Table 1 ) .

,QGLYLGXDO(';VSRWDQDO\VHVRIWKH¿OOHUSDUWLFOHV

show ed t hat t hese phases com pr ise a m ixt ur e of silicon- , alum inium - , and barium - bearing m inerals. Sod iu m w as also n ot ed at ap p r ox im at ely 0 . 1 w t % . The m anufact ur er ’s safet y dat a sheet for Ult r aSeal XT® h y d r o™ ( Fig u r e 11 4) list s sod iu m

PRQRÀXRURSKRVSKDWH 1D2PO3F) at lev els below 0.2 w t % , w hich w er e found t o be below t he EDX

GHWHFWLRQOLPLWIRUÀXRULQH

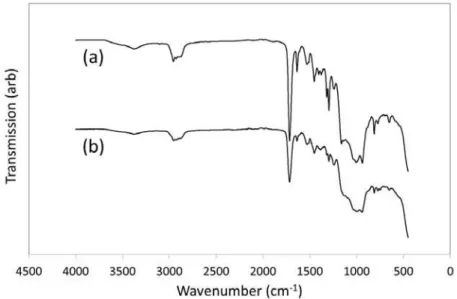

FTI R spe ct r oscopy

The FTI R spect ra of t he m onom er ic Ult raSeal XT® hydr o™ solut ion and light cur ed polym er ised discs ar e show n in Figur e 5, and t he cor r esponding

Score 'H¿QLWLRQ

0 No dye penetration

1 '\HSHQHWUDWLRQXSWRòRIWKH¿VVXUH

2 '\HSHQHWUDWLRQEH\RQGòRIWKH¿VVXUHZLWKRXWWRWDOLQYROYHPHQW

3 Dye penetration to the sealant-base

Figure 3- Microleakage scoring criteria

funct ional group assignm ent s are list ed in Figure 615. Accor ding t o t he m anufact ur er ’s safet y dat a sheet ( Figur e 114) , t he or ganic com ponent of Ult raSeal XT® h y dr o™ com pr ises a m ix t u r e of t r iet hy len e g l y co l d i m e t h a cr y l a t e ( TEGD MA) , d i u r e t h a n e dim et h acr y lat e ( DUDMA) , an d m et h acr y lic acid ( MAA) . Pr esent in t hese m onom er s ar e hydr ophilic c a r b o x y l i c a c i d ( - COOH ) , s e c o n d a r y a m i n e ( - NH) and car bonyl ( - C= O) gr oups, hydr ophobic alk ane ( - CH3) and alkene ( - C= CH2) gr oups, and et her ( - C- O- C- ) gr oups, w hich ar e of am phiphilic charact er. Each of t hese funct ional gr oups appear s in t he FTI R spect ra of bot h t he unset Ult raSeal XT® hydr o™ solut ion and light cur ed polym er ised

discs ( as in dicat ed in Figu r e 5 ) . I n addit ion t o t hese gr oups, ar om at ic car bon- car bon st r et ching vibrat ions ar e also pr esent in t he FTI R spect ra of bot h unset and light cur ed Ult raSeal XT® hydr o™, which indicat e t he presence of undisclosed arom at ic m onom er and/ or init iat or com pounds w it hin t he m ixt ur e.

The v er y br oad com pound signal cent r ed at approxim at ely 1000 cm- 1 wavenum bers in t he unset and light cur ed FTI R spect ra of t he sealant ar ises fr om var ious Si- O and Al- O st r et ching m odes of

WKH VLOLFRQ DQG DOXPLQLXPEHDULQJ PLQHUDO ¿OOHU

phases.

The degree of conversion of resin- based sealant s

Element C O Ba Si Al Ca P

0DVVZW 44 30 9.6 7.7 4.7 2.4 1.8

5HODWLYHVWDQGDUGGHYLDWLRQVDUHOHVVWKDQLQHDFKFDVH

Table 1- Elemental composition of UltraSeal XT® hydro™

Figure 5- FTIR spectra of (a) unset UltraSeal XT® hydro™ and (b) light-cured UltraSeal XT® hydro™

Wavenumber (cm-1) Functional group Compound

3,380 OH and NH stretch MAA, DUDMA

2,950 C-H stretch MAA, DUDMA, TEGDMA

1,717 C=O stretch MAA, DUDMA, TEGDMA

1,637, 1,610 C=C stretch MAA, DUDMA, TEGDMA

1,530, 1,450 C-C aromatic stretch Unassigned

1,403, 1,386, 1,370 C-H bend MAA, DUDMA, TEGDMA

1,320, 1,296 C-O stretch MAA, DUDMA, TEGDMA

1,240 C-H bend MAA, DUDMA, TEGDMA

1,000 Si-O and Al-O stretch 0LQHUDO¿OOHUSKDVHV

812 C=C twist MAA, DUDMA, TEGDMA

770 - 650 Various C-H bend MAA, DUDMA, TEGDMA

LVGH¿QHGDVWKHSHUFHQWDJHRIDFU\ODWH& &JURXSV

fr om t he var ious m onom er s t hat have under gone poly m er isat ion7. Th e m ech an ical, phy sical, an d chem ical int egr it y and clinical per for m ance of t he cur ed sealant ar e st r ongly dependent upon t his pr oper t y. Analy sis of t he FTI R spect ra of unset an d ligh t cu r ed Ult r aSeal XT® hy dr o™ in dicat ed t hat t his sealant achieved a degr ee of conver sion of 5 0 . 6 ± 2 . 2 % under t he select ed ex per im ent al condit ions.

Flu or ide ion r e le a se

Light cur ed Ult raSeal XT® hydr o™ discs failed

WR UHOHDVH DQ\ GHWHFWLEOH IUHH ÀXRULGH LRQV LQWR

deionised wat er during a 14- day observat ion period,

LQGLFDWLQJ WKDW DQ\ ÀXRULGH LRQ UHOHDVH ZDV DW D

concent rat ion below 0.001 ppm . Accor ding t o t he m anufact ur er ’s safet y dat a sheet ( Figur e 114) , t he

OHYHO RI VRGLXP PRQRÀXRURSKRVSKDWH 1D2PO3F) in Ult raSeal XT® hydr o™ is low er t han 0.2 w t % .

7KLV FRUUHVSRQGV ZLWK D PD[LPXP ÀXRULGH LRQ

concent rat ion w it hin t he sealant of 0.0264 w t % .

M icr oh a r dn e ss

Mi cr o h a r d n ess p r o v i d es a m ea su r e o f t h e resist ance of a sealant t o plast ic deform at ion under applied com pr essive for ces. The Vicker s har dness num ber ( VHN) of light cur ed Ult raSeal XT® hydr o™ was found t o be 24.2± 1.5.

M icr ole a k a ge a sse ssm e n t

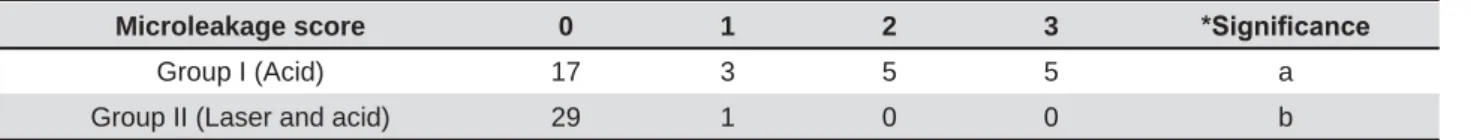

The dist r ibut ions of m icr oleakage scor es for t he acid et ched ( Gr oup I ) and sequent ially lased and acid et ched ( Gr oup I I ) t eet h ar e list ed in Table 2. Thir t een of t he Gr oup I t eet h sect ions exhibit ed m icr oleak age w it h m ax im um dye penet rat ion t o t h e sealan t base; w h er eas, on ly on e Gr ou p I I t oot h sect ion dem onst rat ed m icr oleak age w it hin

WKHXSSHUKDOIRIWKH¿VVXUH7KHVHGDWDLQGLFDWH

t hat t he applicat ion of Er : YAG laser ablat ion under t he select ed exper im ent al condit ions pr ior t o acid

HWFKLQJVLJQL¿FDQWO\LPSURYHVWKHin vit ro resist ance

of t he sealed t eet h t o m icr oleakage ( p< 0.001) .

SEM a n d ED X a n a ly se s of se a le d t e e t h

Back- scat t er ed elect r on im ages of t he enam el-sealant int er faces of acid et ched ( Gr oup I ) and sequent ially lased and acid et ched ( Gr oup I I ) t eet h ar e show n in Figur es 7a and 8a. Enhanced sur face

URXJKQHVVRQDWRNjPVFDOHZDVREVHUYHGIRU

t he enam el sur faces t hat had been pr econdit ioned

ZLWK WKH (U<$* ODVHU 7KLV REVHUYDWLRQ FRQ¿UPV

t h ose of ot h er st u d ies w h ich r ep or t en h an ced

VXUIDFH URXJKQHVV RI XS WR NjP IRU ODVHU

condit ioned t eet h1,9 7KH ¿OOHU ZLWKLQ WKH VHDODQW was observed t o rem ain hom ogeneously dist ribut ed w hen t he m at er ial was placed in cont act w it h t he acid et ched enam el surface; however, t he enhanced sur face r oughness of t he lased t eet h caused t he

VHJUHJDWLRQDQGFRQFHQWUDWLRQRIWKH¿OOHUSDUWLFOHV

at t he enam el- sealant int er face. Cor r esponding elem ent al car bon, bar ium , silicon, and alum inium EDX m aps of t he sealed Gr oup I and I I t eet h ar e pr esen t ed in Figu r es 7 ( b, c, d, e) an d 8 ( b, c, d, e) ,

Microleakage score 0 1 2 3 6LJQL¿FDQFH

Group I (Acid) 17 3 5 5 a

Group II (Laser and acid) 29 1 0 0 b

'LIIHUHQWOHWWHUVLQGLFDWHVLJQL¿FDQWGLIIHUHQFHVS

Table 2- Microleakage scores as functions of enamel conditioning

Figure 7- (a)- Back-scattered scanning electron

r espect iv ely. These im ages highlight t he zoning of t he bar ium - , silicon- , and alum inium - bear ing m ineral phases at t he enam el- sealant int er face of t he lased t eet h.

D I SCUSSI ON

Ch a r a ct e r isa t ion

Scanning elect ron m icroscopy wit h EDX analysis of f r act u r e su r f aces of Ult r aSeal XT® h y d r o™ d e m o n st r a t e d t h a t t h i s se a l a n t i s a d u ct i l e m a t e r i a l t h a t i s h i g h l y f i l l e d w i t h u n i f o r m l y d i st r i b u t ed m i cr o m et r e a n d n a n o m et r e si zed silicon- , alum inium - , and bar ium - bear ing m ineral

SKDVHV 7KLV ¿QGLQJ FRQWUDGLFWV WKH LQIRUPDWLRQ

cont ained in t he m anufact ur er ’s safet y dat a sheet t hat indicat es t hat t his sealant cont ains alum inium and t it anium oxides and does not list const it uent si l i co n - a n d b a r i u m - b e a r i n g m i n e r a l p h a se s ( Figur e 1)14. I t should be not ed t hat , despit e t he

m anufact ur er ’s claim , no t it anium phases w er e det ect ed in t he sealant by EDX analysis.

7KH FXULQJ HI¿FLHQF\ RI WKLV VHDODQW a DSSHDUVWRZDUGVWKHORZHUHQGRIWKHUDQJHa

t o 76% ) r epor t ed for cont em porar y com m er cially

DYDLODEOHUHVLQEDVHG¿VVXUHVHDODQWVFXUHGXQGHU

sim ilar exper im ent al condit ions6,11. I t is consider ed

WKDW WKH KLJK OHYHO RI LQRUJDQLF PLQHUDO ¿OOHU LQ

Ult raSeal XT® hydr o™ m ay im pact t he degr ee of cur e by inhibit ing light penet rat ion and also by pr esent ing a physical bar r ier t o m onom er cr oss-linking.

The m icrohardness of Ult raSeal XT® hydro™ ( VHN

aZDVIRXQGWRIDOOZLWKLQWKHUDQJHUHSRUWHG IRUFRPPHUFLDOUHVLQEDVHGVHDODQWV9+1IURPa

t o 75)2,6,11. I n general, despit e t he r educed cur ing

HI¿FLHQF\ RI KLJKO\ ¿OOHG UHVLQEDVHG VHDODQWV

m icr ohar dness t ends t o incr ease w it h incr easing

¿OOHUFRQWHQW1 1. I n t h is r espect , su bm icr on an d

QDQRVL]HG ¿OOHUV VXFK DV WKRVH SUHVHQW LQ WKLV

sealant , ar e r egar ded t o be par t icular ly effect ive in incr easing m icr ohar dness and r educing plast ic defor m at ion under occlusal for ces11.

$Q\ ÀXRULGH VSHFLHV SUHVHQW LQ 8OWUD6HDO ;7® hydr o™ w er e found t o be below t he det ect ion lim it s of bot h t he EDX inst r um ent and t he ion- select ive elect rode. I n cont rast , during a 30- day period under sim ilar experim ent al condit ions, ot her com m ercially

DYDLODEOHUHVLQEDVHG¿VVXUHVHDODQWVDUHUHSRUWHG WRUHOHDVHXSWRNjJFP- 2RIIUHHÀXRULGHLRQV11.

+RZHYHUWKHVHUHSRUWHGOHYHOVRIÀXRULGHUHOHDVH DUHXQOLNHO\WREHVLJQL¿FDQWUHJDUGLQJDQ\EHQH¿FLDO

im p act on acid - an d car ies- r esist an ce of local enam el, and, in t his r espect , t he lack of det ect ible

ÀXRULGHUHOHDVHIURP8OWUD6HDO;7® hydr o™is not r egar ded t o be a com parat ive disadvant age.

M icr ole a k a ge

Dat a obt ained under t he select ed exper im ent al param et ers in t his st udy indicat e t hat laser ablat ion

SULRU WR FRQYHQWLRQDO DFLG HWFKLQJ VLJQL¿FDQWO\

im pr oves t he in vit r o r esist ance of t he sealed t eet h t o m icr oleakage ( Table 2) . The super ior r esist ance t o m icr oleakage of t he lased t eet h is at t r ibut ed t o t he enhanced r oughness of t he ablat ed enam el

VXUIDFHV7KLV¿QGLQJFRQ¿UPVWKDWRI.KRJOLHWDO10 ( 2013)who invest igat ed t he im pact of laser ablat ion as an adj unct t o acid et ching t o precondit ion m olars

SULRU WR VHDOLQJ ZLWK D ¿OOHG K\GURSKLOLF VHDODQW

Ot her st udies, how ever, r epor t t hat lasing pr ior

WRDFLGHWFKLQJSURYLGHVQRVWDWLVWLFDOO\VLJQL¿FDQW

im pr ovem ent in r esist ance t o m icr oleakage3,5. This lack of consensus on t he effect iveness of Er : YAG laser ablat ion pr ior t o acid et ching is likely t o ar ise f r om t h e r an g e of laser set t in g s em p loy ed b y var ious r esear cher s and t he suit abilit y of differ ent sealant s t o t he lased enam el sur faces3,5,10.

The pr incipal m ode of adhesion of r esin- based

Figure 8- (a) Back-scattered scanning electron

¿VVXUHVHDODQWVWRHQDPHOLVYLDWKHIRUPDWLRQRI

m icr om echanically int er locking t ags t hat penet rat e t he m acr o- and m icr o- por osit ies pr esent ed by t he pr econdit ioned enam el. Ver y lit t le physicochem ical int eract ion exist s bet w een t he high ener gy sur face of t he hydr oxyapat it e in enam el and t he or ganic const it uent s of t he sealant13.

En a m e l p r e c o n d i t i o n i n g b y e t c h i n g w i t h phosphor ic acid gel is cur r ent ly t he m ost com m on m et hod used t o prepare t he occlusal t oot h surface t o

UHFHLYHWKH¿VVXUHVHDODQW7KLVPHWKRGRIHWFKLQJ

m ay n ot pr ov e en t ir ely ef f ect iv e on apr ism at ic

HQDPHOORFDWHGDWWKH¿VVXUHHQWUDQFHDQGLQWKH SUHVHQFH RI UHPQDQW SHOOLFOH ELR¿OP DQG RUJDQLF GHEULVORGJHGLQGHHSQDUURZ¿VVXUHV1,5,9. Pot ent ial advant ages of laser ablat ion prior t o acid et ching are report ed t o be: enhanced roughness and wet t abilit y of t he lased enam el surface; m ore effect ive rem oval of pellicle an d debr is; su per ior con dit ion in g of apr ism at ic hy dr ox yapat it e; an d en h an ced acid-r esist ance of lased enam el5 , 9. Disadvant ages of

ODVHUFRQGLWLRQLQJLQFOXGHWKHSRWHQWLDOYLWUL¿FDWLRQ

of t he enam el sur face at subablat ive laser ener gies and excessive r oughness and m icr ocracking under ext r em e ablat ion5,12. Laser condit ioning of enam el is a relat ively recent t echnique and furt her research is r equir ed t o opt im ise t he operat ing param et er s.

,WLVFRQMHFWXUHGWKDWWKHPRUHYLVFRXV¿VVXUH VHDODQWVPD\IDLOWRÀRZUHDGLO\DQGIXOO\DGDSWWR

t he r ougher sur faces pr esent ed by lased enam el10. I n ad d it ion , t h is st u d y h as d em on st r at ed t h at in or g an ic f iller p ar t icles w it h in a sealan t m ay par t ially separat e out fr om t he r esin phase and

FRQJUHJDWH DW WKH LQWHUIDFH DV LW ÀRZV RYHU WKH

r ou gh lased su r face. I t is n ot pr esen t ly k n ow n

ZKHWKHUWKLVFRQJUHJDWLRQRI¿OOHUSDUWLFOHVDWWKH

int er face of lased enam el w ill have a det r im ent al im pact on t he long- t er m clinical per for m ance of t he sealant .

$WSUHVHQWDOOFRPPHUFLDOUHVLQEDVHG¿VVXUH

sealant s ar e designed for acid et ched enam el. I t is suggest ed t hat , t o t ake full advant age of t he

SRWHQWLDO EHQH¿WV RI ODVHU FRQGLWLRQLQJ D QHZ JHQHUDWLRQRI¿VVXUHVHDODQWVZKLFKDUHVSHFL¿FDOO\

t ailor ed t o adher e and adapt t o lased enam el, is r equir ed.

CON CLUSI ON S

The pur pose of t his st udy was t o charact er ise

WKH QHZ UHVLQEDVHG K\GURSKLOLF ¿VVXUH VHDODQW

Ul t r a S e a l X T® h y d r o ™ ( Ul t r a d e n t Pr o d u c t s , USA) , and t o invest igat e it s in vit r o r esist ance t o m icr oleak age aft er placem ent on convent ionally acid et ched and sequent ially lased and acid et ched m olar s.

Sca n n i n g el ect r o n m i cr o sco p y a n d en er g y disper sive X- ray analysis of fract ur e and polished

su r f aces in d icat ed t h at Ult r aSeal XT® h y d r o™ com p r ises ir r eg u lar su b m icr on an d n an o- sized

VLOLFRQ EDULXP DQG DOXPLQLXPEHDULQJ ¿OOHU

phases em bedded in a duct ile r esin m at r ix. Under st a n d a r d l i g h t cu r i n g , Ul t r a Sea l XT® h y d r o ™ ach iev ed a degr ee of conv er sion ( 5 0 . 6 ± 2 . 2 % ) and a Vicker s m icr ohar dness ( 24.2± 1.5) t owar ds t he low er end of t he r epor t ed ranges for ot her

FRPPHUFLDODFU\ODWHEDVHG¿VVXUHVHDODQWV /DVHUSUHFRQGLWLRQLQJZDVIRXQGWRVLJQL¿FDQWO\

decr ease m icr oleak age an d t o in cr ease en am el

VXUIDFHURXJKQHVVZKLFKFDXVHG]RQLQJRIWKH¿OOHU

par t icles at t he enam el- sealant int er face.

REFEREN CES

1- Baygin O, Kor km az FM, Tüzüner T, Tanr iver M. The effect of

GLIIHUHQWHQDPHOVXUIDFHWUHDWPHQWVRQWKHPLFUROHDNDJHRI¿VVXUH

sealant s. Laser s Med Sci. 2012; 27: 153- 60.

2- Beun S, Bailly C, Devaux J, Leloup G. Physical, m echanical

DQG UKHRORJLFDO FKDUDFWHUL]DWLRQ RI UHVLQEDVHG SLW DQG ¿VVXUH VHDODQWV FRPSDUHG WR ÀRZDEOH UHVLQ FRPSRVLWHV 'HQW 0DWHU

2012; 28: 349- 59.

3- Borsat t o MC, Corona SA, Palm a- Dibb RG, Ram os RP, Pécora JD. Micr oleakage of a r esin sealant aft er acid- et ching, Er : YAG laser

LUUDGLDWLRQDQGDLUDEUDVLRQRISLWVDQG¿VVXUHV-&OLQ/DVHU0HG

Sur g. 2001; 19( 2) : 83- 7.

4- Brinker SP. Prevent ing carious lesions. Clinical st eps for applying a newly int roduced hydrophilic sealant . Dent Today. 2013; 32: 82- 3. 5- Ciucchi P, Neuhaus KW, Em er ich M, Peut zfeldt A, Lussi A. Ev alu at ion of d if f er en t t y p es of en am el con d it ion in g b ef or e

DSSOLFDWLRQRID¿VVXUHVHDODQW/DVHUV0HG6FL

6 - Eliad es A, Bir p ou E, Eliad es T, Eliad es G. Self- ad h esiv e

UHVWRUDWLYHVDVSLWDQG¿VVXUHVHDODQWVDFRPSDUDWLYHODERUDWRU\

st udy. Dent Mat er. 2013; 29: 752- 62.

7- Fer racane JL. Cor r elat ion bet w een har dness and degr ee of

FRQYHUVLRQGXULQJWKHVHWWLQJUHDFWLRQRIXQ¿OOHGGHQWDOUHVWRUDWLYH

r esins. Dent Mat er. 1985; 1: 11- 4.

*RRFK%)*ULI¿Q62*UD\6..RKQ:*5R]LHU5*6LHJDO

M, et al. Pr event ing dent al car ies t hr ough school- based sealant pr ogram s: updat ed r ecom m endat ions and r eview s of evidence. J Am Dent Assoc. 2009; 140: 1356- 65.

9 - Hossain M, Yam ada Y, Masu da- Mu r ak am i Y, Nak am u r a Y. Rem oval of or gan ic debr is w it h Er : YAG laser ir r adiat ion an d m icr oleak ag e of f issu r es sealan t s in v it r o. Laser s Med Sci. 2012; 27: 895- 902.

10- Khogli AE, Cauw els R, Ver cr uysse C, Ver beeck R, Mar t ens L. Micr oleakage and penet rat ion of a hydr ophilic sealant and a convent ional r esin- based sealant as a funct ion of pr eparat ion t echniques: a laborat or y st udy. I nt J Paediat r Dent . 2013; 23: 13-22.

.XúJ|]$7]QHU7hONHU0.HPHU%6DUD\2&RQYHUVLRQ

d eg r ee, m i cr oh ar d n ess, m i cr ol eak ag e an d f l u or i d e r el ease of d if f er en t f issu r e sealan t s. J Mech Beh av Biom ed Mat er. 2010; 3: 594- 9.

12- Moshonov J, St abholz A, Zyskind D, Shar lin E, Per et z B. Acid-et ched and erbium : yt t rium alum inium garnAcid-et laser- t reat ed enam el

IRU¿VVXUHVHDODQWVDFRPSDULVRQRIPLFUROHDNDJH,QW-3DHGLDWU

Dent . 2005; 15: 205- 9.

13- Sezinando A. Looking for t he ideal adhesive – a r eview. Rev Por t Est om at ol Med Med Dent Cir Maxilofac. 2014; 55: 194- 206. 14- Ult radent Pr oduct s, I nc. Safet y Dat a Sheet : Ult raSeal XT® hydr oTM [ I nt er net ] . Sout h Jor dan: Ult radent Pr oduct s I nc.; 2015 [ cit ed Mar ch 31 2016] . Available fr om : ht t ps: / / w w w.ult radent . com / eu/ MSDS/ Ult raSeal% 20XT% 20hydr o.pdf