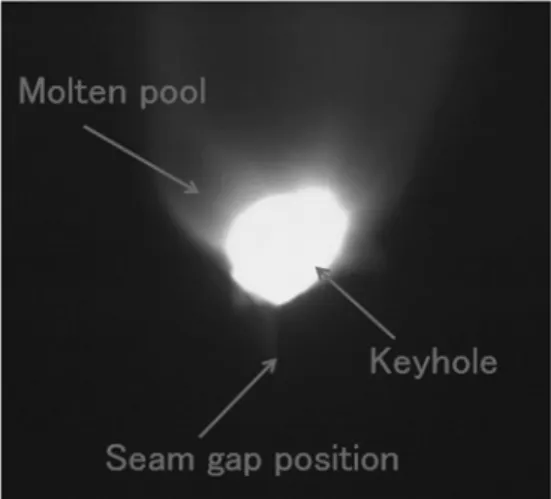

Monitoring of High Power Laser Welding Process by Using Image Difference Algorithm

Texto

Imagem

Documentos relacionados

(2008b) used central composite rotatable full factorial design matrix and conducted experiments for optimization of weld bead geometry in Plasma transferred arc

Laser beam inident on a slab of GRIN glass. where x is measured from beginning of GRIN

Images of the structure inscribed in LiF captured by transmission microscopy (a) cross-sectional image, produced with a laser beam penetrating the crystal from the top surface

Laser beam welding process has narrow fusion zone and narrower residual stress distribution in weld structures, the butt joints are made for thick plates pre and post

To evaluate anisotropy effects in steel plates, two directions of the weld bead were considered: Welding was performed in both parallel and transversal direction of rolled steel

Microstructures at the weld interfaces of Incoloy 800HT side (a) optical micrograph of interfaces between weld metal and Incoloy 800HT base metal (b) SEM images weld

The increase of electrical components in automotive industry and the expansion of renewable energy generation lead to a rising need of a reliable and highly productive welding

The materials used in the fabrication of precast concrete elements are composed of concrete, prestress tendons, reinforcement bars, elastomeric bearing pads and weld for beam,