TOPICS:

Analysis and Design

&LYLO:RUNV

1HZ0DWHULDOVDQG6WUXFWXUHV

/LIH&\FOH'HVLJQ

0RGHOOLQJRI&RQFUHWH

&RQVHUYDWLRQRI6WUXFWXUHV

1XPHULFDO0RGHOLQJ

6DIHW\DQG5HOLDELOLW\

,QQRYDWLRQLQ%XLOGLQJV

35(/,0,1$5<6&,(17,),&352*5$00(

±

6<0326,80

0RQGD\WKWK0D\

Room: Carstensen

9.00-10.30 WELCOME 23(1,1*3(5)250$1&( :(/&20($''5(66

by Kaare K. B. Dahl and Harald S. Müller, ÀE President

35(6(17$7,212)ÀE0('$/2)0(5,7$1'ÀE+2125$5<0(0%(56+,3 by Harald S. Müller, ÀE president

352)(66256%-5$0%//$1'-*+$11(0$11,10(025,$0 by Mikael W. Bræstrup

10.30-11.00BREAK

11.00-12.30

KEYNOTE SPEAKERS Civil works

7+('(9(/230(172)7+(&21&5(7(5(48,5(0(176)(+0$51%(/7),;('/,1. Ulf Jönsson, Construction Manager, Femern A/S

New Materials and Structures

',*,7$/)$%5,&$7,212)$)8//6&$/(6&8/3785$/&21&5(7(6758&785( Thomas Juul Andersen. Danish Technological Institute, Co-authors: Nyholm and Greisen

Life cycle design

7+(52/(2)/,0,767$7(6(/(&7,21,17+('(6,*1$1'0$1$*(0(172)6867$,1$%/( 5(,1)25&('&21&5(7(,1)5$6758&785(

Michael D. Lepech, Stanford University

12.30-14.00LUNCH

MONDAY MORNING

35(6(17$7,212)ÀEAAYE WINNERS

Room: Carstensen

14.00-15.30

Young Engineer Award Session 23(1,1*5(0$5.6 by Fernando Stucchi, Jury Chair :,11(52)5(6($5&+&$7(*25< -223('526$1726 :,11(52)5(6($5&+&$7(*25< <8*8$1*<$1* :,11(52)'(6,*1 &216758&7,21 &$7(*25< /8&$&$5*1,12 63(&,$/0(17,21'(6,*1$1' &216758&7,21 .c5()/,1'7-5*(16(1 &/26,1*5(0$5.6 by Fernando Stucchi, Jury Chair

16.00-17.30

TOPIC: ANALYSIS AND DESIGN

Lead Paper session

,19(67,*$7,212)6+($5'(6,*1$&&25',1* TO ÀE02'(/&2'($1'81'(5/<,1* 7+(25,(6by Norskov, Strørup, Hagsten Session: Shear I

217+('(9(/230(172)$7+(25<)25 )/(;85$/0(0%(56)$,/(',16+($5 by Tung, Tue

6+($5'(6,*12)5(,1)25&('$1' 35(675(66('&21&5(7(%($06%$6('21 $0(&+$1,&$/02'(/by Marí, Jesús Miguel, Cladera, Ribas

$1$/<7,&$/,19(67,*$7,21216+($5 )$,/85(0(&+$1,602)5&7%($06:,7+ 67,55836by Nakamura, Sato

7+(6+($55$7,2$1'7<3(2)$33/,('/2$' (;3(5,0(17$/$1$/<6,6)257+(&5,7,&$/ &52666(&7,21by Bodzak

Room: Harlekin

14.00-15.30

TOPIC: CIVIL WORKS

Session: Civil works I

237,0,=('7%07811(/62/87,21)257+( )(+0$51%(/7),;('/,1.

by Pompeu-Santos

7+(³'(85*$1&.'2./2&.´32572) $17:(53

by Pauwels, De Kesel

6/,3)250,1*2)+,*+675(1*7+ &21&5(7( by Fosså 7+('(6,*1$1'&216758&7,212)$ 67((/&21&5(7(&20326,7(5$,/:$< 9,$'8&7 by Stroscio 7+(³1(:(8523$%5,'*(´&5266(67+( 5,9(5'$18%( by Grange '(6,*1$1'&216758&7,212)7+( 08.2*$:$%5,'*(

by Mizuno, Samizo, Fukuda, Kasuga

16.00-17.30

Session: Civil works II

(1+$1&,1*3(5)250$1&( $33($5$1&( 2)23(163$1'5(/$5&+%5,'*(6 by Panday 7+('(6,*1$1'&216758&7,212) 35(&$67&21&5(7(&20321(176)25 %5,'*(6$/21*$52$':,'(1,1*6&+(0( by Stroscio ,17(*5$/%5,'*(65(&(1775(1'72 (1+$1&(%5,'*()($785(6by Panday %8,/',1*%5,'*(686,1*/,*+7:(,*+7 %5,'*(*,5'(562872)&21&5(7( by Foremniak, Kollegger, Eder

678'<21063$1(;75$'26(' %5,'*(6by Kasuga

'(6,*1$1'&216758&7,212)2.(*$:$ 9,$'8&7:+,&++$635(&$676(*0(17$/ 86+$3('%877(5)/<:(%*,5'(56 by Kasuga, Homma

6$)('(02/,7,21$77$03$,17(51$7,21$/ $,53257by Konz

MONDAY AFTERNOON

15.30-16.00 BREAK-POSTER

RECEPTION

Room: Columbine

14.00-15.30

TOPIC: NEW MATERIALS AND STRUCTURES

Session: Structures I

$66(0%/<$1'/,)7,1*2)3($5/&+$,1 $5&+(6

by Halding, Hertz, Viebæk, Kennedy

+202*(1(,7<$1'675(1*7+2)0257$5 -2,176,13($5/&+$,1%5,'*(6

by Lund, Arvidsson, Kielsgaard Hansen '85$%/((;3$16,21-2,17)25/21* ,17(*5$/$%870(17%5,'*(6 by Eichwalder, Kollegger, Kleiser

7(&+12/2*,&$/'(9(/230(172)3& %5,'*(:,7++,*+'85$%,/,7<726$/7 '$0$*(

by Toyofuko, Uezu, Kamiyama

$33/,&$7,212)(1*,1((5('&(0(17,7,286 &20326,7(67235(&$67%($0&2/801 68%$66(0%/$*(81'(5&2/8015(029$/ 6&(1$5,26 by Kang, Tan

(;3(5,0(17$/$1'$1$/<7,&$/678',(6 21%(+$9,252)%5$&.(76758&785(6 5(,1)25&(':,7+&21&5(7($'+(6,9( $1'&)536+((7

by Yamashita, Hiroi, Arazoe, Yamamoto, Miyagawa

16.00-17.30

Session: Structures II

'(6,*12)$&21&5(7((/(0(17'20()25 526.,/'()(67,9$/

by Ludwigsen

8/75$/,*+7&21&5(7(0(0%(56,163,5(' %<%$0%22

by Busse, Empelmann

())(&72))535(,1)25&(0(1721$5&+,1* $&7,21,1)53675(1*7+(1('&217,18286 &21&5(7(%($06

by Zeng, Caspeele, Taerwe

217+(&21&(37,212))/2$7,1*&21&5(7( 6758&785(6

by Chyra, Arana Villafán, Sigrist

&5$&.,1+,%,7,1*)2581'(5*5281' 6,'(:$//6758&785(%$6('21'8$/ 5(*8/$7,217(&+12/2*<2)7(03(5$785( ),(/'$1'(;3$16,21+,6725<

by Tian, Wang, Zhang, Liu, Miao

&$%/(67$<(')227%5,'*(:,7+8+3&'(&. 29(57+(/$%(5,9(5,1&(/$.29,&( by Kalny, Komanec, Kvasnicka, Broz, Koukolik, Vitek

Room: Pjerrot

14.00-15.30

TOPIC: LIFE CYCLE DESIGN

Session: LCA, LCC and Service Life I 0$,1/,1(0$,17(1$1&(5(1(:$/$1' ,03529(0(172)5$,/75$163257,1)5$6758& -785(725('8&((&2120,&$1'(19,5210(1 -7$/,03$&76by Linneberg, Solgaard, Jensen, Sloth 6867$,1$%,/,7<$1''85$%,/,7<*2+$1',1 +$1'7+($33/,&$7,212)$&20%,1(' 6867$,1$%,/,7<$1''85$%,/,7<$3352$&+72 $/$5*(7811(/352-(&7,1$%8'+$%, by Jackson, Høibye, Edvardsen

+2:/,)(&<&/(&2676&5,7(5,$0$<%(86(' )25'(6,*1/,)($1'255(3/$&(0(17&<&/( by Solgaard, Edvardsen, Matos, McKenna

),(/'$1'/$%25$725<678',(6217+(6(5 -9,&(/,)(35(',&7,212)5&6758&785(6,1 0$5,1((19,5210(17 by Safehian, Ramezanianpour ())(&72)(19,5210(17$/)$&725621&+/2 -5,'(,1*5(66,172&21&5(7(,17+(0$5,1( $70263+(5(=21(2):$.$<$0$35()(&785( by An, Mihoichi, Noguchi, Hata, Kaneshiro, Shirato 3(5)250$1&((9$/8$7,21$1'5(0$,1,1* /,)(35(',&7,212)$1(;,67,1*%5,'*(%< -%06by Miyamoto, Emoto

16.00-17.30

Session: LCA, LCC and Service Life II

6(/(&7,9(86(2)67$,1/(6667((/5(%$572 ,1&5($6(&21&5(7('85$%,/,7<by Borderon 7+(1(:&2$67$/52$'215(81,21,6/$1' )5$1&($33/,&$7,212)'85$%,/,7<02'(/ 72$5($/&$6(by Mai-Nhu, Rougeau, Linger, Denis, Magne ())(&72)&25526,21217+()$7,*8( 6(59,&(/,)(2)5(,1)25&('&21&5(7(%($06 by Veerman 08/7,3+<6,&6$1'08/7,6&$/('(7(5,25$ -7,2102'(//,1*2)5(,1)25&('&21&5(7( 3$57,&283/,1*75$163257$1'&25526,21 $77+(0$7(5,$/6&$/( by Michel

08/7,3+<6,&$/$1'08/7,6&$/('(7(5,2 -5$7,2102'(//,1*2)5(,1)25&('&21&5(7( 3$57,,&283/,1*&25526,21$1''$0$*($7 7+(6758&785$/6&$/(

by Lepech, Rao, Kiremidjian, Michek, Stang, Geiker '85$%,/,7<'(6,*12)7+(/21*(67%5,'*(,1 1(:<25.67$7(by Solgaard, Edvardsen, Langlois

Room: Carstensen

9.00-10.30

TOPIC: ANALYSIS AND DESIGN

Session: Shear II

,19(67,*$7,216,1727+(6+($5/2$' %($5,1*&$3$&,7<2)$35(675(66(' 7:263$1&21&5(7(%($0),1',1*6)520 $/$5*(6&$/((;3(5,0(17 by Gleich 6+($5%(+$9,252)(;,67,1*%5,'*(6 :,7+287$1':,7+$0,1,080$028172) 6+($55(,1)25&(0(17 by Huber

())(&72)6+5,1.$*($1'675(1*7+ '(9(/230(17+,6725,(621+,*+675(1*7+ &21&5(7(%($06,16+($5

by Matsumoto, Osakabe, Niwa

'()250$%,/,7<2)5(,1)25&('&21&5(7( 0(0%(56,16+($5by Hong

7(67$1'$1$/<6,62)3$57/<35(&$675& 6+($5:$//by Li, Lu, Xilin

6(,60,&%(+$9,2852)5(,1)25&('&21 -&5(7(:$//6:,7+0,1,0809(57,&$/ 5(,1)25&(0(17by Lu, Henry

11.00-12.30

Session: Shear III

(;3(5,0(17$/,19(67,*$7,216217+( 6+($5&$3$&,7<2)5&6/$%681'(5 &21&(175$7('/2$'6±,1)/8(1&(2) '(*5((2)5(675$,17$1'020(176+($5 5$7,2

by Reissen, Hegger

/,0,7$1$/<6,6)25381&+,1*6+($5'( -6,*12)&203$&76/$%6$1')227,1*6 E\)HUQiQGH]5XL]6LP}HV0XWWRQL9L~OD)DULD 02',),('%21'02'(/)256+($5,16/$%6 81'(5&21&(175$7('/2$'6

by Lantsoght, Van der Veen, De Boer 381&+,1*2)5&7+,&.3/$7(6 ±(;3(5,0(17$/7(676$1'$1$/<6,6 by Krakowski, Swiniarski, Urban

381&+,1*,132677(16,21('&21&5(7( )/$76/$%6:,7+('*(&2/8016 by Melo, Barban

)/$76/$%381&+,1*%(+$9,28581'(5 &<&/,&+25,=217$//2$',1*

by Almeida, Inácio, Lúcio, Ramos

Room: Harlekin

9.00-10.30

TOPIC: MODELLING OF CONCRETE

Lead Paper Session

$1,1129$7,9((;3(5,0(17$/352&('85( 72(1+$1&(81'(567$1',1*2)

5(%$5&21&5(7(%21' by Dancygier, Leibovitch, Yankelevsky Session: Mechanics

$352%$%,/,67,&02'(/7235(',&7 $**5(*$7(66,=(',675,%87,21())(&721 7+(&2035(66,9(675(1*7+2)1250$/ $1'+,*+675(1*7+&21&5(7(6 by Miled, Limam, Sab

(9$/8$7,212)0(&+$1,&$/3523(57,(62) &21&5(7(

by Munch-Petersen, Meson

&2167,787,9(02'(/)256+($575$16)(5 ,18/75$+,*+3(5)250$1&(),%(5 5(,1)25&('&21&5(7(

by Lee, Hong

,1)/8(1&(2)7(03(5$785(217+()$7,*8( %(+$9,2852)&21&5(7(

by Elsmeier

11.00-12.30

Session: Cracking and Transport I

)$7,*8(%(+$9,2852)+,*+675(1*7+ *5287,1*&21&5(7(7(67('81'(5:$7(5 by Hümme 217+(&5$&.,1*/2&$/,=$7,21,17(16,/( 5(,1)25&('&21&5(7(%$56:,7+67((/ ),%(56

by Dancygier, Karinski

180(5,&$/'02'(//,1*2)$1&+25$*( &25526,21$1'63$//,1*

by Kamyab, Lundgren

$5$3,'$1'5(3($7$%/(0(7+2')25 (67$%/,6+,1*7+(:$7(53(50($%,/,7<2) &5$&.('0257$563(&,0(16

by Palin, Jonkers, Wiktor

/2&$/,=$7,212)$&2867,&(0,66,21,1 5(,1)25&('&21&5(7(86,1*$+(7(52*( -1(2869(/2&,7<02'(/$1'08/7,/,1($5 :$9(3523$*$7,213$7+6by Gollob, Vogel &(0+$33$1$33/,&$7,21)25+<'5$7,21 .,1(7,&6&283/(':,7+08/7,6&$/()(0 $1$/<6,6by Leal da Silva, Šmilauer

TUESDAY MORNING

10.30-11.00BREAK

12.30-14.00LUNCH

Room: Columbine

9.00-10.30

TOPIC: NEW MATERIALS AND STRUCTURES

Session: Structures and UHPC

35()$%5,&$7('12167$1'$5'6+(// 6758&785(60$'(2)8+3&±6758&785$/ &211(&7,216

by Santner, Freytag, Trummer

6+$3(237,0,=('6758760$'(2) 8/75$+,*+3(5)250$1&(&21&5(7( by Henke, Fischer

())(&72)86+$3(':,5(0(6+('8+3&& 3(50$1(17)250217+()/(;85$/ %(+$9,28562)5&%($0by Wu, Lin )8//8+3)5&&3('(675,$1%5,'*(,1 (,1'+29(17+(1(7+(5/$1'6

by Tirimanna, Falbr

675(665(',675,%87,21,1%5,'*(6%8,/7 :,7+8/75$7+,135(&$67*,5'(56 by Suza, Kollegger

35(675(66(',%($060$'(2)8/75$ +,*+3(5)250$1&(&21&5(7()25 &216758&7,212)5$,/:$<%5,'*(6 by Tej, Kolísko, Bouška, Vokác, Cech

11.00-12.30

Session: Materials I

'(6,*12)&21&5(7()25+,*+)/2:$%,/, -7<352*5(665(32572)ÀE7$6.*5283 by Schmidt, Grünewald, Ferrara, Dehn

7,0($1'/2$''(3(1'(17%(+$9,2852) )/2:$%/(&21&5(7(352*5(665(32572)

ÀE7$6.*5283

by Leemann, Hammer, Grunewald, Ferrara, Dehn ,03$&72)02/(&8/$56758&785(2) &20%/,.(32/<0(521',63(56,21 3523(57,(62)&(0(173$67(6 by Qiao, Ran, Liu

7+(&2/285327(17,$/62)66$ &217$,1,1*0257$5

by Kappel, Bache, Ottosen, Kirkelund, Goltermann &2/285(')$,5)$&('&21&5(7( (9$/8$7,212)&2/285721( by Cauberg

Room: Pjerrot

9.00-10.30

TOPIC: LIFE CYCLE DESIGN

Session: LCA, LCC and Service Life III $6867$,1$%,/,7<&203$5,621%(7:((1 5(129$7,21$1'1(:%8,/'237,21)257+( *$/(&233(5%5,'*(by Villa, Den Blanken, Thie 35(&$67&21&5(7()256867$,1$%/( %8,/',1*6by Nieminen

TOPIC: CONSERVATION OF STRUCTURES

Lead Paper session

6(77,1*832)$'$7$%$6('(',&$7('72 '85$%,/,7<,1',&$7256%<7+(&,9,/:25.6 )5(1&+$662&,$7,21$)*&726833257 7+(,03/(0(17$7,212)&21&5(7(3(5)25 -0$1&(%$6('$3352$&+

by Linger, Carcasses, Cussigh, Rougeau, Barberon, Thauvin, Cassagnbere, Mai-Nhu, Dierkens Session: Asset Management

0$1$*(0(172)0(/(9$7('6(&7,21 68%6758&785(6

by Brock, Hendy, Nicholls

11.00-12.30

Session: Asset Management and Diagnosis

%5,'*(0$,17(1$1&(02'(/686,1*(;3(57 23,1,21

by Guimarães, Campos e Matos

/21*7(50$66(70$1$*(0(17$3352$&+ )25&21&5(7(%5,'*(6$1'7811(/6 by Knudsen, Andersen, Nielsen

(;3(57&(175()25,1)5$6758&785( 0$7(5,$/6

by Poulsen, Stang, Sørensen, Pade, Mathiesen 678'<21',$*126,60(7+2')25&$%/( 67$<('$1'(;75$'26('%5,'*(:,7+ &21&5(7(67((/&20326,7(0$,1*,5'(5 by Sakai 6(,60,&3(5)250$1&(2)5&%($06)520 (;,67,1*%8,/',1*6

by Araki, Hibino

'$0$*($66(660(172)$5&6758&785( $))(&7('%<)5267$1'6$/7$&7,216 by Mizuta, Yoshinori, Hisatoshi, Norihiro, Akinori, Tetsuji

12.30-14.00LUNCH

Room: Carstensen

14.00-15.30

TOPIC: ANALYSIS AND DESIGN

Session: Shear IV

(;3(5,0(17$/,19(67,*$7,2162) 381&+,1*6+($5&21&5(7(6/$%6:,7+ ',))(5(177<3(675$169(56(

5(,1)25&(0(17 by Krawczyk, Urban

381&+,1*6+($5675(1*7+(1,1*2))/$7 6/$%6&)53$1'6+($55(,1)25&(0(17 by Moreno /2$'&$55<,1*&$3$&,7<2).(<('-2,176 5(,1)25&(':,7++,*+675(1*7+:,5( 523(/2236

by Joergensen, Hoang

21(:$<6+($5%(+$9,2852),1',5(&7/< /2$'('/$5*()227,1*6by Uzel, Bentz, Collins 217+(5(6,67$1&(2))$67(1,1*3/$7(6 :,7+6833/(0(17$5<5(,1)25&(0(17 E\%XMĖDN)DUEDN%DKOHGD/HLQRQHQ 7+(,1&5($6,1*%($5,1*&$3$&,7<:+,/( 5(029,1*&21&5(7()5205(,1)25&(' %($06

by Hoogen, Vergoossen, Blom

16.00-17.30

Session: Columns and Elements I

/2$'&$55<,1*&$3$&,7<2)5(,1)25&(' &21&5(7(&2/8016,17+(&211(&7,21 =21(:,7+6/$%2)/2:(5675(1*7+ &21&5(7( E\*RáG\Q $&21),1(0(1702'(/)255(,1)25&(' &21&5(7(&2/8016by Tung, Tue

(;3(5,0(17$/678'<21'5&)5$0( :,7+0,''/(&2/8015(029('81'(5 352*5(66,9(&2//$36(

by Lim, Lee, Tan

)25&(,1752'8&7,21,172)/$1*(62) 6758&785$/&21&5(7(7%($06 by Schütte, Sigrist

())(&72)7+(,1$&&85$&<217+(675(66 ',675,%87,21,1'5<&211(&7,2162) 02'8/$5&216758&7,216

by Theiler, Reicht

Room: Harlekin

14.00-15.30

TOPIC: MODELLING OF CONCRETE

Session: Cracking and Transport II

02&.83)259(5,),&$7,212)7(03(5$ -785(6,1/$5*(&21&5(7(6758&785(6 by Aarre, Frederiksen

,19(67,*$7,212)&5$&.'(9(/230(17,1 $)$,5)$&('&21&5(7()/225

by Waldmann, Weiler

&+/25,'(75$163257,1&21&5(7( 6758&785$/(/(0(176$)7(55(3$,5 by Rahimi

1(:,16,*+76)2502'(/,1*&+/25,'( ,1*5(6681'(5)5((=(7+$:/2$',1* by Ferreira, Leivo

$1,19(67,*$7,212)7+(,1)/8(1&(2) 9$5<,1*(;32685(7(03(5$785(21 &+/25,'(,1*5(66,1&21&5(7( by Poulsen, Sørensen

16.00-17.30

TOPIC: ANALYSIS AND DESIGN

Session: Fibre Reinforced Concrete

1(:6:(',6+'(6,*1*8,'()25),%5(&21 -&5(7(6758&785(6by Silfwerbrand, Hedebratt &5$&.:,'7+6,1&21&5(7(:,7+),%(56 $1'0$,15(,1)25&(0(17

by Christensen, Ulfkjær

6+($5&$3$&,7<2)),%(55(,1)25&(' &21&5(7(by Toubia, Ishtewi

,1)/8(1&(2)67((/),%(56$1'67,55836 217+(67((/&21&5(7(%21'%(+$9,25 by El Debs, Correa

&2035(66,9()$7,*8(675(1*7+2)6)& 81'(5/2:&<&/()$7,*8(/2$'by Yoon $1$/<7,&$/02'(/6)256758&785$/ %(+$9,2852)),%5(5(,1)25&('&21&5(7( %($06:,7+67((/25)53%$56

by Ali, Sheikh, Oehlers

TUESDAY AFTERNOON

15.30-16.00 BREAK-POSTER

DINNER

Room: Columbine

14.00-15.30

TOPIC: NEW MATERIALS AND STRUCTURES

Session: Materials II

6(/)+($/,1*&$3$%,/,7<2)&21&5(7( &217$,1,1*&5<67$//,1($'0,;785(6,1 ',))(5(17(;32685(&21',7,216 by Roig-Flores, Moscato, Serna Ros, Ferrara 1$127(&+2/2*,(6,11(:6758&785$/ &21&5(7(635$&7,&($1'287/22. by Falikman, Gusev

&(0(17,7,286+<%5,'0$7(5,$/6$1' ,17(*5$7('7(&+12/2*< by Greisen &+$//(1*(2)7(;7,/(5(,1)25&('+,*+ 3(5)250$1&(&21&5(7()256867$,1$%/( &216758&7,21

by Hajek, Novotna, Chira, Fiala, Vlach, Leiblova &5&±1(:&+$//(1*(6)251(:0$5.(76 86,1*8/75$+,*+3(5)250$1&(),%5( 5(,1)25&('&21&5(7(

by Aarup, Hansen

(;3(5,0(17$/%21'%(+$9,252) '()250('&)535(%$56,1+,*+675(1*7+ &21&5(7( by Akbas, Celik, Yalcin

16.00-17.30

Session: Materials III

3523(57,(62)3(59,286&21&5(7( &217$,1,1**5281'*5$18/$7('%/$67 )851$&(6/$***%)6$6$6833/(0(17$5< &(0(17,1*0$7(5,$/

by Joshaghani, Ramezanianpour

'(6,*1$1'3523(57,(62)6867$,1$%/( &21&5(7(

by Haist, Moffatt, Breiner, Müller

5(&(17'(9(/230(172)8/75$+,*+ 675(1*7+35(675(66,1*:,5(675$1' 00 by Oshima '(/$<('&21&5(7(35(675(66,1*:,7+ 6+$3(0(025<32/<0(57(1'216 by Pilegis, Teall, Hazelwood, Jefferson, Gardner, Lark $129(/'9$6&8/$51(7:25.,1 &(0(17,7,2860$7(5,$/6

by Davies, Jefferson, Gardner

Room: Pjerrot

14.00-15.30

TOPIC: CONSERVATION OF STRUCTURES

Session: Diagnosis, Monitoring and Repair ',$*126,62)6(9(5($/.$/,$**5(*$7( 5($&7,21,1$),11,6+6:,00,1*322/ by Holt, Lindqvist, Orantie, Ferreira

,1129$7,9(),%(5237,&021,725,1*2):$', /(%$1%5,'*(.6$

by Lebon, Paris, Lamour

5(3$,5021,725,1*2)&5$&.('&21&5(7( )/22586,1*7+(,038/6(±5(63216(0(7+2' by Zoidis, Tatsis, Vlachopoulos, Gotzamanis,

Stærke Clausen, Aggelis, Matikas

$33/,&$%,/,7<2)&$7+2',&3527(&7,21%< *$/9$1,&$12'(6<67(0)255&0(0%(5 81'(5&20%,1(''(7(5,25$7,212) &$5%21$7,21$1'0,;('&+/25,'(6 by Yoshida, Otani. Takaya,, Yamamoto, Miyagawa

16.00-17.30 Session: Repair 678'<217+(())(&7,9(3527(&7,21 0(7+2'6$*$,167&+/25,'($77$&.,1 68%:$<7811(/6 by Mutou '(9(/230(172)5(3$,50(7+2')25 &2552'('3&7(1'216,1,1&203/(7( *5287,1*$5($86,1*/,12&217$,1,1* 62/87,21$1'*5287$1'$33/,&$7,2172 (;,67,1*3&%5,'*(s

by Kamotani, Aoyama, Morikawa

3267,167$//('5(,1)25&(0(17&211(&7,216 81'(58/66/6$1'6867$,1('/2$'6 by Kunz, Randl

Room: Carstensen

9.00-10.30

TOPIC: ANALYSIS AND DESIGN

Session: Columns and Elements II

&21&5(7((/(0(1765(,1)25&(':,7+ /$5*(',$0(7(563$57%21'%(+$9,285 $1'/$33('-2,176by Schoening, Hegger &21&5(7((/(0(1765(,1)25&(':,7+ /$5*(',$0(7(563$57&2/8016 by Oettel, Empelmann

%21'$1''()250$7,21%(+$9,2852) 5(,1)25&(',1)5$/,*+7:(,*+7 &21&5(7(,/&by Hückler, Schlaich

'(6,*1&216,'(5$7,216)256+($5)$,/85( 2))/$7&21&5(7(6/$%6(;326('72),5( by Annerel, Taerwe

())(&72),03(5)(&7,21621&21&5(7( &2/801668%-(&7('72),5(7$.,1*,172 $&&28176(&21'25'(5())(&76 by Wang, Caspeele, Taerwe

'(6,*1)25$&&(/(5$7('+,*+675(1*7+ &21&5(7(&216758&7,2186,1*

67587$1'7,(02'(/ by Tantipidok, Stemberk

11.00-12.30

Session: Special Loadings and Conditions I (92/87,212)'()/(&7,2162)+$81&+(' %($0681'(5&<&/,&/2$'6

by Zanuy, Gallego

6(,60,&7(67,1*2)&211(&7,216,1 35(&$67&21&5(7()/225',$3+5$*06 by Henry, Corney, Ingham

&203$5,6,212)6(,60,&3(5)250$1&(2) 5&35(&$67)$%5,&$7('6+($5:$//:,7+ ',))(5(17,1),///('23(1,1*

by Zhai, Hu

6(,60,&$1$/<6,62)5&&2/8016:,7+ 6,0,/,78'(/$:&216,'(5,1*675$,1 ',67257,21())(&7

by Park, Cho

6+($5)$7,*8(%(+$9,2852)5&& $17,/(9(5%5,'*('(&.6/$%681'(5 &21&(175$7('/2$'6

by Fernández Ruiz, Natário, Muttoni

121/,1($5$1$/<6,6/1*&21&5(7(7$1. $7&5<2*(1,&7(03(5$785(6

by Freitas, Mayorca, Eriksen

Room: Harlekin

9.00-10.30

TOPIC: NUMERICAL MODELLING

Lead Paper session

6+(//'(6,*1±()),&,(17$1',1129$7,9( '(6,*1722/)25&21&5(7(6758&785(6 by Nyhus

Session: Numerical Modelling I 35(/,0,1$5<$1$/<6,62)5&:$// (/21*$7,21

by Encina, Henry

'(6,*12)$0,;(')281'$7,21)257+( +,*+63(('5$,/:$<67$7,212)/2'= )$%5<&=1$32/$1'

by Mugnier, Magne Tachago, Landi, Chiriotti 67(3:,6(180(5,&$/352&('85()257+( 7,0('(3(1'(1702'(//,1*2)&21&5(7( %($067$.,1*,172$&&2817&5((3$1' &5((35(&29(5<

by Criel, Caspeele

62/87,21675$7(*<)25/$5*(6&$/( 121/,1($5),1,7((/(0(17$1$/<6(62) &21&5(7(6758&785(6

by Engen, Hendriks, Øverli, Åldstedt

11.00-12.30

Session: Numerical Modelling II ,1)/8(1&(2)&+/25,'(,1'8&(' &25526,21217(16,/(0(0%5$1( %(+$9,2852)5(,1)25&('&21&5(7(6/$%6 by Botte, Caspeele, Taerwe

6,08/$7,212)&21&5(7()5$&785(81'(5 ',))(5(17/2$',1*9(/2&,7,(6

by Beckmann, Schicktanz, Curbach

$180(5,&$/5(6($5&+21352%$%,/,67,& &+$5$&7(5,67,&62)&+/25,'(',))86,9,7< 2)&21&5(7($70(626&$/(

by Chen, Pan

180(5,&$/(9$/8$7,212)7+(,1)/8(1&( 2)),%(5*/$666.,15(,1)25&(0(1721 7+(&5$&.(92/87,212)5&7,(6 by Coccia, Rinaldi, Di Maggio, Imperatore, Rinaldi 3$5$0(75,&$1$/<6,621'()250$7,21 %(+$9,252)&2552'('5(,1)25&('&21 -&5(7(&2/8016by Liu, Jiang

%21'02'(//,1*2)5(,1)25&,1*67((/ 81'(575$169(56(7(16,21

by Zobel, Curbach

WEDNESDAY MORNING

10.30-11.00BREAK

12.30-14.00LUNCH

Room: Columbine

9.00-10.30

TOPIC: NEW MATERIALS AND STRUCTURES

Session: Material Properties

&$5%215(,1)25&('&21&5(7(81'(5 &<&/,&7(16,21/2$',1*by Niederwald, Kauser &203,/$7,21$1'678'<2)$'$7$%$6(2)7(676 $1'5(68/7621)/(;85$/&5((3%(+$9,252) ),%5(5(,1)25&('&21&5(7(63(&,0(16 by Llano-Torre, Garcia-Taengua, Martí Vargas, Serna Ros 6(/)&203$&7$%,/,7<$1'675(1*7+&5,7(5,$ )25&21&5(7(0,;(6:,7+0,1(5$/$'',7,216 $1'),%5(6

by Garcia-Taengua, Sonebi, Crossett, Taylor, Deegan ,1)/8(1&(2)&21&5(7()/2:2163$7,$/',6 -75,%87,21$1'25,(17$7,212)),%5(6,167((/ ),%5(5(,1)25&('6(/)&203$&7,1*&21&5(7( by Andries, Van Itterbeeck, Van Gysel, Vandewalle, Cauberg %21'2)5(%$567267((/),%(55(,1)25&(' &21&5(7(0,1,080&21&5(7(&29(5 5(48,5(0(1767235(9(1763/,77,1* by Garcia-Taengua, Mart-Vargas, Serna Ros

,1)/8(1&(2)7(03(5$785(%(/2:&21 7+(0(&+$1,&$/3523(57,(62)&21&5(7( by Accosta, Haist, Müller

11.00-12.30

TOPIC: SAFETY AND RELIABILITY

Lead paper session

3(5)250$1&($1''$0$*(62)5&6/$%6,1),5( by Giuliani, Gentili

Session: Safety and Reliability

5(92/87,21,1%8,/',1*$1'),5(3522),1* ,1)5$6758&785(6by Hol, Roelfsema

),5('(6,*12)&21&5(7(6758&785(6%$6('21$ /(9(/62)$3352;,0$7,21$3352$&+by Fernández Ruiz, Gómez Navarro, Bamonte

81&(57$,17,(6,15(6,67$1&(62)6281'$1' &25526,21'$0$*('5(,1)25&('&21&5(7( 6758&785(6$&&25',1*72(1by Sykora, Holicky, Prieto, Tanner

&+/25,'(,1'8&(''(/$<(')5$&785(2) 35(675(66,1*:,5(6$1'6758&785$/5(/,$%,/,7< 2)3&%5,'*(6by Mino, Morikawa

63$7,$/9$5,$%,/,7<2)0$7(5,$/3523(57,(6$1' ,76,1)/8(1&(216758&785$/5(/,$%,/,7<2) 8+3)&&2/8016by Tran, Grziwa, Graubner

Room: Pjerrot

9.00-10.30

TOPIC: CONSERVATION OF STRUCTURES

Session: Repair and Strengthening

),567%8,/',1*5(752),77('72(1(8 -52&2'(7(67('%<'(6,*1/(9(/ ($57+48$.(

by Fardis, Liosatou, Kosmopoulos 675(1*7+(1,1*7+(&21&5(7(&2/ -8016:,7+7+(&$5%2132/<0(5),%5(6 $1'%(+$9,28581'(5&(175,&/2$'6by Kabashi, Krasniqi, Nushi

3(5)250$1&(2)&21&5(7(3$1(/6 675(1*7+(1('86,1*&)530$7(5,$/6 by Kim, Jirsa, Ghannoum

675(1*7+(1,1*2)0$%,6+23721 29(5%5,'*(

by McKenna, Dunne

)/(;85$/675(1*7+(1,1*2)5&6/$%6 :,7+35(7(16,21('$1'12135(7(1 -6,21('1($5685)$&(02817('&)53 675,36

by Przygocka, Lasek, Kotynia

11.00-12.30

TOPIC: INNOVATION IN BUILDINGS

Lead paper session

683(5/,*+76/'(&.(/(0(176:,7+ ),;('(1'&211(&7,216

by Hertz

Session: Innovation in Buildings I

'(6,*13$5$0(7(56)2508/7<6725(< 35(&$67&21&5(7(6758&785(6:,7+ 6(0,5,*,'&211(&7,21

by El Debs, Marin

(;3(5,0(17$/678'<217+(6(,60,& %(+$9,2852)$1,1129$7,9(+<%5,' 6+($5/,1.

by Le Bloa, Somja, Palas, Hjiaj

35(6(17$1'(;3(&7('52/(2)5& 35()$%5,&$7('7(&+12/2*,(6,1&+, -1(6(&216758&7,21,1'8675< by Lu, Jianbao

10.30-11.00BREAK

Room: Carstensen

14.00-15.30

TOPIC: ANALYSIS AND DESIGN

Session: Special Loadings and Conditions II $02'(/)257+($1&+25$*(2)&2552'(' 5(,1)25&(0(179$/,'$7,21$1'

$33/,&$7,21

by Lundgren, Zandi, Nilsson

9,%5$7,217(67,1*$1'352%$%,/,7<%$6(' 5(63216(35(',&7,212)$)/225

6758&785(81'(5:$/.,1*(;&,7$7,21 by HongTao, WeiXing, JianPing

,17(5$&7,21%(7:((1&)537(1'216$1' &21&5(7(:+(168%-(&7('72/21*7(50 02,6785((;32685(

by Sivanendran, Lees

6758&785$/6$)(7<$1'&2035(66,9( 0(0%5$1($&7,21,175$169(56(/< 35(675(66('&21&5(7(%5,'*('(&.6 by Amir, Vand der Veen, De Boer, Walraven

Room: Harlekin

14.00-15.30

TOPIC: NUMERICAL MODELLING

Session: Numerical Modelling III 35(',&7,1*7+(121/,1($56+($5 %(+$9,2852)'((3%($06%$6('21$ 7:23$5$0(7(5.,1(0$7,&02'(/ by Mihaylov

180(5,&$/5,*,'3/$67,&02'(//,1*2) 6+($5&$3$&,7<2).(<('-2,176 by Herfelt, Poulsen, Hoang, Jensen

121/,1($5),1,7((/(0(17$1$/<6,62) 6+($5&5,7,&$/5(,1)25&('&21&5(7( %($06

by Gren Pedersen, Vestergaard Nielsen, Fisker 121/,1($5),1,7((/(0(17$1$/<6,62) 6+($5&211(&7256,1$&20326,7(%5,'*( DECKS

by Higgins, McKenna, Smith, Saafi

(;3(5,0(17$/$1'180(5,&$/678'<21 7+(%(+$9,2852)5&$1'6)5&386+2)) 63(&,0(16

by Navarro-Gregori, Mezquida Alcaraz, Serna Ros, Echegaray

81&(57$,17<2)180(5,&$/02'(/6)25 381&+,1*5(6,67$1&(2)5&6/$%6 by Kadlec, Cervenka

WEDNESDAY AFTERNOON

15.30-16.00 BREAK-POSTER

16.00-17.30

CLOSING LECTURE AND CLOSING OF SYMPOSIUM

&/26,1*/(&785(³/$5*('$1,6+ ,1)5$6758&785(352-(&76±$0$77(52) 32/,7,&$/$1'&21&5(7(675(1*7+ by Christian Munch-Petersen

35(6(17$7,212)ÀE6<0326,80,1&$3( 72:16287+$)5,&$

by Harald S. Müller, ÀE President

35(6(17$7,212)ÀE6<0326,80,1 0$$675,&+71(7+(5/$1'6

by Dick A. Hordijk, Delegate

35(6(17$7,212)ÀE&21*5(66,1 0(/%2851($8675$/,$

by Stephen Foster, Delegate

Room: Columbine

14.00-15.30

TOPIC: ANALYSIS AND DESIGN

Session: Crack and SLS

&5$&.&21752/,1%$6(5(675$,1(' 5(,1)25&('&21&5(7(:$//6 by Vollum, Micallef, Izzuddin, Stehle

)/(;85$/&5$&.,1*35(',&7,216)25 /$5*(+,*+675(1*7+21(:$<6/$%6 by Bentz

&21&5(7((/(0(1765(,1)25&(':,7+ /$5*(',$0(7(563$57&5$&.:,'7+ by Schäfer, Schoening

5(675$,17$1'&5$&.:,'7+ '(9(/230(17'85,1*6(59,&(/,)( 5(*$5',1*+$5'(1,1*&$86('675(66(6 by Turner, Ehmann, Schlicke, Viet Tue

Room: Pjerrot

14.00-15.30

TOPIC: INNOVATION IN BUILDINGS

Session: Innovation in Buildings II

7+(78%('0(*$)5$0($1,1129$7,9( 6758&785$/6<67(0)257$//%8,/',1*6 by Hallgren, King, Severin

(;3(5,0(17$/9(5,),&$7,212)(/(0(176 2)/,*+7&21&5(7()5$0()25(1(5*< ()),&,(17%8,/',1*6

by Fiala, Novotna, Bilek, Hejl, Ruzicka, Hajek )536+($575$16)(50(&+$1,60)25 35(&$67&21&5(7(6$1':,&+3$1(/6 by Hodicky, Sopal, Rizkalla, Hulin, Stang &í&$5%215(,1)25&('&21&5(7( &216758&7,212)7+()8785( by Tietze, Schladitz, Curbach

)/(;85$/$1$/<6,6$1'&20326,7( %(+$9,252)35(&$67&21&5(7(6$1':,&+ 3$1(/

by Toubia, Naji

15.30-16.00 BREAK-POSTER

16.00-17.30

CLOSING LECTURE AND CLOSING OF SYMPOSIUM

&/26,1*/(&785(³/$5*('$1,6+ ,1)5$6758&785(352-(&76±$0$77(52) 32/,7,&$/$1'&21&5(7(675(1*7+ by Christian Munch-Petersen

35(6(17$7,212)ÀE6<0326,80,1&$3( 72:16287+$)5,&$

by Harald S. Müller, ÀE President

35(6(17$7,212)ÀE6<0326,80,1 0$$675,&+71(7+(5/$1'6

by Dick A. Hordijk, Delegate

35(6(17$7,212)ÀE&21*5(66,1 0(/%2851($8675$/,$

ANALYSIS AND DESIGN

6+($502'(/)255(,1)25&('&21&5(7( 0(0%(56:,7+28767,55836

by Tran, Graubner

0(&+$1,&$/&+$5$&7(5,67,&2)3(59,286 &21&5(7(&216,'(5,1*7+(*5$'$7,21$1' 6,=(2)&2$56($**5(*$7(6

by Joshaghani, Ramezanianpour, Golroo, Attaei CIVIL WORKS

NEW MATERIALS AND STRUCTURES 0(&+$1,&$/%(+$9,2852)5&%($06 675(1*7+(1(':,7+/$0,1$7('3/$7(62) &$5%21),%5(*5,'$1'32/<0(5&(0(17 0257$5

by Miyauchi, Shimoeda, Kobayashi

0(&+$1,&$/3523(57,(62)+,*+675(1*7+ ),%(55(,1)25&('&21&5(7(:,7+$5$0,' 39$2567((/),%(5

by Sasaki, Taniguchi, Higuchi, Miyagawa

325(35(6685('(9(/230(172)),%(55( -,1)25&('6(/)&2162/,'$7,1*&21&5(7( (;326('72),5(

by Zhang, Ding, Cao

'8&7,/,7<2)6/(1'(58+3)5&%($065(,1 -)25&(':,7++,*+*5$'(67((/

by Randl, Meszöly

(;3(5,0(17$/678',(621,16,78 &211(&7,212)35(&$670(0%(56:,7+ 8+6&$1'/$363/,&('5(,1)25&,1*%$56 by Lee, Song

'(6,*1$1'(;3(5,0(17$/678'<21/,1. 6/$%,135(&$67&21&5(7(02'8/$5 %5,'*(6

by Song, Lee, Joo

&21&5(7(%($065(,1)25&(':,7+35( -675(66('%$6$/7%$56

by Thorhallsson

6,08/$7,212)(;3(5,0(17$/5(6($5&+ 21675(1*7(1,1*&21&5(7(&2/8016%< %$6$/7),%(56+((76

by Thorhallsson

381&+,1*6+($57(676215&6/$%6675(1* -+(1(':,7+&)53675,36

by Bodzak, Urban, Tarka

LIFE CYCLE DESIGN MODELLING OF CONCRETE

&5((3())(&721&20326,7(%($0:,7+ 3(5)(&767((/&21&5(7(&211(&7,21 by Souici

(;3(5,0(17$/'(7(50,1$7,212) 0(&+$1,&$/)5$&785(3$5$0(7(562) 67((/),%(55(,1)25&('&21&5(7()25 352%$%,/,67,&/,)(&<&/($66(660(17 by Lehký, Routil, Keršner, Novák, Šimonová, Havlíková, Schmid

CONSERVATION OF STRUCTURES

'(6,*1,167$//$7,21$1'0$,17(1$1&(2) 7+(3267,167$//('$1&+25&216,'(5,1* )$67(1,1*35$&7,&(

by Fukushima, Adachi, Yoshihara $33/,$1&(2)1(:0$7(5,$/6$1' 7(&+1,48(6)255(6725$7,212) 6758&785(6

by Nushi, Kabashi Nixha

9(5,),&$7,212)%5,'*(/2$'%($5,1* &$3$&,7<:,7+5(63(&772,76&855(17 &21',7,21

E\âRPRGtNRYi'ROHåHO/HKNê1RYiN

NUMERICAL MODELING

180(5,&$/678'<21'5&)5$0(:,7+ 0,''/(&2/8015(029('81'(5 352*5(66,9(&2//$36(

by Lim, Lee, Tan

SAFETY AND RELIABILITY

352%$%,/,67,&6$)(7<$66(660(172) +,6725,&$/5$,/:$<0$6215<$5&+%5,'*(6 by Moreira, Oliveira, Matos

%(+$9,2852)(;7(5,2535(&$67&21&5(7( )5$0(668%-(&772&2/8015(029$/ by Kang, Tan

121'(6758&7,9(7(672)),5('$0$*(' /,0(6721(&21&5(7(

by Pansuk

Concrete – Innovation and Design, fib Symposium, Copenhagen May 18-20, 2015

PUNCHING SHEAR STRENGTHENING OF FLAT SLABS:

CFRP AND SHEAR REINFORCEMENT

Carlos Moreno, Débora Ferreira, Abdelkrim Bennani, Ana Sarmento, and Michel Noverraz

hepia

–University of Applied Sciences Western Switzerland, Geneva, Switzerland

Polytechnic Institute of Bragança, Bragança, Portugal

hepia

–University of Applied Sciences Western Switzerland, Geneva, Switzerland

University of Porto, Porto, Portugal

hepia

–University of Applied Sciences Western Switzerland, Geneva, Switzerland

Abstract

Punching in slabs is usually associated to the application of concentrated loads or to the presence of columns. One of the main concerns related to flat slabs is its punching shear capacity at slab-column connection, which is subjected to a very complex three-dimensional stress state. Provided that bending capacity is installed, punching shear failure is hence characterized by the development of a truncated cone shaped surface at the slab-column connection. The experimental programme carried out by the authors includes four normal strength concrete slabs (1100×1100×100 mm3), with and without shear reinforcement, submitted to punching under a concentrated load. One of the specimens included typical bent-down bars as shear reinforcement. Frequently, there is the need to strengthen existing flat slabs against punching shear failure. Current paper intends to further investigate the structural response of such reinforcement techniques. One of the strengthening practices, which have been tested within current experimental programme, consists on gluing carbon fibre reinforced polymers on concrete surface. Moreover, the near surface mounted technique has also been tested within current experimental work. Finally, a fourth specimen served as reference. The effects of shear reinforcement and of the carbon fibre reinforced polymers enhancing punching shear capacity are observed.

Keywords: Punching shear, CFRP, NSM, Building codes, Experimental tests

1

Introduction

One of the main concerns related to two-way flat slabs is the punching shear capacity at slab-column connection, which is subjected to a very complex three-dimensional stress state. Punching shear failure is hence characterized by the development of a truncated cone shaped surface at the slab-column connection. Punching shear can thus result from a concentrated load or reaction acting on a relatively small area, called the loaded area,of a slab or a foundation. This type of failure is usually both brittle and catastrophic since it may generate the global collapse of the structure due to the increasing load transfer to neighbouring columns and to the slabs located underneath. The load carrying capacity of reinforced concrete (RC) slabs may be compromised for a number of reasons, including structural damage, design errors, building code changes and alteration of functional use.

Two strengthening techniques enhancing directly the bending capacity of slab-column connections are employed. The collateral increase in the ultimate punching shear capacity is analysed. The use of carbon fibre reinforced polymers (CFRP) on structural repair and strengthening has continuously increased during the last years due to the following main advantages of this composite material when compared to conventional materials like steel and concrete: low specific weight, easy installation, high durability and tensile strength, electromagnetic permeability, and practically unlimited availability regarding size, geometry and

dimensions (ACI 2008). The most widely used technique aiming to increase load carrying capacity is to apply CFRP plates on the tension surface of the RC slab as externally bonded (EB) reinforcement. CFRP laminates and sheets are generally applied on the faces of the elements to be strengthened configuring which is commonly designated as the EB reinforcing technique. The research carried out up to now has revealed that this method cannot mobilize the full tensile strength of CFRP materials due to the occurrence of premature debonding phenomenon (Nigro, Ludovico & Bilotta 2008). Due to the fact that CFRP is often directly exposed to the weathering conditions the reinforcing performance of this technique should be accounted for. EB systems are also vulnerable regarding fire action and vandalism acts. Alternatively, the near surface mounted (NSM) technique, which consists of cut-in openings strengthened with CFRP materials, can be used. This technique was used is some practical applications (Barros & al. 2006) and several benefits were pointed out. In order to assess the efficacy of this strengthening system as regards structural elements failing in punching shear, flat slab specimens were tested. The carried out tests are described and the most significant outcomes are presented and analyzed. Experimental results are also compared with design code predictions regarding the punching shear strength.

2

Design code provisions

A review on design code provisions is conducted. The punching shear approaches of CEB-FIP MC 90 (CEB-FIP 1993) and EN 1992-1-1 (CEN 2004) which is based on the former – otherwise referred to as Eurocode 2 – are analysed below.

Both design codes adopt an approach involving critical sections where punching shear capacities are to be checked as represented in Fig. 1: at the face of the column, at the basic control section, and at the outermost control section where shear reinforcement is no longer required if shear reinforcement is needed. The basic control perimeter u1 is taken to be at a distance 2d from

the loaded area (or column perimeter) and should be constructed so as to minimise its length. Punching shear strength is the product of a shear stress times the area of the critical section under consideration. The full contribution of concrete to the design punching shear resistance of flat slabs without shear reinforcement at the basic control section is given by (CEN 2004):

f

u

d

V

l ckc c

Rd

1

3 1

,

100

18

.

0

(1)In (1) c is the concrete partial safety factor, ξ is the size effect factor (defined in Table 1 with d

in mm), l is the ordinary reinforcement ratio, fck is the characteristic value of concrete compressive

strength in MPa, u1 is the length of basic control perimeter, and d is the mean effective depth of the

slab calculated as shown in (2).

d

xd

y

2

d

(2)The value of l is calculated as indicated in (3) as a mean value taking into account a slab width

(C dimension, see Fig. 1) equal to the column width plus 3d each side of the column. Such reinforcement should anchor beyond the control perimeter being considered, u1.

ly lx

l

(3)Where shear reinforcement is required the punching shear strength should be calculated in accordance with (4) where sr is the radial spacing of perimeters of shear reinforcement, fywk,ef is the

effective characteristic strength of the punching shear reinforcement according to (5), s is the

partial safety factor for shear reinforcement steel, Asw is the area of one perimeter of shear

reinforcement around the column, and is the angle between the shear reinforcement and the plane of the slab.

sin2 3 4

3 ,

,

, sw

s ef ywk r c

Rd cs

Rd A

f

s d V

V (4)

With respect to CEB-FIP MC 90 and EN 1992-1-1 punching shear formulations, the original equations have been modified (Moreno 2010) in order to include the partial safety factor related to shear reinforcement steel, leading to (4). Therefore, equation (5) has been derived in order to account for the safety margin coupled with shear reinforcement (d in mm).

ywkef

ywk

d

f

f

,

0

.

2875

1000

(5)kd

y

x

c c

un,ef

c

outermost perimeter of shear reinforcement basic control

perimeter

outermost control perimeter

oute rmos

t pe rime

ter

of she ar r

einf orcemen

t

kd

outerm ost

cont rol

peri met

er

d

d

u0

2d

kd

u1

C=c+6d

Fig. 1 u0, u1 and un,ef control perimeters for interior square loaded areas according to the CEB-FIP MC 90 (CEB-FIP 1993) and EN 1992-1-1 (CEN 2004).

For slabs with transverse shear reinforcement the punching shear resistance should additionally be assessed for the outermost control section which defines the outermost control perimeter un,ef

(see Fig. 1). The outermost perimeter of shear reinforcement should be placed at a distance not greater than kd within un,ef perimeter. According to EN 1992-1-1 the recommended value is k = 1.5

whereas CEB-FIP MC 90 recommends the value k = 2.

Although both code formulations are quite similar, main differences were identified and are summarised in Table 1.

Table 1

Limited parameters on punching shear design codes provisions Design code Parameter

CEB-FIP MC 90 Eurocode 2

Size effect factor, ξ = 1+(200/d)1/2 - ≤ 2

Characteristic concrete strength, fck ≤ 50 MPa -

Ordinary reinforcement ratio, l - ≤ 0.02

k factor (recommended values) 2.0 1.5

In order to fully compare both design code formulations a database has been derived compiling test results for slabs subjected to non-eccentric loading which failed in punching comprising both non-reinforced (128 experiments, see Fig. 2 to Fig. 4) and shear-reinforced slabs (38 experiments). In the following the materials partial safety factors are taken as c = s =1 and the characteristic

values of the material mechanical properties are replaced by the respective average value.

0 2 4 6 8

0 20 40 60 80 100 120

fcm (MPa) Pu,e x p /[ 0. 18 (1 00 l ) 1/ 3 u 1 d] (MP a)

(fcm50)1/3

CEB-FIP MC 90

0 2 4 6 8

0 20 40 60 80 100 120

fcm (MPa) Pu,e x p /[ 0. 18 (1 00 l ) 1/ 3u 1 d] (MP a) fcm 1/3

EN 1992-1-1 Elstner & Hognestad 1956 Kinnunen & Nylander 1960 Moe 1961

Mokhtar, Ghali & Dilger 1985 Marzouk & Hussein 1991 Tomaszewicz 1993 Ramdane 1996 Hallgren 1996 Marzouk & Jiang 1997 Krüger 1999

Oliveira, Melo & Regan 2000 Ramos 2003

Birkle 2004

Guandalini & Muttoni 2004 Mirzaei & Muttoni 2008 Moreno 2010

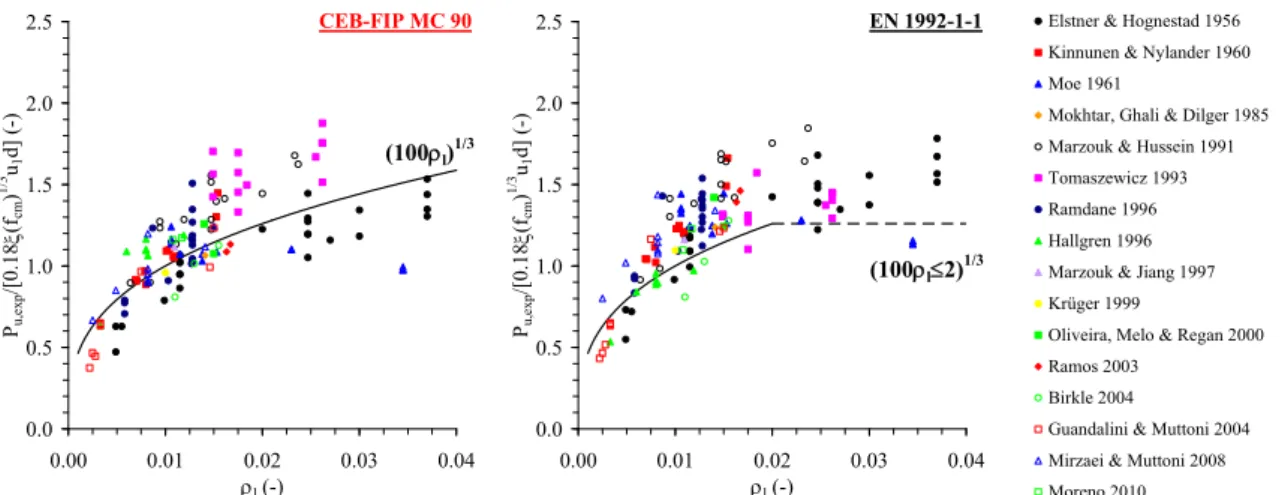

Fig. 2 Experimental punching shear failure load of shear non-reinforced slabs (non-eccentric loading) normalized regarding the average concrete compressive strength.

0.0 0.5 1.0 1.5 2.0 2.5

0.00 0.01 0.02 0.03 0.04

l (-) Pu, e x p /[ 0. 18 (fcm ) 1/ 3 u 1 d] (-)

CEB-FIP MC 90

(100l)1/3

0.0 0.5 1.0 1.5 2.0 2.5

0.00 0.01 0.02 0.03 0.04

l (-) Pu, e x p /[ 0. 18 (fcm ) 1/ 3u 1 d] (-) EN 1992-1-1

(100l2)1/3

Elstner & Hognestad 1956 Kinnunen & Nylander 1960 Moe 1961

Mokhtar, Ghali & Dilger 1985 Marzouk & Hussein 1991 Tomaszewicz 1993 Ramdane 1996 Hallgren 1996 Marzouk & Jiang 1997 Krüger 1999

Oliveira, Melo & Regan 2000 Ramos 2003

Birkle 2004

Guandalini & Muttoni 2004 Mirzaei & Muttoni 2008 Moreno 2010

Fig. 3 Experimental punching shear failure load of shear non-reinforced slabs (non-eccentric loading) normalized regarding the ordinary reinforcement ratio.

0 1 2 3

0 100 200 300 400 500

d (mm)

Pu,

exp

/[

0.1

8

(1

00

l fcm

)

1/

3 u

1

d] (-)

CEB-FIP MC 90

=1+(200/d)1/2

0 1 2 3

0 100 200 300 400 500

d (mm)

Pu,

exp

/[

0.1

8

(1

00

l fcm

)

1/

3u

1

d] (-)

EN 1992-1-1

=1+(200/d)1/22

Elstner & Hognestad 1956 Kinnunen & Nylander 1960 Moe 1961

Mokhtar, Ghali & Dilger 1985 Marzouk & Hussein 1991 Tomaszewicz 1993 Ramdane 1996 Hallgren 1996 Marzouk & Jiang 1997 Krüger 1999

Oliveira, Melo & Regan 2000 Ramos 2003

Birkle 2004

Guandalini & Muttoni 2004 Mirzaei & Muttoni 2008 Moreno 2010

Fig. 4 Experimental punching shear failure load of shear non-reinforced slabs (non-eccentric loading) normalized regarding the size effect factor.

The range of collected values for average concrete compressive strength is between 12.8 MPa and 119 MPa, the mean effective depth of the slab varies from 70 mm to 456 mm, and the ordinary reinforcement ratio is comprised between 0.22% and 3.70%.

From the analysis of Fig. 2 to Fig. 4, one can notice that the CEB-FIP MC 90 condition fck≤ 50

MPa is needless so that the formulation can be extended to high performance concrete. As regards the ordinary reinforcement ratio, the EN 1992-1-1 imposes the limitation l ≤ 0.02 which can

certainly be understood as a concern about the ductility behaviour of the slab-column connections. Regarding the size effect factor, EN 1992-1-1 design code limitation ξ ≤ 2 appears to be unnecessary. The authors propose as well to adopt the value k = 2. The enlargement of the distance comprised between the outermost perimeter of shear reinforcement un,ef and the loaded (or column

cross-section) perimeter from 1.5d to 2d can be justified by the test results of several authors (Elstner & Hognestad 1956; Voet, Dilger & Ghali 1982; Mokhtar, Ghali & Dilger 1985) who observed that the shear stress supported by concrete decreases with increasing distance from the column face and stabilizes at a distance of about 4d from the loaded area. Identical recommendation is done by the Danish national annex to Eurocode 2 (EN-1992-1-1 2007).

Current analysis results for both code formulations are summarised in Table 2.

Table 2

Comparison of test results with codes predictions as they stand Pu,exp/VRm

Experiments Design code

Min. Max. Average CV

CEB-FIP MC 90 0.60 1.49 1.03 0.18

128

non-reinforced slabs Eurocode 2 0.70 1.54 1.14 0.17

CEB-FIP MC 90 0.50 1.46 0.98 0.22

38

shear-reinforced slabs Eurocode 2 0.54 2.16 1.18 0.38

Based on the comparative analysis, and aiming to reduce the high observed dispersion, a sensitivity analysis of the limiting parameters on the code provisions was developed. Consequently, following actions were taken:

1) CEB-FIP MC 90 provision fck≤ 50 MPa is ignored;

2) EN 1992-1-1 recommended value k = 1.5 is replaced by k = 2, and; 3) EN 1992-1-1 design code limitation ξ≤ 2 is not considered.

The above mentioned proposals were further computed and obtained results are summarised in Table 3. The overall effect of those proposals is thus far a significant reduction in standard deviation (CV) and in average value of the observed-to-predicted failure loads Pu,exp/VRm ratio.

Table 3

Comparison of test results with codes predictions including proposals Pu,exp/VRm

Experiments Design code

Min. Max. Average CV

CEB-FIP MC 90 0.60 1.28 0.98 0.13

128

non-reinforced slabs Eurocode 2 0.60 1.28 1.01 0.13

CEB-FIP MC 90 0.44 1.38 0.98 0.22

38

shear-reinforced slabs Eurocode 2 0.44 1.57 0.98 0.25

3

Experimental programme

3.1 Test specimens

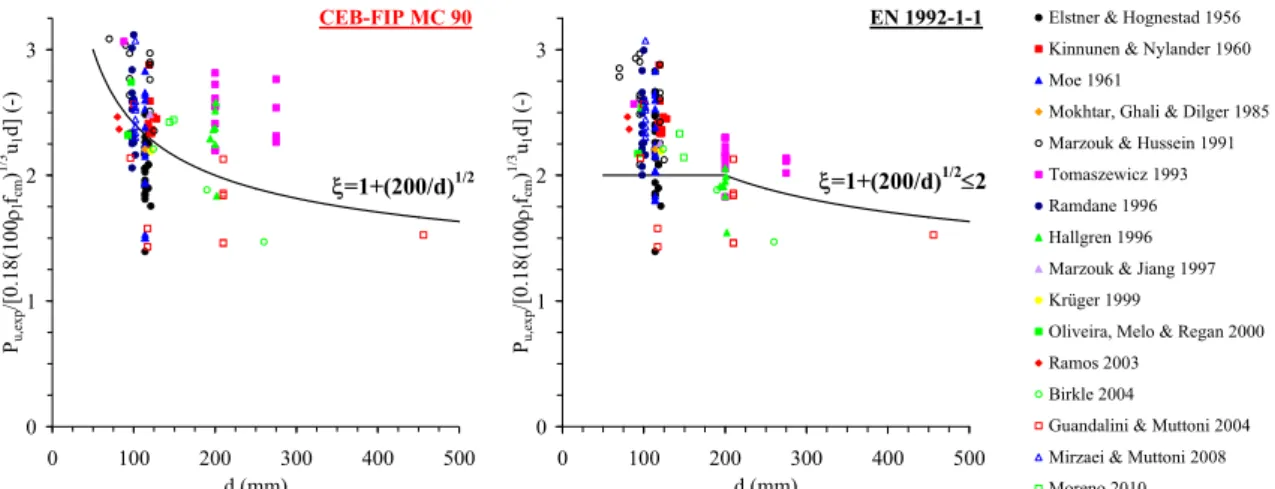

Current experimental programme includes 4 RC square flat slab specimens 1100×1100 mm2 wide and 100 mm height, which were designed so as the bending capacity prevail over the punching shear strength in order for slabs to fail in shear. The ordinary reinforcement ratio remained unchanged for all the tested slabs. Full details of specimen’s geometry are presented in Fig. 5 where the ordinary reinforcement has been omitted in both the CFRP strengthened slabs for interpretation convenience.

The first specimen, denoted BC01, served as the non-strengthened reference slab. The second specimen, BCA1, included typical steel bent-down bars as punching shear reinforcement. The CFRP strengthening techniques were used in the third specimen, BCN1, which include 16 NSM cut-in in each direction, and in the EB specimen denoted BCG1 on which 6 CFRP laminates were bonded in each direction. Both the CFRP strengthened specimens were designed so as approximately similar effective reinforcement ratios were installed (see Table 5 and Table 6). Table 4 below summarises the chronological sequence of the experimental programme.

Table 4

Notation and RC slabs age at strengthening and testing Slab Age at strengthening

(days)

Age at experiment

(days)

BC01 - 31 BCA1 - 28 BCN1 36 41 BCG1 24 29

All the current specimens were reinforced on the top (tensile) side with orthogonal bending reinforcement using 8 mm diameter rebar spaced 50 mm. The main bars were folded up at both ends in order to promote better anchorage. The ratio l of ordinary reinforcement was 1.33% for all

the tested specimens. A 20 mm concrete cover was guaranteed by using plastic rebar-to-formwork spacers.

Regarding BCA1 specimen, shear reinforcement comprising four bent-down bars in each direction were used spaced 50 mm. Shear reinforcement bars (8 mm diameter bars similar to the main reinforcement) were well anchored at their extremities and placed in two perimeters perpendicularly to the column face as shown in Fig. 5. The first perimeter of shear elements was positioned at a distance of approximately half effective depth (d/2) from the column face. The radial spacing of shear reinforcement perimeters was taken as sr ≈ 0.7d. According to (Hallgren

1996) the ratio of ordinary reinforcement should be modified (increased) with the part of the steel bent-down bars which act as main bending reinforcement over the loaded area (100×100×20 mm3 steel plate denoted G in Fig. 5) as indicated:

C

d

A

f

f

swyk ywk l

l

4

mod,

(6)In (6) fywk is the characteristic value of the yielding stress of shear reinforcement steel, fyk is the

characteristic value of the yielding stress of ordinary reinforcement steel, Asw is taken as the total

cross-sectional area of the shear reinforcement, and dimension C is taken as defined in Fig. 1. The ultimate punching shear capacity of slab BCA1 is therefore predicted using (4) where VRd,c is

calculated with l,mod = 1.86% instead of l leading to:

f

u

d

V

l ckc c

Rd

1

3 1 mod ,

,

100

18

.

0

(7)E E

E

E

E

E E

E G

E E

E

E

E

E E

E E

E E

E

E

E E

E

16 NSM each direction 6 EB plates each direction

BC01 BCA1

BCG1 BCN1

10

0

D = 10 00

r

r

50

B = 1100

G

117.2

250 250

250

217.2

250

52

52

G

B = 1

100

B = 1100

G

100

G

G

100

E E

E

E

E

E E

E G

G

140 164 164 164 164 164 140

Fig. 5 Geometry of tested slabs (dimensions in mm).

For the CFRP strengthened slabs BCN1 and BCG1, the indirect effect of the CFRP reinforcement (which represents a reinforcement ratio increase of about 55% with respect to remaining non-strengthened specimens BC01 and BCA1) was accounted for according to the following. For brittle failures in punching, the ordinary reinforcement remains mostly elastic so that an equivalent effective depth deq can be computed as follows according to (Faria & al. 2014):

d

d

E

E

d

d

E

E

d

d

st s st l st st s st l st eq

1

1

2 (8)In (8) st is the strengthening reinforcement ratio, Est is the modulus of elasticity of CFRP, and

dst is the distance between the compressed face and the centroid of the CFRP strengthening

elements. As the bending stiffness of the slabs is therefore increased (Faria & al. 2014) propose the use of an effective reinforcement ratio tot which can be obtained as follows:

3 d d B r E E st s st st l tot

(9)In (9) B and r are taken as the slab dimension and the distance where the strengthening laminates are distributed, respectively (see Fig. 5). The obtained effective reinforcement ratios are summarised in Table 5 and Table 6 below for the BCN1 and BCG1 specimens, respectively.

Table 5

Main reinforcement ratio and geometry for BCN1 specimen Layer # Material Direction d

(mm) l (%) d (mm) st (%) dst (mm) deq (mm) tot (%)

1 y 68

2 Steel x 76 1.33 72.0 - -

3 x 85

4 CFRP y 95 - - 0.45 90.0

76.7 2.07

Table 6

Main reinforcement ratio and geometry for BCG1 specimen Layer # Material Direction d

(mm) l (%) d (mm) st (%) dst (mm) deq (mm) tot (%)

1 y 68

2 Steel x 76 1.33 72.0 - -

3 x 100.6

4 CFRP y 101.8 - - 0.32 101.2

78.4 2.08

3.2 Material properties

The tensile mechanical properties of the steel reinforcement were derived from representative samples testing. The yield and ultimate strength as well as the Young’s modulus were measured and are as given in Table 7.

Table 7

Material properties of bending and shear reinforcement steel Diameter

(mm)

Yield strength, fym

(N/mm2)

Ultimate strength, fum

(N/mm2)

Young modulus, Es

(kN/mm2)

8 535 650 200

The concrete was designed to have a 28-day cube compressive strength of 30 MPa using 20 mm

maximum aggregate size and a 0.55 free water-cement ratio. A 1% cement content of Sika ViscoCrete super-plasticiser was included in the concrete mix. A CEM II/B-M (T-LL) 42.5 cement was employed. Table 8 presents the average mechanical properties obtained on concrete samples (150×150×150 mm3) which were tested on the experiment day of the respective slab specimen.

Conversion between cubic and cylinder compressive strength has been computed according to (Reineck & al. 2003):

cub cm

cm

f

f

0

.

79

, (10)Table 8

Mechanical properties of concrete mix

Slab cm

(kN/m3)

fcm,cub

(N/mm2)

fcm

(N/mm2)

BC01 23.3 53.9 42.6 BCA1 23.4 44.6 35.3 BCN1 24.0 33.4 26.4 BCG1 23.0 34.1 27.0

The used CFRP plates were S&P CFK 150/2000 manufactured in Portugal by S&P Clever Reinforcement. These carbon laminates were used together with adhesive S&P Resin Epoxy 55 certified in accordance with EN 1504-4 (CEN 2004). Material properties of the CFRP plates used in current experimental tests are given in Table 9 (S&P 2014).

Table 9

Material properties and geometry of CFRP laminates

Parameter BCN1 specimen BCG1 specimen

Cross section (mm2) 2.8×10 50×1.2

Modulus of elasticity, Est (kN/mm2) 165 165

Theoretical tensile strength at 0.8% elongation (N/mm2) 1300 -

Recommended tensile strength for the design (N/mm2) - 1650

Tensile strength (N/mm2) 2000 2000

3.3 CFRP strengthened specimens’ preparation

The CFRP strengthened slabs were prepared following the instructions of the manufacturer. Regarding BCN1 slab, the slots of 5.5×20 mm2 and 5.5×10 mm2 were obtained using a circular saw (Fig. 6). For BCG1 specimen, a surface grinder was passed back and forth along pre-aligned paths until a uniform exposure of aggregate was achieved (Fig. 7). A vacuum cleaner allowed a clean surface from dust and loose particles to be obtained.

Fig. 6 BCN1 slots cutting. Fig. 7 BCG1 surface prior to CFRP gluing.

3.4 Test procedure and instrumentation

All tests were conducted under concentrated loading (100×100 mm2) and simply supported on eight points (60×60×10 mm3 steel plates denoted E in Fig. 5) equally spaced along a D = 1000 mm diameter perimeter (see Fig. 5). Tests were performed using a servo-hydraulic test system by means of controlling the vertical force at 0.26 kN/s constant loading rate. The load was applied through a load-controlled hydraulic jack with a nominal range of 300 kN acting against a reaction strong slab. A data acquisition system connected to a personal computer was used to control the loading and to collect test data (load, deflections and CFRP strains).

Externally, five LVDT (L1 to L5) were placed along the diameter D (see Fig. 5) in order to measure the deflections of the four tested slabs. Internally, five strain gauges (A to E) were laterally glued to CFRP laminates on BCN1 slab. Three strain gauges (A to C) were glued to the top surface of CFRP laminates on BCG1 specimen. The instrumentation is located as indicated in Fig. 8 where the truncated cone shaped surface taken accordingly to an estimated failure crack angle of 35 degrees is plotted.

BCG1 BCN1

A B C

C B

A

D E

L1 L2 L3 L4 L5

Fig. 8 Strain gauges and LVDT locations.

4

Experimental results

4.1 Failure load analysis

All the specimens failed in punching. In the following the materials partial safety factors are taken as c = s =1 and the concrete compressive strength is taken as the respective average value.

Experimental failure loads as well as predicted failure modes are indicated in Table 10.

According to (1) and to the actual value of concrete compressive strength, the failure loads of the four tested slabs were predicted based on punching shear approaches of both CEB-FIP MC 90 and Eurocode 2 considering non-strengthened specimens.

Design code approaches accurately predicted the failure load of the non-strengthened reference specimen BC01. Accordingly, Pu,exp/VRm,ns ratio was computed for the remaining specimens and

obtained values are indicated in Table 10. Regarding the slab reinforced with bent-down bars the enhancement on punching shear strength is estimated of about 29%. For the CFRP strengthened specimens, the NSM strengthening technique appears to be more effective (14% estimated enhancement) than EB technique (4% estimated strength increase) as regards punching capacity.

Furthermore, the actual predicted failure loads were calculated using (1) for BCA1 and CFRP

strengthened specimens. For BCA1 specimen it was found that the minimum punching shear strength is attained at the outermost control section so that the outermost control perimeter un,ef and

the value k = 2 were computed in (1). Punching failure loads are consistently overestimated for shear-reinforced and CFRP strengthened specimens (Pu,exp/VRm ratio in Table 10).

Table 10

Experimental and predicted failure loads Slab Experimental

failure load, Pu,exp

(kN)

Non-strengthened

(predicted) failure load,

VRm,ns

(kN)

Strengthened (predicted) failure load,

VRm

(kN)

Pu,exp/VRm,ns

(-)

Pu,exp/VRm

(-)

Predicted failure mode

BC01 176.8 173.4 - 1.02 - Punching

BCA1 209.8 162.9 243.5 1.29 0.86 Punching BCN1 168.7 147.8 186.8 1.14 0.90 Punching BCG1 155.0 149.0 194.4 1.04 0.80 Punching

4.2 Failure pattern analysis

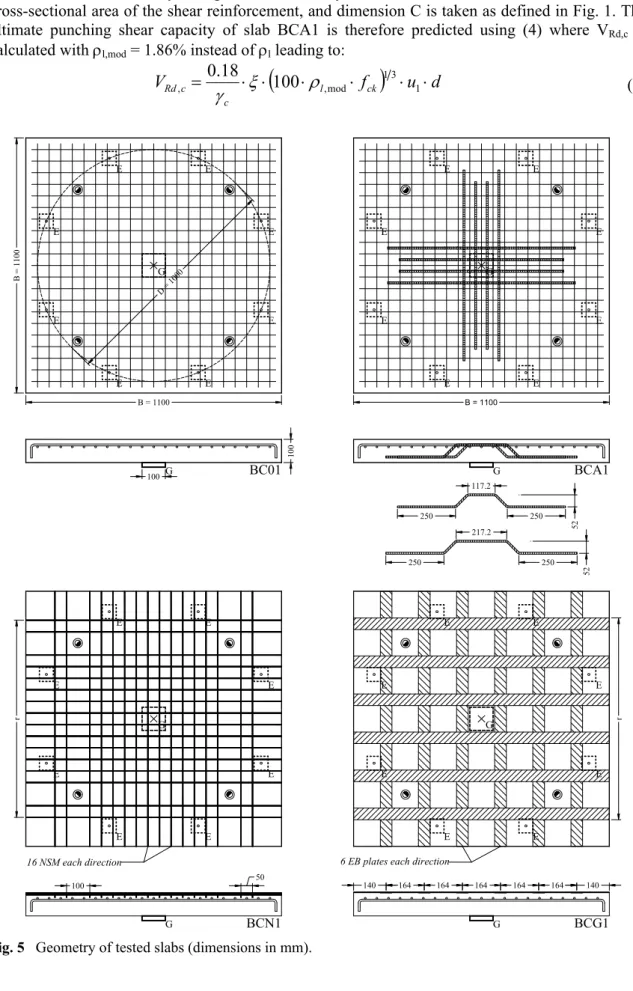

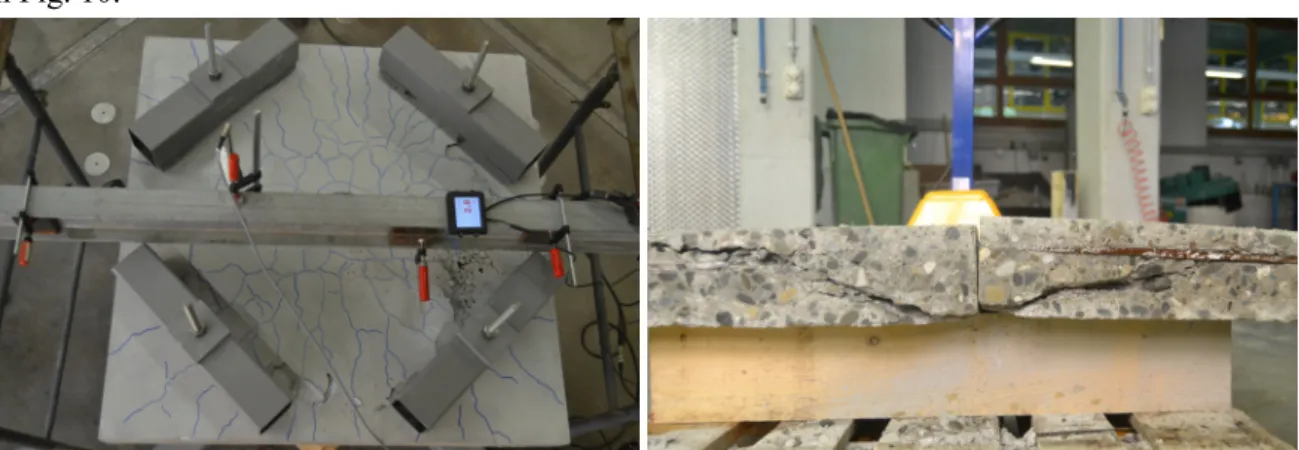

The failure mode of the reference specimen, BC01, which was neither shear-reinforced nor strengthened with CFRP plates, was brittle as can be seen in Fig. 9 and Fig. 14.

Fig. 9 Cracking pattern and internal shear crack of slab BC01 after failure.

The failure mode of the steel shear-reinforced specimen, BA01, was also brittle as can be seen in Fig. 10.

Fig. 10 Cracking pattern and internal shear crack of slab BA01 after failure.

Regarding both the CFRP strengthened specimens, Fig. 11 and Fig. 12 show the final

experiment condition for BCN1 and BCG1 slabs, respectively. No evidence of debonding was observed in the NSM specimen. On the contrary, a pure punching shear failure was attained.

Fig. 11 Final aspect of BCN1 specimen after failure.Fig. 12 Final aspect of BCG1 specimen after failure.

According to the literature the majority of the elements retrofitted using EB strengthening method experienced debonding as a failure method in spite of the efficiency of the strengthening technique.

As regards BCG1 specimen, no significant enhancement could hence be achieved to the overall shear stress using EB strengthening technique. A premature debonding of CFRP laminates located by the centre of the slab was identified at failure. Debonding did not actually occur at the edge of the slab but rather at an interior section. This suggests that the relative displacement perpendicular to the plane of the slab, which is due to the punching cone onset that precedes failure, set off a dowel effect that triggered the overall failure. Fig. 13 confirms the above referenced occurrence.

Fig. 13 Detail of local debonding on CFRP laminates of BCG1 specimen.

In fact, one can point out that the anchorage length of BCG1 specimen was insufficient. However, debonding-to-tensile failure length ratios were calculated. Table 11 shows that the specific anchorage lengths related to both the CFRP strengthened specimens are quite analogous.

Table 11

Specific anchorage lengths

Slab Technique Debonding/tensile length

(m-1/m)

BCN1 NSM 0.71

BCG1 CFRP strengthened EB 0.83

4.3 Load-deflection characteristics

The deflections measured at the centre of the slabs followed an almost linear starting relationship

with applied load as shown in the following (Fig. 14 to Fig. 17). In fact, the load-deflection relationships are nearly linear up to the first cracking occurrence in all the slabs.

No subsequent considerable reduction in stiffness was detected, except for the strengthened slabs BCN1 and BCG1 which is due to the higher effective reinforcement ratio (see section 3.1).

The load-deflection curves have thus confirmed the brittle nature of the failure of slabs collapsing in punching mode. The failure mode of the non-strengthened reference specimen BC01, which was neither shear-reinforced nor CFRP laminates strengthened, was particularly brittle as can be seen in Fig. 14.

0 50 100 150 200 250

0 5 10 15 20

Deflection, (mm)

Lo

ad

, P

ex

p

(kN

)

0 50 100 150 200 250

0 5 10 15 20

Deflection, (mm)

Lo

ad,

Pex

p

(k

N)

Fig. 14 Load-central deflection of the BC01 slab. Fig. 15 Load-central deflection of the BCA1 slab.

Ductility enhancement due to bent-down bars was not noticeable on the shear-reinforced slab response (Fig. 15).

Concerning the NSM strengthened specimen (Fig. 16), the load-deflection curve arched near the end of the experiment while the existing cracks widened and propagate towards the compression zone. The stiffness of both the CFRP strengthened specimens (Fig. 16 and Fig. 17) was markedly increased when compared to the non-strengthened reference specimen BC01 due to the enhanced effective reinforcement ratio. In effect, central deflections of only 3 to 4 mm were measured.

0 50 100 150 200

0 1 2 3 4

Deflection, (mm)

Lo

ad

, P

ex

p

(kN

)

0 50 100 150 200

0 1 2 3 4

Deflection, (mm)

Lo

ad

, P

exp

(kN

)

Fig. 16 Load-central deflection of the BCN1 slab. Fig. 17 Load-central deflection of the BCG1 slab.

4.4 CFRP strains analysis

The load-strain relationships for the CFRP reinforcement of strengthened specimens BCN1 and BCG1 are shown in Fig. 18 and Fig. 19, respectively (strain gauges locations indicated in Fig. 8). Assuming the strain compatibility in the strengthened slabs cross section, one can infer that ordinary reinforcement did not reach yielding on both the CFRP strengthened specimens, as maximum strains of about 0.15% to 0.20% were measured.

Regarding the NSM strengthened specimen (Fig. 18), CFRP strains remained of negligible magnitude until cracking initiation. Centrally located strain gauges (B to E, see Fig. 8) show analogous responses. Additionally, the comparison of collected data in strain gauges A and B, which are located on the same CFRP laminate, indicate that the deformation decreases sharply with increasing distance to loaded area.

0 50 100 150 200

0 500 1000 1500 2000 2500

Microstrain (mm/mm)

Loa

d

, P

ex

p

(kN)

A B C D E

0 50 100 150 200

0 500 1000 1500 2000 2500

Microstrain (mm/mm)

Lo

ad,

Pex

p

(k

N)

A B C

Fig. 18 Load-strain relationship for CFRP laminates of BCN1 specimen.

Fig. 19 Load-strain relationship for CFRP laminates of BCG1 specimen.

As regards the EB strengthened specimen (Fig. 19), the recorded strains confirm the symmetry of the experimental test as coincident strains were obtained in strain gauges A and C.

5

Conclusions

The current work intends to assess the performance of different solutions regarding slabs’ strengthening against punching. Firstly, a specimen was strengthened before casting using steel bent-down bars. For existing slabs, two different design solutions were investigated. One of them consisted in gluing CFRP laminates on slab’s surface while the other design was based on introducing CFRP laminated strips into slits cute on the concrete cover, bonded to concrete using epoxy adhesive (NSM technique). In order to compare these two techniques similar CFRP reinforcement ratios were adopted.

Further to current investigation, following conclusions can be drawn:

Proposals are made for both CEB-FIP MC 90 and EN 1992-1-1 code provisions regarding punching shear strength in order to reduce the standard deviation and the average values of the relationship between experimental and predicted punching failure loads;

Good agreement is found regarding the observed-to-predicted failure load ratios Pu,exp/VRm

when the above referred proposals are taken into account;

Flat slab specimen reinforced with steel bent-down bars showed an enhanced punching shear strength of approximately 29% when compared with non-strengthened reference slab;