REM, Int. Eng. J. vol.70 número3

Texto

Imagem

Documentos relacionados

the contained ore graphic, but the lack of high values reproduction can easily be seen in the following igure 7, where the absence of very high grade blocks (responsible for a

is particularly used when data is too widely spaced to reliably delineate the model, is to obtain a geologic model from mathematical methods (polygons or nearest neighbor),

2.1 Developed computer programs The model developed to obtain a solid model of the mineral deposit about which borehole data is known in the AutoCAD environment consists of the

Even though the simulations indicated that the existing grinding circuit would only achieve the required capacity of 2.0 MTPY for a iner feed, HPGR benchmark- ing indicated that

Along more than ive years, GAUSTEC joined major players in the mining Industry to scavenge Iron from tailings produced by lotation making use of WHIMS (Wet High Intensity

In the present work, surface hardness of the plasma nitrided CA-6NM martensitic stainless steel samples was determined by nanoindentation technique, for different

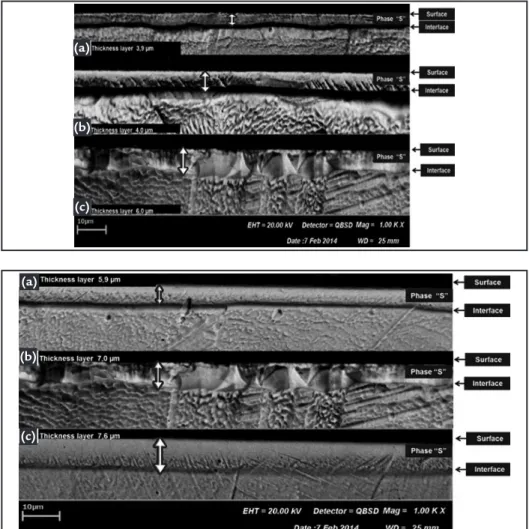

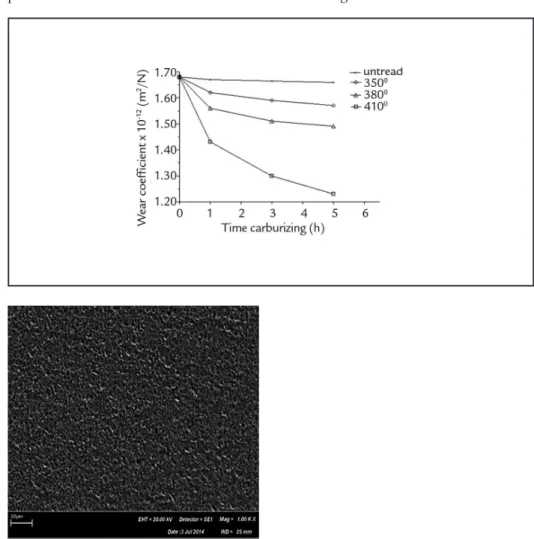

In present work, kinetics data are considered in a comparative study comprising low-temperature plasma assisted carburizing, nitriding and nitrocarburizing of AISI 420

Efect of magnetic ield applied during gas metal arc welding on the resistance to localised corrosion of the heat afected zone in AISI 304 stainless steel. Curiel FF, García R,