Digital Control of Plasma Position

in Damavand Tokamak

M. Emami, A. R.Babazadeh, M. V. Roshan,M. Memarzadeh, and H. Habibi

PlasmaPhysisLab.,NFRC,AEOI,Iran

Reeivedon26June,2001

Plasmapositionontrolisoneoftheimportantissuesinthedesignandoperationoftokamakfusion

researhdevie. Sineatokamakisbasiallyaneletrialsystemonsistingofpowersupplies,oils,

plasmaandeddyurrents,amodelinwhihtheseomponentsaretreatedasaneletrialiruitsis

usedindesigningDamavandplasmapositionontrolsystem. Thismodelisusedforthesimulation

ofthedigital ontrol systemand itsparametershavebeenveriedexperimentally. Inthis paper,

theperformaneofahigh-speeddigitalontrolleraswellasasimulationstudyanditsappliation

totheDamavandtokamakisdisussed.

I Introdution

Tokamak is an eletrial systemonsisting of a

trans-former, plasma, eddy urrents, power supplies and

windings [1℄. The hanges in the plasma parameters

suhasdensity,temperatureandurrentreatefores,

whihmovestheplasmafromitsequilibrium position.

Plasma position feedbak ontrol in tokamaks viathe

appliation of lassial or modern ontrol theory has

beenstudiedextensively. Mosttokamakshaveadopted

analog ontrollers. The rapid development of digital

signal proessors (DSP) has inreased the speeds to

suh an extent whih digital ontrollers have beome

moreattrative[2℄-[6℄.

Thispaperdesribestheontrol systemsimulation

basedonahigh speedTexas-InstrumentDSPandits

appliationtotheplasmapositionontrolinDamavand

tokamak.

II Damavand Plasma Position

Model

Damavand is a tokamak with an elongated plasma

ross-setion [7℄. The ross-setion of Damavand is

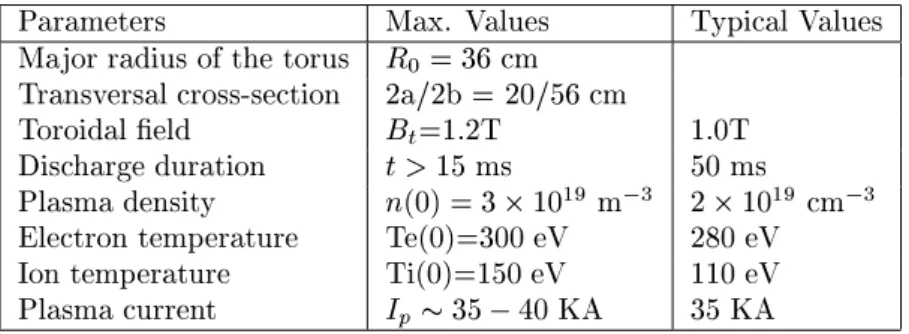

showninFig. 1anditsparametersaregiveninTable1.

Severalforesareatingontheplasma;thesearethe

ex-pansionforeduetotheplasmapressure,theforesdue

to the interations of magneti eld of vauum vessel

eddyurrentsandtheexternalmagnetieldwiththe

oils,vauumvesselandplasmathatform several

mu-tuallyinteratingeletriiruits,generatethesefores.

Theirappliedvoltages,resistane,andselfandmutual

indutaneandesribetheseiruits.

Parameters Max. Values TypialValues

Majorradiusofthetorus R

0

=36m

Transversalross-setion 2a/2b=20/56m

Toroidaleld B

t

=1.2T 1.0T

Dishargeduration t>15ms 50ms

Plasmadensity n(0)=310 19

m 3

210 19

m 3

Eletrontemperature Te(0)=300eV 280eV

Iontemperature Ti(0)=150eV 110eV

Plasmaurrent I

p

35 40KA 35KA

Table1. DAMAVANDParameters.

This systeman be represented by a simpleset of

rst-orderdierentialequationsfortheurrentsin the

iruitelements,augmentedbytheequationofmotion

fortheplasmaolumn[8℄,

d

dt

(MI)+RI=V (1)

mdv

dt =

X

(radialfores) (2)

Here Visthevetorofapplied voltages,Mis the

mu-tual indutanematrix, R is the (diagonal)matrixof

resistane forthe iruitelements, and I is the vetor

of urrents in the iruit elements. In Eq. (2), v is

the plasma olumn radialveloity and m is the mass

oftheplasmaolumn. Solvingtheaboveequationshas

derivedasimplelinearizedplasmapositionmodel

appli-ablenearequilibrium anditsLaplaetransformblok

diagram isshowninFig.2,where

H

(s)=G

p (s)I

(s)+G

1 (s)

p +

l

i

2

(s) (3)

In this equation s, is theLaplae transform operator,

I

(s)istheontroloilurrentLaplaetransform,

p is

thepoloidalbeta,l

i

istheplasmainternalindutane,

and G

p

(s)andG

1

(s)aretheplasmaposition and

dis-turbane Laplae transfer funtions whih have been

desribedindetailin ref. [4℄. Theparametersofthese

transferfuntions aretheomplexfuntions of: 1) the

eletrialharateristisandgeometryofthewindings,

vauum vessel, andinterating eletriiruits,and2)

plasma parameterssuh asurrent, major radius,and

minorradius. Thetwomostimportantparameters

dis-turbingtheplasmapositioninDamavandtokamakare

the plasma temperature (T) and density (n)

utua-tions, whih is inluded in the (

p +l

i

=2) parameter.

InthismodelontroloilurrentI

(t)hasbeenhosen

as ontrol input beause by varying this urrent the

magneti eld in theplasma areaan be easily

modi-Figure2. PlasmapositionLaplaetransformblok

diagram.

III Digital Control System

III.1 Introdution

TheDamavanddigitalontrolsystemblokdiagram

isshown in Fig. 3. Theheart ofthis systemisaDSP

board,basedonahighspeed(12.5MIPS)TMS320C25

hip [9℄. It is used for the implementation of a

digi-talontrolalgorithm;itreeiveserrorsignale(k) and

generatestheontrol outputu(k);whihativatesthe

ontrol oil urrent. The TMS 320 family of

proes-sors is suitablefor implementation of digitallter [9℄,

[10℄.Theyhavethepowerforimplementingapoleand

zeroofadigitallterwith onlytwoinstrutions. Due

to xed-point representation of numbers by the DSP,

overow may our. Appropriatesaling beomes

im-portanttoavoidthisproblem. Theontroloilurrent

I

(t), is generated by a thyristor ontrol iruit with

the maximum time onstant of 200 s. Finally, the

plasmapositionwillbemonitoredandproessedusing

aplasmaposition-proessingunit. Theothertokamak

signals, whih are required for plasma modeling and

Figure3. Plasmapositiondigitalontrolsystem.

III.2 Digital Control System Analysis

Oneof the most widely used ontrol algorithms is

theproportional-integral-derivative(PID).The digital

PID ontrol algorithm implemented for this work is

used in the retangular approximation [11℄, T

(z 1) for

the integraloperation (1=s), and the bakward

dier-eneapproximation z 1

Tz

for thederivativeoperation

(s), where z = e sT

and T is the sampling period. It

shouldberealizedthataslongthesamplingfrequeny

is muh bigger than the system bandwidth the above

approximation holds. A digital PID ontroller

algo-rithmusingtheaboveapproximationanbewrittenin

theformofareursivediereneequation[9℄as

u(k)=u(k 1)+k

0

e(k)+k

1

e(k 1)+k

2

e(k 2): (4)

Wheree(k)andu(k)aretheontrollerinputand

out-putand, k 0 =k p 1+ T d T ; (5) k 1 =k p 1 2 T d T + T T i ; (6) k 2 =k p T d T : (7) WhereK p ,T i andT d

aretheproportionalgain,

in-tegral and derivative time onstant of the equivalent

analogPIDontroller. TheDSPanexeutethe

Equa-tion (4)within 1.3s and thetime required forother

tasks suh as exeuting the timing routine, interrupt

request handling and saling numbers is 13 s. The

output from this alulation u(k) anbe fairly noisy,

but theontroloil urrentdriveriruitwiththe200

stimeonstantatsasagoodlow-passlter.

TheA=D onverteris modeledasanidealimpulse

samplerombinedwith anite timedelayt

A=D to

a-ountfortheonversiontimeandisdesribedby

G (s)=K e t A=D s (8) Where K A=D

is theA=D gain. Finally, for simpliity

D=Aonverteris modeledasazero-order holddevie

[11℄anditsLaplaetransferfuntionisdesribedas

G

D=A

(s)=K

D=A 1 e

Ts

s

(9)

Where T andK

D=A

arethe samplingperiodand

on-vertergain,respetively.

III.3 Digital Controller Performane

The plasma position ontrol system of Damavand

tokamak based on a digital PID algorithm has been

simulatedbyomputerandisomparedwiththeDSP.

ThissimulationshowsthattheperformaneoftheDSP,

operating on 16Bit xed- point arithmeti is in lose

agreementwith the omputer,whih uses double

pre-ision oating- point data. This is obviously due to

thefatthatthesamplingrateismuhhigherthanthe

systembandwidth.

Theprimarymeasureoftheperformaneofthe

on-trollerisitsabilitytoontroltheplasmapositionwhen

it issubjetto disturbanes. Fig. 4showsthe plasma

position evolutionwith and withoutontrollerin a10

mm step-wise disturbane at the instant of time t=8

ms.

10

5

0

4

8

12

16

20

a

b

c

15

∆

H

(t) (m

m

)

Time (ms)

Figure 4. Plasma position ontrol system step response:

a) Digital ontroller, b)Analog ontrollerand )Without

ontroller.

Beauseofthesmallurrentinbuild-upphase(t<

8ms),theplasmapositionisverysensitivetothestray

magneti eld. Also, due to the iruit limitation at

low plasma urrent the plasma position measurement

is notveryaurate and the position is ontrolled by

preprogrammedmagnetield. Asitanbeseenfrom

Fig. 4busingtheanalogontroller,theplasmahasnot

returned tothe enter of thehamber(

H

=0) later

in the disharge. The reason is that the analog

on-troller gains were tuned for thesteady stateregion of

theplasmawhileforthelaststageinthedisharge,

be-auseofthehangesintheplasmaurrent,densityand

temperature, theparameters of theplasma model

gainsshouldhavebeenhangedaordinglyduring

dis-harge. This wasnot onvenientwith theanalog

on-trollerandhasbeenreplaedbydigitalontroller.

IV Conlusion

When model parameters are hanging due to the

plasma parameter variations, the ontroller gains

should be hanged during the disharge. Sine

ana-log ontroller was not exible it was replaed with

a digital ontroller. A digital ontrol system based

onTMS320C25 miroproessorhasbeendesignedand

built. Theresultsshowthedigitalsignalproessor

per-formane is satisfatory as long as the sampling

fre-queny is muh largerthan thebandwidth ofthe

sys-temwhihinludesDSPanditsassoiatediruitry

de-laytime, thyristor urrentontrol iruit,ontrol oil,

vauum vessel, andplasmaposition measurementunit

timeonstants.

Referenes

[1℄ J. Wesson, Tokamak, Oxford Siene Publiation,

(1987).

[2℄ J. R. Ulgum \Digital Feedbak ontrol for TEXT

Upgrade" Fusion Researh Center, Austin, Texas

FRCR#412(1992).

[3℄ J.B. Lister,F.Hofmann, J.M. Moret,M.J. Duth,D.

Y.Martin,A.Perez,andD.J.Ward,\TheControl of

TCVPlasmas"LRP518/95, July1996.

[4℄ M.Emami, H. C.Wood,A. Hirose, \Aontrollerfor

plasma motion in a tokamak based on model

esti-mation",IEEETransationsonIndustrialeletronis,

Vol.37,317(1990).

[5℄ Y.Mizuno,H.Muramatsu, T.AokiandT.Sometani,

\Feedbak position ontrol apparatus of tokamak

plasmahorizontalpositionwithadigital drive",

Ele-trialEngineeringinJapanVol.130,26(2000).

[6℄ A.Coutlis, J.N.Limebeer, J.P.Wainwright, J.B.

Lis-ter,andP.Vyas,\Frequenyresponseidentiationof

dynamisofatokamakplasma"IEEETransationson

ControlSystemTehnology,Vol.8,646(2000).

[7℄ R. Amrollahi, A.V. Bortnikov, N.N. Brevnov, Yu.V.

Gott,andV.A.Shurygin,\ExperimentalStudyofthe

Pre-Disruption in the Damavand Tokamak", Plasma

PhysisReports,Vol.23,561(1997).

[8℄ E.A. Lazarus, G.H. Neilson, \Solutions to the

toka-makiruitequationswithforebalaneforamassless

plasma",NulearFusion,Vol.27,383(1987).

[9℄ TMS320C2XFixed-PointUser'sGuide (Texas

Instru-mentSPRU014C).

[10℄ Hardware Interfaing to the TMS320C2X (Texas

In-strumentSPRA014B).

[11℄ DigitalControlSystems,C.Kuo,HRWseriesin