Large Diamonds Grown at High Pressure Conditions

H. Kanda

NationalInstitute forResearhinInorganiMaterials(NIRIM),1-lNamiki,Tsukuba,

Ibaraki305-0044,Japan

Reeived4January,2000

A tehnique has been established to grow large diamonds up to 2 m. The rystals are bulky

polyhedronwithyellow,blue,greenorbrownoloraswellasolorless,whihdependonimpurities.

Theimpuritiesinorporatedintothediamondarelimited,i.e. nitrogen,boron,nikel,obalt,silion

andphosphorus.

I Introdution

Sineannounementofsuessindiamondsynthesisin

1955[1℄,thetehniquehasbeenimproveddramatially,

and alarge amount of syntheti diamondis produed

forommerialuseinthreeforms,i.e. largesingle

rys-tal, powderand polyrystalline ompat. This artile

is, however, onerned with only large single rystals

made by a growth tehnique named the temperature

gradient method [2-4℄. The largest diamond made so

far is 34.8arats (a. 7g)[5℄, and 10 mm diamondis

ommeriallyavailable [6℄. Synthetidiamondrystals

have appeared in gem market [7℄, although they have

notbeomepopular.

Thisartilesummarizesthegrowthtehnique,and

harateristisofthegrownrystalsarereviewed.

Sev-eralreviewartilespublishedalreadymayalsobe

help-fultolearnmoredetails ofthediamond[8-16℄.

II Growth of diamond:

the temperature gradient

method

The temperature gradientmethod for growth of large

synthetidiamonds was developedbytheGEresearh

group. A number of the diamonds are being made

in many ompanies and researh laboratories in these

days, although details of the method are not opened

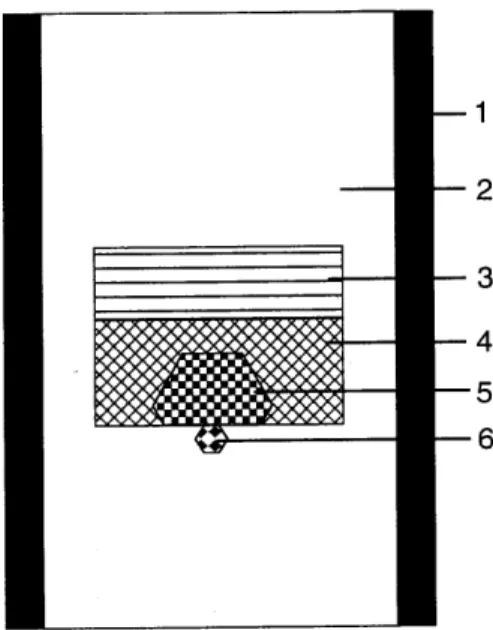

from ompanies. Fig. 1showsaellassembly used in

our laboratory. Carbon soure, a seed rystal and a

growthmediamadeofmetalsolvent-atalystare

essen-tialpartsfor thegrowth. Theyareplaedin aarbon

heatersothatthearbonsouresitsatahigher

temper-atureregionthantheseed. Inasimpleylindrialtube

heatershowninFig. 1,temperaturebeomeshighestat

theenterwheneletriurrentpassestheheater,and,

NaCl powder ompat prepared to t with the other

parts is lled in the graphite heater, surrounding the

three omponents, i.e. arbonsoure, solvent-atalyst

andseedrystal. Othermaterialsmaybeavailable

in-steadofNaClifitishemiallyinerttoarbonandthe

metal. Theseedrystalisembeddedintheompatso

that itontatswiththebottomofthemetal.

Figure1. Sampleassemblyfordiamondgrowthbythe

tem-perature gradient method. 1: Graphite heater, 2: NaCl

pressure medium, 3: Carbon soure, 4: Metalli

atalyst-solvent,5: Growndiamond,6: Seedrystal.

The ell assembly is ompressed up to 5 GPa in

a high pressure vessel and then heated to 1500 o

C.

The pressure and temperature must be so high that

themetalmeltsandthat diamondismorestablethan

graphite. Preise ontrol of pressure is not required,

temperature ontrol may be neessary, beause it

in-uenes growth rates, inorporation of inlusion and

impuritiesasdesribedinfollowingsetions.

At the P, T ondition, more than 10 atomi

per-ent of arbon is dissolved into the molten metal up

to saturation. In the presene of temperature

gradi-entin themetal,solubilityofarbonat thetopofthe

moltenmetalwhihontatswiththearbonsoureis

higher than that at the bottom of themetal, beause

thesolubilityinreaseswithaninreaseoftemperature.

The solubility dierene between the top and bottom

ofthemetalausesdissolutionofthearbonsoureand

transportationofarbonfromthearbonsouretothe

seedrystalwhihontatstothebottomofthemetal,

resulting in growth of new rystal on the seed. The

temperaturegradientisdrivingforetogrowarystal,

and the rystalontinues growingat a onstant

pres-sureandtemperature.

Graphite disk or powder is used as the arbon

soure. The graphite onverts to diamond in a few

minutesafterreahingthegiventemperatureunderthe

high pressure,and, therefore, diamondpowder is also

usefulasthearbonsoure. Qualityofgraphite isnot

sensitiveforthegrowthofdiamond. However,low

pu-rityarbonis notavailable. It hasbeen reportedthat

hydrogenpresentinarbonhasapoisonouseet[17℄.

Aording to the author's experiene, a arbon

mate-rialforapenildidnotonvertto diamond. Additives

suh asresin orlayadded to the arbonmay

deteri-orate the ability of the metal solvent-atalyst for the

onversion.

Carbon ontains1.1% of 13

C isotope with natural

abundane. Isotopially pure or 13

C enrihed arbon

has been used as the arbon soure to grow isotope

modied diamonds. Thermal ondutivity of the

iso-topially pure 12

Cdiamondhasbeenfoundto be50%

higherthanthatofnormaldiamondwithnatural

abun-dane isotope[18℄. 13

C enrihed diamond has helped

toidentifydefetstruturesbyoptialspetrosopyand

ESR[19,20℄. Whenmixed isotopesareused, some

ab-sorptionorluminesenepeakssplitorshift,suggesting

thestruturemodels.

Asmallsinglerystalofdiamondisusedastheseed.

Sizeandqualityinuenegrowthrateandqualityofthe

grownrystalasdesribedin followingsetions[6,21℄.

Anymaterialmaybeusefulforthegrowthmedium

in whih diamondgrows. However,metals ontaining

nikel,obaltorironas amain omponentareusually

used [22℄. Theyarealled atalyst-solventoratalyst.

High reativitywitharbonand lowmelting

tempera-ture are main fatorsto beonsidered for seletion of

the growth medium. Copper has lower melting

tem-perature than nikel, but the former has verylow

re-ativity, and diamond is not grown with high growth

rate [23,24℄. Alloying is a way to derease the

melt-ing temperature[3℄. The melting temperature means

metal-arbonsystem. If thesystemisin euteti

rela-tion, theliquid phase appears at a temperature lower

than that of pure metal. On the other hand, if solid

arbideisformed inthesystem,highertemperatureis

requiredtoformliquidphase. Magnesiumhasalsobeen

usedastheatalyst-solvent,butveryhightemperature,

1800 o

C,is required,beausemagnesiumarbidemelts

atsuh ahightemperature[25℄.

III Crystal size

Crystal size is roughly proportional to growing time,

and, therefore, long time is required to grow a large

rystal. Growthrateis inuenedbytemperatureand

temperaturegradient. The growthrate inreaseswith

inreasing temperature and/or temperature gradient.

Highergrowthratesmaybedesirablefromaviewpoint

of prodution, but inlusions are readilyinorporated

at higher rates. Vagarali et al.[11℄ have summarized

optimumgrowthratesatwhihgoodqualitydiamonds

grow. Agurequotedbythemshowsgoodquality

rys-tals upto 0.5 mg are madewith growthrates of 1 to

3 mg/hr. De Beers and Sumitomo have made larger

diamonds at higher growth rates; 14.2 arats for 500

hrs[11℄and10aratsfor150hrs[6℄,respetively. This

highgrowthrate wasahieved withemployingalarge

seed rystal of 5 mm in diameter. The world largest

rystalis34.80aratsmadebyDeBeersin1992.

Transportationofarboninthegrowthmediumhas

been simulated to alulate growth rates [26℄. The

study revealed that the growth rate has a maximum

at aninitial stage followedby agradual dereaseto a

onstant. Metalliinlusion is readilyinorporated at

theinitial stage ofgrowthbeauseof the high growth

rate. Li et al. [27℄ have proposed amodied ell

as-sembly to suppress theinorporation of theinlusion.

Intheassembly,themetalsolvent-atalysthasalower

partwherediameterissmall,resultinginlowering

ar-bonsupply.

IV Morphology

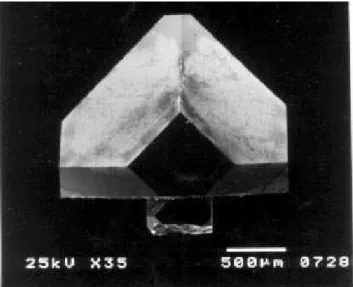

Fig.2showsanexampleofarystalgrownonaseed. It

hassmoothsurfaesexeptabottomsurfae,whih is

roughbeausethissurfaehadfaedwithinnerwallof

theNaClgrowthell. Thesmoothsurfaesareindexed

asf111gandf100g. Inaddition,f113gandf110g

sur-faes appear ommonly as minor surfaes [3℄. f115g

and f117g have also been observed [3,28℄. The

mor-phologydepends ongrowthtemperatureand

omposi-tionof themetalli solvent-atalyst. f111gandf100g

areknowntoappearmostdominantlyonsyntheti

dia-mond. Whenthesurfaesareompared,f100gdevelop

moredominantlythan f111gat lowergrowth

appear when boron is doped [28℄. Aording to

au-thor's experiments, they were seen on rystals grown

fromCo-Ti alloyat lowtemperatures.

Figure2.Diamondgrownonaseedrystal. Asmallrystal

atthebottomistheseed rystalwith0.5 mmindiameter.

(Sanningeletronmirograph).

Crosssetionofagrownrystalrevealsgrowth

his-toryof therystalbeauseofinhomogeneous

distribu-tionofimpurities[30℄. AnexampleisshowninFig. 3.

Change of area of eah growth surfaeduring growth

anbedeterminedfromsuhapiture. Aregion,whih

isformedwith pilingupofagrowthlayer,seenonthe

ross setion is named a growth setor. It has been

demonstrated that utuationof growthondition

in-uenesmorphologyverysensitively[31℄.

Figure 3. Cross setion of a grown rystal after polished

along (110) plane,takenundertransmitted light. A (001)

growth setor is paler yellow than adjaent f111g growth

setorswhihappeardarkerinthisblakandwhitepiture.

Thispitureshowsthatrelativedimensionofthe(001)

sur-faetof111gsurfaeshangedabruptlyinamidwayofthe

growth.

Twin planesparallel to f111gare sometimes seen.

Iftheseedrystalontainsatwinplane,thisextendsto

planeshavegrownat lowertemperaturesaordingto

ourexperiments,whihlooks tobeanaggregates[32℄.

V Growth surfae

The growth surfaes appear smooth marosopially,

butnepatternsarerevealedwithaidofoptial

miro-sopes. Dendriti patterns are ommonlyseen on the

syntheti diamonds ommerially available [33℄. The

patternsdependonompositionofthemetalli

solvent-atalysts,beausetheyarereetedbytexturesformed

whenmoltenmetalssolidify[34℄.Arystalgrownfrom

Fe-30%Ni alloy exhibits dendriti patterns with high

symmetry. Onthe other hand,striations independent

of orientation of diamondare seenonarystal grown

from iron. A growth hillokwhih suggeststhespiral

growthmehanismhasbeenobservedon arystal,

al-thoughitisnotlearlyseenbeauseofthepreseneof

the dendriti pattern [35℄. However,

athodolumines-ene topography showed a lear zoning whih

orre-sponds to viinal surfaes of the growth hillok. The

pattern suggeststhat thehillok onsistsof twotypes

of viinal surfaes, whih have dierent luminesene

nature aused by orientation dependent inorporation

ofimpurities[36℄.

VI Defets

Reently thegrowth tehnique hasbeen sophistiated

to produe defet free rystals [21℄, but a variety of

defets havebeenobserved depending on growth

on-ditions. Thedefets are lassied into four types;

in-lusion, stakingfault, disloationand atomi

impuri-ties, whih orrespond to three-, two-, one- and

zero-dimensional defets, respetively. The defets exept

forstakingfaultaredesribedinthefollowingsetions.

VI.1 Inlusion

Sizeof inlusions varies from 1 m to 1mm. The

largeinlusionisthemetallisolvent-atalyst

enapsu-lated by growingdiamond, andhaveplaty orrod like

shapewithroundorner[37℄. Inorderto suppress

for-mationoftheinlusion,lowergrowthratesarerequired.

Ingeneral,inlusionismorereadilyaptured at

ondi-tionswhere olorlessrystalsgrow[2℄,andprodution

ost of olorless rystal is higher than that of yellow

rystals.

Miron size inlusions are also ommonly present

eveninrystalswhihdonotexhibitanymetalli

inlu-sions[37℄. Darkeldilluminationisasensitivemethod

todetettheneinlusionsdispersingwithlowdensity.

They are sometimes presentas an aggregate.

Chemi-al omposition of the inlusions hasnot been

aggre-from obaltmetalemployingamiro-beamX-ray

uo-resene tehnique[38℄. However, theaggregatehasa

ompletelydierentformfromthelargeinlusion,

sug-gesting that the aggregateis ofsolid partiles suh as

oxide or halides. It may be probable that they were

trapped as solid partiles whih had dispersed in the

moltenmetal. Whentitanium isaddedtothemetalli

solvent-atalyst as anitrogen getter, TiCne rystals

are aptured into grownrystal. Inorporation of the

TiCrystalhassuessfullybeensuppressedbyadding

oppertothesolvent-atalyst[39℄.

VI.2 Disloation

Anumberofdisloationsareobservedevenin

inlu-sion freerystals[30℄. Mostofthem extendtogrowth

diretionsoriginatingfromtheseedrystal. X-rayand

athodoluminesenetopographytehniquesdetetthe

disloationslearly[40℄. Loalstrainausedby

disloa-tions is readilyobserved using apolarized mirosope

[41℄. Reently rystals with low density disloations

havebeenmadeemployingadisloationfreerystalas

theseedrystal[21℄.

VI.3 Impurities in relation to olor

Diamond aptures limited kinds of elements as

atomi impurities that beome optial ative enters.

They are hydrogen, boron, nitrogen, silion,

phospho-rus, nikel and obalt. The impurities exept

hydro-genprodueabsorptionandluminesenebandsaused

byeletronitransitions. Optialpropertiesassoiated

with theimpurities aredesribedin the following

se-tions. Hydrogen is the mostmajorimpurity forCVD

diamond,butnotforhighpressuresynthetidiamond,

andthis isomittedhere.

VI.3.1 Nitrogen

Most of syntheti diamond ommerially available

exhibits yellow olor. The yellow olor is attributed

to 50 to 500 ppm of nitrogen impurity [3,42℄, whih

areinorporatedwithoutintention,probablyfromhigh

pressure media surrounding the growth ell. The

ni-trogenisinorporatedasanisolatedatomondiamond

lattiesite,produingstrongabsorptionwithapeakin

aUV region,atailof whih extendtoavisible region

givingrise toyellowolor. If arystalisgrownabove

1500 o

C,nitrogen impuritiespartlyaggregateto pairs

during growth [43℄. More details on the aggregation

aredesribedbelowin thissetion. Itmaybepossible

todopehigheronentrationsofnitrogenbyadding

ni-trogenontainingompounds. 15

N-enrihedanilinehas

been addedto agrowth ellin order to study isotope

shift ofnitrogen relatedoptial enters [44℄. However,

itisnoteasytodopehigheronentrationsofnitrogen.

800 ppm of the nitrogen onentration is the highest

in rystals grown from onventional metalli

solvent-diamondthat morethan1000 ppmofnitrogen is

on-tained. Reentlymorethan1000ppmofnitrogenhave

beeninorporatedusingnonmetalliatalyst,Na

2 SO

4

[46℄. Non-metalliatalysts are essentialto dope high

onentrationsofnitrogen,beauseitissurethat

natu-raldiamondalsogrowsfrommoltenroks,i.e. akindof

non-metallimaterials. Ontheotherhand,itiseasyto

reduetheonentrationsofnitrogento growolorless

rystals,usingthemetalli solventatalysts.

Inordertoreduethenitrogenonentrations,

om-positionofthealloyusedassolvent-atalystismodied

[3℄. Ni,Co,Feandtheiralloyproduediamond

ontain-ing50 to 300ppmof nitrogen. With adding elements

suh as Ti, Zr and Al to the metals, onentrations

of nitrogen are redued. The elements are, therefore,

alled\nitrogengetter". Afewperentsof Tiadditive

issuÆientto growaolorlessrystal,in whih

nitro-genonentrationsarelessthan1ppm. V,CrandMn,

whih sit at rightpositions of Ti in the priodi table,

havealsoeet to redue the nitrogenonentrations,

buttheir powerislowerthanTi[47℄. Higherontents

oftheelementsmustbepresentinthemetalli

solvent-atalystsinordertogrowolorlessrystals.

Thenitrogenonentrationsindiamondmaybe

re-latedto hemialaÆnity ofnitrogen withthe

solvent-atalystmetal. Ifthesolvent-atalysthavestrong

aÆn-itywithnitrogen,morenitrogenstayinthesolvent

at-alystandlessamountsofnitrogenareinorporatedinto

diamond[47℄. Anotherinterpretationaboutthe

nitro-gengettereethasbeenproposed[39℄;ifthenitrogen

getterelementsarepresentin thesolventatalysts,

ni-tridessuh asTiN and ZrN are formed, and nitrogen

onentrationsinthemoltenmetalbeomeslow,

result-inginlowonentrationsin thegrowingdiamond.

Growth temperature also inuenes nitrogen

on-entrations [29,48℄. The nitrogen onentrations

de-rease with inreasing growth temperature, when Ni

or Co is used as the solvent-atalyst. On the other

hand,thenitrogenonentrationsinreasewith

inreas-ing growth temperature, when solvent-atalysts

on-taining the nitrogen getters are used. This may be

beausethegetter eet beomes weakat higher

tem-peratures.

The inuene of the atalyst-solvent and

temper-ature in inorporation of nitrogen into diamond has

beeninterpretedintermsofsolubilityofnitrogeninthe

atalyst-solvent metals [49℄. If the solubility is large,

morenitrogen stays in the metal and less nitrogen is

inorporatedinto diamond. The solubilityof nitrogen

may beanother wordof aÆnitydesribedabove. The

solubilityinreaseswithinreasingtemperature,

result-inginaderease ofnitrogenonentrations.

Mirosopi observation of the grown rystalgives

usandingofinhomogeneousdistributionofthe

nitro-genrelatedyellowolor. Fig.3isarosssetionofa

hibitthedeepestyellowolor[3℄. Orderofthedepthof

yellowoloris; f111g>f100g>f113g=f110g.

Pre-iseomparisonshowsthatf113gsetorsontainsmore

nitrogenthanf110g[50℄.Thereisareportthata

rys-tal grown at low growth temperatures ontains more

nitrogeninf100gthaninf111g[29℄,indiatingthatthe

nitrogenonentrationsare inuenedbytemperature

moresensitivelyinf100gsetorsthaninf111g. Itmay

beinterestingthat nitrogen isotoperatio, 15

N/ 14

N, in

f111gsetors isdierentfromthatin f100g[51℄.

The nitrogen related yellow olor fades with heat

treatmentabove1500 o

C,beausesinglesubstitutional

nitrogen atomsmigrate tobepairsin the rystal[52℄.

Withheatingabove2500 o

C,thenitrogenpairsonvert

toanotheraggregates,whihareproposedtoonsistof

fournitrogensandavaany[53℄. Theheattreatment

mustbearriedoutunderhighpressureonditions,5to

8GPa,inordertopreventfromgraphitization.Mostof

olorlessnaturaldiamondsontainsigniantamounts

of nitrogen in the aggregatedforms, whereasolorless

syntheti diamonds arenitrogen free. Itis well

estab-lishedthatnaturaldiamondshavebeenheat-treatedin

theEarth solongthatthe nitrogenshavebeen

aggre-gated. Measurementsofthe aggregationrateof

nitro-genhelpustoestimateageofnaturaldiamond[13,54℄.

Theaggregation ratedetermined for the rsttime

wasbasedontheseondorderkinetis[52℄. Thereport

onthekinetisgaveppm 1

valueofkinetioeÆient

of 1:7410 4

(min 1

/ppm 1

) at 1900 o

C, whih

orre-spondsto50%ofonversionofsingleformsto pairsof

100ppm nitrogen with heattreatment at1900 o

Cfor

lhr.

Theaggregationrate is afuntion of temperature,

butithasbeomeapparentthetemperatureisnotonly

a fator whih inuenes the aggregation rate. The

aggregation rate strongly depends on growth setors.

Thereisareportshowingthatitishigherinf111g

se-torsthaninf100g[29℄. Ithasalsobeenpresentedthat

the aggregation rate is not uniform even in a growth

setor[55℄. Thenonuniformityaresuggestedtobe

at-tributedtoinhomogeneousdistributionofotherdefets

[56℄. Ithasbeenpointedoutthat theseondorder

ki-netis an not be applied for the aggregation proess

[57,58℄. Further study is required to understand the

aggregationproess.

Nitrogen impurities produe absorption and

lumi-nesenepeaksotherthanthat givingtheyellowolor

[9,16℄, ommonones ofwhihare theN3enter

(zero-phononpeakat 415nm)onsisting ofthreenitrogens

andavaany,theH3enter(zero-phononpeakat503

nm)onsistingoftwonitrogensandavaany,575nm

zero-phonon peak aused by a nitrogen and vaany,

andtheNVenterwithazero-phononpeakat637nm.

Theseareproduedbyirradiationofhighenergybeam

suh as eletron and neutron followed by heat

treat-ment. However, it is not unusual that these are

ob-produe these bands [59℄. It is well known that the

H3luminesenebandispresentinf100gsetorsof

as-grownsyntheti diamondommeriallyavailable [30℄.

VI.3.2 Boron

Inorporationofboronimpurityproduesblueolor

in diamond [50, 60-62℄ and the diamond has p-type

semiondutingproperty. Theolorisgivenbya

grad-ual inreaseof absorptionfrom highenergy tolow

en-ergy in a visible region. No sharp peak is present in

thevisibleregion,but sharpabsorptionpeaksareseen

around3.5mofaninfraredregion[63℄.

Theblue olordiamondisreadilymade, ifasmall

amountofboronisaddedinagrowthell[50℄.Depthof

blueolorinreaseswithinreasingtheboronadditives.

However,moreamountsofboronadditivearerequired

to produe blue olor, when diamond is grown from

metalsolventatalystswithoutnitrogengetter,beause

boron aeptoris ompensated by nitrogendonorand

onlyunompensatedaeptorontributestoblueolor.

Aordingtoourexperiene,whenpurenikelwhih

produesdiamondontaining200to300ppmof

nitro-genwasused, morethan 10mgofboron wasrequired

to beadded intothegrowthellin orderto growblue

oloreddiamond. Yellowolorpersistedwhenlessthan

10mg boron was added. On the other hand,addition

of 0.1 mgof boron wasenoughfor growthofthe blue

oloredrystalwhenthesolventatalystwasNi-3%Ti,

fromwhihnitrogenfreerystalwasgrown.

The blue olor is not uniform even in a rystal.

Growth setor dependene is observed. f110gsetors

mostsensitivelyhange to blue,whenboron isadded,

whereas f111g setors are the most insensitive. The

f111g setors persist yellow olor, ifboron additiveis

notsuÆient. However,f111gsetorsbeomethe

deep-est in setors,whenalargeamountofboronisadded.

Namely, the order of depth of blue hanges with an

inrease of boron additive. The setor dependene is

understandable,ifweassumetwofators;(1)f111g

se-tors apture both boron and nitrogenmosteasily and

(2) depth of blue olor is proportional to

unompen-satedboron,i.e. [boron℄-[nitrogen℄,wherethebrakets

indiate the onentrationsof boronand nitrogen. As

for f111g setors, if boron additive is little, the

on-entration is lowerthan that of nitrogen, resulting in

persisteneof yellow olor. If boron additive is large,

theonentrationsofunompensatedboronbeomethe

highest.

Theborondopeddiamondsgivebluishgreen

lumi-nesene with eletronbeamexitation

(athodolumi-nesene),inwhihfourbroadbandsarepresentinUV

and visible regions[64℄. Boundexiton peaks arealso

observedin aUV regionof230to240nm. UV

illumi-nationproduesbroadphosphoresenebandspeaking

at2.1and2.5eVfromtheborondopedrystals. They

VI.3.3 Nikel

More than ten of optial bands have been

dou-mentedfromdiamondgrownfromnikelontaining

al-loys. The nikel related bands are also dependent on

onentrationsandstrutureof nitrogenimpurities. A

diamondgrownfrompure Niexhibits brownishyellow

olor,andzero-phononpeaksat2.51eV,1.883eVand

1.4eVareseenin absorptionspetrareordedata

liq-uidnitrogentemperature[66,67℄.Inontrast,diamond

grown from iron does not produe any sharp peak in

spite of having similar yellow olor. A monotoni

in-reaseinabsorptiontoaUVregionisobserved. When

nitrogen getters suh as Ti are added to nikel, green

orbrownrystalsgrow,inwhihharateristi

absorp-tionpeaks,whiharedierentfromthoseobservedfrom

pureNi, areobserved[68,69℄.

The rystalsontainingnikelalso giveunique

lu-minesene bands[67℄. Zero-phononlines ofthebands

areat2.56eVand1.4eV.Thelatterisobservedin

ab-sorptionspetraaswell. Thispeakhasbeenonrmed

to berelatedtoNi fromisotopesplittingmeasuredby

high resolutionspetrosopy[70℄.

ESR studies have determined onentrations and

struture of nikelimpuritiesin pre-annealed rystals

[20, 71℄. Ni 1

whihsubstitutesaarbonatomon

dia-mondlattiehasbeendeteted. Thehighest

onentra-tionmeasuredsofaris70ppm. InterstitialNi +

hasalso

been deteted. Correlation between the Ni impurities

and theoptial bands havenotbeen well established,

althoughithasreentlybeenreportedthatthe

onen-trationsofNi 1

isproportionaltointensityofthe2.51

eVpeak[72℄.

The nikel ontaining rystals hange their olor

withheattreatmentabove1500 o

C.Thebrownish

yel-lowolorhangestobrown,inwhihanumberofsharp

absorptionpeaksareobserved[73℄. Thegreenoloralso

beomes brown. This brown olored rystal does not

haveharateristipeaks,but stronggreenolor

lumi-nesene is produed by UV illumination, and several

luminesene peaks have been reorded [74-76℄. The

olorhangeproduedbytheheattreatmentisrelated

to migration of nitrogenimpurities to form omplexes

withnikelimpurity[74℄.Struturemodelsofthe

om-plexes onsisting of nikel, nitrogen and vaanyhave

beenproposed,basedonESRmeasurements[74-77℄.

Thenikelrelatedoptialentersareloatedonlyin

f111ggrowth setors[68,78℄. X-ray uoresene

teh-nique has also deteted the nitrogen impurity in

syn-theti diamonds, and hasonrmed that the nikelis

onnedtof111ggrowthsetors[79℄. Detailed

observa-tionhasrevealedthatitisnotuniformevenina(111)

setor. Theolorsbeomedeeperinregionswhihgrew

at highergrowthrates[48℄.

VI.3.4 Cobalt

TheX-rayuoresenetehniquehasalsodeteted

loatedonlyinf111ggrowthsetorsasnikelimpurity

is. However,uniqueabsorptionband isveryweak,but

strongyellowlumineseneisobservedfromtherystals

afterheattreated[81℄. Severalluminesenepeakshave

beenseeninphoto-andathodo-luminesenespetra.

Thepeaks depend on degreesof aggregation of

nitro-gen.Cobaltimpuritieshavebeenlessstudiedompared

withnikel.

VI.3.5 Silion

Silionimpurityproduesonlyonepeakat1.681eV

inbothabsorptionand luminesene. It isobservedin

CVDdiamondsommonly,beausesiliaglassand

sil-ionisusually used in areationelland asubstrate,

respetively[82℄. IthasalsobeenobservedinSiion

im-planted diamond [83℄. As for high pressurediamond,

the peak is produed, when silion ontaining alloys

are used as the metalli atalyst-solvents. The peak

wassharperthanthoseobservedintheCVDdiamond,

whih madea preise investigation possible [84℄. The

peak split to 12 lines orresponding to natural

abun-dane silion isotope by high resolution spetrosopy.

This is a diret evidene that silion impurity is

in-volved in the1.681 eVenter. Struturemodelof the

silionrelateddefethasnotbeenestablished,although

ithasbeenproposedthat avaanyisalso involved.

VI.3.6 Phosphorus

n-Type semionduting diamond has been made

withdopingphosphorusbytheplasmaassisted

hemi-alvapordeposition(CVD) tehnique[85℄. The

phos-phorus impurity inorporated in the rystal has been

detetedbytheSIMStehnique,andaunique

athodo-luminesenepeakat5.175eVinaUVregionhasbeen

deteted, whih is expeted to be of a bound exiton

of phosphorus donor [86℄. However, phosphorus

ele-ments or phosphorus related optial enters have not

beenfound in thelargerystalsgrownbythe

temper-aturegradientmethod. A omplexofphosphorus and

nitrogenhasbeendetetedbyESRin arystalgrown

frompurephosphorusunderahighpressureondition,

although thegrown rystalinvestigatedis a verythin

layerformedonaseedrystal[87℄.

VII Conlusion

Sine announement of suess in large diamonds by

thetemperaturegradientmethodin1970,thetehnique

hasbeenimprovedto produe10mmrystalsand

de-fetfreerystalsin aommerialsale. Somekindsof

defettuninghavebeomepossible. Then,therystals

areavailableforbothindustrialappliationsand

sien-tistudy. However,aproblemwehaveis prodution

growth tehnique and an inrease of demands to the

rystals will allow us to produe the diamonds with

heaperost.

Referenes

[1℄ F.P. Bundy, H.T. Hall, H.M.Strong and R.H.

Wen-torf,Jr.,Nature176,51(1955)

[2℄ R.H.Wentorf,Jr.,J.Phys.Chem.75,1833(1971).

[3℄ H.M. Strongand R.M. Chrenko, J.Phys.Chem. 75,

1838(1971).

[4℄ H.M.StrongandR.H.Wentorf,Jr.DieNaturwiss.59,

1(1972).

[5℄ DeBeers,Personalommuniation,(1992).

[6℄ S.SatohandH.Surniya,Rev.HighPressureSi.

Teh-nol.2,315(1993)inJapanese.

[7℄ J.E. Shigley, E. Fritsh, I. Reinitz and T.M. Moses,

GemsGemol.31,256(1995).

[8℄ F.P. Bundy, H.M. Strong and R.H. Wentorf, Jr. in

Chemistry and Physis of Carbon, Vol.10, edited by

P.L. Walker and P.A. Thrower(Marel Dekker, New

York,1973)pp.213-263.

[9℄ G. Davies, in Chemistry and Physis of Carbon,Vol.

13, edited by.P.L.Walkerand P.A. Thrower(Marel

Dekker,NewYork,1977)pp.1-143.

[10℄ G. Munke, inThe Properties of Diamond, edited by

J.E.Field(AademiPress,London,1979)pp.473-99.

[11℄ S.Vagarali,M.LeeandR.C.DeVries,J.HardMater.

1,233(1990).

[12℄ H.M.StrongandR.H.Wentorf,Jr.Amer.J.Phys.59,

1005(1991).

[13℄ T.Evans, inThe Properties ofNaturaland Syntheti

Diamond,editedbyJ.E. Field(Aademi Press,

Lon-don,1992)pp.259-290.

[14℄ R.C.BurnsandG.J.Davies,inThePropertiesof

Nat-uralandSynthetiDiamond,editedbyJ.E.Field

(Aa-demiPress,London,1992)pp395-422.

[15℄ H. Kanda and T. Sekine, in Properties and Growth

of Diamond, edited by G.Davies (INSPEC, London,

1994)pp.403-426.

[16℄ A.M.Zaitsev,inHandbookofIndustrialDiamondsand

Diamond Films, edited by M.A. Prelas, G. Popovii,

L.K.Bigelow(MarelDekker,NewYork1997)

pp.227-376.

[17℄ A.Tsuzuki,S.HiranoandS.Naka,J.Mater.Si. 20,

2260(1985).

[18℄ T.R.Anthony,W.F.Banholzer,J.F.Fleisher,L.Wei,

P.K. Kuo,R.L.Thomas,andR.W.Peyoe,Phys.Rev.

B42,11104(1990).

[19℄ A.T. Collins, P.J.Word, G.S. Woods and H. Kanda,

DiamondRelat.Mater.2,136(1993).

[20℄ J. Isoya, H. Kanda, J.R. Norris, J. Tang and M.K.

Bowman,Phys.Rev.B41,3905(1990).

[21℄ H.Sumiya,N.Toda, Y.NishibayashiandS.Satoh,J.

[22℄ H.P.Bovenkerk, F.P.Bundy, H.T.Hall, H.M.Strong

andR.H.Wentorf,Jr.,Nature184,1094(1959).

[23℄ F.P.Bundy,Nature241,116(1973).

[24℄ H. Kanda, M. Akaishiand S.Yamaoka, Appl. Phys.

Lett.65,784(1994).

[25℄ N.V. Novikov and A.A. Shulzhenko, in Siene and

Tehnology of New Diamond, edited by S. Saito, O.

Fukunagaand M.Yoshikawa,(KTKSi. Pub,Tokyo,

1990)pp.217-219.

[26℄ M. Wakatsuki,W.Li,Y.GohdaandL. Y.Ding,

Dia-mondRelat.Mater.5,56(1996).

[27℄ W. Li, H. Kagi and M. Wakatsuki, J. Cryst. Growth

160,78(1996).

[28℄ M.-L.T.Rooney,J.Cryst.Growth116,15(1992).

[29℄ S.Satoh,H.Sumiya,K.TsujiandS.Yazu,inSiene

andTehnologyofNewDiamond,editedbyS.Saito,O.

Fukunagaand M.Yoshikawa,(KTKSi. Pub,Tokyo,

1990)pp.351-355.

[30℄ G.S.WoodsandA.R.Lang,J.Cryst.Growth28,215

(1975).

[31℄ H.Kanda,T.Ohsawa,O.FukunagaandI.Sunagawa,

J.Cryst.Growth94,115(1989).

[32℄ H. Kanda, T. Ohsawa and S. Yamaoka, J. Cryst.

Growth99,1183(1990).

[33℄ S.TolanskyandI.Sunagawa,Nature184,1526(1959).

[34℄ H.Kanda,M.Akaishi,N.Setaka,S.YamaokaandO.

Fukunaga,J.Mater.Si.15,2743(1980).

[35℄ H.KandaandT.Ohsawa,DiamondRelat.Mater.5,8

(1996).

[36℄ F.C.Frank,A.R.Lang,D.J.F.Evans,M.-L.T.Rooney,

P.M.SpearandC.M.Welbourn,J.Cryst.Growth100,

354(1990).

[37℄ J. Shigley, E. Fritsh, C.M. Stokton, J.I. Koivula,

C.W.Fryer,R. Kane,D.R. Hargett andC.W.Welh,

GemsGemol.23,187(1987).

[38℄ S.Shimomura,H.KandaandH.Nakazawa,Diamond

Relat.Mater.6,1680 (1997).

[39℄ H. Sumiya and S. Satoh, Diamond Relat. Mater. 5,

1359(1996).

[40℄ I.KiawiandA.R.Lang,Philos.Mag.30,219(1974).

[41℄ A.R.Lang,J.Appl.Cryst.27,988(1994).

[42℄ R.M. Chrenko, H.M. Strong and R.E. Tuft, Philos.

Mag.23,313(1971).

[43℄ H.Kanda,T.OhsawaandS.Yamaoka,inSiene and

Tehnology of New Diamond, edited by S. Saito, O.

Fukunagaand M.Yoshikawa,(KTKSi. Pub,Tokyo,

1990)pp.339-344.

[44℄ A.T.Collins,M.StanleyandG.S.Woods,J.Phys.D:

Appl.Phys.20,969(1987).

[45℄ A.T.Collins and S.C.Lawson,Philos. Mag.Lett. 60,

117(1989).

Re-[47℄ H. Kanda, Y. Sato, N. Setaka, T. Ohsawa and O.

Fukunaga, J. Chem. So. Japan, No. 9, 1349 (1981)

inJapanese.

[48℄ H. KandaandS.C. Lawson,IndustrialDiamondRev.

55,56(1995).

[49℄ R.C. Burns, J.O. Hansen, R.A. Spits, M. Sibanda,

C.M. Welbourn and D.L. Welh, Diamond Relat.

Mater.8,1433(1999).

[50℄ R.C.Bums, V.Cvetkovi, C.N.Dodge,D.J.F. Evans,

M.-L.T. Rooney, P.M. Spear and C.M. Welbourn, J.

Cryst.Growth104,257(1990).

[51℄ S.R. Boyd C,T. Pillinger, H.J. Milledge, M.J.

MendelssohnandM.Seal,Nature331,604(1988).

[52℄ R.M. Chrenko, R.E. Tuft and H.M. Strong, Nature

270,141(1977).

[53℄ T. Evansand Z. Qi, Pro.R. So.Lond. A381, 159

(1982).

[54℄ W.R. Taylor,D.Canil andH.J.Milledge,Geohimet

Cosmohim.Ata60,4725(1996).

[55℄ H.KandaandS.Yamaoka,DiamondRelat.Mater.2,

1420 (1993).

[56℄ I.Kiawi,H.Kanda,D.FisherandS.C.Lawson,

Dia-mondRelat.Mater.6,1643(1997).

[57℄ D.Fisher,S.C.Lawson,DiamondRelat.Mater.7,299

(1998).

[58℄ I.Kiawi, H.KandaandA.Mainwood,Diamond

Re-lat.Mater.7,327(1998).

[59℄ E.J. Brookes, A.T. Collins and G.S. Woods, J. Hard

Mater.4,97(1993).

[60℄ R.H.Wentorf,Jr.andH.P.Bovenkerk,J.Chem.Phys.

36,1987(1962).

[61℄ R.M. Chrenko,Phys.Rev.B7,4560(1973).

[62℄ M.-L.T. Rooney, C.M. Welbourn, J.E. Shirley, E.

FritshandI.Reinitz,GemsGemol.29,38(1993).

[63℄ S.D.SmithandW.Taylor,Pro.Roy.So.London79,

1142 (1962).

[64℄ S.C. Lawson, H. Kanda, H. Kiyota, T.Tsutsuni and

H.Kawarada,J.Appl.Phys.77,1729(1995).

[65℄ K.Watanabe,S.C.Lawson,J.Isoya,H.KandaandY.

Sato,DiamondRelat.Mater.6,99(1997).

[66℄ A.T. Collins and P.M. Spear, J. Phys. D 15, L183

(1982).

[67℄ A.T.CollinsandP.M.Spear,J.Phys.C16,963(1983).

[68℄ A.T.Collins. H.KandaandR.C.Burns,Philos.Mag.

B61, 797(1990).

[69℄ S.C. Lawson, H. Kanda and M. Sekita, Philos. Mag.

B68,39(1993).

[70℄ G.Davies, A.J. Nevesand M.H. Nazare, Phys.Rev.

B43,14196 (1991).

[71℄ J.Isoya,H. Kanda andY. Uhida, Phys.Rev.B42,

9843(1990).

[72℄ A.T.Collins, H. Kanda, J. Isoya, C.A.J. Ammerlaan

and J.A. van Wyk, Diamond Relat. Mater. 7, 333

(1998)

[73℄ S.C. Lawson and H. Kanda,J. Appl. Phys.73, 3967

(1993).

[74℄ V.A. Nadolinny and A.P. Yelisseyev, Diamond Relat.

Mater.3,17(1993).

[75℄ I.N. Kupriyanov, V.A. Gusev, Yu.M. Borzdov, A.A.

Kakininand Yu.N.Pal'yanov, DiamondRelat. Mater.

8,1301(1999).

[76℄ H. Kandaand K. Watanabe, DiamondRelat. Mater.

8,1463(1999).

[77℄ R.I. Mashkovtsev and Yu.N. Pal'yanov, Solid State

Com.111,397(1999).

[78℄ A.R.Lang andG.M. Meaden, J.Cryst. Growth108,

53(1991).

[79℄ M.Wakatsuki,S.Hayakawa,A.Aoki,Y.GohshiandA.

Iida,inNewDiamond SieneandTehnology,edited

by R. Messier, J.T. Glass, J.E. Butler and R. Roy

(Mater.Res.So.,Pittsburgh,1991)pp.143-148.

[80℄ X.Jia,S.Hayakawa,W.Li,Y.GohshiandM.

Wakat-suki,DiamondRelat.Mater.8,1895 (1999).

[81℄ S.C. Lawson, H. Kanda,K. Watanabe, I.Kiawi, Y.

SatoandA.T.Collins,J.Appl.Phys.79,4348(1996).

[82℄ A.T.Collins,M.KamoandY.Sato,J.Mater.Res.5,

2507(1990).

[83℄ A.M. Zaitsev, V.S. Vavilov and A.A. Gippius, Sov.

Phys.Lev.Inst.Rep.10,15(1981).

[84℄ C.D.Clark,H.Kanda,I.KiawiandG.Sittas, Phys.

Rev.B51,16681 (1995).

[85℄ S.Koizumi,M. Kamo, Y. Sato,H. Ozaki and T.

In-uzuka,Appl.Phys.Lett.71,1065(1997).

[86℄ H.Stemshulte,K.Thonke andR. Sauer,inPro. of

The5thNIRIMInternationalSymposiumonAdvaned

Materials,editedbyM.Kamoetal.,NIRIM,Tsukuba,

1998)pp.113-116.

[87℄ J. Isoya, H. Kanda, M.A. Kaishi, Y. Morita and T.