Pulsed laser rystallization of SiGe alloys on GaAs

F. Dondeo, 1

P. V. Santos, 2

M.Ramsteiner, 2

D. Comedi, 1

M. A.A. Pudenzi, 1

, and I. Chambouleyron 1

1

InstitutodeFsiaGlebWataghin,UniversidadeEstadual deCampinas, 13081-970Campinas,SP,Brazil

2

Paul-Drude-Institut f urFestkorperelektronik, Hausvogteiplatz5{7, 10117Berlin,Germany

Reeivedon23April,2001

We have investigated the rystallization of amorphous SiGe lms deposited onrystalline GaAs

(001) substrates using ns laser pulses. Analysisof the lm struture usingRaman spetrosopy

indiatestheformationofheteroepitaxialSixGe1 x/GaAsstruturesforSiompositionsuptox =

25%. Higherompositionslead topolyrystallinelms. Thisisattributedtotheinreasedlattie

mismathbetweenSixGe1

x

andGaAsastheSifrationinthealloyinreases.

I Introdution

Pulsedlaserrystallization(LC)[1℄isastandard

teh-nique for the fabriation of large area polyrystalline

lms from theamorphous (a-) phase. This tehnique

analso beused to produe high quality epitaxial Ge

layerswithabruptinterfaesonGaAs (001)substrates

[2℄. Sine Ge and GaAs are well lattie-mathed, an

interesting question is how the epitaxial LC proeeds

when Si is introdued in aontrolled wayinto the Ge

matrix, so as to form Si

1 x Ge

x

alloys with a lattie

onstant dierent from that of the substrate. In this

ontribution,weaddressthisquestionbyinvestigating

theLC of a-Si

x Ge

1 x

alloysdeposited onGaAs (001)

substrates. Raman sattering studies of the LC lms

giveevidenefortheepitaxialrystallizationof

100-nm-thik Si

x Ge

1 x

alloys withompositions x upto 25%.

Higherompositionsleadtopolyrystallinelms. This

behaviorisattributedtotheinreasedlattiemismath

with the substrate, when the silion onentration in

the alloy inreases. Sine the epitaxial rystallization

requiresthemeltingoftheamorphouslmbythelaser

pulse, aseond important issueregarding the

rystal-lizationofSi

x Ge

1 x

alloysonGaAsistheintermixing

at the interfae with the substrate. The intermixing

was investigated using seondaryion mass

spetrome-try(SIMS).

II Experimental

The a-Si

x Ge

1 x

samples were grown by

ion-beam-assisted sputteringon GaAs (001) substrates. Before

lm deposition, the substrates were heated to 350 Æ

C

andbombardedbya30eVhydrogenionbeamfor1min

removal wasmonitored in-situ using x-ray

photoele-tron spetrosopy. 100-nm-thik a-Si and a-Ge lms

were thendeposited from Si and Ge targets(99.999%

pure) using 1000 eVKr +

ionsfrom aKaufmanngun.

a-Si

0:1 Ge

0:9

lmsofthesamethiknessweregrown

us-ing a Ge target overed with a piee of Si. In order

to obtainlaserrystallizedSi

x Ge

1 x

alloyswithother

ompositions x (x = 0.25, 0.50, and 0.75), a-Si/a-Ge

multilayerswithindividualSi andGelayerthiknesses

below 25 nmwere deposited. Eah multilayersample

onsists of 6 layers adding up to a total thikness of

100nm. Aswillbedemonstratedbelow,thelayers

om-pletelyintermixduringthelaserrystallizationproess,

leadingto the formationof ahomogeneousrystalline

(-)SiGealloywiththeompositiondeterminedbythe

relativethiknessesoftheoriginala-Geanda-Silayers.

The samples were rystallized with single pulses

(pulsewidthofapprox. 7ns)fromafrequeny-doubled

Nd:Yaglaser(=532nm). AGaussian-likelaserbeam

prolewithadiameter ofapprox. 4mmwasobtained

byusingavauumspatiallter. Thelaserpulse

uen-ieswereestimatedfromthemeasuredpulseenergyby

assumingaGaussianproleforthedistributionoflight

intensity on the irradiated area. The rystallization

proess was monitored in-situ by reording the

tran-sientreetivityofawdiodelaserbeam(=675nm)

during theLCproess. Theinreaseinthereetivity

indiates thatthea-SiGe alloysmeltduring laser

irra-diation[3℄.

Raman spetrosopy was employed to study the

strutural properties of the samples. The

measure-ments were performed at room temperature in the

baksattering geometry using the z(x; y)z, z(y; y)z,

z(x 0

; y 0

)z, and z(y 0

; y 0

)z sattering ongurations,

wherex;y;z;z;x 0

andy 0

denote,respetively,the[100℄,

retions of the (001) GaAs substrates. Note that

de-formation potential Ramansattering by longitudinal

optial(LO)phononsisallowedbyseletionrulesonly

for theongurationsz(x; y)z andz(y 0

; y 0

)z [4℄. The

redlines(

L

=676:4or647.1nm)ofaKr +

-laserwere

used forexitation.

250

300

350

400

450

500

λ

L

= 676.4 nm

Si

0.25

Ge

0.75

LO-GaAs

Ge-Ge

Ge-Si

Si-Si

z(y',y')z

z(x',y')z

In

te

n

s

ity

(a

rb

. u

n

its

)

Raman Shift (cm

-1

)

Figure 1. Raman spetra of a LC -Si

0:25 Ge

0:75 alloy

reorded inthe z(y 0

; y 0

)z (thik line, upperurve)and in

the z(x 0

; y 0

)z (thin line,lowerurve)sattering

ongura-tions. Thelaseruenywasapprox. 500mJ/m 2

.

III Results and Disussion

The Raman spetra of as-grown a-SiGe multilayers

showbroadRamanlinesentered around270and470

m 1

,whihareattributed totheGe-Geand Si-Si

vi-brationsofthea-Geanda-Silayers,respetively. After

LC, these lines narrowand shift somewhat in energy.

ARamanspetrumofaLC-Si

0:25 Ge

0:75

alloywithan

averageompositionx=25%reordedinthez(y 0

; y 0

)z

ongurationis shown by thesolidline in Fig.1. The

three mainpeaksfoundat290,400and470m 1

or-respond,respetively,toGe-Ge,Ge-SiandSi-Si

vibra-tionsofa-Si

0:25 Ge

0:75

alloy[5℄. TheGe-Siline,whih

onlyappearsafterLC,evidenestheintermixingofthe

SiandGelayersduringlaserirradiation. Thesharpline

at292m 1

(losetotheGe-Gevibration)orresponds

to satteringbyLOphononsin theGaAssubstrate.

Thespetrumreorded in the forbiddenz(x 0

; y 0

)z

ongurationin Fig. 1(thin line)showsastrongly

re-duedsatteringintensity. Thisredutionisattributed

to theepitaxialorientationoftheSi

0:25 Ge

0:75

lm

rel-ativeto the GaAs substrate. Similarresultswere also

obtainedforalloyswithx =10%. Onlypolyrystalline

regionswereobservedforx>25%,thusindiatingthat

thelargemismath preventstheformationof epitaxial

lms.

TheRamanspetrumandthusthestrutureofthe

LClayersdependssensitivelyonthelaserpulseueny.

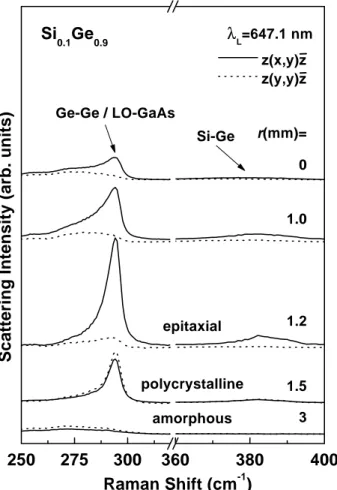

Thisresultisillustratedin Fig. 2,whihdisplaysa

se-250

275

300

360

380

400

λ

L

=647.1 nm

r(mm)=

Si-Ge

epitaxial

polycrystalline

Ge-Ge / LO-GaAs

amorphous

Si

0.1

Ge

0.9

3

1.5

1.2

1.0

0

Scattering Intensity (arb. units)

Raman Shift (cm

-1

)

z(x,y)z

z(y,y)z

Figure2. RamanspetraofaLC-Si

0:1 Ge

0:9

alloyreorded

atdierentradialdistanesrfromtheenteroftheLCspot.

Theueniesforx=0,1,1.2,1.5,and3mmareestimated

tobe2000,1250, 1000,650,and0mJ/m 2

.

distanesr fromtheenterofthespotproduedbyLC

onamultilayerwithx=0.10. Thelaserpulse ueny

dereases with r following theGaussian-likeprole of

the laser beam. Forlarge distanes (r = 3 mm), the

pulse energy is insuÆient to indue the phase

tran-sition, so that the material remains amorphous. For

r = 1.5 mm, omparable intensities are measuredin

the z(x; y)z and z(y; y)z geometries, thus indiating

theformationofapolyrystalline-Si

0:1 Ge

0:9

alloy. For

r <1.2mm,theratiobetweenthesatteringintensities

intheallowedandforbiddensatteringgeometries

be-omesverylarge. Weattribute this large ratioto the

formationof anepitaxiallmwith thesame

rystallo-graphiorientationasthesubstrate.

The laser ueny of 1000 mJ/m 2

estimated for

r=1.2 isapproximatelythesameasthat required to

obtainhighqualityLC-GelmsonGaAs. Althoughthe

materialstillrystallizesepitaxiallyforr <1.2mm,the

peakintensityoftheRamanlinesatapprox. 290m 1

reordedin theallowedsattering onguration(thik

0

5

10

15

10

1

10

2

10

3

10

4

10

5

10

6

10

7

10

1

10

2

10

3

10

4

10

5

10

6

10

7

(b)

Ge

Si

Ga

counts/s

sputtering time (min)

(a)

counts/s

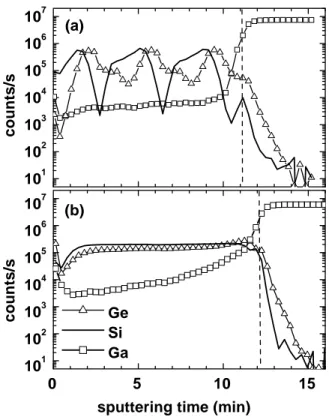

Figure3. ConentrationsofGe,Si,andGaasafuntionof

SIMSsputteringtimeforana-Si/a-Gemultilayer(a)before

and(b)afterLC. Theompositionofthe-Si

x Ge

1 x alloy

isx=0:25. Theoriginalpositionof theinterfaewiththe

substrateisindiatedbythevertialdashedline.

the high temperatures indued in the Si

1 x Ge

x layer

under high laser uenies, whih leads to strong

ma-terialintermixingattheGaAs/Si

1 x Ge

x

interfaeand,

eventually,toapartialmeltingoftheunderlyingGaAs.

WhentheSi

1 x Ge

x

alloyrystallizes,itsabsorption

o-eÆient dereases, and it beomes almost transparent

totheinident(andsattered)light. Asaresult,a

sub-stantial fration of the Raman signal deteted in LC

lmsoriginatesfromthemateriallosetotheinterfae

with the substrate. The broadened Raman line

en-tered at280m 1

is attributed tothesattering from

oupled LO-phonon-plasmonmodes in theintermixed

p-typeGaAs:Gelayer[6, 7℄.

Thestrongintermixingfor high pulseuenies

be-omesevidentin theSIMSprolesdisplayedinFig.3,

whihwerereordedonana-Si/a-Gemultilayerbefore

[Fig.3(a)℄andafter LC [Fig.3(b)℄. TheSIMS

experi-beam. The dashed vertial lines indiate the original

positionoftheSi

0:25 Ge

0:75

/GaAsinterfae,loated

ap-prox. 100nmbelowthesurfae. Themodulationofthe

Ge andSi onentrationsin theas-grownmultilayeris

evidentinFig.3(a). Thismodulationdisappearsasthe

individualSiandGelayersompletelyintermixduring

LC, giving rise to a homogeneous -Si

0:25 Ge

0:75 lm

[Fig. 3(b)℄. The proles also show a strong

interdif-fusion of Ga into the -Si

0:25 Ge

0:75

lm and a muh

less pronouned diusion of Ge and Si into the

sub-strate. Arsenidiusion(notshown)wasalsoobserved

in SIMSproles measured with aesium primary ion

beam.

IV Conlusions

Inonlusion,wehavestudiedthestrutureofLCSiGe

alloysgrownon(001)GaAssubstrates. Epitaxiallms

with a thikness of 100 nm were obtained for Si

on-entrations up to 25%. Higher Si onentrations lead

to polyrystallinelms.

Aknowledgments

The investigation are partially supported by a

DAAD(Germany)- CAPES(Brazil)international

o-operationprogram.

Referenes

[1℄ J.M.PoateandJ.W.Mayer,LaserAnnealingof

Semi-ondutors (AademiPress,New York,1982).

[2℄ J.E.Greene,K.C.Cadien,D.Lubben,G.A.Hawkins,

G.Erikson,andJ.R.Clarke,Appl.Phys.Lett.39,232

(1981).

[3℄ G. Aihmayr, D. Toet, M. Mulato, P. V. Santos, A.

Spangenberg, S. Christiansen, M. Albreht, and H. P.

Strunk,J.Appl.Phys.85,1040(1999).

[4℄ M.Cardona,LightSattering inSolidsII,(Ed.M.

Car-dona and G.Guntherodt, Springer, Berlin, 1982), pp.

153.

[5℄ M. A.Renui,J.B.Renui,and M.Cardona, Light

Sattering in Solids, (Ed. M. Balkanski, Flammarion,

Paris,1971),pp.326-329.

[6℄ A.Mlayah, R.Carles, andA.Leyuras, J.Appl.Phys.

71,422(1992).

[7℄ D.OlegoandM.Cardona,SolidStateCommun.32,375