Sample Preparation Method for

Sanning Fore Mirosopy

I.R. Jankov 1

,R.N. Szente 2

,I.D. Goldman 1

, M.N.P. Carre~no 3

,

J.W. Swart 4

, and R. Landers 5

1

InstitutodeFsia,Universidadede S~aoPaulo,S~aoPaulo,SP, Brazil

2

MehanialandEletrialDivision,IPT,CidadeUniversitaria,

CEP01064-970,S~aoPaulo,SP,Brazil

3

Laboratorio deMiroEletr^onia, EsolaPolitenia,

Universidadede S~aoPaulo,S~aoPaulo,SP,Brazil

4

CCS,UniversidadedeCampinas, Campinas,SP,Brazil

5

InstitutodeFsia,UNICAMP,Campinas,SP, Brazil

Reeivedon21May,2001

We present a method of sample preparation for studies of ion implantation on metal surfaes.

Themethod,employingamehanialmask,isspeiallyadaptedforsamplesanalysedbySanning

Fore Mirosopy. Itwassuessfully testedonpolyrystallyne oppersubstratesimplantedwith

phosphorusionsatanaelerationvoltageof39keV.Thehangesoftheeletrial propertiesofthe

surfaeweremeasuredbyKelvinProbeForeMirosopyandthesurfaeompositionwasanalysed

byAugerEletronSpetrosopy.

I Introdution

Changesinduedonasurfaeduetoaertain

pro-essanbe,inpriniple,detetedbytwodierenttypes

ofmeasurements: a)thedeterminationoftheabsolute

valueofthesampleharateristisbeforeandafterthe

proessthatinduedthehanges;b)theuseofadiret

omparison, i.e., relative measurements, between the

sample(orpartofif)thatdidnotundergoanyproess

andthesample(orpartofit)that wasexposedtothe

hangingproess.

The rst type of measurement usually requires a

standardreferenesamplewithharateristis(theones

ofinterest)thatarewelldenedanddonothangewith

time. However,apossibleproblem withthis approah

isthateventheharateristisofthestandardreferene

samples are notalwaysonstantand might vary with

someunknownexperimentalparameter(forhangesof

some properties of gold; see for example [1℄). This is

partiularly the asefor measurementsnot performed

underUHVonditions[2,3℄. Evenmeasurementsunder

UHV onditionsmightnotprovideabsolutevalues

un-lessthestandardreferenesampleispreparedinsitu.

Themajoradvantageoftheseondtypeof

measure-mentsisthatthereisnoneedfortheseparatestandard

referene sample, sine thereferene value anbe

ob-to envision a method where partof thesample is

ex-posedto themodifyingproesswhiletheotherpartof

thesample iskeptat thesameinitial onditions, thus

avoidingtheneedofaseparatestandardreferene.

Inthis paper, we use the seond approah to

pro-poseasamplepreparationproedureforsanningfore

mirosopy(SFM) studies. Theproedure reates, on

thesamesample, twotypesofregions, i.e., oneregion

that is exposed to the modifying proess and another

regionthat isnotmodied. Intheasepresentedhere

themodifyingproesswasionimplantation, whih

in-dued varioushangesonthematerial, inludingwork

funtion hanges, determinedbyaKelvinProbeFore

Mirosopy[4-6℄.

Thevalidityoftheproposedmethodisbasedontwo

assumptions:

a)during themodifyingproessthe harateristis

of parts ofthe samplesnot exposed to theproess

re-main onstant;

b)afterthehangeswereinduedinertainregions

of thesample, the harateristis of everyregion

II Experimental proedures

II.1. General desription

In order to prepare a samplefor KPFM using the

seond methodology presented above, a mehanial

mask with ne denition, positioned above the

sub-strate,wasusedasdesribedbelow.

Theexperimentalproeduresinvolvedthehoieof

materials to be studied, the method of ion

implanta-tion tobeused, thedesignand onstrutionof a

suit-able tool in order to have, in the same sample, areas

exposedand notexposedto the ionimplantation

pro-ess (aording to the method proposed above), and

surfae analysis of the produed sample. Speially,

thedevelopedexperimentalproeduresonsistedofthe

following steps: a) Sample preparationb) Prodution

of amehanialmask;) Ion implantationproess; d)

Surfae analysis. A moredetailed desriptionofthese

stepsisgivenbelow.

II.2. Sample preparation

The method developed for preparingsamples that

arepartiallyexposedtoamodifyingproesswasarried

outonpolyrystallineopper.

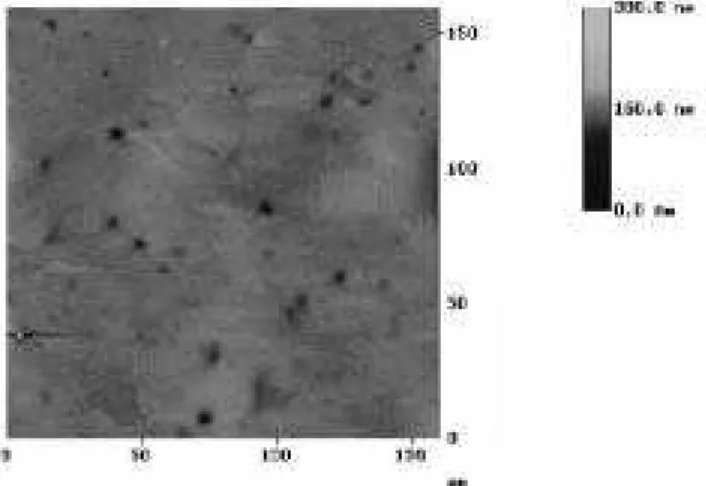

First, the substrates were mehanially abraded

with sand paper up to 2400 mesh. After leaning in

ethanol, the polishing proess was ontinued with

di-amond pastes (produed byKG Sorensen) of6 m,3

mand1mingrainsizerespetively. Thesubstrates

were leaned in ethanol and distilled water after eah

step. Afterthepolishingproess,thesampleswere

ex-aminedusinganatomiforemirosopefor

determin-ing thesubstrate topography. In thesemeasurements,

themaximumtopographydierenewasoftheorderof

250nm asitanbeseenin Fig.1.

Figure1. Topographyofoppersubstratemeasuredwith

II.3. Mehanial mask

Aspeialmehanialmaskwasdesignedand

manu-faturedtobeusedduringtheionimplantationproess.

Themainobjetiveforusingamehanialmaskon

thetopof the sampleundergoingan ionimplantation

proessistoreate,onthesamplesurfae,adetermined

patternofimplantedandnon-implantedregions. This

allowsthedeterminationofhangesinduedbythe

pro-essonthesamesampleasexplainedabove(although

somesurfaeanalyseswerearriedoutfordierent

sam-ples exposed to the same proess). The main points

whih were onsidered in the design of the mask are

presentedbelow,andfollowedbythedesriptionofthe

produtionstepsusedinmanufaturingofthe

mehan-ialmask.

II.3.1 Designof themehanialmask

Thedesignofthemehanialmaskhadtotakeinto

onsiderationthefollowinglimitationsand

harateris-tis:

1. The piezoeletri devie of a SFM

equipment limits the maximum sanned

area to around 100100m for a typial

onguration. Ifonewantstobesurethat,

within this sanned area, there is at least

oneborderregion(betweentheregionswith

and withoutimplantedions) themask has

to reateregionssmallerthan afewtenths

ofamiron.

2. Sine SFM measurements annot

provide surfae omposition, the

mehan-ial mask should allow the prodution of

twosamplessimultaneouslyunderthesame

onditions. This would provide one

sam-ple to be used in the SFM measurements

and another one (presumably idential to

therst sample) to be used in the

ompo-sitiondetermination. Thisproedureisdue

to the fat that mostof the surfae

analy-sesaredestrutive;ifonesampleisusedfor

bothtypesofanalyses,therewillbealways

unertainty if some sample harateristis

were hanged during the ion implantation

proessorduring thepreviousanalysis.

3. Depending on the dose of ions

im-planted on the sample, it ould be

impos-sible to dierentiate an implanted from a

sample by the proess due to the

impos-sibility of determining the border between

the implanted and the non- implanted

re-gions. Therefore, the mask should reate

thelargestpossiblenumberofborders(this

meansthelargestpossiblenumberof

sepa-rateimplantedregions).

4. Thedimensionsofthemaskwerealso

limited by the equipment used in its

pro-dution and by the equipment used in the

proessof ionimplantation.

A speial version of the programme AutoCAD 10

was used for thedesign of themehanialmask. The

designofthemehanialmaskusedinthisworkanbe

seenin Fig.2.

Figure2. Themehanialmasklay-out(frontpart).

The used ion implantation equipment limited the

mask size to 25 25 mm. The mask anbe used for

theprodution of twopairs ofsamples simultaneously

(in ase just onepair is needed, half of the mask an

beoveredduringtheionimplantation). Twodierent

typesoffeaturesanbeseenonFig.2.: a\nine-island"

sreenanda\three-island"sreen. Thesampleforthe

SFM measurementsis plaed under the \nine-island"

sreenandthesampleforsurfaeompositionanalysis

under the\three-island"sreen. Eightoutofthe nine

regionsonthe\nine-island"sreenand twooutofthe

threeregionsonthe\three-island"sreenontain

hun-dredsofretangularareaswithsizeof100 40m(those

The sreen is approximately 4.5 m thik and

shouldbeabletostopompletelyphosphorusionswith

upto24MeVaelerationvoltage(thefatwhetheran

ion beamwith ertainenergyanbestopped depends

on thesreen thikness). The ionbeamwill just pass

throughtheretangularareas,thushangingthe

prop-ertiesof thesamplein theretangular-shapedregions.

Thereasonforhavingeightseparateregionswith

ret-angular struture on the \nine-island" sreen instead

of onebigregion, is that thesreen materialis fragile

and an rak due to the surfaetension. The

spa-ing between the retangular areas is 50 m, whih is

suÆientfordistinguishingbetweentheimplantedand

non-implantedregions(implantedones should be

nar-rower).

The regions without the retangular struture on

the \nine-island"sreen and the\three-island"sreen

areatuallylargeholesinthesreen(withsizesof22

mmand8:55:5mmrespetively)whereanionbeam

an passandhit thesamplesurfaeuniformly. Onthe

\nine-island"sreen, the regionwithoutthe

retangu-lar struture was designed to failitate the searh for

the areas of interest on the sample after the ion

im-plantationproess(inasetheimplantedareasarenot

visible,thesamplesurfaeanbemarkedthroughthis

hole). The region without the retangular struture

on the\three-island"sreen was designedin order to

be used for surfae omposition analysis (the area is

suÆiently large for most of the surfae omposition

analysis tehniques). The two regions with the

ret-angular struture on the \three-island"sreen an be

used for omparison between the SFM results on the

sample used just for this type of measurements (i.e.

the one under the \nine-island" sreen)and the

sam-pleusedforsurfaeompositionanalysis(i.e. underthe

\three-island"sreen). Inthisway,theinuenedueto

thesurfaeompositionanalysisontheresultsofSFM

measurementsanalsobestudied.

II.3.2. Prodution ofthe mehanialmask

The mask, was designed and manufatured in the

MiroEletroni Laboratory of the Polytehni

Engi-neering Shool of the University of S~ao Paulo. The

produtionof themaskanbedividedintotwomajor

stages:

1. Produtionofhromepatternmasks

Sineitisnotpossibletotransferthe

de-siredomputerdesign diretly into the

sil-ion mehanial mask used in the ion

im-plantation proess, an intermediate mask

originally designed in the omputer. One

produed, the intermediate masks an be

used for the prodution of an indenite

numberofsilionmehanialmasks.

2. Prodution of silion mehanial

masks

Themehanialmaskonsists ofa

sub-strate, made of silion, and of a sreen,

made of silion, oxygen and nitrogen,

re-atedon thesilionsubstrate. The

geomet-rial patternfrom ahromemaskis

trans-ferredtothesreenmaterialofthe

mehan-ialmask. Thesilionsubstrateatsonlyas

asupportfortheomplexoxidesreen. The

sreen isformed ononeof the sides ofthe

silionsubstrate andthe omplexoxideon

theothersideofthesubstrateisremoved

al-mostompletelytopreventundesired

stop-ping of ions (the substrate is not removed

ompletely in order to protet the silion

substrateduringthesilionorrosionstage;

seestage8ofthemehanialmask

produ-tionin theAppendix). Therefore, two

dif-ferenthrome pattern masks (one for eah

sideofthesilionsubstrate)areneeded(see

Fig.3.).

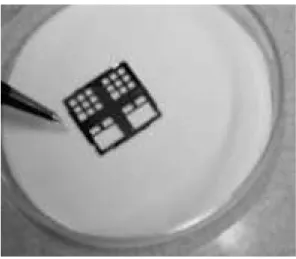

Figure4. Mehanialmask.

Eahofthetwomajorprodutionstagesonsistsof

severalsub-stages. Thestepsneededfortheprodution

of the hrome pattern and the silion mask are given

in detailin theAppendix. Themehanialmask used

in the experiments an be seen in Fig. 4. The small

divisionsinsideeahsquareannotbeidentiedinthis

magniation.

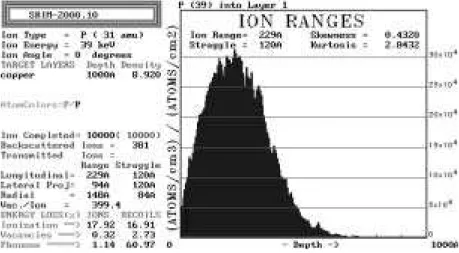

II.4. Ion Implantation

Two polished opper substrates were implanted

with phosphorus ions (with a dose of 8:45 10 15

ions/m 2

)atanaelerationvoltageof39keV.Theion

implantation was performed with an Eaton GA 4204

implanteroftheCentreofSemiondutorComponents

of theUniversity of Campinas. In order to determine

therangesofthephosphorusionswiththeaeleration

of 39 keV, TRIM simulations were performed (SRIM

version2000.10[7℄). Inthose simulations, 10.000ions

wereusedandthemaximumionrangewasaround600

A

(seeFig.5.), thusonrmingthat themehanialmask

produed here (with a 4.5 m thik oxide layer

om-pletely stopping the inident ions) ould be used for

theexperiments.

II.5. Surfae Analysis

One of the two implanted samples was used for

AugerEletronSpetrosopy(AES)in order to

deter-minethesurfaeomposition. For determiningthe

in-ueneof the ion implantation proess on thesurfae

omposition of samples, one substrate whih did not

undergotheionimplantationproesswasalsousedfor

AES.TheAESanalyseswereperformedin theSurfae

PhysisLaboratoryoftheInstituteofPhysis,

Univer-sityofCampinas.

The other implanted sample was used for Kelvin

or-is diretly related tothe work funtion ofthe surfae.

The VoltaPotentialbetween the tip (madeof Pt and

Ir) and a freshly leaned polyrystalline opper

sub-stratewasusedasareferenevalue. Itshouldbe

men-tionedthattheonlusionsdrawnfromthese

measure-ments are not dependent on whih referene material

wasused. Simultaneously to the Volta Potantial,

to-pographymeasurementsoftheoppersamplewere

per-formed with KPFM equipment. The KPFM analyses

wereperformed in theLaboratoryof Material Siene

andEngineeringoftheOhioStateUniversity.

Figure5. SRIMresultsforphosphorusionswithenergyof39keV.

III Results and Disussion

Oneofthemostimportantpartsofthepreparation

proedurefortheSFMsampleisthetreatmentreeived

by thesubstrate. Sine hanges onthe topographyof

thesampleaninuenetheSFMmeasurements,great

areshouldbetakeninordertoprodueuniformly

pla-narsubstratesurfaes. Althoughthepreparationofthe

opper substrates that were used for the experiments

desribedhereyieldedgoodresults,theproedure an

befurther improved. Reently, Wadsak et al. [8℄

ar-riedoutaomparisonofdierentpreparationmethods

of oppersubstrates forsanning fore mirosopy

in-vestigations.

Thesurfaeoftheimplantedoppersubstrateswere

investigatedwithanoptialmirosope. The

retangu-larareasinFig. 6. areregionswhihreeived

phospho-rusionsduringtheionimplantation. The

retangular-shaped struture mathes the geometrial pattern of

themehanialmask. Somesarsontheoppersurfae

wereobserved,whihareprobablyduetothehandling

ofboththemehanialmaskandtheoppersubstrates

duringtheionimplantationproess.

The results of AES analyses for the opper

sub-strates(before ion implantation) are shown in Fig.7a.

The presene of some ontaminants wasobserved. In

order to determine the thikness of the ontaminant

layer,athiklayerofabout50

Aofthesubstrate

sur-fae wasremoved by Ar sputtering. The omposition

analysis of the opper substrate after the sputtering

proessisshowninFig.7b.

ItanbeseenfromtheseguresthatonlyOandC

are present on theopper surfaeafter the sputtering

proess. It anbe onluded that the other

ontami-nantsobservedontheoppersurfaewithout

sputter-ing(S,ClandN)werejustpartofaontaminantlayer

of lessthiknessthan50

A.Thefat that OandCare

stillfoundevenaftertheremovalofapproximately50

A

of thesurfaeisexpeted sineopper,in air,forms a

relativelythikoxidelayerveryquikly[9,10℄. Carbon

Theresultsobtainedfrom theAESanalysisforthe

implanted opper sample are shown in Fig. 8. The

ontaminants found on the opper substrate without

ion implantation(Fig. 7.) analso beseenonthe

im-planted sample. One new peak, around 120 eV, was

found. Thispeakindiates thepreseneof phosphorus

onthesamplesurfae. Itshouldbenotedthat no

on-taminantsdueto theuseof themehanialmaskwere

found.

Figure7a. Coppersubstratebeforesputtering.

Figure7b. CoppersubstrateaftersputteringFigure7.

ResultsofAESforoppersubstrate.

Figure8. ResultsofAESforimplantedoppersample.

Sometopographyresults andVolta Potential

mea-surementsforaertainregionoftheimplantedsample

areshowninFig. 9(whereweanseenthe

retangular-shaped patternof the implantedareas.) Thereare no

notieablehangesonthetopographyoftheimplanted

regions.

Eightdierentareaswitharetangular-shaped

pat-ternonthesamesamplewereexaminedfortopography

andVolta Potential. Theresults forthe Volta

Poten-tial are shown in Table 1. The results for both the

implanted and non implanted regions are given with

respet to the referene oppersubstrate used for the

measurements. Sinethesameopperrefereneisused

for the measurements of the implanted and non

im-plantedareas,there isnoinuene ontheobtained

re-sults.

TheVoltaPotentialdiereneindiatesthehange

oftheopperworkfuntion duetothephosphorusion

bombardment. In this ase, an inrease of 25mV in

averagewasobservedifweomparetheionimplanted

region with the non implanted region. Although the

valuesfortheVoltaPotentialdierenehangeslightly

from area to area, the work funtion of the opper

learly shows an inrease for the implanted areas as

omparedwiththeoriginaloppersurfae.

Itisnotyetlearwhethertheworkfuntionhanges

were indued by the presene of phosphorus on the

surfaeorby the ion implantation proess (for

exam-ple, heating of the sample, hange of the topography

by sputtering, et.) [11,12℄. Further experiments are

needed in order to determine what is the mehanism

for the work funtion inrease. Nevertheless, the

re-sultsoftheexperimentsobtainedin thisworkindiate

that the method for reating implanted and non

im-planted regions in a sample is satisfatory for KPFM

Area Non-implanted ImplantedRegions VoltaPotential

Regions Dierene

1 0.110V 0.122V 12mV

2 0.150V 0.172V 22mV

3 0.150V 0.170V 20mV

4 0.110V 0.166V 56mV

5 0.150V 0.170V 20mV

6 0.120V 0.150V 30mV

7 0.115V 0.140V 25mV

8 0.155V 0.170V 15mV

Table1. KPFMresultsfordierentareasofanimplantedoppersample.

Figure9. ResultsofKPFMforimplantedoppersample.

Itshouldbenotedthatthemethodommonlyused

in the eletroni industry for produing dierent

pat-terns ona surfae, i.e., themethod employinga

pho-toresistordiretlyonthesubstrate(whihwouldatas

the mehanial mask desribed above), ould be used

onlyforoneexperiment,sinethephotoresistor would

beattahed tothesamplebeingprepared. This isone

oftheadvantagesoftheuseofthemehanialmaskto

preparesamplesforKPFM.

IV Conlusions

In this paper, we desribe a methodology for

prepar-ing samples to be used by a KPFM equipment. The

method wasused tostudytheinueneofion

implan-tationofphosphorusontheworkfuntion ofopper.

Changesoftheworkfuntiononoppersurfaewere

notied due to the implantation of phosphorus ions.

However,thedeterminationoftheexatmehanismfor

Aknowledgements

Oneof theauthors (I.R.J.) would liketo

aknowl-edgethenanialsupportreeivedfrom FAPESP.

Referenes

[1℄ W.N.Hansen,K.B.Johnson,Surf.Si.316,373(1994).

[2℄ M. Saint Jean, S. Hudlet, C. Guthmannm, J. Berger,

Phys.Rev.B56,15391(1997).

[3℄ M. Nonnenmaher, M.P. O'Boyle, H.K.

Wikramas-inghe,Ultramirosopy42-44,268(1992).

[4℄ Y. Martin, C.C. Williams, H.K. Wikramasinghe, J.

Appl.Phys.61,4723(1987).

[5℄ J.M.R.Weaver,D.W.Abraham,J.Va.Si.Tehnol.B

9,1559(1991).

[6℄ M. Nonnenmaher, M.P. O'Boyle, H.K.

Wikramas-inghe,Appl.Phys.Lett.58,2921(1991).

[7℄ J.F. Ziegler, J.P.Biersak, U. Littmark, The Stopping

[8℄ M.Wadsak,M.Shreiner,T.Aastrup,C.Leygraf,Appl.

Surf.Si.157,39(2000).

[9℄ J.C. Yang, B.Kolasa, J.M. Gibson, M. Yeadon, Appl.

Phys.Lett.73,2841(1998).

[10℄ K.I.Tanaka,T.Fujita,Y.Okawa,SurfSi.401,L407

(1998).

[11℄ P.J.Ratlie,R.A.Collins,Phys.Stat.Sol.A 78,547

(1983).

[12℄ B.J. Love, P.F. Pakman, J. Mater. Si. 33, 1359

(1998).

Appendix

1)Preparationofthehromemask. Athin hrome

layer(300nm)wasdepositedbyasputteringdeposition

tehnique,usingaMagnetronBalzersBAS450

Sputter-ingSystem,onglassplates(Croningglass)whihwere

rinsedinthreedierentsolutionspriortothedeposition

proess:

15-20 minutes in TriChloroEthylene (TCE) on

80 Æ

C;

15-20minutesinaetoneon80 Æ

C;

15-20minutesinisopropanolon80 Æ

C.

2)Cleaningofthehromemaskswasperformedby

plaing the prepared hrome wafers in a solution of

H 2 SO 4 and H 2 O 2

(proportion 3:1) at a temperature

of 105 Æ

Cduring 15 minutes; andthen byleaning the

maskswithdeionizedwaterfor10minutes. Afterwards,

thehromemaskswereimmersedinalohol(40 Æ

C)for

20minutesand driedwithajetofN

2 .

3) The photoresistor used in the reported

exper-iments was a positive photoresistor AZ1518 diluted

in AZ1500 Thinner (proportion 16:9) produed by

Hoehst. Theappliationtehniqueinvolvestwostages:

statiappliationofaphotoresistorsolutiononthe

sur-fae of hrome wafer and subsequent aeleration in

thespinnerfor30seondswithonstantrotationspeed

of 4000rpm. This proess generates auniform lmof

thephotoresistorwith about0.7mofthikness. The

hromemasks witha photoresistorwere submittedto

softbakingfor20minutesatatemperatureof 80 Æ

C.

4)Thephotoresistorlmwasthenexposedtolight

using a Miropattern printer, Imagen 100, Researh

Devies Instruments, at the UV-lose spetrum

(350-500nm). The omputer oupled to this equipment

transfersthedesignedgeometry patternto thesystem

memory. This image is reprodued onthe

photoresis-torlmbyexposingthelmthroughthemovableslits

(whihletlightpassonthedesiredregionsonly). The

whole proedure takesapproximately3hoursfor eah

hromewafer.

5) The parts of the photoresistor lm whih were

exposed to light were removedusing a351Developer,

made by Hoehst, diluted in water (proportion 5:1).

temperature treatment (90-100 Æ

C) during 30 minutes

(hardbaking).

6) Thehromemaskswith theremaining

photore-sistorlmwereplaedduring3minutesinasolutionof

160gof eriumammonium nitrate and45ml ofglaial

aetiaid. Thissolutiondissolvesunprotetedhrome

only, leavingintatthephotoresistorlmandthe

pro-tetedhromebelowthelm.

Inordertoremovetheremainingphotoresistorlm,

thehromemaskswererstimmersedfor5-20minutes

inaetone(40 Æ

C)andtheninTCE(5-10minutes). The

masksarethenwashedwithajetofaetone,waterand

isopropanol.

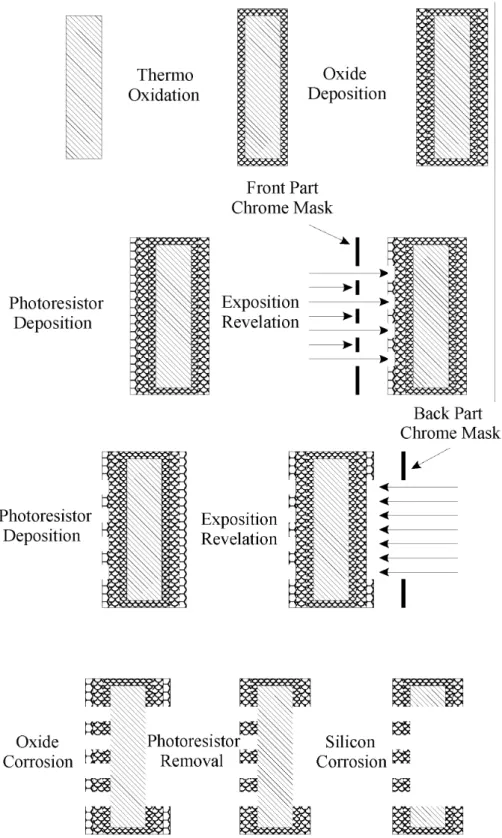

The prodution of the silion mehanial mask is

dividedinto sub-stages (the shemati diagram of the

produtionanbeseeninFig.10.):

1) Before the use, the silion substrates were ut

(2525mm)andleaned,followingthestepsmentioned

below: 15 minutes in asolution of H

2 SO 4 and H 2 O 2

(proportion 3:1) at a temperature of 105 Æ

C; 10

min-utesintapwater;5minutesindeionizedwaterltered

with Millipore Milli-Q Plus (water with resistivity of

18.2Mm);15minutesinasolutionofH

2 O,NH 4 OH and H 2 O 2

(proportion 5:1:1) at temperatures up to

75 Æ

C; 10minutes intapwater;5minutesin deionized

water ltered with Millipore Milli-Q Plus; 15 seonds

inasolutionofNH

4

F(40%)andHF(49%)(proportion

25:4)BOEEthant;15 minutes in tapwater; 15

min-utesin asolution of H

2 O, H

2 O

2

and HCl (proportion

6:1:1)atatemperatureof80 Æ

C;10minutesindeionized

waterlteredwithMilliporeMilli-QPlus;

Thesubstratewasnally driedwithanitrogenjet.

As mentioned, the reation of the oxide layer on

thesilionsubstrateisveryimportantintheproessof

fabriation of the mehanialmask, sine the pattern

ofthehromemaskistransferredtothislayerandnot

tothesilionsubstrate.

Theoxidelayerisreatedintwosteps. First,it

o-ursathermo-oxidationandthenadepositionofa

om-plexoxidelayer (Si, O and N). The thermo-oxidation

wasobtainedbyplaingthesubstratesinanoven

ham-ber at 1100 Æ

C, lled suessively with various gases

(rst5minuteswith O

2

, followed by25 minutes with

H

2

Ovapourandnally40minuteswithN

2

). This

pro-essreatesalayerofathermo-oxideofapproximately

0.5m.

Thedepositionoftheomplexoxidewasperformed

usingaPECVD2system(PlasmaEnhanedChemial

VapourDeposition)usinganeletridishargethrough

amixture of high purity SiH

4

(99.89%) and high

pu-rity N

2

O(99.999%). Theowrates ofthe gaseswere

37.5smfor N

2

Oand 15sm forSiH

4

. That proess

reatesaomplex oxidelm of SiO

x N

y

(the

omposi-tionanalysis ofthis lm determinedvaluesof 1.57for

xand0.34fory). Contrarytothermo-oxidation,where

eahsideofthesubstratehastoundergothedeposition

separately. Theappearaneofanapproximately4m

thiklmtakesabout3hours.

Afterwards, the substrates were rinsed in dierent

solutions: 15-20 minutesin TCEat 80 Æ

C;15-20

min-utesinAetoneat80 Æ

C;15-20minutesinIsopropanol

at80 Æ

C.

Thethermo-oxidehasatwo-fold role. It promotes

theadhesionofthedepositedoxidelmanditgives

ex-traprotetiontothesilionsubstrateduringthesilion

orrosionproess(stage8of themehanialmask

pro-dution). Thethikness ofthe lmshould betailored

aordingtotheionspeiesandtheenergyofthebeam

usedintheionimplantationexperiments.

Inorder to promotethedehydrationof thesurfae

a primer was overedon the substrate surfae before

theappliationofthephotoresistor(the samesolution

asin the hrome mask prodution). The thikness of

thereatedphotoresistor lmwas about2.2 m. The

silion substrateswith a photoresistorlayerwere

sub-mittedtoasoftbakingfor20minutesatatemperature

of80 Æ

C.

AKarl Suss MJB3Mask Alignerwasused forthe

lightexposingproess(lightof350-500nmwavelength).

This step lasted 100 seonds for eah side of the

sil-ionsubstrate. That equipmentuses the hrome

pat-ternmasksinordertoreatethedesiredpatternonthe

photoresistorlmofthesilionsubstrate,i.e.,lightan

passthroughonlyifthereisnohromeonthepattern

mask.

Afterthelightexposingproess,thesubstrateswere

submittedtotheproessofdevelopingandhardbaking,

desribedin stage5of thehromemaskprodution.

Beforethepartialremovalof theoxide(just in the

areas where the photoresistor lm was destroyed) on

one side of the substrate, the other side of the

sub-strate was proteted with Apiezon r

. The substrates

wereplaedinasolutionofNH4F(40%)andHF(49%)

(proportion25:4),BOE r

Ethant,for7minutes,whih

removesompletelytheoxideatthedesiredareas.

After the partial removal of the oxide layer, the

Apiezon r

wasremovedwithTCE.Thestrippingofthe

photoresistor and the leaning of the substrate were

performedasdesribed in stage 7of thehromemask

prodution.

Thestages 3-7 were repeated for the other side of

thesilionsubstrate.

Aftertheoxidelayerwaspartiallyremovedonboth

sidesofthesubstrate,aorrosionproessofthesilion

substratewasthenperformed. Onlythesilionloated

belowtheoxideareasremovedintheproess(desribed

instage6above)isdissolved. Thesubstratewasplaed

for7hours,at atemperatureof80 Æ

C,inasolutionof:

108mldeionizedwater;51mlisopropanol;50gKOH.

Aftertheorrosionstep,thesubstrateswereleft10

minutesinastreamofdeionizedwaterandleanedwith