o ABSTRACT: The aim of this study was to investigate the effects

of hygrothermal exposure, ultraviolet (UV) radiation, salt spray and thermal shock aging on the thermomechanical behavior of glass iber reinforced by poly (ether-imide) (PEI) composites. Dynamic mechanical (DMA) and Thermomechanical (TMA) analyses have been performed on the aged PEI composites after being submitted to the climatic chambers. Additional techniques have been used to characterize the laminates, such as optical microscopy and infrared spectroscopy (FT-IR) in order to evaluate possible structural changes in these materials. Slight changes were observed both in glass transition temperature and in thermal expansion coeficient as a result from the environmental conditioning used (hygrothermal, salt spray, UV radiation and thermal shock conditioning). Thus, when exposed to these conditions, PEI/glass iber laminates maintain its compromise with the performance component.

KEYWORDS: Thermoplastic composites, Environmental conditioning, Glass transition temperature, PEI/glass iber.

Environmental Effects on Thermal Properties

of PEI/Glass Fiber Composite Materials

Edson Cocchieri Botelho1, José Carlos Bravim Júnior1, Michelle Leali Costa1, Maria Candida Magalhaes de Faria1

INTRODUCTION

Lightweight composite materials are currently inding extensive use in a wide range of load-bearing engineering applications due to its low density and its high performance in terms of strength and stifness, besides high cost competitive market. hese factors place it in a position to replace the traditional metallic materials already used in the sectors of interest of new technologies such as civil, naval, automotive and aerospace principally (Diaz and Rubio, 2003; Botelho et al., 2003).

With the constant necessity of the development of lightweight structures, the advancements of science and technology in several areas has contributed to the improvement of aviation parts. Structural components of aircrat for civilian and military purposes, such as laps, rudders, fairings, aileron, fuel tanks, elevator, tail cone and others that were previously made of metal alloys are recently being manufactured in laminated structures of advanced polymeric composites (Kim and Ye, 2005). Currently, several companies are already introducing these parts in their aircrat, among which may be cited as Airbus, Boeing and Embraer (Botelho and Rezende, 2000).

hermoplastic composite materials have several advantages over traditional thermoset composites in the manufacture of lightweight structures, among them the fact that these materials can be reprocessable, have good cost-efectiveness and solidify in a short time compared with slow curing of the thermoset resins, which facilitate their use (Botelho et al., 2003). Between the thermoplastic matrix, the poly (ether-imide) (PEI) is a polymer of high performance

1. Faculdade de Engenharia de Guaratinguetá – Guaratinguetá/SP – Brazil

Author for correspondence: Edson Cocchieri Botelho | Departamento de Materiais e Tecnologia/FEG | Avenida Ariberto Pereira da Cunha, 333 – Pedregulho |

CEP 12.516-410 Guaratinguetá/SP – Brazil | E-mail: ebotelho@feg.unesp.br

with good properties, such as strength and stifness at elevated temperatures, good electrical properties, ample chemical resistance, besides low cost. Furthermore, its glass transition temperature Tg is high compared to other engineering polymers and can be used in aeronautical applications (Oliveira et al., 2009; Zenasni et al., 2006; Viña et al., 2008; Chevali et al., 2010).

Fiber-reinforced thermoplastic composites in outdoor applications encounter ambient moisture, variation of temperature, salinity and ultraviolet (UV) radiation in addition to stress and temperature, which afects mechanical properties (White and Shyichuk, 2007). hese materials are used for long periods of time on airplanes, so it is necessary to know exactly which inluence of such factors ensure its safe operation, preserving their properties for the period desired (Yakimets et al., 2004).

When these composite materiais are subjected to distinct and repetitive ranges of temperature, the heating and cooling processes can generate interlaminar stresses, causing defects in the microstructure or delamination of their laminas, and in this cases can occur mechanical deformations of thermal origin (thermal fatigue) (Boualem and Sereir, 2011; Chawla, 2001; Costa et al., 2012; Botelho et al., 2005; Hufenbach et al., 2011; Ramanujam et al., 2008). In this context, a better prediction of the long-term durability of composite materials with organic matrix is essential. In particular, the study of the coupled efects of mechanical cyclic loads, of temperature variations and of a more or less oxidative environment on the damage of these materials remains to be made. When composite laminates with long continuous ibers are subjected to temperature variations, the mismatch of thermal expansion coeicients of ibers and matrix as well as the diference of ply orientation in the lay up are such that local stresses appear, which can take part in the degradation of the laminate. When these thermal variations are cyclic, they induce, at the ply level, cyclic stress variations which can be compared, at this scale, to a fatigue phenomenon. Various types of damage similar to those observed in mechanical fatigue result from these cyclic stresses, like transverse matrix cracking, iber/matrix debonding and delamination. Few works deal with the long-term behavior of composites subjected to thermal chock condition (Boualem and Sereir, 2011; Chawla, 2001; Costa et al., 2012; Botelho et al., 2005; Hufenbach et al., 2011; Ramanujam et al., 2008).

Concerning moisture inluence, this can penetrate into the composite structure by difusive and/or capillaries

processes in accordance with the second Fick’s law. It is commonly assumed that water difuses into the amorphous regions of the polymer where hydrolysis should occur at a rate which depends upon the crystallinity and the initial content of end-groups. In particular, the increase of humidity decreases the mechanical properties of some materials and it is aggravated when combined with high temperatures (Jedidi et al., 2006; Kellogg et al., 2003; Costa et al., 2010; Ray, 2006; Botelho and Rezende, 2010). Moisture absorption may induce severe mechanical and physicochemical changes in polymer matrix or iber/matrix interphase: polymer chains can undergo a reversible plasticization process, which lowers the glass transition temperature, be subjected to irreversible hydrolysis (Jedidi et al., 2006) and the iber/matrix interphase can be damaged due to the coupling with internal stresses, for instance. he moisture difusion process is highly dependent on the temperature and relative humidity (Jedidi et al., 2006; Kellogg et al., 2003; Costa et al., 2010; Ray, 2006; Botelho and Rezende, 2010).

In the case of incidence of UV radiation, it is known that energy is comparable to the covalent bonds in the polymers, thus photo-oxidative reactions may occur and cause degradation in the polymeric matrix, crosslinking among other efects which afects the mechanical resistance of the laminate (White and Shyichuk, 2007; Yakimets et al., 2004).

o

2011; Chawla, 2001; Costa et al., 2012; Botelho et al., 2005; Hufenbach et al., 2011; Ramanujam et al., 2008).

So, in addition to mechanical properties (tensile, compression, shear etc.), it is important that the maximum service temperature be veriied making sure the aircrat light envelope, based on knowledge of Tg and melting temperature (Tm).

In this study, moisture, UV radiation, salinity and temperature inluences on thermal properties of PEI/glass iber laminate have been investigated. he efects of environment on this thermoplastic composite were studied by Dynamical Mechanical Analyses (DMA) and hermomechanical Analyses (TMA). Additional techniques have been used to characterize the laminates, such as optical microscopy and FT-IR (infrared spectroscopy) in order to evaluate possible structural changes in these materials.

EXPERIMENTAL

MATERIALS

he material used in this work is a composite laminated with glass iber fabric reinforcement and PEI thermoplastic matrix, supplied by the Ten Cate Advanced Composites (Dutch company). Its coniguration consists of a laminate with around 2.0 mm of nominal thickness and woven made in 8 Hardness Satin (HS) coniguration.

ENVIRONMENTAL CONDITIONING

In order to check the mass gain per unit of time on these laminates, the specimens (in triplicate) remained for 60 days at temperature of 80°C with a relative humidity of 90% in climatic chamber. he hygrothermal exposure is based on ASTM D5229/D5229M-04 for composite materials. he samples were dried for 48 hours in a vacuum oven at 60°C in order to remove all the moisture present before to be subjected to hygrothermal chamber. he mass control allowed knowing the material moisture absorbing by the Eq. 1.

M = M u-Ms

Ms . 100 (1)

Where M is the mass percentage; Mu, the wet mass and Ms is the dry mass.

In the conditioning by thermal shock, it was used a chamber with a hot zone (upper) and a cold zone (lower) interconnected by a vertical lit, which remained for 30 minutes for each step. his chamber was programmed to operate during 1,800 cycles in temperature range from -50 to +80°C in order to simulate the light envelope of the aircrat (Yakimets et al., 2004; Boualem and Sereir, 2011).

he conditioning methodology by UV exposure was conducted according to ASTM 4329-99 standard. he system used consists of UVB-313 lamps emitting radiation during 8 hours at 60°C with an intensity of 0.76 W/(m2nm), alternating with 4 hours of water condensation coming from vapor generated at 50°C. Samples were used in order to set the time intervals of 200, 600 and 1,200 hours. During exposure, the samples were photographed to check the degradation of the material up to 1,200 hours of exposure. In order to evaluate if UV radiation generated a degradation process in PEI/glass iber, FT-IR analyses were used in this work. he equipment utilized was a Spectrum One of Perkin-Elmer and the parameters were: analyzed range of 4,000 to 400 cm-1, resolution of 4 cm-1 and gain of 20 scanning. he specimens were analyzed according to the relective technique (UATR), in which only the surface of the specimen is evaluated.

he coupons submitted to salt spray climatic chamber remained exposed for 15 days, following the ASTM B117-03 standard. he salt solution was prepared with 1 kg of NaCl in 19 L of distilled water, and the inal pH was around 7. he chamber test temperature was set in 47°C, the solution, in 35°C and the pressure was 1 kgf/cm².

THERMAL AND MORPHOLOGICAL EVALUATION

Optical microscopy was used to evaluate the structural quality of the laminates as received and also ater the environmental conditionings (hygrothermal, thermal shock and salt spray conditionings), generating information about the quality of the processing. It was used an optical microscope with a Zeiss stereoscopic magniier.

assessment to identify the defects. A-scan graph aided to calibrate the patterns of a typical structural composite peaks (reference-without defects) and the diference between the reference peak and the other peaks is referred as attenuation signal. he intensity of the attenuation signals can inform what type of defect might occur. Each point of the laminate creates an A-scan signal, ater scanning the entirely laminate. he referred map shows the background echo produced by the A-scan, which can show any laws along the thickness.

DMA tests were conducted in a bending loading mode, by the DMA equipment, model DMS 6100 from Seiko – SII Nanotechnology on samples with thickness of 2.0 mm, width of 12.0 mm and length of 50 mm. All measurements were performed with frequency of 1Hz, N2 atmosphere (20 mL/min) and heating rate of 3°C/min, in the temperature range from 30 to 210°C. his experiment was used in order to determine the Tg.

TMA was conducted in order to determine Tg (ASTM E1545) and also thermal expansion coeicient (ASTM E831) for all conditioning studied in the composite PEI/glass iber. For the TMA tests, it was used N2 atmosphere (20 mL/min) and heating rate of 3°C/min in the temperature range from 30 to 210°C. All TMA tests have been carried out in TMA SS 6100 equipment, EXSTAR6000 model, version 6.2U, from SII Nanotechnology.

RESULTS

MOISTURE ABSORPTION

Figure 1 displays the weight gain curves of the PEI/ glass iber laminates ater being submitted to hygrothermal conditioning at 80°C and 90 RH. he composite weight gain has been normalized according to Eq. 1. he results of three composite specimens are shown in the plot. he reproducibility of the uptake curve is fairly good among diferent specimens. he uptake curves of the composite obey the Fick’s law, with the weight gain initially increasing linearly with respect to (time)1/2 and gradually leveling of. Furthermore, the normalized composite weight gain is very close to that of the neat matrix, as can be observed in the literature (Yakimets et al., 2004; Boualem and Sereir, 2011).

According to the results found, the maximum moisture content absorbed by the specimens was 0.18%, determined ater around 25 days — showed in Fig. 1 as (hours)1/2. Water is only absorbed by the amorphous part of the thermoplastic matrix (Botelho and Rezende, 2010). However, in composite materials reinforced by glass iber, the surface treatment of the iber can absorb the moisture, increasing the weight gain promoted by moisture, inside of composite. herefore, as explained before, in this work, it was not found signiicant diferences between the neat matrix (Botelho and Rezende, 2010) and the results obtained from PEI/glass iber laminate.

Note that the absorption rate was nearly constant during the irst two weeks, about 0.01% by mass gain. Ater this period, the composite reaches a state called pseudo-equilibrium with the amount of water maintained practically constant. his behavior is explained by the fact that the free water penetrates the matrix by the concentration gradient with the continuous exposure. Ater the conditioning period, the amount of moisture in the composite did not vary signiicantly.

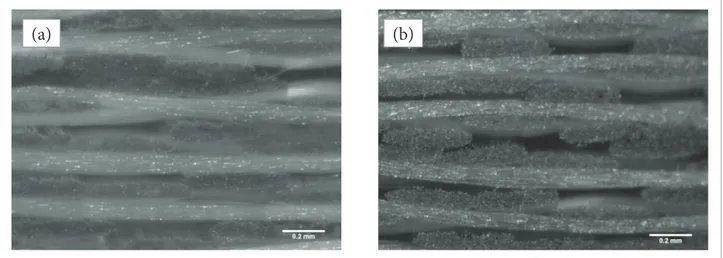

Figure 2 shows representative optical micrographs of the composite submitted to the hygrothermal conditioning (Fig. 2b). he rate of moisture difusion is controlled by the difusivity. It is a strong function of temperature and a weak function of relative humidity. Moisture can potentially cause debonding at the iber/matrix interface not only through chemical attack and reaction, but also through mechanical-chemical efects such as osmotic pressure. he mechanism of attack at the interface is

Figure 1. Moisture absorption curve for poly (ether-imide) (PEI)/glass iber composites.

0.25

0.20

0.15

0.10

0.05

0.00

M

o

is

tur

e G

ain (%)

Time (h½)

o

decisively governed by the chemistry, structure, morphology, and modes of failure at that interface (Boualem and Sereir, 2011; Chawla, 2001; Costa et al., 2012; Botelho et al., 2005; Hufenbach et al., 2011; Ramanujam et al., 2008).

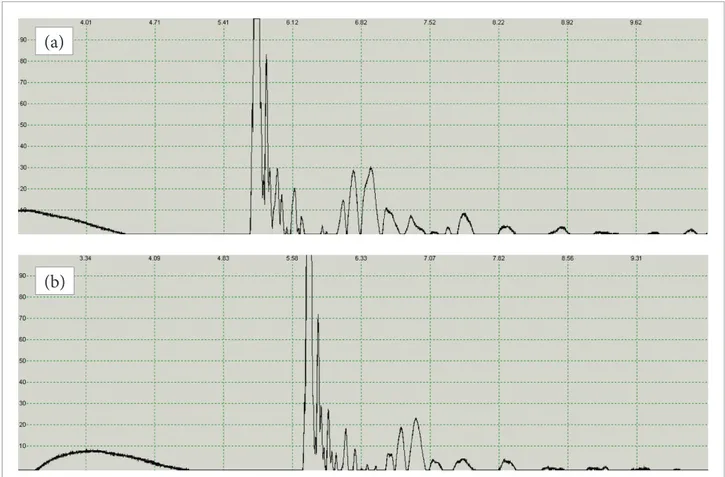

Figure 3 depicted the A-scan ultrasound results for the PEI/glass i ber specimens at er being submitted to hygrothermal conditioning. From these results, for specimens subjected to hygrothermal conditioning, there is a small

Figure 2. Microscopy of the composite poly (ether-imide) (PEI)/glass i ber. (a) Unweathered hygrothermal conditioning; (b) after hygrothermal conditioning.

(a)

(b)

Figure 3. A-scan ultrasound results for poly (ether-imide) (PEI)/glass i bers composites. (a) Unweathered hygrothermal conditioning; (b) after being hygrothermally weathered.

(a)

change of the reference peaks, in which a decrease lower than 10% in the bottom echo signal can be observed. h is small change is not enough to indicate modii cation in the structure of the laminate, coni rming the optical microscopy results.

ULTRAVIOLET DEGRADATION

Surfaces of all specimens exposed to UV radiation exhibited a distinct change in color from yellow to dark yellow during early stages of the exposure. h e discoloration established that photo-oxidation resulted in the formation of chromophoric chemical species, which were absorbed in the visible range of light. Minor changes in surface roughness were also visible for all specimens exposed to UV radiation. Exposure to water vapor condensation did not result in any visible changes in specimen morphology. According to the literature (Botelho and Rezende, 2010), further details regarding the physical processes that

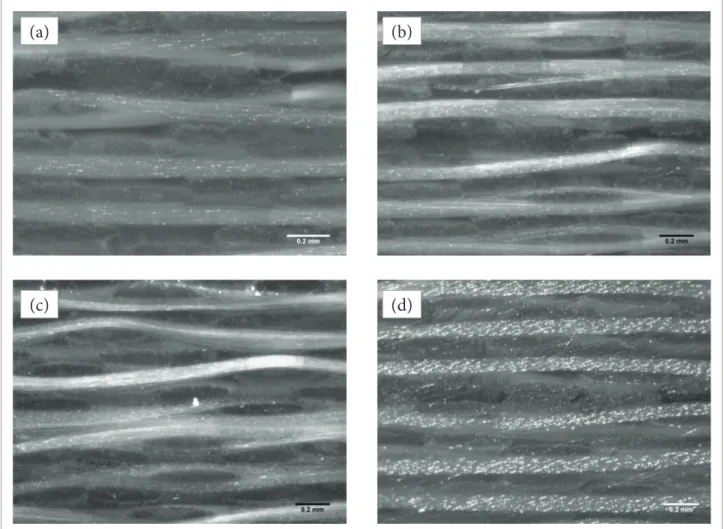

govern material degradation can be revealed by examination of the specimens under an optical microscope (OM). h erefore, in this work, no changes in morphology — using OM — were observed for either the specimen surface or edge, for specimens exposed to UV radiation (Fig. 4). Also, it was observed that the i bers were more exposed at er the radiation process. h is behavior is expected since it was happen degradation of the matrix during the UV conditioning.

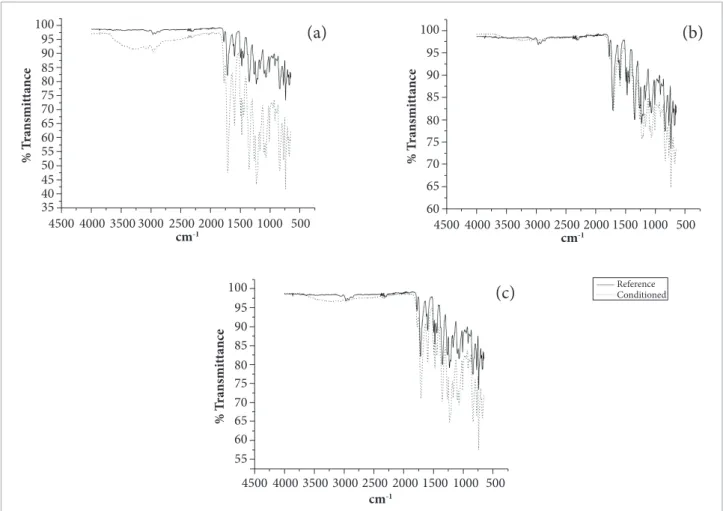

In Fig. 5, the FT-IR spectra for the unconditioned specimens and that one submitted to UV radiation conditioning for dif erent times of exposure are depicted. Analyzing the samples before and at er conditioning by UV radiation, small changes can be observed in the chemical structures of the material. In this study, up to 200 hours of exposure, the principal absorption is in the region of 3,300 cm-1, corresponding to stretching (v) hydroxyl group (-OH); beyond the range 3,300–3,600 cm-1, it

Figure 4. Optical microscopy results for poly (ether-imide) (PEI)/glass i ber composites after being submitted to ultraviolet radiation. (a) 0 hours; (b) 200 hours; (c) 600 hours; (d) 1,200 hours.

(a)

(c)

(b)

o

corresponds to the stretching amine (NH). At 600 hours of exposure, it is observed, in addition to the aforementioned events, the band of 2,950 cm-1, which shows a small change, indicating an elongation of aliphatic CH groups. As for the maximum interval conditioning (1,200 hours), there were small changes, indicating that the compound undergoes degradation (but probably not signii cant to modify their structural application) in incidence of radiation.

EFFECTS OF THERMAL SHOCK CONDITIONING

Figure 6 shows the optical micrographs of PEI/glass i ber specimens at er being submitted up to 1,000 thermal cycles. Concerning thermal fatigue process, it is expected that the porous generate failures or delaminations process during the thermal cycling. As can be observed in this work, this behavior was not verii ed by means of OM for either the specimen surface or edge, at er being exposed to thermal

cycling condition. h is behavior coni rms that the cycling number used was not enough to generate thermal fatigue in the composite. In this study, the amount of porosity was not considered, since this behavior depends on the analyzed region of the specimen.

Figure 7 depicts the A-scan ultrasound results for the PEI/glass i ber specimens at er being submitted to thermal cycle conditioning. From these results, signii cant changes in the peaks were not observed, indicating that probably there are no signii cant dif erences in thermal expansion coei cients between the layers.

EFFECTS OF AGING ON THE THERMAL BEHAVIOR: DYNAMICAL MECHANICAL ANALYSES AND THERMOMECHANICAL ANALYSES

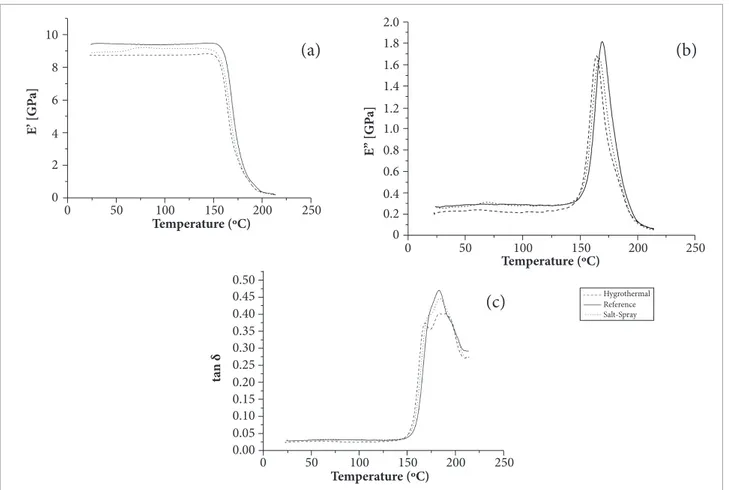

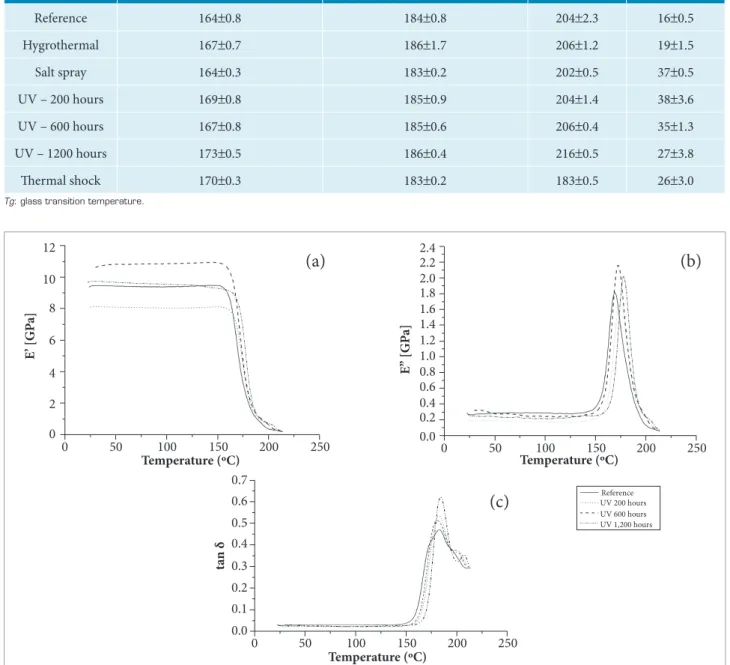

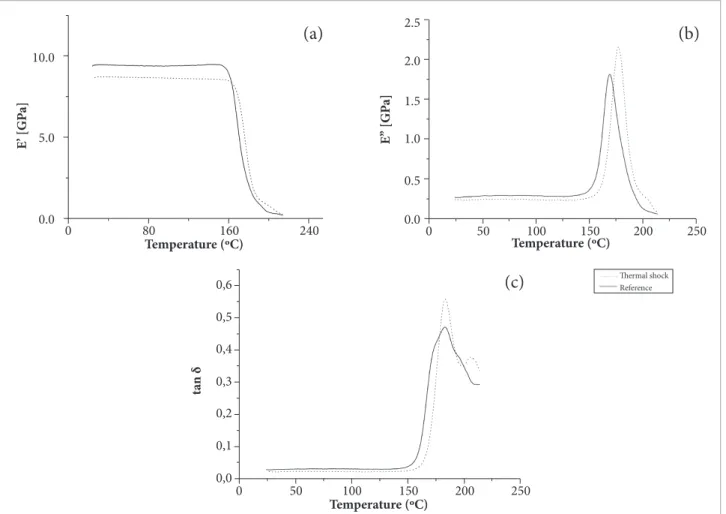

Figures 8 to 10 show the dynamic-mechanical behavior of PEI/glass i ber composite as received and at er being

Figure 5. Infrared spectroscopy (FT-IR) results of the samples subjected to ultraviolet radiation. (a) 200 hours; (b) 600 hours; (c) 1,200 hours.

60 55 50 45 40 35 % T ra ns mi tta nc e cm-1 4500 4000 65 70 75 80 85 90 95 100

3500 3000 2500 2000 1500 1000 500 60

% T ra ns mi tta nc e cm-1 4500 4000 65 70 75 80 85 90 95 100

3500 3000 2500 2000 1500 1000 500

60 % T ra ns mi tta nc e cm-1 4500 4000 65 70 75 80 85 90 95 100

3500 3000 2500 2000 1500 1000 500 55

(a)

(b)

Figure 6. Optical microscopy of poly (ether-imide) (PEI)/glass i ber laminates. (a) Unweathered thermal shock conditioning; (b) after thermal shock conditioning.

Figure 7. A-scan ultrasound results for poly (ether-imide) (PEI)/glass i bers composites. (a) Unweathered thermal shock conditioning; (b) after thermal shock conditioning.

(a)

(a)

(b)

o

submitted to hygrothermal and salt spray conditioning, UV exposition and thermal shock, respectively. Figures 11 to 13 present the TMA curves for all conditioning studied in this work.

h e method of determining the Tg in the DMA can be a manner for disagreement, as at least i ve ways are in current use. Depending on the industry standards or background of the operator, the peak or onset of the tan delta curve, the onset of the E’ drop, or onset or peak of the E” curve may be used. h e values obtained from these methods can dif er up to 25°C from one another on the same run. In addition, a 10–20°C dif erence from Dif erencial Scaning Cromatography (DSC) or TMA is also seen in many materials. Dif erences as great as 25°C have been reported. In practice, it is important to specify exactly how the Tg should be determined (Menard, 2008). According to Table 1, the Tg values obtained by DMA (peak of tan d) are lower than the values of Tg measured by TMA, in the order of 20°C.

As can be observed in Fig. 8 and also in Table 1, the hygrothermally aged glass i ber reinforced specimen did not show signii cant decrease in the magnitude of the relaxation peak (Tg), since the samples subjected to hygrothermal conditioning had a reduction of only 3.7% compared to the unweathered sample values; and this decrease for sample subjected to saline conditioning was only 2.7% (Tg obtained from onset E’ drop values). Similar behaviors were observed when Tg was obtained from E’’ and tan δ. h e phenomenon of decrease in the Tg temperature for the hygrothermally aged glass i ber reinforced sample is related to plasticization, which induces an increase in the amorphous chain mobility but, since for PEI/glass i ber composite the absorbed moisture content was very low, this ef ect was not so pronounced.

In the characteristic plot of the storage modulus (Fig. 8a), hygrothermally and salt spray aged glass i ber reinforced samples had a lower storage modulus compared to unweathered specimen, but it was observed only around

10

8

6

4

2

0

E

’ [GP

a]

Temperature (ºC)

0 50 100 150 200 250

1.0 1.2 1.4 1.6 1.8 2.0

0.8 0.6 0.4 0.2 0

E

’’ [GP

a]

Temperature (ºC)

0 50 100 150 200 250

0.40

0.20 0.15 0.10 0.05 0.00

ta

n δ

Temperature (ºC)

0 50 100 150 200 250

0.25 0.30 0.35 0.45 0.50

Figure 8. Dynamic mechanical analysis (DMA) curves of the poly (ether-imide) (PEI)/glass i bers composite after being conditioned in salt spray and hygrothermal chamber. (a) E’; (b) E’’; (c) tan δ.

(a)

(b)

5% of decrease of this property. h is behavior is probably related to the plasticizing ef ect promoted by the moisture absorption. Also, it was observed a second peak in Fig. 8c, probably related to the beginning of plasticizing ef ect.

Figure 9 and Table 1 show the results of DMA for the samples submitted to the UV exposure. As can be seen, the Tg value increases as the time of exposure to the UV radiation

increases. As can be observed from this result, the Tg value obtained from the onset of E’ was 164°C for the unweathered specimen. At er being submitted to UV radiation during 200, 600 and 1,200 hours, the PEI/glass i ber laminate increases the Tg values in 1.89, 2.31 (table shows the contrary) and 4.98%, respectively. h is increase in Tg at er exposure to UV condensation indicates that the PEI matrix underwent

10 12

8

6

4

2

0

E

’ [GP

a]

Temperature (ºC)

0 50 100 150 200 250

1.0 1.2 1.4 1.6 1.8 2.4

0.8 0.6 0.4 0.2

E

’’ [GP

a]

Temperature (ºC)

0 50 100 150 200 250

0.0 2.0 2.2

0.4 0.3 0.2 0.1 0.0

ta

n δ

Temperature (ºC)

0 50 100 150 200 250

0.5 0.6 0.7

Figure 9. Dynamic mechanical analysis (DMA) curves of the poly (ether-imide) (PEI)/glass i ber composite after being submitted to ultraviolet (UV) radiation. (a) E’; (b) E’’; (c) tan δ.

(a)

(b)

(c)

UV 200 hoursReference

UV 600 hours UV 1,200 hours

Conditioning Tg (onset E’ drop – DMA) (°C) Tg (peak of tan δ – DMA) (°C) Tg (TMA) (°C) α x 10-6 (°C-1)

Reference 164±0.8 184±0.8 204±2.3 16±0.5

Hygrothermal 167±0.7 186±1.7 206±1.2 19±1.5

Salt spray 164±0.3 183±0.2 202±0.5 37±0.5

UV – 200 hours 169±0.8 185±0.9 204±1.4 38±3.6

UV – 600 hours 167±0.8 185±0.6 206±0.4 35±1.3

UV – 1200 hours 173±0.5 186±0.4 216±0.5 27±3.8

h ermal shock 170±0.3 183±0.2 183±0.5 26±3.0

Tg: glass transition temperature.

o

10.0

5.0

0.0

E

’ [GP

a]

Temperature (ºC)

0 80 160 240

1.0 1.5 2.5

0.5

E

’’ [GP

a]

Temperature (ºC)

0 50 100 150 200 250

0.0 2.0

0,4

0,3

0,2

0,1

0,0

ta

n δ

Temperature (ºC)

0 50 100 150 200 250

0,5 0,6

Figure 10. Dynamic mechanical analysis (DMA) curves of the poly (ether-imide) (PEI)/glass i ber composite after being submitted to thermal shock conditioning. (a) E’; (b) E’’; (c) tan δ.

(a)

(b)

(c)

Thermal shockReference

hydrolysis and irreversible crosslink process, but very slightly, coni rming the FT-IR results. However, since this process was signii cant only for specimens submitted to UV radiation at er 1,200 hours, higher periods are necessary to coni rm this result.

h e measurement of Tg, among other reasons, presents scatter because the glass transition is actually dei ned as a temperature range within large range molecular motion is activated by the temperature increase. h e problem is more complex in the case of wet polymer samples with high Tg values, because the samples lose moisture to a signii cant extent in the glass transition region, where the molecular mobility and the moisture dif usion are enhanced. h us, probably there is a gradient of moisture concentration through the samples in the Tg region, and a corresponding distribution of temperature dependent of the molecular relaxation times (Costa et al., 2005).

h e moisture level leads to dif erent changes in Tg depending on the particular characteristics of molecular structures and matrix/i ber interface interactions of the matrix system. h e dif erent behavior of the samples studied (samples submitted to the hygrothermal conditioning and samples submitted to the UV radiation and humidity) and changes in the distribution of relaxation times associated with the α-transition (Tg) could not have been caused only by the plasticization ef ect, because the both specimens were submitted to the humidity conditioning before the DMA tests. When Tg variations and FT-IR results are compared, initial breaks of chains apparently occur, with a maximum of reticulation in 600 hours, and some breaks of chains happen in 1200 hours, when the E’ results are evaluated.

1200

900

600

300

0

T

MA (mm)

Temperature (ºC)

0 40 80 120 160 200 240

1500 Thermal shockReference

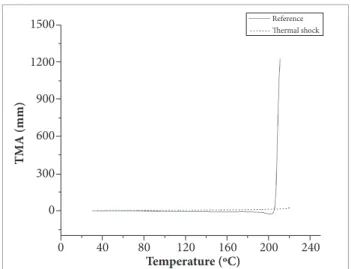

Figure 13. Thermomechanical analysis (TMA) curves of the poly (ether-imide) (PEI)/glass i ber composite for shock thermal conditioning and reference state.

shock chamber during 1,000 cycles. In this case, it is observed that the Tg value, as determined by onset of E’, increases slightly in only 3.54% in the sample at er being submitted to thermal cycling (170°C), due probably to the reticulation process of the matrix. Since there is no evidence that this conditioning generates thermal fatigue, as showed from OM experiments, these results were expected.

Figures 11 to 13 and Table 1 present the results obtained from TMA experiments. As can be observed, the Tg tendency values were similar to those found by using DMA experiments with exception of thermal shock sample.

Also from TMA experiments, it was observed that the values of thermal expansion coefficient change as a function of the kind of conditioning to which the sample was submitted. The polymeric matrices used in composite present positive and high thermal expansion coefficient (typically higher than the steel alloy and aluminum).

However, because of their polar groups, these matrices may both absorb moisture and expand, or release moisture and shrink. These expansions and contractions dimensional per unit length are called hygroscopic deformation, and in many cases are directly proportional to the amount of water that the matrix absorbs or releases. Thus, it can be seen that all α values obtained after the conditioning increased, indicating that the system PEI/fiberglass expanded by moisture absorption.

CONCLUSION

From the results of this research work, it was found that the material absorbed about 0.18% of moisture, which is considered low when compared to other composites used in aeronautical applications found in the literature, and the absorption rate was constant during the i rst two weeks of hygrothermal exposure. h e hygrothermal conditioning does not show signii cant evidence that the plasticizing ef ects

1200

900

600

300

0

T

MA (mm)

Temperature (ºC)

0 50 80 120 160 200 240

1500

Reference Salt-spray Hygrothermal

Figure 11. Thermomechanical analysis (TMA) curves of the poly (ether-imide) (PEI)/glass i ber composite for saline and hygrothermal conditionings and reference state.

1600

1200

800

400

0

T

MA (mm)

Temperature (ºC)

0 80 160 240

UV 200 Reference

UV 600 UV 1200

o resulted in decrease of properties of PEI/glass iber laminates.

Similar observation can be attributed to the salt spray conditioning efects on thermal properties of PEI/glass iber, since Tg was not signiicantly afected by this conditioning.

he specimens submitted to UV radiation presented small changes in the chemical structures of the material, indicating that the compound undergoes degradation, but this behavior was not so appreciable to indicate decreases of thermal properties. he increase of Tg ater UV condensation exposure during 1,200 hours indicates an irreversible crosslink process, but very slight.

he thermal shock conditioning promotes slight increase in the Tg value, but the cycling number used was not enough

REFERENCES

Botelho, E.C. et al., 2005, “Processing and Hygrothermal Effects on Viscoelastic Behavior of Glass Fiber/Epoxy Composites”, Journal of Materials Science, Vol. 40, No 14, pp. 3615-3623.

Botelho, E.C. et al., 2003, “Mechanical Behavior of Carbon Fiber Reinforced Polyamide Composites”, Composites Science and Technology, Vol. 63, No 13, pp. 1843-1855.

Botelho, E.C. and Rezende, M.C., 2010, “Evaluation by Free Vibration Method of Moisture Absorption Effects in Polyamide/Carbon Fiber Laminates”, Journal of Thermoplastic Composite Materials, Vol. 23, No 2, pp. 207-225.

Botelho, E.C. and Rezende, M.C., 2000, “O uso de Compósitos Estruturais na Indústria Aeroespacial”, Polímeros, Vol. 10, No 2, pp. e4-e10.

Boualem, N. and Sereir, Z., 2011, “Accelerated aging of unidirectional hybrid composites under the long-term elevated temperature and moisture concentration”, Theoretical and Applied Fracture Mechanics, Vol. 55, No 1, pp. 68-75.

Chawla, N.E.A, 2001, “Thermal-shock behavior of a Nicalon-iber-reinforced hybrid glass-ceramic composite”. Composites Science and Technology, Vol. 61, No 13, pp. 1923-1930.

Chevali, V.S. et al., 2010, “Effect of environmental weathering on lexural creep behavior of long iber-reinforced thermoplastic composites”, Polymer Degradation and Stability, Vol. 95, pp. 2628-2640.

Costa, A.A. et al., 2012, “The effect of thermal cycles on the mechanical properties of iber-metal laminates”, Materials & Design, Vol. 42, pp. 434-440.

Costa, A.P. et al., 2010, “Inluence of environmental conditioning on the shear behavior of poly (phenylene sulide)/glass iber composites”, Journal of Applied Polymer Science, Vol. 118, No 1, pp. 180-187.

Costa, M.L. et al., 2005, “Hygrothermal Effects on Dynamic Mechanical Analysis and Fracture Behavior of Polymeric Composites”, Materials Research, Vol. 8, No 3, pp. 335-340.

Diaz, J. and Rubio, L., 2003, “Developments to manufacture structural aeronautical parts in carbon ibre reinforced thermoplastic materials”, Journal of Materials Processing Technology, Vol. 143-144, pp. 342-346.

Hufenbach, W. et al., 2011, “The effect of temperature on mechanical properties and failure behaviour of hybrid yarn textile-reinforced thermoplastics”, Materials & Design, Vol. 32, No 8-9, pp. 4278-4288.

Jedidi, J. et al., 2006, “Accelerated hygrothermal cyclical tests for carbon/epoxy laminates”. Composites Part A: Applied Science and Manufacturing, Vol. 37, No 4, pp. 636-645.

Kellogg, K.G. et al., 2003, “Inluence of moisture and reduced-temperature thermal cycles on the izod notch toughness of a pultruded glass-iber composite”, International Journal of Offshore and Polar Engineering, Vol. 13, No. 3, pp. 232-239.

Kim, K.Y. and Ye, L., 2005, “Inluence of Matrix and Interface on Transverse Mechanical Properties of CF-PEI Thermoplastic Composites at Elevated Temperatures”, Journal of Reinforced Plastics & Composites, Vol. 24, No 4, pp. 429-445.

Menard, K.P., 2008, “Dynamic Mechanical Analysis: a practical introduction”, CRC Press, Taylor & Francis Group, USA, 218p.

Oliveira, G.H. et al., 2009, “Inluência da Temperatura no Desempenho Mecânico de Compósitos PEI/Fibras de Vidro”, Polímeros: Ciência e Tecnologia, Vol. 19, No 4, pp. 305-312.

Ramanujam, N. et al., 2008, “Interlaminar fatigue growth of cross-ply composites under thermal cycles”, Composite Structure, Vol. 85, pp.175-187.

Ray, B.C., 2006, “Temperature effect during humid ageing on interfaces of glass and carbon fibers reinforced epoxy composites”, Journal of Colloid and Interface Science, Vol. 298, No 1, pp.111-117.

to generate thermal fatigue in the composite. According to this work, it was not observed signiicant diferences before and ater shock conditioned specimens on thermal properties to disqualify this composite when applied in aeronautical ield, when changes of the temperature are evaluated.

ACKNOWLEDGMENTS

Viña, J. et al., 2008, “Wear Behavior of a Glass Fiber-Reinforced PEI Composite”, Journal of Thermoplastic Composite Materials, Vol. 21, No 3, pp. 279-286.

White, J.R. and Shyichuk, A.V., 2007, “Effect of stabilizer on scission and crosslinking rate changes during photo-oxidation of polypropylene”, Polymer Degradation and Stability, Vol. 92, No 11, pp. 2095-2101.

Yakimets, I. et al., 2004, “Effect of photo-oxidation cracks on behaviour of thick polypropylene samples”, Polymer Degradation and Stability, Vol. 86, No 1, pp. 59-67.