Thermal Analysis of Heat Pipe Using Taguchi Method

Texto

Imagem

Documentos relacionados

This paper has successfully used the finite element method for the simulation and analysis of micro LED packaging structure heat transfer and thermal stress concentration location at

2 Heat conduction concepts, thermal resistance, and the overall heat transfer coefficient 49 2.1 The heat diffusion

When connected on the anode, the heating up of the sample is caused by the irradiation of heat generated in the cathode described above. In this case, the thermal efficiency of

Using Taguchi method and ANOVA the percentage contributions of the effect of parameters-speed, load, injection timing plunger diameter, nozzle valve opening

The microparticles were characterized in terms of their morphology, size, size distribution, thermal analysis and encapsulation efficiency using the HPLC validated

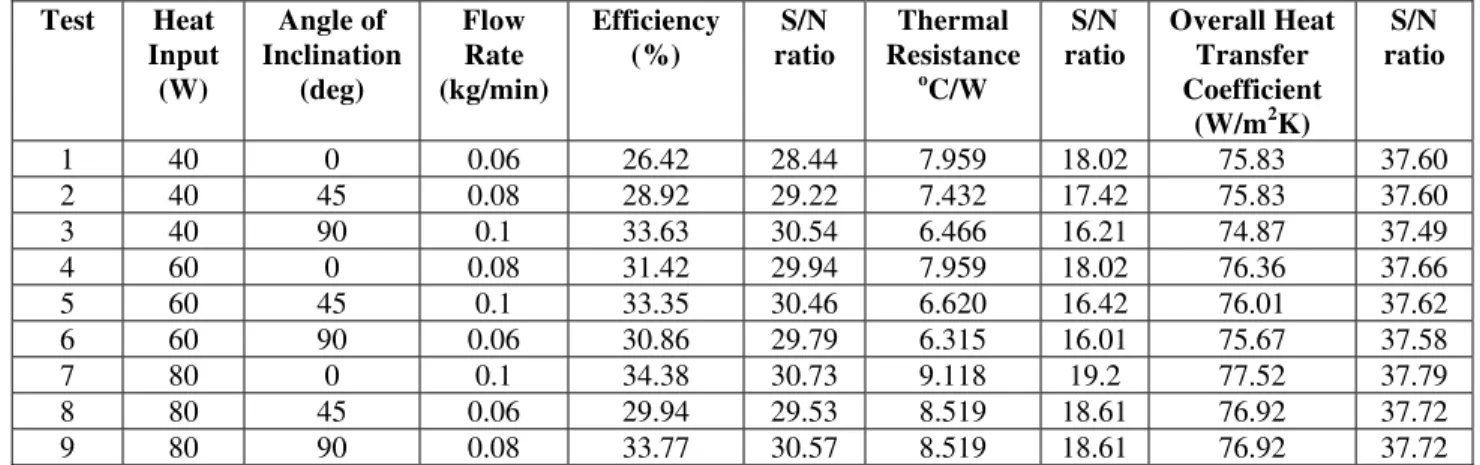

9, the thermal resistance of the heat pipe using the base fluid, nanofluid, and hybrid nanofluids is higher at low heat loads, because of the formation of a thin liquid film in

The two points considered at the alternate sides, of the tangents through the diameter of the circle, and then the line joining these points divides the circle

The CEOHP cooling module had better thermal performance than conventional heat sink.. Key words: Closed - end oscillating heat-pipe, CPU cooling,